30. Furan-Based Adhesives

30. Furan-Based Adhesives

30. Furan-Based Adhesives

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

a few furanic monomers and resins are involved, namely: 1, 2, 3, 5, and 6, as well as liquid<br />

oligomers of 2 (poly2) and3 (poly3). The properties of these monomers together with<br />

the mechanisms of their resinification and the composition of poly2 and poly3 will<br />

be briefly dealt with before discussing their use in the manufacture of resins for binders<br />

and adhesives.<br />

II. PROPERTIES OF FURANIC MONOMERS<br />

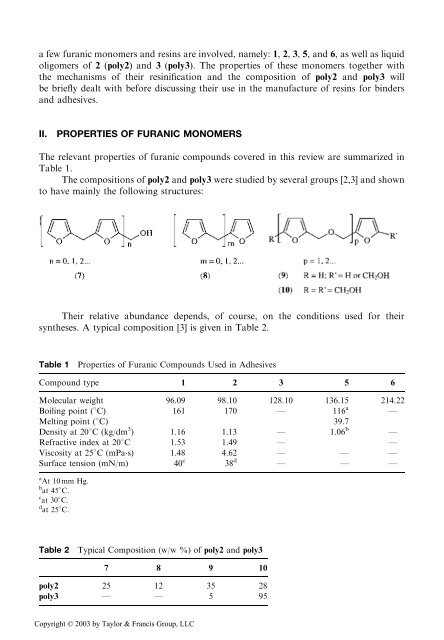

The relevant properties of furanic compounds covered in this review are summarized in<br />

Table 1.<br />

The compositions of poly2 and poly3 were studied by several groups [2,3] and shown<br />

to have mainly the following structures:<br />

Their relative abundance depends, of course, on the conditions used for their<br />

syntheses. A typical composition [3] is given in Table 2.<br />

Table 1 Properties of <strong>Furan</strong>ic Compounds Used in <strong>Adhesives</strong><br />

Compound type 1 2 3 5 6<br />

Molecular weight 96.09 98.10 128.10 136.15 214.22<br />

Boiling point ( C) 161 170 — 116 a<br />

—<br />

Melting point ( C) 39.7<br />

Density at 20 C (kg/dm 3 ) 1.16 1.13 — 1.06 b<br />

—<br />

Refractive index at 20 C 1.53 1.49 — —<br />

Viscosity at 25 C (mPa s) 1.48 4.62 — — —<br />

Surface tension (mN/m) 40 c<br />

38 d<br />

— — —<br />

a At 10 mm Hg.<br />

b at 45 C.<br />

c at 30 C.<br />

d at 25 C.<br />

Table 2 Typical Composition (w/w %) of poly2 and poly3<br />

7 8 9 10<br />

poly2 25 12 35 28<br />

poly3 — — 5 95<br />

Copyright © 2003 by Taylor & Francis Group, LLC