Design 461 Anti-Coke Valve Body

Design 461 Anti-Coke Valve Body

Design 461 Anti-Coke Valve Body

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Fisher Controls<br />

(FISHEBj<br />

INTRODUCTION<br />

Scope Of Manual<br />

Instruction Manual<br />

<strong>Design</strong> <strong>461</strong> <strong>Anti</strong>-<strong>Coke</strong><br />

<strong>Valve</strong> <strong>Body</strong><br />

<strong>Design</strong> <strong>461</strong><br />

May 1981 Form 5170<br />

This instruction manual provides installation, maintenance, and parts ordering<br />

information for the <strong>Design</strong> <strong>461</strong> anti-coke valve body. Information regarding<br />

actuators and other accessories can be found in separate instruction manuals.<br />

Description<br />

The <strong>Design</strong> <strong>461</strong> is a self-cleaning, increased-outlet, angle-style valve body.<br />

It is specifically designed to control the flow of erosive or sticky fluids<br />

while preventing particle build-up on internal valve parts. It is used in<br />

both throttling and on-off applications. Because of its venturi-type outlet,<br />

the <strong>Design</strong> <strong>461</strong> valve body is often chosen for applications where flashing is a<br />

problem.<br />

INSTALLATION<br />

WARNING<br />

To avoid personal injury or equipment damage caused<br />

by sudden release of pressure, install the valve<br />

assembly only where service conditions will not<br />

exceed the limits given on the appropriate nameplate.<br />

1. Before installing a <strong>Design</strong> <strong>461</strong> valve body, inspect it for any foreign<br />

material that may have collected during crating or shipping.<br />

2. Check that the pipelines are free of pipe scale, chips, welding slag, and<br />

other foreign material.<br />

8 Fisher Controls Company 1981; All Rights Reserved

I <strong>Design</strong> <strong>461</strong><br />

3. Use accepted piping practices when installing the valve.<br />

4. Do not install the valve in a system where the service conditions exceed<br />

those specified when the valve was ordered.<br />

5. If continuous operation is required during maintenance and inspection,<br />

install a three-valve bypass around the body so that it will be isolated.<br />

6. Orient the body so that the flow will be in the direction indicated by<br />

the flow direction arrow located on the outside of the valve body to<br />

ensure proper self-cleaning action.<br />

7. If the actuator and valve are shipped separately, refer to the actuator<br />

mounting procedure outlined in the appropriate actuator instruction<br />

manual.<br />

MAINTENANCE<br />

<strong>Valve</strong> parts are subject to normal wear and must be inspected and replaced as<br />

necessary. The frequency of inspection and replacement depends upon the<br />

severity of service conditions.<br />

Replacing Packing<br />

WARNING<br />

To avoid personal injury and equipment damage, isolate<br />

the control valve from the system, and release all<br />

pressure from the body and actuator before starting<br />

maintenance operations.<br />

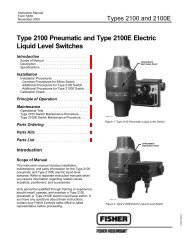

Refer to figure 1 unless otherwise indicated.<br />

1. Turn the spring adjustor to release all spring compression in the actuator.<br />

2. Disconnect the operating lines from the actuator. Disconnect the stem<br />

connector, and then remove the actuator from the valve.<br />

3. Remove the hex nuts (key 8, figure 2) from the bonnet flange, and loosen<br />

the packing flange nuts (key 25) so that the packing is not tight on the<br />

valve stem.<br />

4. Lift the bonnet (key 14) off the valve stem (key 10, figure 2). If the<br />

valve plug and stem assembly starts to lift with the bonnet, tap it back<br />

down using a brass or lead haoxner on the end of the stem. Set the bonnet<br />

on a cardboard or wooden surface to prevent damage to the bonnet gasket<br />

surface.<br />

5. Remove the packing flange nuts (key 25), packing flange (key 23), and<br />

packing follower (key 29) from the bonnet (key 14).<br />

-2-

6.<br />

7.<br />

8.<br />

9.<br />

<strong>Design</strong> <strong>461</strong><br />

Pull out the packing rings (key 19), male adaptor (key Zl), and spring<br />

(key 17) with a packing hook (take care to avoid scratching the packing<br />

box wall), or push them out using a rod inserted through the bottom of<br />

the bonnet.<br />

Clean the packing box and all metal parts.<br />

Inspect the valve stem threads for any sharp edges that might cut the<br />

packing. Use a wheatstone or emery cloth to smooth the threads if<br />

necessary.<br />

Install a new gasket (key 6, figure 2). Slide the bonnet over the stem<br />

and onto the stud bolts (key 7, figure 2).<br />

10. Replace packing parts in the order indicated in figure 1. Avoid scratch-<br />

ing the packing box walls. Install the hex nuts (key 8, figure 2) on the<br />

bolts (key 7, figure 2), and tighten in a range from 350 to 400 foot-pounds<br />

(474 to 542 newton-meters), using lubrication such as Never-See2 Nickel<br />

Special* or an equivalent on the bolts.<br />

11. Replace the packing flange (key 23) and packing flange nuts (key 25), and<br />

lubricate the bolts. Tighten the nuts to 37 foot-pounds (50 newton-meters)<br />

to deaerate packing;<br />

(34 newtonmeters).<br />

then loosen the nuts, and tighten to 25 foot-pounds<br />

12. Mount the actuator on the bonnet (key 14), and make up the stem connection<br />

according to the procedure given in the appropriate actuator instruction<br />

manual.<br />

Replacing Trim<br />

Refer to figure 2 unless otherwise indicated.<br />

1. Remove the actuator and the bonnet according to steps 1 through 4 of the<br />

Replacing Packing section.<br />

2. Remove the valve plug and stem assembly (keys 3 and 10) from the valve.<br />

If the stem needs to be replaced, drive the groove pin (key 11) out, and<br />

unscrew the stem from the plug.<br />

CAUTION<br />

Never use an old stem with a new valve plug. The use<br />

of an old stem requires drilling a new groove pin<br />

hole through the stem, which will weaken the stem.<br />

*Never-See2 is a trademark of Never-See2 Corp.<br />

.

I <strong>Design</strong> <strong>461</strong> I<br />

3. If the valve plug needs replacing, replace the entire valve plug and stem<br />

assembly. Do not reuse the old stem on a new valve plug. If only a new<br />

stem is necessary, screw the plug onto the new stem. Drill a 3/16-inch<br />

(4.8 mm) hole through the stem using the plug pin hole as a guide. Drive<br />

the pin into the stem and plug.<br />

4. With the stem and valve plug assembly removed, slide the liner (key 5)<br />

out of the valve body. Inspect the seat ring (key Z).for nicks and<br />

scratches.<br />

5. To replace the seat ring (key 2), remove the valve from the line, or<br />

remove the pipe connected to the lower flange. Then, unscrew the seat<br />

ring retainer (key 4), and remove the seat ring through the bottom of the<br />

valve body. Make sure the valve plug and seat ring contact surfaces are<br />

free of nicks and scratches.<br />

6. To remove the liner (key 5), break it loose by using the cap screws in<br />

the tapped holes located in the liner's flange. (In some very hard<br />

materials, i.e., Alloy 6, the holes have been omitted; therefore, a<br />

sleeve puller or similar device must be used.),<br />

Assembly<br />

---_<br />

1. When assembly, use a new bonnet gasket (key 6), and wipe all sealing<br />

surfaces (body, bonnet, and gaskets) with a clean cloth. If the seat<br />

ring (key 2) was removed, install it in the valve body (key l), and then<br />

screw the seat ring retainer (key 4) in the valve body. Since there is<br />

no gasket between the seat ring and the valve body, make sure that the<br />

mating surfaces are clean and free of nicks and scratches.<br />

2. Replace the liner (key 5), and tighten securely. Then, slide the valve<br />

plug and stem assembly (keys 3 and 10) into the body (key 1).<br />

3. Mount the bonnet (key 14, figure 1) onto the valve body (key 1).<br />

Note<br />

If the seating surfaces of the valve plug and seat<br />

ring require lapping, refer to the Lapping Seating<br />

Surfaces section before continuing to assemble the<br />

valve.<br />

4. If it is necessary to replace the packing, perform steps 5 through 8 of<br />

the Replacing Packing section. However, if it is not necessary to<br />

replace the packing, make sure to install the bonnet carefully on the<br />

valve body to avoid damaging the packing with the valve stem threads.<br />

-4-

I <strong>Design</strong> <strong>461</strong><br />

5. Lubricate the body stud bolts (key 7) with Never-Seez* lubricant or<br />

equivalent, and install the nuts (key 8) on the bolts. Tighten the nuts<br />

in a range from 350 to 400 foot-pounds (474 to 542 newton-meters) in a<br />

crisscross pattern to ensure a positive seal and even pressure on the<br />

bonnet.<br />

Note<br />

It may be necessary to repeat the bolting pattern<br />

several times until the bonnet-to-body seal is made<br />

since the tightening of one nut might loosen an<br />

adjacent nut. It is recommended that the pattern be<br />

repeated until none of the nuts will turn at the<br />

recommended torque.<br />

6. Mount the actuator on the bonnet, and make up the stem connection<br />

according to the procedure given in the appropriate actuator instruction<br />

manual.<br />

Lapping Seating Surfaces<br />

A certain amount of leakage should be expected with metal-to-metal seating in<br />

any valve body. If the leakage becomes excessive, however, the condition of<br />

the seating surfaces of the valve plug and seat ring can be improved by grinding.<br />

Large nicks should be machined out rather than ground out. Use a conunercial<br />

lapping compound or a mixture of 600-grit Carborundum and solidified vegetable<br />

oil. Apply the compound to the bottom of the valve plug, and apply white lead<br />

to the seat ring to prevent excessive tearing or cutting during lapping. The<br />

white lead should not be mixed with the grinding compound, but rather applied<br />

separately.<br />

The valve must be assembled to the extent that the valve plug and stem assembly<br />

(keys 3 and 10) and the seat ring (key 2) are in place and the bonnet (key 14)<br />

is bolted to the body (key 1). A simple handle can be made from a piece of<br />

strap iron locked to the valve plug stem with nuts. Rotate the handle alternately<br />

in each direction to lap the seats. After lapping, remove the bonnet, and<br />

clean the seating surfaces.<br />

Completely assemble as described in the Assembly<br />

part of the Haintenace section, and test the valve for shutoff. Repeat the<br />

lapping procedure if leakage is still excessive.<br />

PARTS ORDERING<br />

Whenever corresponding with the Fisher sales office or sales representative<br />

regarding <strong>Design</strong><br />

on the nameplate<br />

<strong>461</strong> valve bodies, be sure to provide the serial<br />

of the unit. When ordering replacement parts,<br />

number given<br />

specify the<br />

11-character part number given in the parts list.<br />

*Never-See2 is a trademark of Never-See2 Corp.

I <strong>Design</strong> <strong>461</strong> I<br />

PARTS LIST<br />

Key<br />

5<br />

Note<br />

Most part numbers appear in tables following the<br />

individual key number listings.<br />

Description Part Number<br />

Liner .<br />

2 x 3 in. body, 416 stainless steel<br />

Class 300 & 600<br />

Class 900 & 1500<br />

Class 2500<br />

3 x 4 in. body, 416 stainless steel<br />

Class 300 & 600<br />

Class 900 & 1500<br />

4 x 6 in. body, 410 stainless steel _<br />

Class 300 St 600<br />

Class 900 St 1500<br />

6 x 8 in. body, 410 stainless steel<br />

Through Class 600<br />

Gasket, monel & asbestos<br />

2 x 3 in. body<br />

Class 600, 900, & 1500<br />

Class 2500<br />

3 x 4 in. body<br />

Through Class 1500<br />

Class 2500<br />

4 x 6 in. body<br />

Through Class 600<br />

Class 900 & 1500<br />

6 x 8 in. body<br />

Class 300, 600, & 1500<br />

Bolt Stud, steel (8 req'd)<br />

2 x 3 in. body<br />

Class 600<br />

Class 900 & 1500<br />

Class 2500<br />

3 x 4 in. body<br />

Through Class 600<br />

Class 900 St 1500<br />

Class 2500<br />

4 x 6 in. body<br />

Through Class 600<br />

Class 900 & 1500<br />

020454 <strong>461</strong>72<br />

020707 <strong>461</strong>72<br />

lB4032 <strong>461</strong>72<br />

2A2096 <strong>461</strong>72<br />

2C1289 <strong>461</strong>72<br />

lA6745 <strong>461</strong>92<br />

2C4834 <strong>461</strong>92<br />

266885 X0012<br />

OT0556 99232<br />

0x0925 99232<br />

lA2156 99232<br />

lD6848 99232<br />

lB1674 99232<br />

020999 99232<br />

LA7627 99232<br />

lA3770 31012<br />

183771 31012<br />

lB2321 31012<br />

lA3770 31012<br />

12A3277 X012<br />

lD3645 31012<br />

lB2318 31012<br />

lB2320 31012

I(ey<br />

1<br />

9<br />

11<br />

12<br />

16<br />

17<br />

18<br />

19<br />

21<br />

22<br />

Description Part Number<br />

6 x 8 in. body<br />

Through Class 600<br />

Class 1500<br />

Hex Nut, steel<br />

2 x 3 in. body (16 req'd)<br />

Class 600, 900, & 1500<br />

Class 2500<br />

3 x 4 in. body (16 req'd)<br />

Through Class 600<br />

CIass 900 & 1500<br />

Class 2500<br />

4 x 6 in. body (16 req'd)<br />

Through Class 600<br />

Class 900 & 1500<br />

6 x 8 in. body (24 req'd)<br />

Through Class 600<br />

Class 1500<br />

Line Position Pin, 303 stainless steel<br />

Groove Pin, 316 stainless steel<br />

2 x 3 in. body<br />

3 x 4 in. body<br />

4 x 6 and 6 x 8 in. body<br />

Pipe Plug (not shown)<br />

2 x 3 and 3 x 4 in. body<br />

For WCB steel body, steel<br />

For C5 steel body, 316 stainless steel<br />

4 x 6 and 6 x 8 in. body<br />

WCB steel body, carbon steel<br />

C5 steel body, 316 stainless steel<br />

Upper Wiper for 1 in. (25.4 mm) stem, felt<br />

Spring, 316 stainless steel<br />

3/4 in. (19.1 mm) stem<br />

1 in. (25.4 mm) stem<br />

Washer, 316 stainless steel (not shown)<br />

3/4 in. (19.1 mm) stem<br />

Packing Ring, TFE<br />

3/4 in. (19.1 mm) stem<br />

1 in. (25.4 mm) stem<br />

Male Adaptor<br />

<strong>Design</strong> <strong>461</strong> I<br />

12A3277 X012<br />

lA5010 31012<br />

lC1727 24072<br />

IA4452 24072<br />

lC1727 24072<br />

IA4409 24072<br />

lA5011 24072<br />

lA4409 24072<br />

lA4453 24072<br />

lA4409 24072<br />

lA5011 24072<br />

OT0548 35032<br />

lB6007 35072<br />

lL3023 35072<br />

lL3026 35072<br />

IA3692 24492<br />

lA3692 35072<br />

lA7715 28992<br />

lA7715 35072<br />

158729 06332<br />

lF1256 37012<br />

ID5829 37012<br />

lF1250 36042<br />

lC7528 01012<br />

lC7529 01012<br />

3/4 in. (19.1 mm) stem, TFE lF1246 01012<br />

1 in. (25.4 mm) stem, 316 stainless steel lC7537 35072<br />

Female Adjustor (not shown)<br />

3/4 in. (19.1 mm) stem, TFE lF1242 01012

I Desisn <strong>461</strong> I<br />

Key<br />

23<br />

24<br />

25<br />

26<br />

27<br />

28<br />

29<br />

Dscription<br />

Packing Flange, steel<br />

3/4 in. (19.1 mm) stem<br />

1 in. (25.4 mm) stem<br />

Class 300-1500<br />

Class 2500<br />

Packing Stud, steel (2 req'd)<br />

3/4 in. (19.1 mm) stem<br />

1 in. (25.4 mm) stem<br />

Class 300-1500<br />

Class 2500<br />

Packing Nut, steel (2 req'd)<br />

3/4 in. (19.1 mm) stem<br />

1 in. (25.4 mm) stem<br />

Class 300-1500<br />

Class 2500<br />

Yoke Locknut, steel (not shown)<br />

3/4 in. (19.1 mm) stem<br />

Cap Screw, steel (not shown)<br />

1 in. (25.4 mm) stem (8 req'd)<br />

Hex Nut, steel (not shown)<br />

1 in. (25.4 mm) stem (8 req'd)<br />

Follower, 316 stainless steel<br />

3/4 in. (19.1 mm) stem<br />

1 in. (25.4 nun) stem<br />

33 Companion Flange (2 req'd) (not shown)<br />

WCB steel body<br />

C5 steel body<br />

34 Gasket, monel St asbestos (not shown)<br />

35<br />

(2 req'd)<br />

Stud Bolt, steel (not shown) (4 req'd)<br />

36 Hex Nut, steel (not shown) (4 req'd)<br />

37 Equalizing Connection (not shown)<br />

3/4 in. (19.1 IMI) stem<br />

2 x 3 in. body<br />

Class 300 or 600<br />

Class 900 or 1500<br />

Class 2500<br />

3 x 4 in. body<br />

4 x 6 in. body<br />

6 x 8 in. body<br />

1 in. (25.4 mm) stem<br />

Part Number<br />

IX9448 23072<br />

OVO024 25052<br />

0x0905 x0012<br />

lE9i49 31012<br />

OVO025 31032<br />

0x0904 x0022<br />

IX9446 24112<br />

IA3760 24112<br />

IA3520 XOOBZ<br />

lE8327 23062<br />

IA9362 24052<br />

IA3433 24122<br />

IX9447 35072<br />

lC7545 35072<br />

OU0523 22012<br />

OU0523 29022<br />

OU0524 99232<br />

lB2317 31012<br />

IA3772 24072<br />

27A4509 X012<br />

27A4510 X012<br />

27A4511 X012<br />

27A4512 X012<br />

27A4513 X012<br />

2764514 X012<br />

4 x 6 in. body 22A1996 X012<br />

-8-

z<br />

::<br />

r(<br />

N<br />

. * . . .<br />

.<br />

fi<br />

w<br />

::<br />

:: x . . .<br />

I4 . . .<br />

z<br />

s<br />

2<br />

8<br />

.x . .<br />

* . .<br />

.cq . .<br />

;:<br />

Y<br />

m<br />

%<br />

8 w . . .<br />

r( . . .<br />

s<br />

w<br />

<strong>Design</strong> <strong>461</strong> I

I <strong>Design</strong> <strong>461</strong><br />

I<br />

Key 2 Seat Ring, 316 stainless steel<br />

BODY PORT CLASS<br />

SIZE, DIA.<br />

IN. IIl. uml 300 & 600 900 & 1500 2500<br />

3/4 19.1 lB3614 46072 lB3605 46072 lB3605 46072<br />

2x3 l-114 31.8 lB3994 46072 lB9721 46072 . . .<br />

l-518 41.3 lH5351 x0012 lB7966 46072. lB7966 46072<br />

1 25.4 X9322 46072 . . . . . .<br />

3x4 l-1/4 31.8 lB6987 46072 lB6987 46072 . . .<br />

l-1/2 38.1 lB3886 46072 lB3886 46072 . . .<br />

l-3/4 44.5 lC4540 46072 lC4540 46072 . . .<br />

4x6 2-l/2 63.5 lB3670 46072 lC9559 x0012 . . .<br />

3 76.2 lB3669 46072 . . . . . .<br />

6x8 3-l/2 88.9 lC1075 46072 . . . . . .<br />

Key 3 <strong>Valve</strong> Plug, 440 stainless steel<br />

BODY PORT CLASS<br />

SIZE, TRAVEL DIA. 300 & 600 900 St 1500 2500<br />

IN. In. ml IIl. ma.<br />

Standard<br />

2x3 3/4 19 314 19.1 2v9410 x0012 2v9410 x0012 2v9410 x0012<br />

l-118 29 l-114 31.8 2v9412 x0012 2v9412 x0012 2v9412 x0012<br />

l-s/a 41.3 2v9414 x0012 2v9414 x0012 2v9414 x0012<br />

3x4 3/4 19 1 25.4 2v9297 x0012 2v9297 x0012 2v9297 x0012<br />

l-l/a 29 l-114 31.8 2v9298 x0012 2v9298 x0012 2v9298 x0012<br />

l-1/2 38.1 2V9416 X0012 2V9416 X0012 2V9416 X0012<br />

l-318 34.9 2v9419 x0012 289419 x0012 2v9419 x0012<br />

4 x 6 l-112 38 2-l/2 63.5 2V9638 x0012 289523 x0012 - * *<br />

3 76.2 2V9640 X0012 2V9525 X0012 . - -<br />

6x8 2 51 3-l/2 88.9 2V9646 X0012 2V9646 X0012 . . .<br />

-lO-

Key 4 Seat Ring Retainer, 416 stainless steel<br />

<strong>Design</strong> <strong>461</strong><br />

BODY PORT CLASS<br />

SIZE, DIA.<br />

IN. IKL. lmu. 300 & 600 900 St 1500 2500<br />

314 19.1 lB3641 <strong>461</strong>72 lB3612 <strong>461</strong>72 lH6740 X0012<br />

2x3 l-1/4 31.8 lB3995 <strong>461</strong>72 lC2644 <strong>461</strong>72<br />

l-518 41.3 lH.5352 X0012 ID1672 <strong>461</strong>-72 lB796;'iOOl2<br />

1 25.4 lC9321 x0012 . . . . . .<br />

3x4 l-1/4 .31.8 lC9787 X0012 ID6365 X0012 . . .<br />

l-1/2 38.1 ID7603 X0012 lC6475 XOOA2 . . .<br />

l-314 44.5 lE1195 X0012 lC4541 <strong>461</strong>72 . * .<br />

4x6 2-l/2 63.5 lB3677 <strong>461</strong>92 lC9784 X0012 . . .<br />

3 76.2 lB3676 <strong>461</strong>92 ..* . . .<br />

6x8 3-l/2 88.9 lC1077 x0012 .*. . . .<br />

CJ5864-B<br />

Figure 1. Bonnet Assembly for <strong>Design</strong> <strong>461</strong> <strong>Valve</strong> <strong>Body</strong><br />

-11-

Destgn <strong>461</strong><br />

Key 10 <strong>Valve</strong> Stem, 316 stainless steel<br />

BODY PORT CLASS<br />

SIZE, DIA.<br />

IN. In. mm. 600 900 & 1500 2500<br />

For Use With Standard Bonnet<br />

2 x 3l Std. Std. lOA X012 1069265 X862 . lOA X692<br />

3 x 4l Std. Std. . . . 1069265 X832 lOA X602<br />

4 x 62 2 to 3 51 to 76 a. . llA3429 x012 . . .<br />

4 x 63 2 to 3 51 to 76 . . . llA3429 X082 . . .<br />

6 x 82 3-l/2 to 89 to 114 llA3429 Xl62 llA3429 x112 . . .<br />

4-l/2<br />

6 x 83 3 to 4-l/2 76 to 114 llA3429 Xl22 llA3429 Xl32 . . .<br />

2 x 3l<br />

4 x 62<br />

4 x 63<br />

i6 x 82<br />

For Use With Radiation Bonnet<br />

HA3429 Xl42 HA3429 Xl52<br />

1183429 X112<br />

3 to 4-l/2 76 to 114 HA3429 Xl22 llA3429 Xl32 . . .<br />

1. For use with Group 1 actuators.<br />

2. For use with Group 100 actuators.<br />

3. For use with Group 101 actuators.<br />

Key 14 Standard Bonnet without equalizing connection<br />

STRMSIZR<br />

In. mm<br />

314 19.1<br />

1 25.4<br />

BODY BODY CLASS<br />

MATERIAL SIZE 300 or 600 1900 or 1500 1 2500<br />

WCB steel<br />

-1<br />

WCB steel<br />

2x3 2F8952 22012 2F6994 22012 lF8886 22012<br />

3x4 . . . 3F7897 22012 3F7818 XOOft2<br />

4x6 . . . 32Ao597 x012 . . .<br />

2x3 ..* 3B2408 22012 OX0912 22012<br />

3x4 . . . 2U8146 XOOA2 3D6819 22012<br />

.4 x 6 ..* 3B1592 22012 . . .<br />

-12-

Key 14 Radiation Fin Bonnet for 3/4 in. (19.1 mm) stem<br />

BODY CLASS<br />

SIZE, IN. 300 or 600 I 900 or 1500 2500<br />

2x3<br />

3x4<br />

4x6<br />

6x8<br />

2x3<br />

3x4<br />

4x6<br />

6x8<br />

WCB Steel <strong>Body</strong> Without Equalizing Cotiection<br />

<strong>Design</strong> <strong>461</strong> I<br />

3P1511 22012 3P1513 22012 3P1521 22012<br />

3F6997 XOOA2 2P1539 x0012 2P1535 X0012<br />

3P1515 22012 3P1537 x0012 . . .<br />

3P1541 x0012 . . . . . .<br />

WCB Steel <strong>Body</strong> With Equalizing Connection<br />

3P1512 XOOA2 3P1514 22012 3P1522 X0012<br />

3F6997 X0022 2P1540 X0032 2P1536 X0012<br />

3P1516 22012 3P1538 X0012 . . .<br />

3P1542 X0012 . . . . . .<br />

C5 Steel <strong>Body</strong> Without Equalizing Connection<br />

3P1515 29022 3P1537 x0022<br />

3P1512 X0012 3P1514 29022 3P1522 X0022<br />

3P1516 29022 3P1538 X0022 . . .<br />

3P1542 X0022 . . . . . .<br />

-13-

I <strong>Design</strong> <strong>461</strong><br />

I<br />

Key 14 Radiation Fin Bonnet for 1 in. (25.4 mm) stem<br />

BODY<br />

SIZE, IN. 300 or 600<br />

CLASS<br />

900 or 1500<br />

I<br />

WCB Steel <strong>Body</strong> Without Equalizing Connection<br />

2500<br />

2x3 3E6696 X0012 3D4085 22012 336695 X0012<br />

3x4 336705 22012 3c4534 22012 3LlO53 x0012<br />

4x6 336694 X0012 3E6692 X0012 . . .<br />

6x8 3E6704 X0012 3V8431 X0012 . . .<br />

2x3<br />

3x4<br />

4x6<br />

6x8<br />

2x3<br />

3x4<br />

4x6<br />

6x8<br />

WCB Steel <strong>Body</strong> With Equalizing Connection<br />

3E6696 X0032 3134085 X0012- 336695 X0032<br />

3E6705 X0022 3c4534 x0022 3L1053 X0032<br />

3E6694 X0032 3E6692 X0032 . . .<br />

3E6704 X0012 3V8431 X0032 . . .<br />

C5 Steel <strong>Body</strong> Without Equalizing Connection<br />

3E6696 X0022 3134085 29022 3E6695 X0022<br />

3E6705 X0012 3c4534 x0012 3L1053 x0022<br />

3E6694 X0022 3E6692 X0022 . . .<br />

336704 X0022 3V8431 X0022 . . .<br />

C5 Steel <strong>Body</strong> With Equalizing Connection<br />

2x3 3E6696 X0042 3D4085 X0022 3E6695 X0042<br />

3x4 3E6705 X0032 3C4534 X0032 3LlO53 X0042<br />

4x6 3E6694 X0042 3E6692 X0042 . . .<br />

6x8 3E6704 X0042 3V8431 X0042 . . *<br />

-14-

.<br />

<strong>Design</strong> <strong>461</strong><br />

Key 31 Pipe Plug, Lubricator, or Lubricator/Isolating <strong>Valve</strong> for use<br />

with both 3/4-inch (19.1 mn) and l-inch (25.4 mn) stems<br />

Part<br />

Pipe Plug<br />

Lubricator<br />

Lubr/ISO <strong>Valve</strong><br />

Bonnet Material<br />

WCB steel<br />

Cast chrome moly-steel<br />

All materials<br />

Actuator Groups (by Type Number)<br />

Carbon, chrome moly,<br />

carbon-moly<br />

Group 1<br />

2-l/8 in. (54 mm), 2-13/16 in. (71 mm),<br />

or 3-9/16 in. (90 mm) Yoke Boss<br />

350 - 2-13/16 in. (71.4 mm) Yoke Boss<br />

422 & 424<br />

470 Series - 2 in. (50.8 nnn) travel<br />

472 & 473<br />

512 & 512R<br />

513 & 513R<br />

603 Sr 1B<br />

608 84 618<br />

610 & 688<br />

611<br />

612 & 612R<br />

613 & 613R<br />

644 & 645<br />

655<br />

657 & 667 - 3 in. (76.2 mm) travel<br />

1008 - 2-13/16 in. (71.4 mm) Yoke Boss<br />

-15-<br />

Part Number<br />

llA7675 24662<br />

. llA7675 35072<br />

KMFXl-F9<br />

KMKKl-FlO<br />

Group 100<br />

5 in. (127 mm) Yoke Boss<br />

350<br />

470<br />

471<br />

472<br />

473<br />

474<br />

475<br />

476<br />

657<br />

1008<br />

Group 101<br />

5 in. (127 mm) Yoke Boss<br />

667

AFJ506<br />

<strong>Design</strong> <strong>461</strong><br />

Figure 2. <strong>Design</strong> <strong>461</strong> <strong>Valve</strong> <strong>Body</strong> Assembly<br />

(RSHRI”) Fisher Controls<br />

For intomtatlon write:<br />

P.O. Box 190, Marshmown. low8 50158. USA.<br />

or Brenchlay House. Maidstone. Ken1 ME 14 1UQ. England

![ratings & DEFINITIONS452-467_Technical Information[1].pdf](https://img.yumpu.com/49871719/1/190x245/ratings-definitions452-467-technical-information1pdf.jpg?quality=85)