TW190 Turbo 2764.pdf - Arbtalk

TW190 Turbo 2764.pdf - Arbtalk

TW190 Turbo 2764.pdf - Arbtalk

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

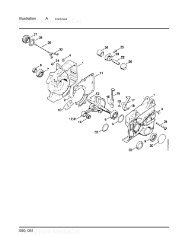

SERVICE INSTRUCTIONS 21<br />

GREASE THE ROLLER BOX SLIDES<br />

NOTE: This should be done every 50 hours. In dirty or dusty conditions or during periods of<br />

hard work it should be done more frequently. If the slides become dry the top roller will tend<br />

to hang up and the pulling-in power of the rollers will<br />

be much reduced. Excessive wear will ensue.<br />

1<br />

1. Remove the near side roller box guard.<br />

2. Open the rotor housing.<br />

3. Apply multipurpose grease directly to the slide surfaces<br />

indicated. DO NOT USE GRAPHITE BASED GREASE.<br />

4. Close the rotor housing.<br />

5. Refit the near side roller box guard.<br />

GREASE THE ROLLER SPLINE AND BEARING<br />

NOTE: This should be done regularly. In dirty and dusty conditions or during periods of hard<br />

work it should be weekly. If the bearings and splines are allowed to run dry premature wear<br />

will occur resulting in a breakdown and the need for replacement parts. This failure is not<br />

warranty. Early signs of insufficient grease includes squeaking or knocking rollers.<br />

1. Open the rotor housing.<br />

2. Locate two grease nipples; one in the centre of each roller shaft.<br />

3. Use a pump action grease gun to apply a generous amount of grease to<br />

each roller drive. DO NOT USE GRAPHITE BASED GREASE.<br />

4. Close the rotor housing.<br />

5. To penetrate all the bearing surfaces thoroughly, start the machine and<br />

operate the rollers for 20 seconds. Switch off the machine. Repeat this<br />

greasing/running procedure a further 3 times.<br />

GREASE THE JACK STAND<br />

The jack stand requires intermittent greasing to maintain a smooth operation.<br />

1. Brush off dirt with a stiff brush.<br />

2. Apply grease liberally to screw thread using a brush.<br />

3. Wind mechanism up and down a couple of times to ensure grease has covered all surfaces.<br />

2<br />

GREASE THE DISCHARGE FLANGE<br />

1. Remove the discharge tube.<br />

2. Apply multipurpose grease to surface shown.<br />

3. Refit discharge tube.<br />

GREASING ROTOR BEARINGS<br />

Both front and rear bearings are sealed and do not need greasing.<br />

ENGINE MANUFACTURER’S HANDBOOK<br />

Refer to your Engine Manufacturer’s Handbook for detailed instructions on the following:<br />

Changing the fuel filter Checking the engine oil Changing the engine oil Changing the engine oil filter<br />

3<br />

2<br />

3<br />

2