download - Compact Equipment

download - Compact Equipment

download - Compact Equipment

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Departments<br />

4 Editor’s Message<br />

6 News<br />

82 CE Advertisers Index<br />

Promoting the use of compact equipment by the owner/operator and<br />

business professional in the commercial, private and rental markets<br />

VOLUME 11 • NUMBER 6 • JUNE 2012 • CEUNBOUND.COM<br />

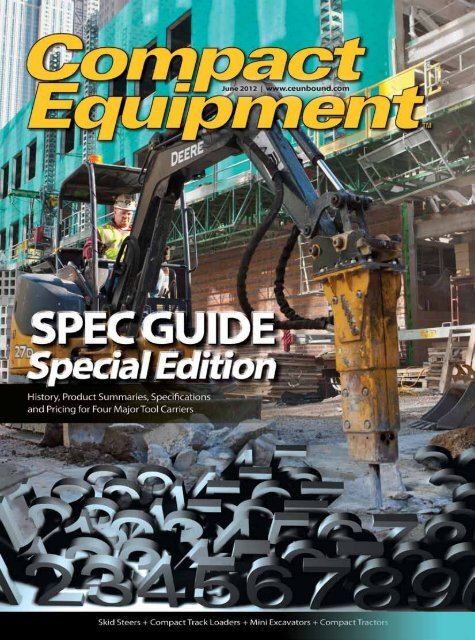

On the Cover:<br />

The John Deere 27D compact excavator<br />

capitalizes on a zero tail swing design, which<br />

allows this nimble excavator to rotate fully<br />

without banging its tail into something<br />

important. It’s great for working in city streets.<br />

11 Skid Steer Loader Section<br />

The core American machine in the compact equipment category<br />

is the venerated skid steer loader. Since its inception in the<br />

1950s, the skid steer has redefined the tool carrier concept<br />

in the construction machinery industry, using hundreds of<br />

hydraulically operated attachments to fit into almost any worksite<br />

— construction, landscape, farming and beyond.<br />

29 <strong>Compact</strong> Track Loader Section<br />

The compact track loader is one of the most versatile and<br />

useful tools a contractor can find on tracks, providing<br />

improved capability over soft terrain and increased capacity<br />

compared to skid steers. Engineered with a dedicated<br />

track undercarriage, compact track loaders extend the<br />

construction season into spring, fall and winter.<br />

47 Mini Excavator Section<br />

Excavators are the ultimate digging tools, and compact excavators<br />

are the ultimate digging tools when it comes to urban areas and<br />

confined jobsite applications. <strong>Compact</strong> excavators (also called mini<br />

excavators) are defined as excavators under 6 metric tons (although<br />

we cover a few bigger ones in this section too), fitting into cramped<br />

worksites while still giving big dig power.<br />

69 <strong>Compact</strong> Tractor Section<br />

The compact utility tractor is a do-it-all tool carrier used<br />

by farmers, landscapers, groundskeepers, golf courses,<br />

large estate owners and operators of every type. <strong>Compact</strong><br />

tractors are a versatile breed of machine with the ability<br />

to take implements in the front, rear and under the belly,<br />

utilizing a unique power take off attachment system called<br />

the PTO.<br />

COMPACT EQUIPMENT (ISSN 1552-1281) is published monthly by Benjamin Media, Inc. 1770 Main Street, P.O. Box 190, Peninsula, OH 44264. Copyright 2012, Benjamin Media, Inc. All rights reserved. No part of this publication may be reproduced or transmitted by any means<br />

without written permission from the publisher. One-year subscription rates: complimentary for qualified readers in the United States and Canada. Single copy rate: $10.00. Subscriptions and classified advertising should be addressed to the Peninsula office. Periodicals postage<br />

paid at Peninsula, OH and additional mailing office. POSTMASTER: send address changes to COMPACT EQUIPMENT, 1770 Main Street P.O. BOX 190, PENINSULA, OH 44264 USA.<br />

Canadian Subscriptions: Canada Post Agreement Number 40040393. Send change of address information and blocks of undeliverable copies to Canada Express; 7686 Kimble Street, Units 21 & 22, Mississauga, ON L5S 1E9 Canada.<br />

www.ceunbound.com June 2012 <strong>Compact</strong> <strong>Equipment</strong> 3

FROM THE EDITOR...<br />

The First of Many<br />

Launching the Annual CE Spec Guide for <strong>Compact</strong> Tool Carriers<br />

First off, thanks to all the manufacturers that participated in the first-ever <strong>Compact</strong> <strong>Equipment</strong> Spec<br />

Guide. If we could send all of you Champagne and pedicures we would, but rest assured next time we<br />

see you, there will be lots of hugs. This 84-page cannon of compact machinery required a lot of research,<br />

and a lot of that legwork came from the equipment manufacturers who provided us the information.<br />

Pricing was an especially sticky subject, and we appreciate PR folks going to bat for us time and time<br />

again. Getting machine makers to allow us to publish in-house “manufacturer’s suggested retail price”<br />

felt a little like marriage counseling. Daily conference calls, shameless begging, months of e-mails and<br />

the occasional game of hardball pushed most manufacturers to consent. We did not publish any summaries<br />

or specs if manufacturers did not provide some idea of how much a unit costs.<br />

We hope most contractors<br />

realize the prices provided<br />

are ballpark figures (usually<br />

base models), and that your<br />

local dealer is the place to<br />

truly price out your exact<br />

model. Of course pricing is<br />

only one aspect of the Spec<br />

Guide. The real meat of this<br />

guide is in the product summaries<br />

and specs. The magazine<br />

overall is divided into<br />

four main sections using<br />

thick, 100-lb card stock, easy<br />

for your fingers to find: 1)<br />

We’d like to thank all the manufacturers who participated in the first annual<br />

<strong>Compact</strong> <strong>Equipment</strong> Spec Guide.<br />

skid steers; 2) compact track<br />

loaders; 3) mini excavators;<br />

and 4) compact tractors.<br />

Manufacturers are listed in alphabetical order, and each listing has a history, product summary, photo<br />

and list of essential model specifications (everything from bucket breakout force to boom lift orientation).<br />

Contact information is provided up in the corner of each listing, so you can continue your journey<br />

over the phone, online or with your local dealer. We’re so pleased with the 2012 version of the Spec<br />

Guide, we’re hoping to make it an annual specialty issue. Each year’s version will be designed as a<br />

12-month reference guide, so find a handy place to store this magazine — an office shelf, glove box or<br />

maybe the cab of your favorite piece of iron.<br />

When it comes to versatile solutions, compact tool carriers like skid steers and mini excavators give<br />

companies hundreds of different solutions to get the job accomplished. It’s what makes these multitasking<br />

machines such good investments. There are a ton of brands on the market, so this guide should<br />

be a great reference point to begin to compare model to model. We hope this is just the first of many<br />

ultimate guidebooks geared toward the ever-expanding compact equipment industry.<br />

Keith Gribbins<br />

Managing Editor<br />

kgribbins@benjaminmedia.com<br />

President<br />

Bernard P. Krzys<br />

bkrzys@benjaminmedia.com<br />

Publisher<br />

Robert D. Krzys<br />

robk@benjaminmedia.com<br />

Managing Editor<br />

Keith Gribbins<br />

kgribbins@benjaminmedia.com<br />

Associate Editor<br />

Pam Kleineke<br />

pkleineke@benjaminmedia.com<br />

Assistant Editor<br />

Kelly Pickerel<br />

kpickerel@benjaminmedia.com<br />

Contributing Staff Editors<br />

Sharon M. Bueno<br />

sbueno@benjaminmedia.com<br />

Bradley Kramer<br />

bkramer@benjaminmedia.com<br />

Graphic Designer<br />

Sarah Hayes<br />

shayes@benjaminmedia.com<br />

Marketing Director<br />

Kelly Dadich<br />

kdadich@benjaminmedia.com<br />

Regional Sales Manager<br />

Dan Sisko<br />

dsisko@benjaminmedia.com<br />

Regional Sales Manager<br />

Ryan Sneltzer<br />

rsneltzer@benjaminmedia.com<br />

Regional Sales Representatives<br />

Lindsie Bowman<br />

lbowman@benjaminmedia.com<br />

Tim Richards<br />

trichards@benjaminmedia.com<br />

Audience Development Manager<br />

Alexis R. White<br />

awhite@benjaminmedia.com<br />

Web Manager<br />

Mark Gorman<br />

mgorman@benjaminmedia.com<br />

Reprint Information<br />

Wright’s Media<br />

Ph: 877.652.5295<br />

Fax: 281.419.5712<br />

Editorial & Advertising Offices<br />

1770 Main St., P.O. Box 190<br />

Peninsula, OH 44264 USA<br />

Ph: 330.467.7588<br />

Fax: 330.468.2289<br />

www.ceunbound.com<br />

4 <strong>Compact</strong> <strong>Equipment</strong> June 2012 www.ceunbound.com

CE News<br />

Editors at Large<br />

Covering Kubota’s Tennessee Press Event and the Volvo Ocean Race in Miami<br />

By Keith Gribbins and Kelly Pickerel<br />

The world of construction<br />

equipment requires a lot of<br />

travel, and May was a busy<br />

month for machine manufacturers.<br />

Mid-month, Kubota invited<br />

<strong>Compact</strong> <strong>Equipment</strong> down<br />

to Shelbyville, Tenn., to operate<br />

two of its most interesting offerings<br />

in the UTV industry —<br />

the RTV1100 and the RTV400.<br />

The famous orange engine and<br />

equipment brand cleverly held<br />

the event at Shelbyville’s Celebration<br />

Arena, a 105-acre complex<br />

that houses the Tennessee<br />

Walking Horse National Celebration<br />

(a festival that began in<br />

1939 and today gives more than<br />

$650,000 in prizes and awards).<br />

The Tennessee Walking Horse<br />

would make a pretty good mascot<br />

for Kubota’s RTV Series of<br />

utility vehicles — both are work<br />

focused, but still like to play<br />

a little after hours. Tennessee<br />

Walking Horses were originally<br />

bred by the farmers of middle<br />

Tennessee who wanted to develop<br />

a breed that could work<br />

in the fields during the day and<br />

also give the owner a comfortable<br />

saddle gait after the job was<br />

done. Kubota’s line of off-road RTV utility vehicles were<br />

raised the same way — as workhorses that still provide a nice<br />

ride when all the work is finished.<br />

Behind the wheel, editors explored the dirt-covered outdoor<br />

arenas with dozer blades and broom attachments, putting<br />

the Kubota RTVs to the test.<br />

“The 1100 has been out for a while [a year plus], but the<br />

rotary broom that we featured today has only been out for<br />

a few months,” said Dan Muramoto, RTV product manager<br />

with Kubota. “And the broom completes our hydraulic<br />

front-implement selection for now, which includes the 72in.<br />

commercial straight blade, 72-in. V-blade and the 60-in.<br />

rotary broom.”<br />

Front-mounted hydraulic attachments complete the<br />

RTV1100’s work resume; the new, cool, quick-attach system<br />

is a synergy with RAD Technologies. Attachment work is awesome<br />

with the RTV1100 because it comes with a Premium<br />

Grand Cab, the industry’s first factory-installed all-weather<br />

cab with standard air conditioning, heater and defroster. The<br />

CE managing editor Keith Gribbins (left) talks with Dan Muramoto (RTV product manager)<br />

last month at the Kubota press event in Shelbyville, Tenn.<br />

RTV1100 is available in both worksite and recreational models<br />

and packs plenty of power with a three-cylinder, 24.8-hp<br />

Kubota diesel engine that boasts a best-in-class 50.3 ft-lbs<br />

of torque for all-around durability and drive. It also comes<br />

standard with a hydraulic bed lift system and a cargo load<br />

capacity of more than 1,100 lbs. The attachment system is<br />

operated using a nice, center-mounted joystick.<br />

“This attachment system brings front-implement capability<br />

that didn’t exist before,” explained Muramoto. “It gives<br />

a commercial contractor — a snow removal contractor, landscaper,<br />

rancher or groundskeeper — it gives those people options<br />

that were non-existent before. Prior to this, they either<br />

had to use a skid steer or tractor.”<br />

It should be noted that folks like Bobcat and Polaris also<br />

offer UTV attachment systems, but they all greatly differ.<br />

Besides implements, Kubota also introduced the new RT-<br />

V400Ci, a 16-hp utility vehicle that fits into the bed of a<br />

full-sized pickup truck, making it ideal for anything from<br />

hunting to routine work around the jobsite. It’s a fun little<br />

unit, but still made for work.<br />

6 <strong>Compact</strong> <strong>Equipment</strong> June 2012 www.ceunbound.com

“I like to say the RTV is the Clydesdale in a field of race<br />

ponies,” smiled Muramoto. “There are a lot of other utility<br />

vehicles that are faster and better in terms of extreme offroading,<br />

but that’s not what we’re about. We’re about trying<br />

to make your work day a little better.”<br />

The Volvo Ocean Race<br />

The only U.S.-stopover for the Volvo Ocean Race provided<br />

a great opportunity for Volvo Construction <strong>Equipment</strong> to<br />

highlight its advances in sustainability. Volvo invited industry<br />

journalists down for the Miami leg of the race to learn<br />

more about the company’s approach to a fuel efficient future,<br />

its partnership with the World Wildlife Fund’s (WWF)<br />

Climate Saver program and its Stage IIIB/Tier 4i emissions<br />

compliant range of engine systems, with a little bit of nautical<br />

fun thrown in. The best way to understand how to do<br />

more with less is to see the cramped quarters 11 men must<br />

occupy for nine months on the high seas. The seamen’s passion<br />

to push through and win the race is the same passion<br />

Volvo CE puts forth in its dedication to its core values —<br />

quality, safety and environmental care.<br />

At a press conference, Volvo CE president and chief executive<br />

Pat Olney emphasized the company’s portfolio of<br />

more than 60 new fuel-efficient<br />

products, all with Tier<br />

4i compliant engine systems.<br />

Powertrain expert Dave Hahn<br />

stressed Volvo CE’s four point<br />

strategy to answering the call<br />

for long term, significant and<br />

sustainable machine efficiency.<br />

“Engine technology continues<br />

to make tremendous strides<br />

in finding improvements in<br />

fuel efficiency while at the<br />

same time reducing harmful<br />

emissions,” Hahn stated. “But<br />

this alone will be insufficient to<br />

meeting our long term environmental<br />

and productivity goals.<br />

Volvo CE is addressing the issue<br />

of machine sustainability<br />

from a holistic viewpoint, one<br />

that includes engines, systems,<br />

emerging technologies and<br />

even operator behavior.”<br />

The cooperation between<br />

Volvo CE and the WWF forms<br />

part of the Volvo Group’s wider<br />

commitment to reduce carbondioxide<br />

emissions by 30 mil-<br />

lion tons from construction equipment, buses and trucks<br />

made between 2009 and 2014. Of this total, Volvo CE is<br />

dedicated to cutting its carbon dioxide output by 15 million<br />

tons in that timeframe. Volvo Construction <strong>Equipment</strong> officially<br />

joined the program in February 2012.<br />

“The WWF’s Climate Savers program is a challenging initiative<br />

that will help us to further reduce our CO 2 emissions,<br />

increase our products’ fuel efficiency and demonstrate that<br />

we’re truly committed to environmental sustainability,”<br />

Olney said.<br />

One steamy morning of the press event, a group of journalists<br />

had the rare opportunity to tour one of the Ocean<br />

Race boats — the Abu Dhabi vessel headed by double Olympic<br />

medalist and 2008-2009 Volvo Ocean Race skipper, Ian<br />

Walker. It was invigorating to witness the great technology<br />

and dedication involved with the competition, something<br />

Olney said correlates to the advances at Volvo CE.<br />

“The thing with the Volvo Ocean Race, it’s a global event<br />

and it goes through all our major markets which allows us<br />

the opportunity to connect with our customers around the<br />

world,” he said. “I think the athletes that are involved are a<br />

very special breed of committed people that reflects well the<br />

leadership values that we appreciate inside Volvo CE.”<br />

CE assistant editor Kelly Pickerel (in black dress on right) and fellow industry journalists<br />

take in the experiences of the race village at the Volvo Ocean Race stopover in Miami.<br />

www.ceunbound.com June 2012 <strong>Compact</strong> <strong>Equipment</strong> 7

CE News<br />

Economists Say Housing Outlook<br />

Continues to Slowly Brighten<br />

Mirroring the uneven economic recovery, the housing<br />

market is expected to move in a slow, gradual upward<br />

path in 2012. It will still encounter its share of speed<br />

bumps along the road, according to economists participating<br />

in a recent National Association of Home Builders<br />

(NAHB) construction forecast webinar on the housing and<br />

economic outlook.<br />

While the latest monthly housing data has shown signs<br />

of a slight softening, NAHB chief economist David Crowe<br />

said this is more reflective of typical month-to-month volatility<br />

in the numbers and unusual seasonal factors than<br />

they are an indication of any significant downward trend<br />

in the broader housing market.<br />

“The aggregate information suggests we’re just in a<br />

pause mode right now in terms of these measures,” said<br />

Crowe, who noted this could partly be the result of an<br />

early spring that brought much better weather than usual<br />

into the picture at the start of this year and pulled some<br />

housing activity forward. Pointing out that less volatile<br />

quarterly data has continued to show modest improvement<br />

in key housing indicators such as builder sentiment,<br />

new-home sales and housing production, Crowe said, noting<br />

the “housing outlook continues to slowly brighten.”<br />

Crowe also noted that numerous other fundamentals<br />

remain positive for housing at this time, including demographic<br />

factors (with pent-up household demand expected<br />

to ramp up and echo-boomers heading into their prime<br />

household formation ages), historically favorable mortgage<br />

rates that are not expected to move higher than 5 percent<br />

by the end of next year, more than 100 local markets currently<br />

listed on the NAHB/First American Improving Markets<br />

Index and the fact that house price-to-income ratio<br />

has now returned to its historical average of about three-toone<br />

versus the nearly five-to-one to which it had previously<br />

risen during the height of the housing boom.<br />

However, he cautioned that housing still continues to<br />

face formidable challenges of its own — such as rising foreclosures,<br />

persistently tight lending standards for homebuyers<br />

and builders and difficulties in obtaining accurate<br />

appraisals. Moreover, disappointing job growth numbers<br />

in March and uncertainty in the European economy are<br />

undermining prospects for a vigorous recovery.<br />

“No one is anticipating that an upward path for housing<br />

will run in a straight-line trajectory,” said Crowe. “The<br />

economy is in an uneven recovery, and we can expect some<br />

corresponding ups-and-downs in the housing market in the<br />

months ahead. However, NAHB believes that on the whole,<br />

we can expect a slow and gradual recovery in housing starts,<br />

home sales and the overall housing market in 2012.”<br />

New-home sales are expected to climb from a record-low<br />

of 305,000 units in 2011 to 357,000 this year and 505,000<br />

in 2013. Existing single-family sales are expected to fol-<br />

low suit and rise from 3.8 million last year to 4.4 million<br />

in 2012 and 5.4 million next year. Housing starts are also<br />

anticipated to move in the same upward trajectory, Crowe<br />

said, with single-family housing production increasing<br />

from 434,000 units last year to 503,000 this year and a<br />

more solid 660,000 in 2013. On the multifamily side, starts<br />

posted a healthy 55 percent increase in 2011 over 2010.<br />

“A lot of newly formed households have become renters,<br />

so we need more rental units,” Crowe said. “We don’t<br />

expect to see the same rate of increase moving forward, but<br />

we should continue to see a healthy recovery.”<br />

NAHB is anticipating that multifamily starts will rise from<br />

177,000 units last year to 216,000 in 2012 and 235,000 in<br />

2013. With many households choosing to stay in place and<br />

remodel their homes rather than move, residential remodeling<br />

is expected to rise 12 percent this year and another<br />

7.9 percent in 2013. Looking at various state statistics behind<br />

the national numbers, Robert Denk, NAHB’s assistant<br />

vice president for forecasting and analysis, noted a range of<br />

conditions across the country and differences among the<br />

states in the amount of distress suffered during the recession<br />

and the headway that is being made in recovering.<br />

Housing nationwide bottomed out at an average 27 percent<br />

of normal production, which he defines as the residential<br />

building that occurred in 2000 to 2003, before the<br />

housing boom. The hardest hit states — such as California,<br />

Florida, Nevada and Arizona — bottomed out at between 10<br />

percent and 15 percent of normal production, while better<br />

states, in sharp contrast, declined to 50 percent of normal<br />

production.<br />

Denk said that housing prices are drifting back to nearnormal<br />

in many states. The number of states where house<br />

prices now exceed their historic trend are continuing to<br />

recede, joining the states where prices are in the normal<br />

range. Some states however, such as Arizona and Nevada,<br />

have seen an overcorrection of boom prices and will take<br />

longer to get back to normal. Nationally, he said prices<br />

have dropped back to normal. “What we are seeing is stabilization<br />

of house prices across the country, back to nearly<br />

their historical averages,” Denk said.<br />

Most states saw their foreclosure rates jump from an<br />

average of 0.5 percent during the period before the boom<br />

to a peak of nearly 1.5 percent in the third quarter of<br />

2009, but there were those — such as California, Arizona,<br />

Florida and Nevada — where foreclosures increased by a<br />

factor of four, five or six times normal. Nationally, foreclosure<br />

rates have dropped back down to an average of 1<br />

percent, and while they remain a problem in most markets,<br />

they are at crisis proportions in only a few, Denk<br />

said. He added that Texas and Florida have roughly the<br />

same number of mortgages, but Florida has four times as<br />

many foreclosures.<br />

8 <strong>Compact</strong> <strong>Equipment</strong> June 2012 www.ceunbound.com

CE<br />

News<br />

OPEI Announces First-Ever Standard for Utility Vehicles<br />

Utility vehicles can be used for both work and play. It’s a<br />

multipurpose piece of equipment, yet these multipurpose<br />

type off-road vehicles (that straddle the markets between<br />

commercial and recreational) don’t really have many standards.<br />

The Outdoor Power <strong>Equipment</strong> Institute (OPEI) announced<br />

in May that it had issued the first-ever ANSI standard<br />

for what it called Multipurpose Off-Highway Utility<br />

Work or pleasure? Utility<br />

vehicles can do both,<br />

which is why the Outdoor<br />

Power <strong>Equipment</strong> Institute<br />

created a standard for<br />

Multipurpose Off-Highway<br />

Utility Vehicles.<br />

Modest Cement Consumption<br />

Growth Expected for 2012<br />

Stronger than expected job creation and the beginning<br />

of a construction industry recovery means gains<br />

in real construction spending will materialize this year<br />

— after seven years of consecutive declines. According to<br />

the new forecast from the Portland Cement Association<br />

(PCA), increases in cement consumption will follow.<br />

PCA revised its fall forecast upward, anticipating a<br />

modest 3.7 percent increase in 2012, followed by a<br />

7.6 percent jump in 2013 and a 14.1 percent increase<br />

in 2014. The forecast includes marginal improvements<br />

to nonresidential construction, an upward revision to<br />

housing starts and an aggressive cement intensity gain,<br />

which is the amount of cement used per real dollar of<br />

construction activity.<br />

Vehicles (MOHUVs), encompassing off-highway vehicles<br />

that operate between 25 to 50 mph and are utilized for<br />

multipurpose applications.<br />

“Up until now, there was no standard for MOHUVs. Developing<br />

this standard was really a priority for OPEI as this<br />

type of vehicle enjoys growing popularity,” said Kris Kiser,<br />

president and CEO of OPEI. “Now, MOHUV manufacturers<br />

have clear guidance and minimum<br />

requirements on voluntary, consensus<br />

driven standards as approved by ANSI.”<br />

Before the newly announced MOHUV<br />

standard, only work-focused utility vehicles<br />

(limited to 25 mph or lower) and<br />

recreation-focused off-highway vehicles<br />

(operating above 30 mph) had published<br />

standards. The new OPEI standard fills<br />

the gap by defining standards for utility<br />

vehicles that are capable of a broad spectrum<br />

of uses.<br />

OPEI’s MOHUV committee developed<br />

the standard after a rigorous American National<br />

Standards Institute (ANSI) process<br />

which included additional input and crossfunctional<br />

reviews by a consensus group<br />

comprising vehicle users, industry representatives<br />

and government/independent<br />

agencies. To learn more, visit www.opei.org.<br />

Start spreading the<br />

news: Cement usage<br />

is on the rise, which<br />

means construction is<br />

going up.<br />

“Cement usage is greatest at the early stages of construction with foundation work. The retreat of building starts during<br />

the recession had a huge impact on consumption and intensity,” said Ed Sullivan, PCA chief economist. “A construction<br />

start rebound in 2012 coupled with concrete’s competitive price compared to other building materials translates to<br />

increases.”<br />

With successive years of economic and employment growth, the structural issues facing the construction industry will<br />

diminish, Sullivan said. For example, foreclosures’ adverse impact will fade and return on investment for nonresidential<br />

investments will improve. Partially because of these improvements, state deficits will eventually be replaced by surpluses.<br />

PCA forecasts all sectors of construction to be positive during 2014-2015, which typically results in large gains in cement<br />

consumption. For more information, visit www.cement.org.<br />

www.ceunbound.com June 2012 <strong>Compact</strong> <strong>Equipment</strong> 9

CE News<br />

Infrastructure 2012 Report Highlights Innovative Solutions at State,<br />

Regional and Local Level<br />

Constrained public budgets and a growing recognition at<br />

the local level of the importance of infrastructure — combined<br />

with lack of action at the federal level — are causing<br />

states, regions and cities across the United States to seek innovative<br />

infrastructure approaches and solutions. Local governments<br />

are utilizing a range of strategies, including ballot<br />

measures taken directly to the public, increased utilization<br />

of technology and pricing and public-private partnerships,<br />

according to Infrastructure 2012: Spotlight on Leadership, recently<br />

released by the Urban Land Institute (ULI) and Ernst<br />

& Young LLP.<br />

This year’s report looks at an overall decline in infrastructure<br />

funding globally, and it focuses on funding solutions<br />

underway in the United States. Even as efforts to increase<br />

infrastructure revenues at the federal level remain stalled,<br />

states and localities are looking at other ways of overcoming<br />

fiscal woes in an effort to move forward with projects that<br />

can lay the foundation for economic growth. State and local<br />

governments are funding critical infrastructure building or<br />

refurbishment needs with increased sales or gas taxes, bond<br />

issues and user fees, including tolls. Public-private partnerships<br />

are a growing part of the equation.<br />

Infrastructure 2012 notes that in many localities, people<br />

are voting to raise taxes for infrastructure investment. From<br />

2008 through 2011, ballots allocating funds to transit capital<br />

or operations had a 73 percent success rate. More than<br />

a dozen states have raised fuel taxes over the past year, and<br />

drivers nationwide are accepting higher tolls for roads and<br />

bridges. Local governments are taking advantage of tax increment<br />

financing and special assessment districts as well<br />

as public-private partnerships, while exploring alternative<br />

sources of private investment such as sovereign wealth funds<br />

and pension plans.<br />

The study highlights six case studies showing how local<br />

and regional governments are moving forward with muchneeded<br />

infrastructure investments such as transit, ports,<br />

bridges, roads, parks and water supply. “Global economic<br />

competitiveness demands new kinds of regional entrepreneurship,”<br />

the report states, noting that each of the case<br />

studies can provide insight and inspiration for other localities<br />

seeking infrastructure solutions.<br />

Cited examples include:<br />

• North Carolina’s Research Triangle is raising local funds<br />

for a planned regional transit system spanning three<br />

counties. In late 2011, one of the three counties (Durham)<br />

passed a ballot referendum to fund its portion of<br />

the system; now the other two must follow suit.<br />

• Ballot measures also are being used in Oklahoma City,<br />

which has achieved success with bundling proposed<br />

civic projects into short-term, focused packages and<br />

subjecting them to a vote. The city’s third Metropolitan<br />

Area Projects initiative passed in late 2009 and is generating<br />

$777 million for downtown parks and other civic<br />

infrastructure.<br />

• In Los Angeles, strong leadership from public officials<br />

and grass-roots campaigning supported a $40 billion<br />

ballot initiative, Measure R, to fund critical transportation<br />

investments.<br />

The report calls out New York City as a national<br />

infrastructure innovator, citing its investments<br />

in the World Trade Center transit hub, the<br />

long-awaited Second Avenue subway, the Long<br />

Island Railroad tunnel and more.<br />

10 <strong>Compact</strong> <strong>Equipment</strong> June 2012 www.ceunbound.com

Skid Steers Are the Stars of the<br />

<strong>Compact</strong> <strong>Equipment</strong> Tool<br />

Carrier Category<br />

By Keith Gribbins<br />

To construct a summer blockbuster analogy, skid steers are<br />

the Transformers of the construction and landscape industry.<br />

With its quick-attach plate and hundreds of unique attachments,<br />

this protean piece of utility equipment is like a Constructicon,<br />

able to shift gears, change implements and dig,<br />

saw, load, cut, lift and work through most jobs and jobsites.<br />

It’s been more than 50 years since the inception of the<br />

skid steer and much has changed since the M-400 Melroe<br />

self-propelled loader was introduced from the modern<br />

day Bobcat Co. From the skid steer’s controls to its brute<br />

strength, today’s compact equipment jack-of-all-trades is<br />

an evolved machine mongrel, vastly different from its<br />

1960 self. Working its way to the top of the industry,<br />

the skid steer’s story follows it from three wheels to four,<br />

radial to vertical lift, hand and foot controls to pilot joysticks<br />

and beyond.<br />

Today’s skid steers are going where no tool carriers have<br />

gone before — and in comfort and style. While loaders<br />

of yore had a bad reputation for rattling teeth, today’s<br />

skid steers are smooth rides, engineered with low-effort<br />

joysticks. Today’s cabs are quieter, engineered with heat<br />

and AC, satellite radio, attachment automation and<br />

everything in between. Considering expansive options,<br />

skid steer attachments have been<br />

a major motivator for skid steer<br />

innovations. Anyone who has<br />

operated a skid steer within the<br />

past 15 years should be familiar<br />

with the universal quick-attach<br />

system. You simply scoop the top<br />

of the attachment frame under the<br />

attachment’s top flange, curl the<br />

bucket up to pick up the attachment<br />

and flip the pins to secure the<br />

attachment to the machine.<br />

To power the latest and greatest attachments,<br />

the skid steer’s hydraulic<br />

system needs to provide an ample<br />

amount of hydraulic oil flow and<br />

pressure. High-flow hydraulic systems<br />

originated in the 1980s to power larger<br />

niche attachments and today are<br />

an option on nearly every skid steer.<br />

Spanning flow ranges from 16 to 40<br />

gpm, the hydraulic system pulls hydraulic<br />

fluid from a reservoir, using<br />

fluid under pressure to power the attachment. The more flow<br />

you have, the larger the displacement motor and the larger<br />

the motor, the more torque you’ll have for a desired speed.<br />

Generally, standard-flow hydraulic pressures range from 16<br />

to 25 gpm, while high-flow hydraulic pressures range from<br />

26 to 40 gpm.<br />

As skid steers grow in power and productivity, the importance<br />

of daily maintenance checks cannot be understated.<br />

To make daily service checks less painful, manufacturers<br />

have made access to service points easy and localized. Additionally,<br />

many manufacturers build the skid steer’s cab to<br />

either roll forward or backward for quick engine access and<br />

major repair work.<br />

The choice of a vertical- or radial-lift machine could potentially<br />

be the most important decision. After all, matching<br />

the machine to your tasks is the path to a wise investment.<br />

For forklift-type and loading applications, the vertical lift<br />

does a great job, but heavier digging and attachment applications<br />

tend to be better suited for radial lift. To learn more,<br />

visit your local skid steer dealer.<br />

Keith Gribbins is managing editor for <strong>Compact</strong> <strong>Equipment</strong>, based in<br />

Peninsula, Ohio.<br />

After Bobcat’s patent on its quick-attach system, Bob-Tach, expired in 1989, every other<br />

attachment manufacturer has adopted the now universal quick-attachment system.<br />

www.ceunbound.com June 2012 <strong>Compact</strong> <strong>Equipment</strong> 13

Case Skid Steer Loaders<br />

Nine Alpha Series Models Deliver Power, Economy and Comfort<br />

In 2010, Case celebrated production<br />

of its 250,000 skid steer loader. Case has<br />

been among the world’s leading skid<br />

steer manufacturers since launching<br />

its skid steer line in 1969. Today, Case<br />

Construction <strong>Equipment</strong> offers nine<br />

Alpha Series skid steer models, which<br />

deliver superior horsepower, breakout<br />

force and operator comfort. Engines in<br />

the Alpha Series skid steers range from<br />

46 to 90 hp, with rated operating capacities<br />

ranging from 1,300 lbs in the<br />

SR130 to 3,000 lbs in the SV300. Case<br />

Alpha Series skid steers deliver industry-leading<br />

bucket breakout force, says<br />

the company — up to 8,585 lbs.<br />

The Alpha Series includes both radial-<br />

and vertical-lift models. The radial-lift<br />

machines (designated with an<br />

R in the model name), are engineered<br />

for digging, prying and pushing, while<br />

the vertical-lift models (designated with a V), excel in liftand-carry<br />

applications. The Case Alpha Series includes<br />

six radial-lift skid steers, the SR130, SR150, SR175, SR200,<br />

SR220 and SR250, and three vertical-lift models, the SV185,<br />

SV250 and SV300.<br />

Improved visibility, operator comfort and operator controls<br />

define the new Case Alpha Series machines. To begin,<br />

the skid steer cabs are 25 percent larger, the widest in<br />

the industry, says Case. They feature an ultra-narrow wire<br />

side-screen design that improves operator visibility. Plus,<br />

the glass surface provides 360-degree visibility. The Case<br />

Alpha Series cabs also provide a superior climate management<br />

system. The Alpha Series models feature larger fuel<br />

tanks. Thanks to improved fuel efficiency and new 16- to<br />

25.5-gal fuel tanks, Case skids steers can easily run for eight<br />

to 10 hours without refueling.<br />

The Case Power Stance chassis design features a longer<br />

wheelbase. This added stability means that operators will<br />

be able to lift and haul more material. Case skid steers feature<br />

a front/rear weight distribution of 30/70. Combined<br />

with the longer wheel base, this keeps the center of gravity<br />

from moving when the loader arms are raised. Electrohydraulic<br />

switchable controls are available on all Alpha<br />

Series models. When two or more people operate the same<br />

Case Skid Steer Specs<br />

Contact Info<br />

Case Construction <strong>Equipment</strong><br />

621 State St.<br />

Racine, WI 53402<br />

(866) 542-2736<br />

www.casece.com<br />

machine, they can easily switch between control patterns<br />

based on preference.<br />

Easy access to filters and engine fluids makes maintenance<br />

on the Case Alpha Series models a breeze. The regular maintenance<br />

points are grouped in one area so operators do not<br />

need to walk around the machine to find specific service<br />

points. Maintenance points, such as the radiator, fuel filter,<br />

battery terminals and engine oil fill, are easy to find at the rear<br />

of the machine. Case skid steers offer extreme versatility in<br />

dozens of applications. More than 70 attachments are available,<br />

including augers, rakes, grapples, pallet forks, brooms,<br />

dozer blades and hammers, to take on the toughest jobs.<br />

Advice for Buyers<br />

“When considering a skid steer for purchase, buy a machine<br />

that’s easy to maintain,” says Tim O’Brien, brand marketing<br />

manager with Case Construction <strong>Equipment</strong>. “Serviceability<br />

has become a big focus for equipment of all sizes.<br />

At Case, our philosophy is that the easier it is to perform<br />

service, the more likely it will get done. Also, work with a<br />

dealer you trust. You should feel that your dealer is part of<br />

your team — someone you can trust and rely on when the<br />

chips are down. Whether you need parts, service or support,<br />

you should be confident in your dealer’s commitment and<br />

ability to deliver whatever you need, whenever you need it.”<br />

Model Engine Horsepower Operating Capacity Bucket Breakout Force Operating Weight Tip Capacity Lift Height (Orientation) Price<br />

Net HP 50 Percent Height to Hinge Pin National MSRP<br />

SR130 43 hp 1,300 lbs 4,160 lbs 5,000 lbs 2,600 lbs 9 ft, 4 in. (Radial) $30,800<br />

SR150 49 hp 1,500 lbs 4,160 lbs 5,300 lbs 3,030 lbs 9 ft, 4 in. (Radial) $33,000<br />

SR175 57 hp 1,750 lbs 7,145 lbs 6,200 lbs 3,500 lbs 10 ft, 2 in. (Radial) $34,400<br />

SR200 70 hp 2,000 lbs 7,145 lbs 6,900 lbs 4,000 lbs 10 ft, 3 in. (Radial) $40,300<br />

SR220 76 hp 2,200 lbs 8,585 lbs 7,400 lbs 4,400 lbs 10 ft, 5 in. (Radial) $42,100<br />

SR250 84 hp 2,500 lbs 8,585 lbs 7,700 lbs 5,000 lbs 10 ft, 5 in. (Radial) $51,500<br />

SV185 57 hp 1,850 lbs 5,435 lbs 6,500 lbs 3,700 lbs 10 ft (Vertical) $37,300<br />

SV250 76 hp 2,500 lbs 8,585 lbs 8,000 lbs 5,000 lbs 10 ft, 10 in. (Vertical) $44,200<br />

SV300 84 hp 3,000 lbs 8,585 lbs 8,300 lbs 6,000 lbs 10 ft, 10 in. (Vertical) $56,500<br />

14 <strong>Compact</strong> <strong>Equipment</strong> June 2012 www.ceunbound.com

Gehl Skid Loaders<br />

Wisconsin’s <strong>Equipment</strong> Wunderkind Offers Nine Models<br />

Gehl began manufacturing agricultural<br />

implements in 1859,<br />

in West Bend, Wis. From those<br />

humble beginnings in a blacksmith<br />

shop, the Gehl brand has<br />

become a major force in the compact<br />

equipment industry worldwide.<br />

Today, Gehl’s headquarters<br />

remains in West Bend with a<br />

state-of-the-art research and design<br />

facility. Manufactured and<br />

assembled in Madison, S.D., Mustang<br />

skid steer models range from<br />

24 to 71 hp, with rated operating<br />

capacities from 850 to 3,300 lbs.<br />

Models in the small-frame family<br />

include the 1640E and 3640E<br />

skid loaders. These compact powerhouse<br />

units define productivity<br />

in confined areas, says Gehl.<br />

When configured with narrow<br />

tires, the 1640E is less than 36 in. in width, allowing the machine<br />

to access and work in restricted work environments.<br />

The medium-frame family includes hard-working, durable<br />

4240E, 4640E and 5240E models. These models feature exceptional<br />

strength relative to the most compact dimensions<br />

in the industry, notes Gehl. With engines rated from 46 to<br />

68 hp and clearance circles (including bucket) from 69 to 80<br />

in., these mighty little giants offer outstanding power in a<br />

compact frame.<br />

Large-frame skid loaders round out Gehl’s range with the<br />

5640E, 6640E, V270 and V330 models. The stalwart yet nimble<br />

5640E and 6640E feature radial-lift path geometries, providing<br />

ideal performance in ground engaging applications.<br />

The V270 and V330 are equipped with vertical-lift path configurations,<br />

offering greater capability in lift-and-place applications.<br />

All Gehl skid loaders feature one of the broadest<br />

ranges of control patterns in the industry, allowing operators<br />

to do what they do best, how they do it best.<br />

Versatility is ensured with standard auxiliary hydraulic<br />

flow for attachment power and optional high flow on larger<br />

models. The exclusive Gehl Powerview boom provides<br />

outstanding visibility to work areas along the side of the<br />

machine, as well as to the bucket. Extra-long wheelbase<br />

lengths provide smooth rides, while powerful and efficient<br />

www.ceunbound.com<br />

Gehl Skid Loader Specs<br />

Contact Info<br />

Gehl Co.<br />

One Gehl Way<br />

West Bend, WI 53090<br />

(262) 334-9461<br />

info@gehl.com<br />

www.gehl.com<br />

Yanmar engines tirelessly deliver performance. Serviceability<br />

is not an afterthought, but thoughtfully designed into<br />

every skid loader, says Gehl. Service points are easily located,<br />

and ROPS structures tilt for full access when needed.<br />

Industry-leading safety is also standard on Gehl skid loaders,<br />

with Level 2 ROPS structures to protect operators. Additional<br />

features include ample grab handles and standard<br />

front and rear work lighting.<br />

All models can be configured to individual preference<br />

though options such as fully enclosed cabs, hydraulic quickattach<br />

units, two-speed motors, rear counterweights and<br />

much more.<br />

Advice to Buyers<br />

“There are many choices and options available to today’s<br />

compact equipment buyer,” says Sean Bifani, Gehl skid loader<br />

product manager. “The most important step in choosing a<br />

skid loader is to determine the application or applications in<br />

which it will be used. For maximum return on investment,<br />

it is essential to purchase a right-sized skid loader, which will<br />

complete immediate application needs, but will also allow<br />

room to grow. Your local dealer is an expert on providing<br />

knowledge and assistance and will be able to help narrow<br />

the field. Finally, request a demonstration to be sure a particular<br />

skid loader is the best match for applications.”<br />

Model Engine Horsepower Operating Capacity Bucket Breakout Force Weight Tip Capacity Lift Height (Orientation) Price<br />

Net HP 50 Percent Tilt (Lift) Height to Hinge Pin National MSRP<br />

1640E 24 hp 850 lbs 1,494 lbs (1,771 lbs) 2,980 lbs 1,709 lbs 8 ft (Radial) $22,495<br />

3640E 35 hp 1,050 lbs 2,800 lbs (2,200 lbs) 4,000 lbs 2,100 lbs 9 ft (Radial) $24,367<br />

4240E 46 hp 1,350 lbs 2,800 lbs (2,449 lbs) 4,600 lbs 2,700 lbs 9 ft, 1 in. (Radial) $25,903<br />

4640E 68 hp 1,650 lbs 3,900 lbs (3,590 lbs) 6,300 lbs 3,300 lbs 9 ft, 6 in. (Radial) $31,026<br />

5240E 68 hp 1,900 lbs 4,160 lbs (4,260 lbs) 6,700 lbs 3,800 lbs 10 ft, 1 in. (Radial) $32,441<br />

5640E 70.7 hp 2,200 lbs 4,244 lbs (4,344 lbs) 7,610 lbs 4,400 lbs 10 ft, 2 in. (Radial) $36,693<br />

6640E 70.7 hp 2,600 lbs 4,244 lbs (4,344 lbs) 8,740 lbs 5,200 lbs 10 ft, 3 in. (Radial) $40,512<br />

V270 70.7 hp 2,700 lbs 5,233 lbs (4,372 lbs) 8,100 lbs 5,400 lbs 10 ft, 8 in. (Vertical) $43,981<br />

V330 70.7 hp 3,300 lbs 5,850 lbs (4,779 lbs) 9,010 lbs 6,600 lbs 10 ft, 9 in. (Vertical) $46,839<br />

June 2012 <strong>Compact</strong> <strong>Equipment</strong> 15

JCB Skid Steers<br />

Ten One-Armed Loaders Make a Uniquely Safe Product Offering<br />

In 1993, JCB entered the skid steer market<br />

with the first mono-boom, side-entry skid<br />

steer, a design based on the company’s telescopic<br />

handlers. Over the years, JCB’s skid<br />

steer line has evolved, going from the Series<br />

I and Series II machines to today’s New Generation<br />

models. The New Generation line,<br />

initially introduced in November 2010, includes<br />

both large and small platform models<br />

offering vertical or radial lift. Today, JCB’s<br />

skid steers are designed to compete within<br />

the active North American marketplace, as<br />

well as worldwide.<br />

JCB’s New Generation skid steer line includes<br />

10 models ranging in operating capacity<br />

from 1,350 to 3,295 lbs and offering<br />

vertical or radial lift along with JCB’s unique<br />

“PowerBoom” design for enhanced visibility<br />

and safety. The newest models include the<br />

five small-platform models introduced in<br />

March 2012: the 135, 155, 175, 195 and 205.<br />

Currently, the large platform models — the 225, 260, 280, 300<br />

and 330 — are popular due to their versatility on more complex<br />

projects that would otherwise require multiple dedicated<br />

machines, like a compact wheel loader or compact excavator.<br />

JCB offers over 30 attachment families that can help operators<br />

quickly complete a wide variety of tasks, from fence-post digging<br />

to snow removal and everything in between.<br />

JCB’s most well-known and visually apparent safety feature<br />

is its PowerBoom — a single-arm boom that allows operators<br />

to safely enter the machine from a left-side entry<br />

door, clear of any potentially dangerous attachments or under<br />

an unsupported boom. The PowerBoom also makes it<br />

possible for these machines to operate without a rear torque<br />

tube, further increasing visibility from inside the cab to 270<br />

degrees. Because operators are better able to view their surroundings,<br />

they gain confidence in their ability to operate<br />

the machine safely, further improving their productivity.<br />

In fact, the National Institute of Occupational Safety and<br />

Health (NIOSH) has actually recognized the many benefits<br />

of the PowerBoom side-entry design by rewriting their safety<br />

alert accordingly to exclude side-entry skid steers.<br />

JCB Skid Steer Specs<br />

Contact Info<br />

JCB North America<br />

2000 Bamford Blvd.<br />

Pooler, GA 31322<br />

(912) 447-2000<br />

www.jcbvision.com<br />

JCB skid steer cabs feature a suspension seat for maximum<br />

operator comfort and a sealed and pressurized cab, which<br />

prevents dust and dirt from entering the cab even on the<br />

grittiest of worksites. Servo controls help operators use the<br />

machines for longer periods of time without experiencing<br />

fatigue. This not only increases productivity, but also improves<br />

operator safety.<br />

Advice to Buyers<br />

“Choosing the right machine for the job is imperative,”<br />

says Ashby Graham, product specialist for JCB. “First,<br />

always get a machine large enough to lift your heaviest<br />

possible load. Also, consider what type of ground the machine<br />

will be working on. A wheeled skid steer is best for<br />

hard surfaces or harsh applications, while a compact track<br />

loader is better on wet or soft surfaces. Choose radial lift<br />

if you need more reach at the midpoint of the arc [loading<br />

flatbed trailers]. Choose vertical lift if you need more<br />

reach at the top of the arc [loading high-sided trucks or<br />

performing fork work]. Determine if there are other options<br />

available that might allow jobs to be completed faster<br />

or more easily.”<br />

Model Engine Horsepower Operating Capacity Bucket Breakout Force Operating Weight Tip Capacity Lift Height (Orientation) Price *<br />

Net HP 50 Percent Height to Hinge Pin National MSRP<br />

135 47.9 hp 1,350 lbs 4,012 lbs 6,067 lbs 2,989 lbs 9 ft, 10 in. (Radial) $27,972-$29,848<br />

155 59.9 hp 1,550 lbs 4,012 lbs 6,270 lbs 3,100 lbs 9 ft, 10 in. (Radial) $29,099-$34,224<br />

175 59.9 hp 1,750 lbs 4,718 lbs 6,638 lbs 3,500 lbs 9 ft, 10 in. (Vertical) $30,607-$35,732<br />

190 59.9 hp 1,900 lbs 4,718 lbs 6,874 lbs 3,800 lbs 9 ft, 10 in. (Vertical) $33,958-$39,083<br />

205 59.9 hp 2,050 lbs 4,718 lbs 7,136 lbs 4,100 lbs 9 ft, 10 in. (Vertical) $34,958-$40,083<br />

225 84 hp 2,250 lbs 5,699 lbs 7,709 lbs 4,908 lbs 10 ft, 5 in. (Radial) $36,015-$43,996<br />

260 84 hp 2,600 lbs 5,699 lbs 7,971 lbs 5,448 lbs 10 ft, 5 in. (Vertical) $37,237-$45,307<br />

280 84 hp 2,800 lbs 5,699 lbs 8,060 lbs 5,608 lbs 10 ft, 5 in. (Vertical) $38,237-$46,218<br />

300 92 hp 3,000 lbs 7,187 lbs 8,430 lbs 6,024 lbs 10 ft, 5 in. (Vertical) $43,783-$54,104<br />

330 92 hp 3,300 lbs 7,187 lbs 8,728 lbs 6,590 lbs 10 ft, 6 in. (Vertical) $48,412-$56,393<br />

*The first price is a low spec price (canopy, standard flow, three-way controls and general purpose bucket) and the second dollar amount represents typical high spec price<br />

(cab with AC, high flow, multi-function controls and general purpose bucket).<br />

16 <strong>Compact</strong> <strong>Equipment</strong> June 2012 www.ceunbound.com

John Deere Skid Steers<br />

Seven Units from the Popular Construction, Landscape and Ag Brand<br />

Since their inception in a small<br />

town in Minnesota at the dawn of<br />

the 1970s, skid steers have grown<br />

in stature as compact, efficient<br />

and valuable machines for worksites<br />

of all shapes and sizes. From<br />

construction to landscape to agriculture,<br />

industries have seen an<br />

increased need for smaller, more<br />

affordable, yet equally efficient<br />

machines to get the job done.<br />

Over the years, John Deere has<br />

improved each generation of skid<br />

steer from the original 24 Model to<br />

the current state-of-the-art lineup,<br />

which, despite their compact size,<br />

can handle tasks that were once reserved<br />

for larger equipment.<br />

John Deere’s lineup of skid steers<br />

range in size and power from under<br />

50 hp (313 and 315) to 50 to 75 hp<br />

(318D, 320D and 326D) to over 75<br />

hp (328D and 332D). The under 50hp<br />

models are lightweight and agile<br />

yet surprisingly powerful. They<br />

boast a 2.4-L turbocharged diesel<br />

engine that is EPA Interim Tier 4<br />

certified. Features such as heavy-duty drive chains that never<br />

need adjustment, easy-to-fill large-capacity fuel tanks and selfcleaning,<br />

no-grease Quik-Tatch systems ensure it’s as easy to<br />

maintain as it is to run. Compatibility with many of the John<br />

Deere Worksite Pro attachments, such as forks, snowblades and<br />

rakes, allow for the use of the machine year round.<br />

The 318D, 320D and 326D models incorporate a roomier<br />

operator station, a quieter pressurized cab with best-in-class<br />

visibility and a curved-glass, swing-out door. Operators also<br />

have a choice of numerous productivity-boosting options<br />

including electro-hydraulic joysticks with selectable control<br />

pattern and variable boom and bucket speed settings. Additional<br />

features include a highly efficient and easy-to-clean Vplenum<br />

cooling system and an electronic fuel-injected PowerTech<br />

E diesel engine that is EPA Interim Tier 4 certified.<br />

Grouped checkpoints, advanced diagnostics and wide-open<br />

access help speed servicing, minimize maintenance and lowering<br />

daily operating costs.<br />

John Deere Skid Steer Specs<br />

Contact Info<br />

John Deere<br />

Worldwide Construction<br />

& Forestry Div.<br />

P.O. Box 8806<br />

Moline, IL 61266<br />

www.johndeere.com<br />

The 328D and 332D feature optimal weight distribution,<br />

low center of gravity, high ground clearance and long wheelbase<br />

to deliver superior stability. But getting there is only<br />

half the battle. These skid steers also excel at putting material<br />

in its place. The patented vertical-lift boom rises to the<br />

occasion, delivering exceptional lift height and reach, so<br />

you can do more with less effort.<br />

Advice to Buyers<br />

“Skid steers are great machines for contractors to consider<br />

if they’re starting a fleet or only looking to buy one<br />

piece of equipment,” says Gregg Zupancic, John Deere<br />

product marketing manager for skid steers and compact<br />

track loaders. “Attachments allow skid steers to become<br />

a Jack of all trades from dozing and trenching to mulching<br />

and compacting. The compact size allows for easy<br />

maneuverability around a variety of worksite landscapes<br />

and transportation is as easy as attaching a trailer to a<br />

pickup truck.”<br />

Model Engine Horsepower Operating Capacity Bucket Breakout Force Operating Weight Tip Capacity Lift Height (Orientation) Price<br />

Net HP 50 Percent Height to Hinge Pin National MSRP<br />

313 45 hp 1,260 lbs 3,300 lbs 5,150 lbs 2,525 lbs 9 ft (Radial) $25,760<br />

315 45 hp 1,500 lbs 3,300 lbs 5,200 lbs 3,000 lbs 9 ft, 5 in. (Radial) $27,510<br />

318D 58 hp 1,800 lbs 5,125 lbs 6,450 lbs 3,600 lbs 9 ft, 8 in. (Vertical) $32,662<br />

320D 63 hp 2,000 lbs 5,125 lbs 6,600 lbs 4,000 lbs 9 ft, 9 in. (Vertical) $34,858<br />

326D 70 hp 2,600 lbs 7,750 lbs 8,125 lbs 5,200 lbs 10 ft, 4 in. (Vertical) $38,994<br />

328D 80 hp 2,800 lbs 10,300 lbs 8,400 lbs 5,600 lbs 10 ft, 5 in. (Vertical) $43,581<br />

332D 89 hp 3,200 lbs 13,875 lbs 9,170 lbs 6,400 lbs 10 ft, 5 in. (Vertical) $47,501<br />

18 <strong>Compact</strong> <strong>Equipment</strong> June 2012 www.ceunbound.com

Mustang Skid Steers<br />

The Second Oldest Skid Steer Manufacturer Still Makes 10 Models<br />

Mustang began in the 19th<br />

century as the Owatonna Mfg.<br />

Co. It started as an agricultural<br />

implement manufacturer and<br />

has since grown into a 21st<br />

century compact equipment<br />

powerhouse. Mustang is the<br />

second-oldest skid steer loader<br />

manufacturer in the world,<br />

building its first skid steer in<br />

1965 — the Mustang Series 1000.<br />

Mustang currently offers a broad<br />

range of 10 skid steer loader models.<br />

Raw power, a hallmark Mustang<br />

feature, is provided by high-output,<br />

high-torque Yanmar engines on<br />

every model. Superior ground-engaging<br />

capabilities and cycle-time<br />

performance are made possible by<br />

advanced, well-balanced hydraulic<br />

systems. Hundreds of attachments<br />

are easily interchangeable to expand<br />

the uses of a Mustang skid steer loader.<br />

The Mustang 2012 and 2026 comprise the small-frame skid<br />

steer loader family. These radial-lift models offer substantial<br />

productivity relative to their super-compact size. The 2012<br />

can be configured to a width of less than 36 in., providing<br />

access to restricted work environments. Size does not limit<br />

performance however, with a lift height of 96 in., and a rated<br />

operating capacity of 850 lbs. The equally strong and maneuverable<br />

2026 has a rated operating capacity of 1,050 lbs.<br />

The medium-frame Mustang skid steer models include<br />

the 2041, 2044, 2054 and 2056. With rated operated capacities<br />

ranging from 1,350 to 1,900 lbs, these radial-lift<br />

skid steer loaders are characterized by their outstanding<br />

performance in a compact frame. With engines rated between<br />

46 and 68 hp, there is ample power to complete<br />

the most demanding of applications. Mustang 2076,<br />

2086, 2700V and 3300V large-frame models complete<br />

the skid steer loader range. These powerful 71-hp workhorses<br />

are loaded with features that other manufacturers<br />

consider optional. Standard hydraulic self-leveling for<br />

performance and mechanical suspension seats for comfort<br />

are two examples of many. Mustang models 2076<br />

Mustang Skid Steer Specs<br />

Contact Info<br />

Mustang<br />

P.O. Box 179<br />

West Bend, WI 53090<br />

(262) 334-9461<br />

info@mustangmfg.com<br />

www.mustangmfg.com<br />

and 2086 are radial-lift path models, while the 2700V<br />

and 3300V are vertical-lift path models.<br />

All loaders are equipped with universal mechanical quickattach<br />

plates, for accepting a comprehensive range of attachments.<br />

A hydraulic power attach is optional, to facilitate<br />

easy change-overs. Auxiliary hydraulic flow is standard, as is<br />

self-leveling on many models. Operator comfort and safety<br />

are provided through a standard Level 2 ROPS structure. The<br />

roomy, quiet operator area can be configured to operator<br />

preference through a variety of options, including heat and<br />

air conditioning.<br />

Advice to Buyers<br />

“When purchasing a skid steer loader, an equipment buyer<br />

should first determine the primary applications in which<br />

it will be used today and in the future,” says Sean Bifani,<br />

Mustang skid steer loader product manager. “From there, the<br />

equipment buyer should evaluate if the model’s lift height,<br />

rated capacity, size and available attachments will meet<br />

those needs. Ease of maintenance and comfort are also important<br />

factors to consider. Finally, make sure that you are<br />

comfortable with the level of service and support offered by<br />

the equipment dealer.”<br />

Model Engine Horsepower Operating Capacity Bucket Breakout Force Operating Weight Tip Capacity Lift Height (Orientation) Price<br />

Net HP 50 Percent Tilt (Lift) Height to Hinge Pin National MSRP<br />

2012 24 hp 850 lbs 1,494 lbs (1,771 lbs) 2,980 lbs 1,709 lbs 8 ft (Radial) $24,744<br />

2026 35 hp 1,050 lbs 2,800 lbs (2,200 lbs) 4,000 lbs 2,100 lbs 9 ft (Radial) $26,803<br />

2041 46 hp 1,350 lbs 2,800 lbs (2,449 lbs) 4,600 lbs 2,700 lbs 9 ft, 1 in. (Radial) $28,491<br />

2044 46 hp 1,450 lbs 4,000 lbs (3,500 lbs) 5,623 lbs 2,900 lbs 9 ft, 3 in. (Radial) $30,329<br />

2054 46 hp 1,650 lbs 5,000 lbs (4,400 lbs) 6,080 lbs 3,300 lbs 9 ft, 6 in. (Radial) $33,196<br />

2056 68 hp 1,900 lbs 4,160 lbs (4,260 lbs) 6,700 lbs 3,800 lbs 10 ft, 1 in. (Radial) $35,685<br />

2076 70.7 hp 2,200 lbs 4,764 lbs (4,315 lbs) 7,610 lbs 4,400 lbs 10 ft, 2 in. (Radial) $41,488<br />

2086 70.7 hp 2,600 lbs 4,759 lbs (5,067 lbs) 8,740 lbs 5,200 lbs 10 ft, 3 in. (Radial) $45,395<br />

2700V 70.7 hp 2,700 lbs 5,233 lbs (4,372 lbs) 8,100 lbs 5,400 lbs 10 ft, 8 in. (Vertical) $48,382<br />

3300V 70.7 hp 3,300 lbs 5,850 lbs (4,779 lbs) 9,010 lbs 6,600 lbs 10 ft, 9 in. (Vertical) $51,524<br />

www.ceunbound.com June 2012 <strong>Compact</strong> <strong>Equipment</strong> 19

New Holland Skid Steers<br />

The Inventor of Vertical-Lift Loaders Offers Seven Models<br />

New Holland began manufacturing skid steer<br />

loaders in 1972, barely a decade after the first<br />

four-wheel skid steer loader was invented (1960).<br />

Not only was New Holland one of the very first<br />

manufacturers of skid steer loaders, but it was<br />

the first to offer a fully enclosed operator station<br />

(ROPS) on every machine and a vertical-lift boom<br />

with its patented Super Boom style lift arms.<br />

The new 200 Series from New Holland Construction<br />

marks the sixth generation of skid<br />

steer loaders for New Holland Construction<br />

and represents major advancements in technology,<br />

such as pattern switching electro-hydraulic<br />

controls. New Holland Construction has also<br />

taken the next step in operator comfort with<br />

the industry’s largest skid steer cab, according<br />

to the company, which provides superior visibility.<br />

Skid steer loaders represent the flagship<br />

product for New Holland Construction in North<br />

America. In 2012, New Holland Construction is<br />

celebrating the 40th anniversary of its skid steer<br />

loaders. The company is on track to manufacture<br />

its 250,000 unit.<br />

New Holland Construction’s 200 Series skid steer loaders<br />

include seven models. The L218, L220, L223, L225 and L230<br />

skid steer loaders feature the patented vertical-lift Super Boom<br />

design, delivering best-in-class forward dump height and<br />

reach. The 200 Series also includes two compact models — the<br />

L213 and L215 — which feature a radial-lift design, providing<br />

excellent digging performance.<br />

With the Super Boom loader arm, New Holland skid steer<br />

loaders deliver superior lift and reach, says the company. Unlike<br />

competitive models, they can load material to the center<br />

of trucks, finishing jobs faster. The 53-degree dump angle on<br />

the 200 Series skid steer loaders is also best in class, says New<br />

Holland. This lets operators empty the bucket faster, increasing<br />

cycle times and productivity.<br />

New Holland 200 Series skid steer loaders provide a superior<br />

working environment. The cab is one of the widest, most<br />

comfortable cabs in the industry, providing more head and<br />

foot room and offering superior visibility in critical zones.<br />

New Holland skid steer loaders give operators a 360-degree<br />

view of the jobsite. The new rear window provides best-inclass<br />

rear visibility, and the new lighting package delivers superior<br />

jobsite visibility.<br />

Contact Info<br />

New Holland Construction<br />

621 State St.<br />

Racine, WI 53402<br />

www.newholland.com<br />

Stability is an important part of being productive on the<br />

jobsite. The increased wheelbase on the New Holland 200 Series<br />

skid steer loaders allows operators to lift and haul more<br />

material, increasing productivity. Daily maintenance on the<br />

200 Series skid steer loaders is quick and easy, says New Holland,<br />

so operators can stay on schedule. Regular ground-level<br />

maintenance points are grouped together and service can<br />

be performed by opening the rear engine compartment and<br />

door. For complete access to major components, the service<br />

technician only needs to remove two nuts and washers to tilt<br />

the cab forward. There is nothing to disconnect, and no special<br />

tools required. The new hydraulic system uses hydraulic<br />

oil, extending the service internal to 2,000 hours and significantly<br />

reducing the amount of disposed oil.<br />

New Holland offers more than 50 skid steer loader attachments<br />

— including augers, brooms, dozer blades, grapples,<br />

hammers, pallet forks and rakes — to handle countless construction,<br />

landscaping or agricultural jobs. From material handling,<br />

digging, lifting and hammering to trenching, planing<br />

or drilling, operators can count on New Holland attachments<br />

to boost their productivity. For customers who frequently<br />

change attachments, the skid steer loaders feature a hydraulic<br />

heavy-duty coupler.<br />

Model Engine Horsepower Operating Capacity Bucket Breakout Force Operating Weight Tip Capacity Lift Height (Orientation) Price *<br />

Net HP 50 Percent Height to Hinge Pin National MSRP<br />

L213 43 hp 1,300 lbs 4,150 lbs 5,070 lbs 2,600 lbs 9 ft, 4 in. (Radial) $28,400<br />

L215 49 hp 1,500 lbs 4,150 lbs 5,370 lbs 3,000 lbs 9 ft, 4 in. (Radial) $30,400<br />

L218 57 hp 1,800 lbs 5,435 lbs 5,630 lbs 3,600 lbs 10 ft (Vertical) $33,500<br />

L220 57 hp 2,000 lbs 7,145 lbs 6,170 lbs 4,000 lbs 10 ft, 1 in. (Vertical) $37,700<br />

L223 68 hp 2,300 lbs 8,585 lbs 7,050 lbs 4,600 lbs 10 ft, 9.5 in. (Vertical) $39,300<br />

L225 76 hp 2,500 lbs 8,585 lbs 7,565 lbs 5,000 lbs 10 ft, 9.5 in. (Vertical) $41,700<br />

L230 T4a 84 hp 3,000 lbs 8,585 lbs 7,965 lbs 6,000 lbs 10 ft, 11.5 in. (Vertical) $51,400<br />

*MSRPs represent base model prices.<br />

New Holland Skid Steer Specs<br />

20 <strong>Compact</strong> <strong>Equipment</strong> June 2012 www.ceunbound.com

Terex Skid Steers<br />

Eight Loader Tool Carriers from the Big <strong>Equipment</strong> Manufacturer<br />

Terex introduced its line of skid steer loaders,<br />

vertical-lift path and radius-lift path units, to complement<br />

its line of compact equipment in January<br />

2011. Terex skid steer loaders are designed to be<br />

more productive, says the company, thanks to high<br />

ground clearances and rear angles of departure,<br />

high travel speeds, increased fuel capacities, strong<br />

tractive effort and mechanical-faced axle seals.<br />

Terex offers a full line of skid steer loaders to<br />

match the needs of customers — four vertical-lift<br />

units and four radius-lift units, ranging from 1,500<br />

to 3,000 lbs of rated operating capacity and 50 to<br />

83 hp. The company’s wide offering gives customers<br />

loader options for most any job they might encounter.<br />

Terex says its skid steer loaders are built<br />

to get loading, picking and carrying, grading, back<br />

dragging or snow removal jobs done faster and<br />

more efficiently. Terex skid steer loaders have many<br />

unique features, including: 10 in. of ground clearance<br />

for pushing through rugged underfoot conditions;<br />

one-side daily service checks to make routine<br />

maintenance easy; mechanically faced axle seals to<br />

provide long life for the axles bearings; low tower design for<br />

excellent visibility; high tractive effort to push harder; joystick<br />

control for smooth and easy operation; tilt-up ROPS<br />

Contact Info<br />

Terex Corp.<br />

8800 Rostin Rd.<br />

Southaven, MS 38671<br />

(662) 393-1800<br />

www.terexconstruction.com<br />

to accommodate maintenance checks; and an optional hydraulic<br />

quick-attach system.<br />

To get more done on every jobsite, Terex offers performance-matched<br />

attachments for its skid steer loader line,<br />

www.ceunbound.com June 2012 <strong>Compact</strong> <strong>Equipment</strong> 21

including auger, backhoe, rotary broom, general purpose<br />

bucket, light-material bucket, multi-purpose bucket, dozer<br />

blade, pallet forks, power box rake, snow blade, snow blower,<br />

stump grinder, trencher, vibratory roller and the Loegering<br />

Eliminator rake. Each attachment comes standard with<br />

the necessary hydraulic lines and connectors or electric connections<br />

for a quick, easy fit.<br />

Advice to Buyers<br />

“The first thing contractors need to assess, whether renting<br />

or buying, is what tasks are they going to be performing<br />

with this unit,” says Jamie Wright, product manager at Terex<br />

Construction. “Then, they need to discuss what lift capacity,<br />

lift height and horsepower will be needed to perform those<br />

tasks. Also, they need to understand whether they would<br />

be more productive with a vertical-lift path or a radius-lift<br />

Terex Skid Steer Specs<br />

path unit. Once those factors have been determined, other<br />

attributes potential buyers will need to investigate are: how<br />

easy is the unit to maintain; what amount of hydraulic flow<br />

do they need to match their attachment needs; and will they<br />

need to use over-the-tire tracks on any of their projects?<br />

“For renters, matching the size of the loader to the task<br />

is the most vital of decisions — renting a larger unit than<br />

needed can result in additional rental and fuel consumption<br />

costs, and the larger unit could be less productive because<br />

it may not be as efficient or as nimble at performing<br />

smaller tasks. Renting a unit that is too small for a job can<br />

overextend the limitations of the loader, which can result<br />

in unsafe operating conditions, and that may cost renters<br />

more in rental charges for extra days needed on the job to<br />

complete the task.”<br />

Model Engine Horsepower Operating Capacity Bucket Breakout Force Operating Weight Tip Capacity Lift Height (Orientation) Price<br />

Net HP 50 Percent Height to Hinge Pin National MSRP<br />

TSR50 50 hp 1,500 lbs 3,900 lbs 6,475 lbs 3,000 lbs 9 ft, 5 in. (Radial) $29,929<br />

TSV50 50 hp 2,000 lbs 4,130 lbs 6,981 lbs 4,000 lbs 9 ft, 8 in. (Vertical) $31,267<br />

TSR60 60 hp 1,500 lbs 3,900 lbs 6,480 lbs 3,000 lbs 9 ft, 5 in. (Radial) $31,983<br />

TSV60 60 hp 2,000 lbs 4,130 lbs 6,986 lbs 4,000 lbs 9 ft, 8 in. (Vertical) $35,098<br />

TSR70 74 hp 2,000 lbs 5,500 lbs 7,450 lbs 3,987 lbs 10 ft, 4 in. (Radial) $37,996<br />

TSV70 74 hp 2,653 lbs 5,878 lbs 8,100 lbs 5,270 lbs 10 ft, 7 in. (Vertical) $41,423<br />

TSR80 83 hp 2,320 lbs 5,500 lbs 7,750 lbs 4,640 lbs 10 ft, 4 in. (Radial) $40,505<br />

TSV80 83 hp 3,000 lbs 5,878 lbs 8,600 lbs 6,000 lbs 10 ft, 7 in. (Vertical) $46,654<br />

22 <strong>Compact</strong> <strong>Equipment</strong> June 2012 www.ceunbound.com

Don’t Miss<br />

An Issue!<br />

Signature ______________________________________ Date ________________________________________<br />

E-mail _______________________________________________________________<br />

Yes, I want The CE Unbound Update: <strong>Compact</strong> <strong>Equipment</strong>’s bi-weekly E-newsletter.<br />

Name: ________________________________________________________________________________________________<br />

Title: __________________________________________________________________________________________________<br />

Company: _____________________________________________________________________________________________<br />

Address: ______________________________________________________________________________________________<br />

City: __________________________________________________________________________________________________<br />

State/Province: _________________________________________________________________________________________<br />

Zip/Postal Code: ______________________ Country: _________________________________________________________<br />

Phone: ______________________________ Fax ______________________________________________________________<br />

CONSTRUCTION<br />

1. ❑ Residential Construction<br />

2. ❑ Highway & Heavy<br />

Construction<br />

3. ❑ Bridge Construction<br />

4. ❑ Commercial Building<br />

Construction<br />

5. ❑ Utility Construction<br />

6. ❑ Concrete/Masonry Work<br />

7. ❑ Demolition<br />

8. ❑ Excavation/Site Prep<br />

9. ❑ Other — Specify:<br />

________________________<br />

LANDSCAPE<br />

10. ❑ Design/Build<br />

11. ❑ Nursery<br />

12. ❑ Golf Course<br />

13. ❑ Grounds Maintenance<br />

14. ❑ Parks & Recreation<br />

15. ❑ Water Features<br />

16. ❑ Irrigation<br />

17. ❑ Erosion Control<br />

18. ❑ Other— Specify:<br />

________________________<br />

AGRICULTURE<br />

19. ❑ Crop Farmer<br />

20. ❑ Dairy Farmer<br />

21. ❑ Feed Distribution<br />

22. ❑ Livestock Farming<br />

(Pigs, Poultry, Cattle, etc.)<br />

23. ❑ Orchard Farming<br />

24. ❑ Horticulture<br />

25. ❑ Animal Husbandry/<br />

Stockbreeding<br />