Film Extrusion Guide.pmd - LyondellBasell

Film Extrusion Guide.pmd - LyondellBasell

Film Extrusion Guide.pmd - LyondellBasell

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

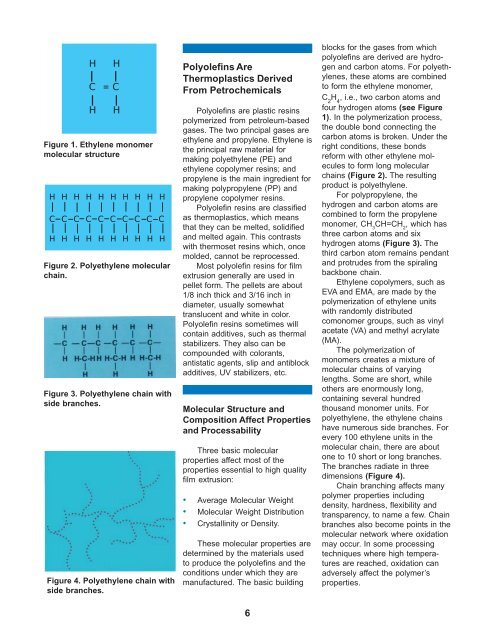

H H<br />

C = C<br />

H H<br />

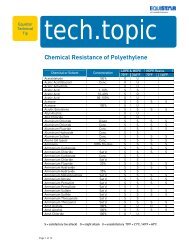

Figure 1. Ethylene monomer<br />

molecular structure<br />

H H H H H H H H H H<br />

C C C C C C C C C C<br />

H H H H H H H H H H<br />

Figure 2. Polyethylene molecular<br />

chain.<br />

Figure 3. Polyethylene chain with<br />

side branches.<br />

Figure 4. Polyethylene chain with<br />

side branches.<br />

Polyolefins Are<br />

Thermoplastics Derived<br />

From Petrochemicals<br />

Polyolefins are plastic resins<br />

polymerized from petroleum-based<br />

gases. The two principal gases are<br />

ethylene and propylene. Ethylene is<br />

the principal raw material for<br />

making polyethylene (PE) and<br />

ethylene copolymer resins; and<br />

propylene is the main ingredient for<br />

making polypropylene (PP) and<br />

propylene copolymer resins.<br />

Polyolefin resins are classified<br />

as thermoplastics, which means<br />

that they can be melted, solidified<br />

and melted again. This contrasts<br />

with thermoset resins which, once<br />

molded, cannot be reprocessed.<br />

Most polyolefin resins for film<br />

extrusion generally are used in<br />

pellet form. The pellets are about<br />

1/8 inch thick and 3/16 inch in<br />

diameter, usually somewhat<br />

translucent and white in color.<br />

Polyolefin resins sometimes will<br />

contain additives, such as thermal<br />

stabilizers. They also can be<br />

compounded with colorants,<br />

antistatic agents, slip and antiblock<br />

additives, UV stabilizers, etc.<br />

Molecular Structure and<br />

Composition Affect Properties<br />

and Processability<br />

Three basic molecular<br />

properties affect most of the<br />

properties essential to high quality<br />

film extrusion:<br />

• Average Molecular Weight<br />

• Molecular Weight Distribution<br />

• Crystallinity or Density.<br />

These molecular properties are<br />

determined by the materials used<br />

to produce the polyolefins and the<br />

conditions under which they are<br />

manufactured. The basic building<br />

6<br />

blocks for the gases from which<br />

polyolefins are derived are hydrogen<br />

and carbon atoms. For polyethylenes,<br />

these atoms are combined<br />

to form the ethylene monomer,<br />

C 2 H 4 , i.e., two carbon atoms and<br />

four hydrogen atoms (see Figure<br />

1). In the polymerization process,<br />

the double bond connecting the<br />

carbon atoms is broken. Under the<br />

right conditions, these bonds<br />

reform with other ethylene molecules<br />

to form long molecular<br />

chains (Figure 2). The resulting<br />

product is polyethylene.<br />

For polypropylene, the<br />

hydrogen and carbon atoms are<br />

combined to form the propylene<br />

monomer, CH 3 CH=CH 2 , which has<br />

three carbon atoms and six<br />

hydrogen atoms (Figure 3). The<br />

third carbon atom remains pendant<br />

and protrudes from the spiraling<br />

backbone chain.<br />

Ethylene copolymers, such as<br />

EVA and EMA, are made by the<br />

polymerization of ethylene units<br />

with randomly distributed<br />

comonomer groups, such as vinyl<br />

acetate (VA) and methyl acrylate<br />

(MA).<br />

The polymerization of<br />

monomers creates a mixture of<br />

molecular chains of varying<br />

lengths. Some are short, while<br />

others are enormously long,<br />

containing several hundred<br />

thousand monomer units. For<br />

polyethylene, the ethylene chains<br />

have numerous side branches. For<br />

every 100 ethylene units in the<br />

molecular chain, there are about<br />

one to 10 short or long branches.<br />

The branches radiate in three<br />

dimensions (Figure 4).<br />

Chain branching affects many<br />

polymer properties including<br />

density, hardness, flexibility and<br />

transparency, to name a few. Chain<br />

branches also become points in the<br />

molecular network where oxidation<br />

may occur. In some processing<br />

techniques where high temperatures<br />

are reached, oxidation can<br />

adversely affect the polymer’s<br />

properties.