download - Compact Equipment

download - Compact Equipment

download - Compact Equipment

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

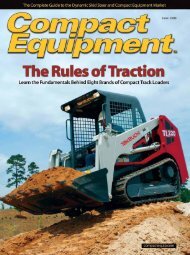

Mustang Track Loaders<br />

Two Radial-Lift Loaders with the HydraTrac Auto Tensioning System<br />

Mustang began in the 19th century as<br />

the Owatonna Mfg. Co. Starting as an agricultural<br />

implement manufacturer, Mustang<br />

has since grown into a 21st century<br />

compact equipment leader. Mustang built<br />

its first skid steer in 1965. Entering the<br />

track loader market in 2001, Mustang has<br />

a lot of experience in the dedicated track<br />

loader industry. Mustang track loaders are<br />

manufactured in Yankton, S.D.<br />

Mustang offers two track loader models<br />

to meet the needs of today’s compact<br />

equipment users. The 1750RT and 2100RT<br />

integrate innovation with proven experience<br />

to bring a new breed of track loader<br />

to the market. Powerful and efficient Yanmar<br />

engines rated at 68 and 71 hp are at<br />

the core of Mustang track loaders. These<br />

engines, in concert with standard anti-stall<br />

technology and planetary final drive, contribute<br />

to class-leading tractive effort and<br />

fuel efficiency, says Mustang.<br />

Models feature radial-lift loader arm geometry, offering<br />

excellent power in ground-engaging applications, and additional<br />

reach at trailer loading height. A low profile boom<br />

design enhances visibility, while providing a class-leading lift<br />

height of 128 in. Auxiliary hydraulic flow is standard (high<br />

flow optional), with connect-under-pressure couplers. A standard<br />

universal mechanical quick-attach plate contributes to<br />

versatility, while an optional hydraulic quick-attach facilitates<br />

change-over. Adjustable response control (5x5 Ride Control<br />

System) is standard equipment, allowing operators to customize<br />

machine response to joystick movements. Adjustable<br />

speed control is optional, allowing operators to manage precise<br />

ground speeds at specific engine revolutions.<br />

Mustang track loaders feature a dedicated welded undercarriage<br />

designed to withstand the most arduous of applications.<br />

The undercarriage design assists in superior weight distribution,<br />

which enhances stability, grading, tractive effort and ride control.<br />

The HydraTrac automatic track tensioning system introduces a<br />

new level of innovation, by automatically maintaining proper<br />

track tension. Track life is extended, reducing operating costs,<br />

and less maintenance is required to maintain track tension. Critical<br />

drive hoses are routed on the interior of the chassis, unlike<br />

competitors, protecting these vital components from damage.<br />

Operators will appreciate the spacious, ergonomic operator<br />

environment, says Mustang. Industry-leading safety is provided<br />

by a standard Level 2 ROPS structure. A cab-forward<br />

design offers excellent visibility to the bucket. Seat-mounted<br />

joystick controls move with the contoured, fully adjustable<br />

standard mechanical suspension seat. A two-piece restraint<br />

Mustang Track Loader Specs<br />

Contact Info<br />

Mustang Mfg. Co.<br />

P.O. Box 179<br />

West Bend, WI 53090<br />

(262) 334-9461<br />

info@mustangmfg.com<br />

www.mustangmfg.com<br />

makes easy work of operator ingress and egress. A standard<br />

customizable color display monitors machine performance<br />

and allows operators to customize machine functionality. An<br />

exclusive tilt-out foot pod is easily cleaned when needed. An<br />

optional sealed and pressurized cabin is available, with heat<br />

and/or air conditioning. Electro-hydraulic controls are standard,<br />

facilitating ease of operation.<br />

The 1750RT and 2100RT are packed with standard features,<br />

including hydraulic self-leveling, two-speed drive motors,<br />

maintenance-free rollers, HydraTrac auto track tensioning<br />

system and much more. In the RT Series, Mustang boasts, it<br />

brings a whole new breed of track loader to the marketplace.<br />

Advice to Buyers<br />

“Even though there are a multitude of brands and options<br />

when it comes to making a track loader purchase, you will soon<br />

find that the major components are basically the same,” says<br />

Sean Bifani, Mustang track loader product manager. “The key is<br />

to first determine what you plan to do with the machine. What<br />

tasks do you need to accomplish? What terrain and space do you<br />

work in most often? What attachments do you already own and<br />

what ones do you still need? Be sure to also consider the future<br />

needs of the machine. Once these needs are established it will<br />

be simple to narrow down your options in the market. Consider<br />

the machine’s lift height, rated capacity and overall size. Review<br />

the attachment options available as well as the requirements of<br />

the hydraulic system on the machine. Review carefully the basic<br />

daily maintenance of the machine and the tracks. Daily maintenance<br />

should be easy to perform and components easy to access.<br />

If you will be the operator, make sure the operator’s compartment<br />

is comfortable and meets your environmental needs.”<br />

Model Engine Horsepower Operating Capacity Operating Capacity Operating Weight Tip Capacity Lift Height (Orientation) Price<br />

Net HP 50 Percent 35 Percent (Ground Pressure) Height to Hinge Pin National MSRP<br />

1750RT 68.4 hp 2,500 lbs 1,750 lbs 8,605 lbs (6.2 psi) 5,000 lbs 10 ft, 6 in. (Radial) $51,700<br />

2011RT 70.7 hp 3,000 lbs 2,100 lbs 9,890 lbs (4.7 psi) 6,000 lbs 10 ft, 6 in. (Radial) $61,600<br />

www.ceunbound.com June 2012 <strong>Compact</strong> <strong>Equipment</strong> 39