Metallography: Principles and Practices - ASM International

Metallography: Principles and Practices - ASM International

Metallography: Principles and Practices - ASM International

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Metallography</strong>: <strong>Principles</strong> <strong>and</strong> Practice (#06785G)<br />

Author(s): George F. V<strong>and</strong>er Voort<br />

26 METALLOGRAPHY<br />

Copyright © 1984 <strong>ASM</strong> <strong>International</strong> ®<br />

All rights reserved.<br />

www.asminternational.org<br />

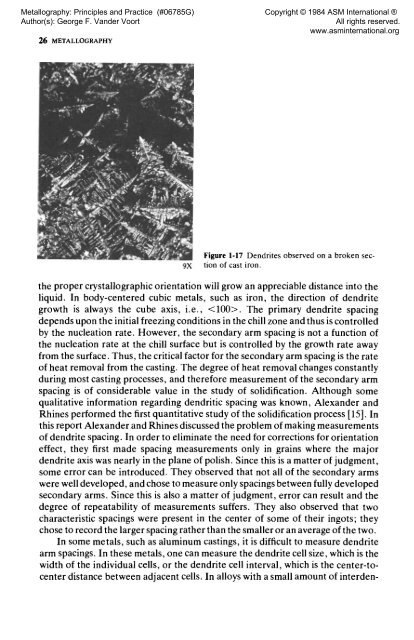

Figure 1-17 Dendrites observed on a broken sec-<br />

9X tion of cast iron.<br />

the proper crystallographic orientation will grow an appreciable distance into the<br />

liquid. In body-centered cubic metals, such as iron, the direction of dendrite<br />

growth is always the cube axis, i.e., . The primary dendrite spacing<br />

depends upon the initial freezing conditions in the chill zone <strong>and</strong> thus is controlled<br />

by the nucleation rate. However, the secondary arm spacing is not a function of<br />

the nucleation rate at the chill surface but is controlled by the growth rate away<br />

from the surface. Thus, the critical factor for the secondary arm spacing is the rate<br />

of heat removal from the casting. The degree of heat removal changes constantly<br />

during most casting processes, <strong>and</strong> therefore measurement of the secondary arm<br />

spacing is of considerable value in the study of solidification. Although some<br />

qualitative information regarding dendritic spacing was known, Alex<strong>and</strong>er <strong>and</strong><br />

Rhines performed the first quantitative study of the solidification process [15]. In<br />

this report Alex<strong>and</strong>er <strong>and</strong> Rhines discussed the problem of making measurements<br />

of dendrite spacing. In order to eliminate the need for corrections for orientation<br />

effect, they first made spacing measurements only in grains where the major<br />

dendrite axis was nearly in the plane of polish. Since this is a matter of judgment,<br />

some error can be introduced. They observed that not all of the secondary arms<br />

were well developed, <strong>and</strong> chose to measure only spacings between fully developed<br />

secondary arms. Since this is also a matter of judgment, error can result <strong>and</strong> the<br />

degree of repeatability of measurements suffers. They also observed that two<br />

characteristic spacings were present in the center of some of their ingots; they<br />

chose to record the larger spacing rather than the smaller or an average of the two.<br />

In some metals, such as aluminum castings, it is difficult to measure dendrite<br />

arm spacings. In these metals, one can measure the dendrite cell size, which is the<br />

width of the individual cells, or the dendrite cell interval, which is the center-tocenter<br />

distance between adjacent cells. In alloys with a small amount of interden-