Workshop engine manual

Workshop engine manual

Workshop engine manual

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

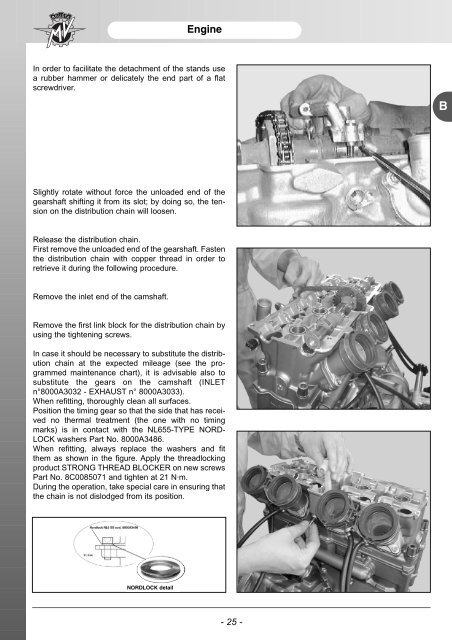

Engine<br />

In order to facilitate the detachment of the stands use<br />

a rubber hammer or delicately the end part of a flat<br />

screwdriver.<br />

Slightly rotate without force the unloaded end of the<br />

gearshaft shifting it from its slot; by doing so, the tension<br />

on the distribution chain will loosen.<br />

Release the distribution chain.<br />

First remove the unloaded end of the gearshaft. Fasten<br />

the distribution chain with copper thread in order to<br />

retrieve it during the following procedure.<br />

Remove the inlet end of the camshaft.<br />

Remove the first link block for the distribution chain by<br />

using the tightening screws.<br />

In case it should be necessary to substitute the distribution<br />

chain at the expected mileage (see the programmed<br />

maintenance chart), it is advisable also to<br />

substitute the gears on the camshaft (INLET<br />

n°8000A3032 - EXHAUST n° 8000A3033).<br />

When refitting, thoroughly clean all surfaces.<br />

Position the timing gear so that the side that has received<br />

no thermal treatment (the one with no timing<br />

marks) is in contact with the NL655-TYPE NORD-<br />

LOCK washers Part No. 8000A3486.<br />

When refitting, always replace the washers and fit<br />

them as shown in the figure. Apply the threadlocking<br />

product STRONG THREAD BLOCKER on new screws<br />

Part No. 8C0085071 and tighten at 21 N·m.<br />

During the operation, take special care in ensuring that<br />

the chain is not dislodged from its position.<br />

NORDLOCK detail<br />

- 25 -<br />

B

![Use the clutch holder [B] to prevent the](https://img.yumpu.com/11393415/1/184x260/use-the-clutch-holder-b-to-prevent-the.jpg?quality=85)