TW190 Turbo 2764.pdf - Arbtalk

TW190 Turbo 2764.pdf - Arbtalk

TW190 Turbo 2764.pdf - Arbtalk

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

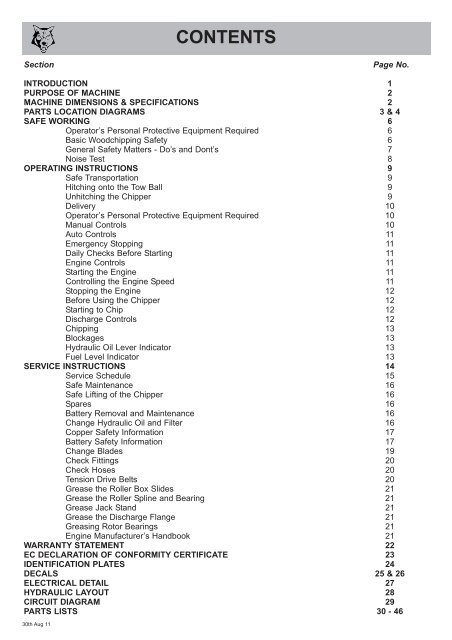

CONTENTS<br />

Section Page No.<br />

INTRODUCTION 1<br />

PURPOSE OF MACHINE 2<br />

MACHINE DIMENSIONS & SPECIFICATIONS 2<br />

PARTS LOCATION DIAGRAMS 3 & 4<br />

SAFE WORKING 6<br />

Operator’s Personal Protective Equipment Required 6<br />

Basic Woodchipping Safety 6<br />

General Safety Matters - Do’s and Dont’s 7<br />

Noise Test 8<br />

OPERATING INSTRUCTIONS 9<br />

Safe Transportation 9<br />

Hitching onto the Tow Ball 9<br />

Unhitching the Chipper 9<br />

Delivery 10<br />

Operator’s Personal Protective Equipment Required 10<br />

Manual Controls 10<br />

Auto Controls 11<br />

Emergency Stopping 11<br />

Daily Checks Before Starting 11<br />

Engine Controls 11<br />

Starting the Engine 11<br />

Controlling the Engine Speed 11<br />

Stopping the Engine 12<br />

Before Using the Chipper 12<br />

Starting to Chip 12<br />

Discharge Controls 12<br />

Chipping 13<br />

Blockages 13<br />

Hydraulic Oil Lever Indicator 13<br />

Fuel Level Indicator 13<br />

SERVICE INSTRUCTIONS 14<br />

Service Schedule 15<br />

Safe Maintenance 16<br />

Safe Lifting of the Chipper 16<br />

Spares 16<br />

Battery Removal and Maintenance 16<br />

Change Hydraulic Oil and Filter 16<br />

Copper Safety Information 17<br />

Battery Safety Information 17<br />

Change Blades 19<br />

Check Fittings 20<br />

Check Hoses 20<br />

Tension Drive Belts 20<br />

Grease the Roller Box Slides 21<br />

Grease the Roller Spline and Bearing 21<br />

Grease Jack Stand 21<br />

Grease the Discharge Flange 21<br />

Greasing Rotor Bearings 21<br />

Engine Manufacturer’s Handbook 21<br />

WARRANTY STATEMENT 22<br />

EC DECLARATION OF CONFORMITY CERTIFICATE 23<br />

IDENTIFICATION PLATES 24<br />

DECALS 25 & 26<br />

ELECTRICAL DETAIL 27<br />

HYDRAULIC LAYOUT 28<br />

CIRCUIT DIAGRAM 29<br />

PARTS LISTS 30 - 46<br />

30th Aug 11

TIMBERWOLF 190TDHB (<strong>Turbo</strong>) 1<br />

Thank you for choosing this Timberwolf brushwood chipper. Timberwolf chippers are<br />

designed to give safe and dependable service if operated according to the instructions.<br />

Before using your new chipper, please take time to<br />

read this manual which contains<br />

IMPORTANT HEALTH AND SAFETY INFORMATION<br />

and explains the chipper controls. Failure to do so could result in:<br />

- personal injury<br />

- equipment damage<br />

- damage to property<br />

- a member of the general public becoming injured<br />

This manual covers the operation and maintenance of the Timberwolf TW 190TDHB<br />

(<strong>Turbo</strong>). All information in this manual is based on the latest product information<br />

available at the time.<br />

All the information you need to operate the machine safely and effectively is contained<br />

within pages 2 to 13. Ensure that all operators are properly trained for operating this<br />

machine, especially with regard to safe working practices.<br />

Timberwolf's policy of constantly improving their products may involve major or minor<br />

changes to the chippers or their accessories. Timberwolf reserves the right to make<br />

changes at any time without notice and without incurring any obligation.<br />

Due to improvements in design and performance during production there may be, in<br />

some cases, minor discrepancies between the actual chipper and the text in this<br />

manual.<br />

The manual should be considered a permanent part of the<br />

machine and should remain with it if the machine is resold.<br />

!<br />

INTRODUCTION<br />

Always follow safe operating and maintenance practices<br />

CAUTION or WARNING<br />

Be aware of this symbol and where shown,<br />

carefully follow the instructions.<br />

This caution symbol indicates important safety messages in this manual. When<br />

you see this symbol, be alert to the possibility of injury to yourself or others, and<br />

carefully read the message that follows.

The Timberwolf TW 190TDHB (<strong>Turbo</strong>) brushwood chipper is designed to chip solid wood material up<br />

to 190 mm in diameter. It is capable of chipping up to 6.5 tonnes of brushwood per hour.<br />

2310 mm<br />

1300 mm<br />

TIMBERWOLF 190TDHB (<strong>Turbo</strong>) 2<br />

Engine type Kubota 4-cylinder turbo diesel<br />

Maximum power 33kW (45hp)<br />

Cooling method Water cooled<br />

Overall weight 1018kg<br />

Starting method Electric<br />

Roller feed Twin series hydraulic motors<br />

PURPOSE OF MACHINE<br />

DIMENSIONS<br />

TIMBERWOLF<br />

45/190 TURBO VORTEX<br />

1510 mm<br />

3990 mm with standard tow head (3385 mm with feed tray folded)<br />

Serial No. Location<br />

The serial number can be<br />

found on the identification<br />

plate located on the<br />

chassis beam.<br />

TIMBERWOLF TW 190TDHB FIXED TOWHEAD SPECIFICATION<br />

Maximum diameter material 190mm (7½")<br />

Fuel capacity 50 litres<br />

Hydraulic oil capacity 15 litres<br />

Material processing capacity up to 6.5 tonnes/hr<br />

Fuel type Diesel

2300mm<br />

TIMBERWOLF 190TDHB (<strong>Turbo</strong>) 3<br />

TIMBERWOLF 190TDHBA ADJUSTABLE TOWHEAD SPECIFICATION<br />

1640mm<br />

Engine type Kubota 4-cylinder turbo diesel<br />

Maximum power 33kW (45hp)<br />

Cooling method Water cooled<br />

Overall weight 1150kg<br />

Starting method Electric<br />

Roller feed Twin series hydraulic motors<br />

TIMBERWOLF<br />

45/190 TURBO VORTEX<br />

1510mm<br />

4900mm with adjustable tow head (4280mm with feed tray folded)<br />

ADJUSTING THE TOWHEAD HEIGHT<br />

Serial No. Location<br />

The serial number can be<br />

found on the identification<br />

plate located on the<br />

chassis beam.<br />

Maximum diameter material 190mm (7½")<br />

Fuel capacity 50 litres<br />

Hydraulic oil capacity 15 litres<br />

Material processing capacity up to 6.5 tonnes/hr<br />

Fuel type Diesel<br />

The TW 190TDHBA chipper has the ability to adjust the towhead height to correspond with the<br />

vehicles towing point.<br />

The preferred towing angle of any chipper is with the<br />

1<br />

chassis level to the ground. The adjustable head has<br />

the ability to move between 300mm from the ground<br />

to 875mm giving an overall adjustment of 575mm.<br />

The towhead latch and handbrake fundamentally<br />

work the same as a fixed standard towhead,<br />

however the front section of the head is retained in<br />

position via a locking ring and single clamp handle.<br />

To adjust the height the locking handle located on<br />

the side of the head (1) is turned in an anticlockwise<br />

direction to allow for the locking ring to disengage<br />

from its apposing ring. An internal damper is fitter to<br />

support the heads weight allowing both hands free<br />

to adjust the height. Once the desired height has<br />

been achieved the locking handle is turned<br />

clockwise until tight. The latching of the hitch is as normal as is the fitting of the light plug and<br />

breakaway cable as outlined in the ‘Hitching onto the tow ball’ section on page 9.

FEED FUNNEL<br />

SAFETY BAR<br />

FUEL TANK<br />

TOOL BOX<br />

HYDRAULIC<br />

OIL TANK<br />

HYDRAULIC<br />

OIL FILTER<br />

PARTS LOCATOR 4<br />

ROLLER<br />

CONTROLS<br />

DISCHARGE<br />

TUBE<br />

TIMBERWOLF<br />

45/190 TURBO VORTEX<br />

ROTOR<br />

HOUSING<br />

DISCHARGE<br />

BUCKET<br />

DISCHARGE<br />

ADJUSTMENT<br />

CONTROL<br />

LIFTING EYE<br />

THROTTLE<br />

AIR INTAKE<br />

ENGINE<br />

GUARDS<br />

TOW HEAD

ROTOR<br />

PULLEY<br />

DRIVE<br />

PULLEY<br />

ROTOR<br />

PARTS LOCATOR 5<br />

AIR INTAKE<br />

HYDRAULIC<br />

PUMP<br />

IN-LINE<br />

FUEL FILTER<br />

TOP<br />

ROLLER SLIDE<br />

ENGINE<br />

CONTROL PANEL<br />

FUEL<br />

PUMP<br />

BATTERY<br />

FUEL FILTER<br />

DIP<br />

STICK<br />

OIL FILTER<br />

AIR FILTER<br />

ALTERNATOR<br />

EXHAUST<br />

RESERVE TANK<br />

DIRECTIONAL<br />

CONTROL<br />

VALVE<br />

RADIATOR<br />

JOCKEY<br />

WHEEL<br />

ASSEMBLY<br />

STARTER<br />

MOTOR

!<br />

SAFE WORKING 6<br />

WARNING<br />

The chipper will feed material through on its own. To do this, it relies on<br />

sharp blades on the chipper rotor. To keep the blades sharp, only feed the<br />

machine with clean brushwood. DO NOT put muddy/dirty wood, roots,<br />

potted plants, bricks, stones or metal into the chipper.<br />

OPERATOR'S PERSONAL PROTECTIVE EQUIPMENT REQUIRED<br />

Chainsaw safety helmet<br />

fitted with mesh visor and<br />

recommended ear defenders<br />

to the appropriate<br />

specifications.<br />

Work gloves with<br />

elasticated wrist.<br />

Steel toe cap safety boots.<br />

BASIC WOODCHIPPING SAFETY<br />

The operator should be aware of the following points:<br />

MAINTAIN A SAFETY EXCLUSION ZONE around the chipper of at least 10 metres for the<br />

general public or employees without adequate protection. Use hazard tape to identify this<br />

working area and keep it clear from debris build up. Chips should be ejected away from any<br />

area the general public have access to.<br />

HAZARDOUS MATERIAL - Some species of trees and bushes are poisonous. The chipping<br />

action can produce vapour, spray and dust that can irritate the skin. This may lead to<br />

respiratory problems or even cause serious poisoning. Check the material to be chipped before<br />

you start. Avoid confined spaces and use a facemask if necessary.<br />

BE AWARE when the chipper is processing material that is an awkward shape. The material<br />

can move from side to side in the funnel with great force. If the material extends beyond the<br />

funnel, the brash may push you to one side causing danger. Badly twisted brash should be<br />

trimmed before being chipped to avoid thrashing in the feed funnel.<br />

BE AWARE that the chipper can eject chips out of the feed funnel with considerable force.<br />

Always wear full head and face protection.<br />

ALWAYS work on the side of the machine furthest from any local danger, e.g. not road side.<br />

!<br />

Close fitting heavy-duty<br />

non-snag clothing.<br />

Face mask if<br />

appropriate.<br />

DO NOT<br />

wear rings, bracelets,<br />

watches, jewellery or any<br />

other items that could be<br />

caught in the material and<br />

draw you into the chipper.

ALWAYS stop the chipper engine before making<br />

any adjustments, refuelling or cleaning.<br />

ALWAYS check rotor has stopped rotating and<br />

remove chipper ignition key before maintenance<br />

of any kind, or whenever the machine is to be left<br />

unattended.<br />

ALWAYS check the machine is well supported<br />

and cannot move.<br />

ALWAYS operate the chipper with the engine set<br />

to maximum speed when chipping.<br />

ALWAYS check (visually) for fluid leaks.<br />

ALWAYS take regular breaks. Wearing personal<br />

protective equipment for long periods can be<br />

tiring and hot.<br />

ALWAYS keep hands, feet and clothing out of<br />

feed opening, discharge and moving parts.<br />

ALWAYS use the next piece of material or a push<br />

stick to push in short pieces. Under no<br />

circumstances should you reach into the funnel.<br />

<br />

ALWAYS keep the operating area clear of people,<br />

animals and children.<br />

ALWAYS keep the operating area clear from<br />

debris build up.<br />

ALWAYS keep clear of the chip discharge tube.<br />

Foreign objects may be ejected with great force.<br />

ALWAYS ensure protective guarding is in place<br />

before commencing work. Failure to do so may<br />

result in personal injury or loss of life.<br />

ALWAYS operate the chipper in a well ventilated<br />

area - exhaust fumes are dangerous.<br />

SAFE WORKING 7<br />

GENERAL SAFETY MATTERS<br />

DO’S AND DON’TS<br />

DO NOT operate chipper unless available light is<br />

sufficient to see clearly.<br />

DO NOT use or attempt to start the chipper<br />

without the feed funnel, guards and discharge<br />

unit securely in place.<br />

DO NOT stand directly in front of the feed funnel<br />

when using the chipper. Stand to one side.<br />

DO NOT allow -<br />

BRICKS STRING CLOTH PLASTIC STONES<br />

METAL GLASS RUBBER ROOTS BEDDING<br />

PLANTS<br />

- to enter the machine, as damage is likely.<br />

DO NOT smoke when refuelling.<br />

DO NOT let anyone who has not received<br />

instruction operate the machine.<br />

DO NOT climb on the machine at any time.<br />

DO NOT handle material that is partially engaged<br />

in the machine.<br />

DO NOT touch any exposed wiring while<br />

machine is running.<br />

DO NOT use the chipper inside buildings.<br />

!

MACHINE:<br />

NOTES:<br />

SAFE WORKING 8<br />

TW 190TDHB (<strong>Turbo</strong>)<br />

NOISE TEST<br />

Tested Chipping 120 mm x 120 mm Corsican Pine 1.5m in<br />

length<br />

Noise levels above 80dB (A) will be experienced at the working position. Wear ear protection<br />

at all times to prevent possible damage to hearing. All persons within a 4 metre radius must<br />

also wear good quality ear protection.<br />

89.4dB Calculated<br />

96.6 dB<br />

R= 4 metres<br />

R= 10 metres<br />

95.6 dB<br />

99.9 dB<br />

98.9 dB<br />

Guaranteed Sound Power: 119dB (A)<br />

95.2 dB<br />

95.1 dB<br />

As required by Supply of Machinery (safety) regulations of 2008.<br />

89.4dB Calculated<br />

89.4dB Calculated

OPERATING INSTRUCTIONS 9<br />

SAFE TRANSPORTATION<br />

WARNING<br />

! DO NOT RIDE ON THE CHIPPER WHEN IT IS BEING TOWED. !<br />

WHEN towing a chipper do not exceed the maximum permitted towing speed for the country<br />

concerned.<br />

ON rough or bumpy road surfaces reduce speed accordingly to protect your machine from<br />

unnecessary vibration.<br />

WHEN towing off road be aware of objects that may catch the chipper undergear.<br />

WHEN towing off road ensure inclination is not excessive.<br />

AVOID excessively pot holed ground.<br />

WHEN reversing the chipper the short wheel base will react quickly to steering input.<br />

ALWAYS check the discharge tube is tight before moving.<br />

KEEP tyre pressures inflated to 2.9 bar or 42 psi.<br />

CHECK wheel nuts are tightened to 90Nm or 65 lbs ft.<br />

CLEAR loose chippings and debris from the machine before departing.<br />

ENSURE the feed funnel is closed and the catches are is properly engaged before departing.<br />

HITCHING ONTO THE TOW BALL<br />

CHECK the ball head is well greased.<br />

WIND jockey wheel assembly anticlockwise until the tow head is above the height of the ball<br />

hitch on the vehicle.<br />

REVERSE the vehicle so the ball hitch is directly below the tow head.<br />

ATTACH the breakaway cable to a strong point on the vehicle, not the ball hitch.<br />

GRASP handle on tow head and push back catch with thumb.<br />

WIND the jockey wheel assembly clockwise, to lower the tow head onto the ball hitch.<br />

RELEASE handle and continue to wind jockey wheel clockwise. The tow head should snap<br />

into place on the ball hitch. If it doesn't, repeat previous 2 steps.<br />

WIND jockey wheel up until fully retracted and the jockey wheel frame is seated in its notch on<br />

the stem. The chipper weight should be fully on the vehicle.<br />

RELEASE the jockey wheel clamp and slide the jockey wheel assembly fully up.<br />

TIGHTEN clamp on the jockey wheel assembly.<br />

CONNECT electrical plug to socket on rear of towing vehicle and check operation of all the<br />

trailer and vehicle lights.<br />

THE chipper is now properly attached to the vehicle.<br />

UNHITCHING THE CHIPPER<br />

APPLY handbrake.<br />

DISCONNECT the electrical cable from the vehicle socket.<br />

RELEASE breakaway cable.<br />

RELEASE the jockey wheel assembly clamp.<br />

LOWER the jockey wheel assembly fully.<br />

RETIGHTEN the jockey wheel assembly clamp.<br />

WIND the jockey wheel assembly anticlockwise until it starts to take the weight of the chipper.<br />

GRASP the handle and release the catch with your thumb.<br />

CONTINUE to wind the jockey wheel anticlockwise. This should lift the tow head clear of the ball hitch.<br />

DRIVE the vehicle clear of the chipper.<br />

WIND the jockey wheel assembly to a suitable point where the chipper is level.<br />

THE chipper is now fully detached from the vehicle.

OPERATING INSTRUCTIONS 10<br />

DELIVERY<br />

All Timberwolf 190TDHB (<strong>Turbo</strong>) machines have a full pre - delivery inspection before leaving the factory<br />

and are ready to use. Read and understand this instruction manual before attempting to operate the<br />

chipper. In particular, read pages 6-8 which contain important health and safety information and advice.<br />

OPERATOR’S PERSONAL PROTECTIVE EQUIPMENT REQUIRED<br />

CHAINSAW SAFETY HELMET fitted with visor<br />

and recommended ear defenders to an<br />

appropriate specification.<br />

HEAVY-DUTY work gloves with elasticated wrist.<br />

Control Panel Diagram<br />

See page 6 for more detailed information.<br />

MANUAL CONTROLS<br />

CLOSE - FITTING heavy-duty non-snag clothing.<br />

SAFETY footwear.<br />

FACE MASK (if appropriate).<br />

Roller control box - is the control box above the feed opening of the chipper funnel. Its function is to control<br />

the feed rollers. The feed rollers draw material into the machine. It does not control the main rotor.<br />

RED SAFETY BAR = This is the large red bar that surrounds the feed tray and side of the feed<br />

funnel. The bar is spring loaded and connected to a switch that will interrupt the power to the rollers.<br />

The switch is designed so that it only activates if the bar is pushed to the limit of its travel. The rollers<br />

stop instantly, but can be made to turn again by pressing either the GREEN FEED or BLUE REVERSE<br />

control buttons.<br />

RED SAFETY BAR TEST<br />

To ensure the safety bar is always operational it must be activated once before each work session.<br />

The rollers will not function until the bar is activated. This procedure must be repeated each time the<br />

ignition is switched off.<br />

WARNING<br />

DO NOT remove, jam, disable, bypass, override or otherwise<br />

impede the effectiveness of the red safety bar.<br />

! !<br />

GREEN BUTTON = Forward feed - Push the button once - this activates the rollers and will allow you<br />

to start chipping (if the rotor speed is high enough).<br />

RED BUTTON = Emergency stop - This button stops the rollers from feeding. It overrides all other<br />

buttons or bars and will not allow the other buttons to function until it has been reset. To reset, pull out until<br />

it returns to its original position. The forward and reverse buttons will now function.<br />

BLUE BUTTON = Reverse feed - allows you to back material out of the rollers. The rollers will only<br />

turn in reverse as long as you keep pressing the button. You do not have to press the STOP button<br />

before pressing the GREEN FEED button to recommence feeding.<br />

BLUE<br />

REVERSE<br />

FEED<br />

PANEL<br />

RED STOP FEED - EMERGENCY<br />

STOP BUTTON<br />

PUSH TO STOP<br />

PULL TO RESET<br />

RED SAFETY BAR<br />

GREEN<br />

FORWARD<br />

FEED<br />

PANEL<br />

Do not rely on the red bar to keep the rollers stationary if it is<br />

necessary to clear or touch the rollers. Always switch off the<br />

machine and remove ignition key before approaching the rollers.

OPERATING INSTRUCTIONS 11<br />

AUTO CONTROLS<br />

The engine management unit controls the feed rate of the material going into the chipping chamber.<br />

If the engine speed is below the predetermined level, the engine management unit will not allow the<br />

feed rollers to work in the forward “infeed” direction, until the rotor speed rises above the<br />

predetermined level. At this point, the feed rollers will start turning without warning. The reverse<br />

function will work at any engine speed.<br />

EMERGENCY STOPPING<br />

There are two ways of stopping the TW 190TDHB (<strong>Turbo</strong>) chipper in the event of an emergency.<br />

STOPPING THE ROLLERS<br />

-Activating the red safety bar will stop the rollers immediately. To restart the rollers, just push the<br />

green forward button or blue reverse button.<br />

-Pushing the red Emergency button on the roller control box will also stop the rollers immediately. The<br />

button will stay in the “pushed in” position, and will require resetting (pulling out) before being able to<br />

restart the roller functions.<br />

DAILY CHECKS BEFORE STARTING<br />

LOCATE the machine on firm level ground.<br />

CHECK machine is well supported and<br />

cannot move.<br />

CHECK jack stand is lowered and secure.<br />

CHECK all guards are fitted and secure.<br />

CHECK the discharge unit is in place and<br />

fastened securely.<br />

CHECK discharge tube is pointing in a safe<br />

direction.<br />

ENGINE CONTROLS<br />

The engine controls are in two locations. The engine ignition is on the<br />

control panel in the centre of the machine, and the throttle lever is on the<br />

bonnet (see parts locator on pg. 3).<br />

STARTING THE ENGINE<br />

ENSURE throttle lever is in the slow (tortoise)<br />

position.<br />

INSERT key. Turn to heat.<br />

HEATER LED comes on.<br />

WAIT FOR HEATER LED TO GO OUT.<br />

TURN key to engage starter motor.<br />

RELEASE key once engine starts.<br />

Do not engage starter motor for more than 20<br />

seconds - allow one minute before attempting to<br />

start. Investigate reasons for failure to start.<br />

CHECK the feed funnel to ensure no objects<br />

are inside.<br />

CHECK feed tray is in up position - to<br />

prevent people reaching rollers.<br />

CHECK controls as described below.<br />

CHECK (visually) for fluid leaks.<br />

CHECK fuel and hydraulic oil levels.<br />

For parts location see diagrams on pages 4 & 5.<br />

OFF ON HEAT START<br />

0<br />

1<br />

CONTROLLING ENGINE SPEED<br />

The engine has two throttle settings, idle and fast. These are controlled by the throttle<br />

lever on the bonnet. Moving the lever towards the ‘Hare’ on the pictogram will<br />

increase engine speed while moving it towards the ‘Tortoise’ will decrease engine<br />

speed.<br />

2<br />

POWER<br />

ON LED<br />

HEATER<br />

ON LED<br />

POWER<br />

ON /OFF<br />

& START<br />

HOURS<br />

COUNTER<br />

0<br />

1<br />

1462975<br />

2

OPERATING INSTRUCTIONS 12<br />

BEFORE USING THE CHIPPER<br />

IT IS ESSENTIAL TO CARRY OUT THE FOLLOWING TESTS to check safety equipment - this<br />

sequence of tests will only take a few seconds to carry out. We recommend that these tests are<br />

carried out daily. Observing the function as described will confirm that the safety circuits are working<br />

correctly. This is also a good opportunity to remind all operators of the control and emergency stop<br />

systems.<br />

1 2<br />

PRESS THE GREEN<br />

BUTTON<br />

THE ROLLERS<br />

SHOULD TURN FORWARDS<br />

PRESS THE RED<br />

SAFETY BAR<br />

THE ROLLERS<br />

SHOULD STOP<br />

4 5 6<br />

7<br />

PRESS THE GREEN<br />

BUTTON AGAIN<br />

THE ROLLERS SHOULD<br />

TURN FORWARDS<br />

STOPPING THE ENGINE<br />

MOVE the throttle lever to the ‘Tortoise’ to reduce the engine speed to idle.<br />

LEAVE the engine running for 1 minute.<br />

TURN the power switch to position 0. The engine should stop after a few seconds.<br />

REMOVE the ignition key.<br />

WITH THE ENGINE RUNNING AT FULL SPEED<br />

PRESS THE EMERGENCY<br />

RED BUTTON<br />

THE ROLLERS<br />

SHOULD STOP<br />

3<br />

PRESS THE BLUE BUTTON<br />

THE ROLLERS SHOULD TURN<br />

BACKWARDS ONLY WHILE THE<br />

BUTTON IS PRESSED<br />

PRESS THE BLUE<br />

BUTTON<br />

THE ROLLERS<br />

SHOULD NOT TURN<br />

PULL TO RESET<br />

THE RED BUTTON<br />

THE MACHINE IS<br />

READY TO USE<br />

STARTING TO CHIP<br />

WARNING<br />

Do not use or attempt to start the chipper without the protective<br />

! !<br />

guarding and discharge unit securely in place. Failure to do so may<br />

result in personal injury or loss of life.<br />

CHECK that chipper is running smoothly.<br />

RELEASE the catches on the feed tray and lower. Pull to release the red emergency stop button.<br />

PRESS the green control button. The rollers will commence turning.<br />

STAND to one side of the feed funnel.<br />

PROCEED to feed material into the feed funnel.<br />

DISCHARGE CONTROLS<br />

ROTATION<br />

Controlling the discharge is an essential part of safe working.<br />

BUCKET ANGLE<br />

1. Slacken nut using<br />

integral handle.<br />

1<br />

4. Adjust the bucket to the desired<br />

angle using the handle provided.<br />

2. Rotate tube.<br />

3. Retighten nut.

OPERATING INSTRUCTIONS 13<br />

CHIPPING<br />

Wood up to 190 mm diameter can be fed into the feed funnel. Put the butt end in first and engage it<br />

with the feed roller. The hydraulic feed rollers will pull the branch into the machine quite quickly. Large<br />

diameter material will have its feed rate automatically controlled by the engine management unit.<br />

Sometimes a piece of wood that is a particularly awkward shape is too strong for the feed rollers to<br />

break. This will cause the top roller to either bounce up and down on the wood or both rollers to stall.<br />

If this occurs press the BLUE REVERSE button until the material has been released. Pull the material<br />

out of the feed funnel and trim it so the chipper can handle it.<br />

Both feed rollers should always turn at the same speed. If one or both rollers stop or suddenly slow<br />

down it may be that a piece of wood has become stuck behind one of the rollers. If this occurs press<br />

the BLUE REVERSE button and hold for 2 seconds - then repress GREEN FEED button. This should<br />

enable the rollers to free the offending piece of material and continue rotation at the correct speed. If<br />

the rollers continue to stall in the 'forward feed' or 'reverse feed' position push the RED STOP<br />

BUTTON, turn engine off, remove ignition key and investigate.<br />

BLOCKAGES<br />

Always be aware that what you are putting into the chipper must come out. If the chips stop coming<br />

out of the discharge tube but the chipper is taking material in - STOP IMMEDIATELY. Continuing to<br />

feed material into a blocked machine may cause damage and will make it difficult to clear.<br />

If the chipper becomes blocked proceed as follows:<br />

STOP the engine and remove the keys.<br />

REMOVE the two rotor housing bolts.<br />

OPEN the rotor housing fully.<br />

THE material causing the blockage should fall clear.<br />

WARNING<br />

Do not reach into the rotor housing with unprotected hands. There are<br />

sharp blades and any small movement of the rotor may cause serious injury.<br />

! !<br />

EMPTY loose debris from inside the rotor housing.<br />

CHECK that the discharge tube is clear before continuing.<br />

THE rotor housing does not have to be completely clear to continue.<br />

SHUT the rotor housing and replace both bolts securely.<br />

RESTART the engine.<br />

ALLOW machine time to clear excess chips still remaining in rotor housing before you continue<br />

feeding brushwood. Feed in a small piece of wood while watching to make sure that it comes out of<br />

the discharge. If this does not clear it, repeat the process and carefully inspect the discharge tube to<br />

find any obstruction.<br />

NOTE<br />

Continuing to feed the chipper with brushwood once it has become blocked will cause the chipper to<br />

compact the chips in the rotor housing and it will be difficult and time consuming to clear.<br />

AVOID THIS SITUATION - WATCH THE DISCHARGE TUBE AT ALL TIMES.<br />

HYDRAULIC OIL LEVEL INDICATOR<br />

This can be viewed through the wall of the tank. Maximum and minimum marks are provided.<br />

FUEL LEVEL INDICATOR<br />

The fuel level can be seen through the wall of the fuel tank.

SERVICE INSTRUCTIONS 14<br />

THE FOLLOWING PAGES DETAIL ONLY<br />

BASIC MAINTENANCE GUIDELINES SPECIFIC<br />

TO YOUR CHIPPER.<br />

! !<br />

THIS IS NOT A WORKSHOP MANUAL.<br />

THE FOLLOWING GUIDELINES ARE NOT EXHAUSTIVE AND DO NOT EXTEND<br />

TO GENERALLY ACCEPTED STANDARDS OF ENGINEERING/MECHANICAL<br />

MAINTENANCE THAT SHOULD BE APPLIED TO ANY PIECE OF MECHANICAL<br />

EQUIPMENT AND THE CHASSIS TO WHICH IT IS MOUNTED.<br />

AUTHORISED TIMBERWOLF SERVICE AGENTS ARE FULLY TRAINED IN ALL<br />

ASPECTS OF TOTAL SERVICE AND MAINTENANCE OF TIMBERWOLF<br />

WOODCHIPPERS. YOU ARE STRONGLY ADVISED TO TAKE YOUR CHIPPER TO<br />

AN AUTHORISED AGENT FOR ALL BUT THE MOST ROUTINE MAINTENANCE<br />

AND CHECKS.<br />

TIMBERWOLF ACCEPTS NO RESPONSIBILITY FOR THE FAILURE OF THE<br />

OWNER/USER OF TIMBERWOLF CHIPPERS TO RECOGNISE GENERALLY<br />

ACCEPTED STANDARDS OF ENGINEERING/MECHANICAL MAINTENANCE<br />

AND APPLY THEM THROUGHOUT THE MACHINE.<br />

THE FAILURE TO APPLY GENERALLY ACCEPTED<br />

STANDARDS OF MAINTENANCE, OR THE PERFORMANCE<br />

OF INAPPROPRIATE MAINTENANCE, MAY INVALIDATE<br />

WARRANTY IN WHOLE OR IN PART.<br />

PLEASE REFER TO YOUR AUTHORISED<br />

TIMBERWOLF SERVICE AGENT FOR<br />

SERVICE AND MAINTENANCE.<br />

! !

!<br />

SERVICE INSTRUCTIONS 15<br />

WARNING<br />

Always immobilise the machine by stopping the engine, removing the ignition<br />

key and disconnecting the battery before undertaking any maintenance work. !<br />

SERVICE SCHEDULE<br />

Check water. <br />

Check radiator is clear. <br />

Check engine oil - top up if necessary (10W-30). <br />

Check for engine oil / hydraulic oil leaks. <br />

Check fuel level.<br />

Check feed funnel, feed roller cover, access covers,<br />

<br />

engine covers and discharge unit are securely fitted. <br />

Check blades. <br />

Clean air filter element.<br />

DEPENDING ON WORKING ENVIRONMENT<br />

Check tyre pressure is 2.9 Bar (42 psi). <br />

Check safety bar mechanism.<br />

Check for tightness all nuts, bolts and fastenings<br />

<br />

making sure nothing has worked loose. <br />

Grease discharge flange.<br />

Check tension of main drive belts<br />

<br />

(and tension if necessary). <br />

Grease the roller box slides. OR AS REQUIRED - SEE PAGE 21<br />

Grease the roller spline and bearing. OR AS REQUIRED - SEE PAGE 21<br />

Check fuel pipes and clamp bands. <br />

Check battery electrolyte level. <br />

Check for loose electrical wiring. <br />

Grease jack stand.<br />

Replace hydraulic oil filter - every year or 100 hours<br />

<br />

after service or repair work to the hydraulic system. OR <br />

Replace hydraulic oil. OR <br />

Replace fuel pipes and clamp bands.<br />

Check coolant.<br />

Change engine oil.<br />

Replace engine oil filter cartridge.<br />

Check valve clearance.<br />

Replace anvils.<br />

Axle maintenance.<br />

Tow head maintenance.<br />

Daily<br />

Check<br />

50<br />

Hours<br />

100<br />

Hours<br />

500<br />

Hours<br />

REFER TO YOUR ENGINE<br />

SUPPLIERS MANUAL<br />

1<br />

Year<br />

RETURN TO DEALER - 1500 HRS OR 3 YRS<br />

REFER TO SUPPLIERS<br />

INSTRUCTION SHEET<br />

NOTE: Your Timberwolf woodchipper is covered by a full 12 months parts and labour warranty.<br />

Subject to correct maintenance and proper machine usage, the bearings are guaranteed for 12<br />

months regardless of hours worked by the machine. In conditions of 'heavy usage' - i.e. in excess of<br />

500 hours per year - it is recommended that the bearings are changed annually to ensure that the<br />

machine retains optimum working performance.

SERVICE INSTRUCTIONS<br />

HANDLE blades with extreme caution to<br />

avoid injury. Gloves should always be<br />

worn when handling the cutter blades.<br />

THE drive belts should be connected<br />

while changing blades, as this will restrict<br />

sudden movement of the rotor.<br />

SAFE MAINTENANCE<br />

ALWAYS IMMOBILISE THE ENGINE BEFORE UNDERTAKING ANY MAINTENANCE WORK ON THE<br />

CHIPPER BY REMOVING THE KEY AND DISCONNECTING THE NEGATIVE LEAD AT THE BATTERY.<br />

SPARES<br />

THE major components of this machine<br />

are heavy. Lifting equipment must be<br />

used for disassembly.<br />

CLEAN machines are safer and easier to<br />

service.<br />

AVOID contact with hydraulic oil and fuel.<br />

Only fit genuine Timberwolf replacement blades, screws and chipper spares. Failure to do so<br />

will result in the invalidation of the warranty and may result in damage to the chipper, personal<br />

injury or even loss of life.<br />

BATTERY REMOVAL AND MAINTENANCE<br />

16<br />

WARNING<br />

Refer to the battery safety section on pages 17-18. !<br />

!<br />

BATTERY MAINTENANCE<br />

1. Undo the two M10 nuts on the battery cover.<br />

2. Remove the battery cover.<br />

3. The battery can be serviced in this position.<br />

SAFE LIFTING OF THE CHIPPER<br />

The lifting eye is designed to lift the machine’s weight only. Do not use<br />

hoist hook directly on the lifting eye, use a correctly rated safety shackle.<br />

Inspect the lifting eye prior to each use - DO NOT USE LIFTING EYE IF<br />

DAMAGED.<br />

BATTERY REMOVAL<br />

1. Remove the negative battery lead.<br />

2. Remove the positive battery lead.<br />

When reinstalling the battery apply a small smear of Vaseline to the terminals.<br />

CHANGE HYDRAULIC OIL AND FILTER<br />

WARNING<br />

Use plastic gloves to keep oil off skin and dispose of the used oil and filter in<br />

an ecologically sound way. The oil and filter should be changed once a year<br />

or at any time it becomes contaminated. Before starting check that the<br />

chipper is standing level and brush away loose chips.<br />

1. Remove the black screw cap from the top of the filter housing.<br />

1<br />

2. Partially remove filter element from inner cup. Leave filter to<br />

drain for 15 minutes.<br />

3. Remove filter element from cup when clear of hydraulic oil.<br />

4. Remove drain plug and drain oil into a suitable container.<br />

5. Replace drain plug.<br />

2<br />

6. Refill with VG 32 hydraulic oil until the level is between the min and<br />

max lines marked on the tank (about 40 litres).<br />

4<br />

7. Refit the filter cup, install a new filter element and refit the<br />

black screw cap, to the filter housing, ensuring o-ring remains<br />

in place.<br />

! !

Product name: Copper Ease.<br />

SERVICE INSTRUCTIONS 17<br />

Copper Ease contains no hazardous ingredients at or above regulatory disclosure limits, however,<br />

safety precautions should be taken when handling (use of oil-resistant gloves and saftey glasses are<br />

recommended - respiratory protection is not required). Avoid direct contact with the substance and<br />

store in a cool, well ventilated area avoiding sources of ignition, strong oxidising agents and strong<br />

acids. Dispose of as normal industial waste (be aware of the possible existance of regional or national<br />

regulations regarding disposal), do not discharge into drains or rivers.<br />

In case of fire: in combustion the product emits toxic fumes, extinguish with alcohol or polymer foam,<br />

carbon dioxide or dry chemical powder. Wear self-contained breathing apparatus and protective clothing<br />

to prevent contact with skin and eyes.<br />

FIRST AID<br />

COPPER EASE SAFETY INFORMATION<br />

Skin contact: there may be mild irritation at the site of contact, wash immediately with plenty of soap<br />

and water.<br />

Eye contact: there may be irritation and redness, bathe the eye with running water for 15 minutes.<br />

Ingestion: there may be irritation of the throat, do not induce vomiting, wash out mouth with water.<br />

A safety data sheet for this product can be obtained by writing to the manufacturer at the<br />

following address: Comma Oil and Chemicals Ltd., Deering Way, Gravesend, Kent DA12 2QX.<br />

Tel: 01474 564311, Fax: 01474 333000.<br />

WARNING NOTES AND SAFETY REGULATIONS FOR FILLED LEAD-ACID BATTERIES<br />

For safety reasons, wear eye protection<br />

when handling a battery.<br />

Keep children away from acid and<br />

batteries.<br />

BATTERY SAFETY INFORMATION<br />

Fires, sparks, naked flames and smoking are<br />

prohibited.<br />

-Avoid causing sparks when dealing with cables<br />

and electrical equipment, and beware of<br />

electrostatic discharges.<br />

-Avoid short circuits, otherwise:<br />

Explosion hazard:<br />

-A highly explosive oxyhydrogen gas mixture is<br />

produced when batteries are charged.<br />

Corrosive hazard:<br />

-Battery acid is highly corrosive, therefore:<br />

-Wear protective gloves and eye protection.<br />

-Do not tilt the battery, acid may escapefrom the<br />

vent openings.<br />

First aid:<br />

-Rinse off acid splashed in the eyes immediately<br />

for several minutes with clear water! Then<br />

consult a doctor immediately.<br />

-Neutralise acid splashes on the skin or clothes<br />

immediately with acid neutraliser (soda) or soap<br />

suds, and rinse with plenty of water.<br />

-If acid is swallowed, consult a doctor immediately.<br />

Warning notes: The battery case can become brittle, to<br />

avoid this:<br />

-Do not store batteries in direct sunlight.<br />

-Discharged batteries may freeze up, therefore<br />

store in an area free from frost.<br />

Disposal:<br />

-Dispose of old batteries at an authorised<br />

collection point.<br />

-The notes listed under item 1 are to be followed<br />

for transport.<br />

-Never dispose of old batteries in household<br />

waste.

SERVICE INSTRUCTIONS 18<br />

BATTERY SAFETY INFORMATION...cont.<br />

1. Storage and transport<br />

- Batteries are filled with acid.<br />

- Always store and transport batteries upright<br />

and prevent from tilting so that no acid can<br />

escape.<br />

- Store in a cool and dry place.<br />

- Do not remove the protective cap from the<br />

positive terminal.<br />

- Run a FIFO (first in-first out)warehouse<br />

management system.<br />

2. Initial operation<br />

- The batteries are filled with acid at a density of<br />

1.28g/ml during the manufacturing process and<br />

are ready for use.<br />

- Recharge in case of insufficient starting power<br />

(cf. section 4).<br />

3. Installation in the vehicle and removal from<br />

the vehicle<br />

- Switch off the engine and all electrical<br />

equipment.<br />

- When removing, disconnect the negative<br />

terminal first.<br />

- Avoid short circuits caused by tools, for example.<br />

- Remove any foreign body from the battery tray,<br />

and clamp battery tightly after installation.<br />

- Clean the terminals and clamps, and lubricate<br />

slightly with battery grease.<br />

- When installing, first connect the positive<br />

terminal, and check the terminal clamps for<br />

tight fit.<br />

- After having fitted the battery in the vehicle,<br />

remove the protective cap from the positive<br />

terminal, and place it on the terminal of the<br />

replaced battery in order to prevent short<br />

circuits and possible sparks.<br />

- Use parts from the replaced battery, such as<br />

the terminal covers, elbows, vent pipe<br />

connection and terminal holders (where<br />

applicable); use available or supplied filler caps.<br />

- Leave at least one vent open, otherwise there<br />

is a danger of explosion. This also applies<br />

when old batteries are returned.<br />

4. Charging<br />

- Remove the battery from the vehicle;<br />

disconnect the lead of the negative terminal first.<br />

- Ensure good ventilation.<br />

- Use suitable direct current chargers only.<br />

- Connect the positive terminal of the battery to<br />

the positive output of the charger. Connect the<br />

negative terminal accordingly.<br />

- Switch on the charger only after the battery has<br />

been connected, and switch off the charger first<br />

after charging has been completed.<br />

- Charging current-recommendation: 1/10<br />

ampere of the battery capacity Ah.<br />

- Use a charger with a constant charging voltage<br />

of 14.4V for re-charging.<br />

- If the acid temperature rises above 55 o Celsuis,<br />

stop charging.<br />

- The battery is fully charged when the charging<br />

voltage has stopped rising for two hours.<br />

5. Maintenance<br />

- Keep the battery clean and dry.<br />

- Use a moist anti-static cloth only to wipe the<br />

battery, otherwise there is a danger of<br />

explosion.<br />

- Do not open the battery.<br />

- Recharge in case of insufficient starting power<br />

(cf. section 4).<br />

6. Jump Starting<br />

- Use the standardised jumper cable in<br />

compliance with DIN 72553 only, and follow the<br />

operating instructions.<br />

- Use batteries of the same nominal voltage only.<br />

- Switch off the engines of both vehicles.<br />

- First connect the two positive terminals (1) and<br />

(2), then connect the<br />

negative terminal of the<br />

charged battery (3) to a<br />

metal part (4) of the<br />

vehicle requiring<br />

assistance away from the battery.<br />

- Start the engine of the vehicle providing<br />

assistance, then start the engine of the vehicle<br />

requiring assistance for a maximum of 15<br />

seconds.<br />

- Disconnect the cables in reverse sequence<br />

(4-3-2-1).<br />

7. Taking the battery out of service<br />

- Charge the battery; store in a cool place or in<br />

the vehicle with the negative terminal<br />

disconnected.<br />

- Check the battery state of charge at regular<br />

intervals, and correct by recharging when<br />

necessary (cf. section 4).<br />

12V<br />

(2)<br />

(1)<br />

(3) (4)<br />

12V

!<br />

4<br />

SERVICE INSTRUCTIONS 19<br />

CHANGING BLADES<br />

WARNING<br />

Wear heavy duty gloves for the blade changing operation.<br />

1. Turn off the chipper and remove the key.<br />

2. Remove the negative battery lead.<br />

3. Turn the discharge tube to point across the<br />

machine.<br />

4. Use a 24mm socket with extension bar to<br />

remove the two M16 nuts clamping the rotor<br />

housing shut.<br />

5. Carefully lift the rotor housing until its rests on<br />

its stop.<br />

6. Using the fan blades turn the rotor so the first<br />

blade to be changed is in a convenient<br />

position. Wedge rotor against the housing<br />

with a wooden block to prevent turning.<br />

7. Brush away all dirt and debris from the rotor<br />

and blades.<br />

8. With a 24mm spanner/socket undo the two<br />

nyloc nuts that are holding the blade in place.<br />

9. Grasp the blade by the flat edges while<br />

wearing heavy duty gloves.<br />

10. Withdraw the blade from the rotor.<br />

11. If the blades are being rotated and not<br />

replaced, do not remove the blade bolts.<br />

12. If the blades are to be renewed, place the<br />

blade on a flat surface and tap the top of<br />

the blade bolts with a hammer. The bolts<br />

are designed for this. They should loosen<br />

from the blade. Withdraw them completely.<br />

13. Clean the back surface of the blade, blade<br />

bolts and blade area of the rotor before<br />

WARNING<br />

Always sharpen blades on a regular basis. Failure to do so will cause the machine<br />

to under perform and will overload engine and bearings causing machine<br />

breakdown. Blades must not be sharpened beyond the wear mark (see diagram).<br />

! Failure to comply with this could result in machine damage, injury or loss of life.<br />

5<br />

THIS PROCEDURE SHOULD ONLY BE UNDERTAKEN WITH THE DISCHARGE IN PLACE.<br />

10<br />

reseating blades. The blades must not<br />

have any material underneath them<br />

when tightened. If they are not flat and<br />

tight they will become loose quickly.<br />

14. Reassemble the blades, bolts, washers and<br />

nuts in the order shown in the diagram<br />

above. Use only genuine Timberwolf nuts<br />

and washers, as they are of a higher grade<br />

than normally stocked at fastener factories.<br />

Failure to use the appropriate grade nuts or<br />

washers may result in damage, injury or<br />

death. The use of genuine Timberwolf<br />

blades and bolts is recommended.<br />

15. Apply a smear of anti seize compound<br />

(copper ease) to the bolt threads and back<br />

face of the nuts. Do not apply copper grease<br />

onto the counter bore faces of the blades or<br />

bolts.<br />

16. Wedge rotor against housing with a wooden<br />

block to tension nuts.<br />

17. A calibrated torque wrench must be used<br />

to tighten the bolts to a torque setting of<br />

125 lbs ft (170 Nm).<br />

18. Repeat this procedure for the other blade.<br />

19. Slowly lower the rotor housing to its original<br />

position.<br />

20. Refit the two M16 nuts and tighten to<br />

60 lbs ft (80Nm).<br />

21. Re-attach battery lead.<br />

6<br />

WEAR<br />

MARK<br />

8<br />

!<br />

!

1<br />

2<br />

SERVICE INSTRUCTIONS 20<br />

CHECK FITTINGS<br />

The TW 190TDHB (<strong>Turbo</strong>) is subject to large vibrations during the normal course of operation.<br />

Consequently there is always a possibility that nuts and bolts will work themselves loose. It is<br />

important that periodic checks are made to ensure the security of all fasteners. Uncalibrated torque<br />

wrenches can be inaccurate by as much as 25%. It is therefore essential that a calibrated<br />

torque wrench is used to achieve the tightening torques listed below.<br />

Size Pitch Head Torque Ibs.ft Torque Nm<br />

Blade Bolts M16 Fine 24 mm Hex 125 170<br />

Anvil Retaining Bolts M12 Standard 10 mm Allen Key 65 88<br />

Rotor Housing Clamp Bolts M16 Standard 24 mm Hex 60 80<br />

Hyd Motor Retaining Cap Screws M12 Standard 10 mm Allen Key 60 81<br />

Roller Box Retaining Bolts M16 Standard 24 mm Hex 105 140<br />

Rotor Main Shaft Retaining Screws M12 Standard 10 mm Allen Key 105 140<br />

Rotor Stub Shaft Retaining Screws M10 Fine 8 mm Allen Key 45 61<br />

Large Rotor Shaft Retaining Nut M39 Nut 60 mm Hex 450 610<br />

Funnel Retaining Nuts M12 Standard 19 mm Hex 60 80<br />

General M8 Standard 13 mm Hex 17 23<br />

General M10 Standard 17 mm Hex 34 46<br />

General M12 Standard 19 mm Hex 60 80<br />

Drain Bung in Fuel Tank 3/8” BSP - 22 mm Hex 25 33.8<br />

Fuel Take-off in Fuel Tank 3/4” BSP - 32 mm Hex 40 54.2<br />

CHECK HOSES<br />

All the hydraulic hoses should be regularly inspected for chafing and leaks. The hydraulic system is<br />

pressurized to 150 Bar (2175 PSI) and thus the equipment containing it must be kept in good condition.<br />

Identify the hoses that run to the top motor. These have the highest chance of damage as they are<br />

constantly moving. If any hydraulic components are changed new seals should be installed during<br />

reassembly. Fittings should then be retightened.<br />

TENSION DRIVE BELTS<br />

NOTE: There will normally be a rapid drop in tension during run-in period for new belts. When new<br />

belts are fitted, check the tension every 2 - 3 hours and adjust until the tension remains constant.<br />

Belt failures due to lack of correct tensioning will not be covered under your Timberwolf warranty.<br />

1. Remove the near side roller box guard.<br />

2. Open the rotor housing.<br />

3. Slacken the four 24 mm nuts that retain the<br />

roller box (bolt is retained underneath).<br />

4. Slacken the lock nuts on the belt tension bracket.<br />

5. Turn appropriate lock nut to move roller box in<br />

desired direction. Take care to keep roller box<br />

square. Slightly tighten nut A (see diagram)<br />

when tension is near desired amount. Continue<br />

to tension belts until correct tension is achieved.<br />

3<br />

A<br />

For instructions on checking belt tension &<br />

correct belt tension values, please refer to<br />

the Timberwolf V-Belt Tensioning Data Table<br />

(pg. 45).<br />

6. When the belt tension is correct tighten<br />

the four 24 mm roller box retaining nuts.<br />

7. Tighten the lock nuts.<br />

8. Grease the roller box slides and rollers.<br />

9. Close the rotor housing and fasten securely.<br />

10. Refit the near side roller box guard.<br />

4

SERVICE INSTRUCTIONS 21<br />

GREASE THE ROLLER BOX SLIDES<br />

NOTE: This should be done every 50 hours. In dirty or dusty conditions or during periods of<br />

hard work it should be done more frequently. If the slides become dry the top roller will tend<br />

to hang up and the pulling-in power of the rollers will<br />

be much reduced. Excessive wear will ensue.<br />

1<br />

1. Remove the near side roller box guard.<br />

2. Open the rotor housing.<br />

3. Apply multipurpose grease directly to the slide surfaces<br />

indicated. DO NOT USE GRAPHITE BASED GREASE.<br />

4. Close the rotor housing.<br />

5. Refit the near side roller box guard.<br />

GREASE THE ROLLER SPLINE AND BEARING<br />

NOTE: This should be done regularly. In dirty and dusty conditions or during periods of hard<br />

work it should be weekly. If the bearings and splines are allowed to run dry premature wear<br />

will occur resulting in a breakdown and the need for replacement parts. This failure is not<br />

warranty. Early signs of insufficient grease includes squeaking or knocking rollers.<br />

1. Open the rotor housing.<br />

2. Locate two grease nipples; one in the centre of each roller shaft.<br />

3. Use a pump action grease gun to apply a generous amount of grease to<br />

each roller drive. DO NOT USE GRAPHITE BASED GREASE.<br />

4. Close the rotor housing.<br />

5. To penetrate all the bearing surfaces thoroughly, start the machine and<br />

operate the rollers for 20 seconds. Switch off the machine. Repeat this<br />

greasing/running procedure a further 3 times.<br />

GREASE THE JACK STAND<br />

The jack stand requires intermittent greasing to maintain a smooth operation.<br />

1. Brush off dirt with a stiff brush.<br />

2. Apply grease liberally to screw thread using a brush.<br />

3. Wind mechanism up and down a couple of times to ensure grease has covered all surfaces.<br />

2<br />

GREASE THE DISCHARGE FLANGE<br />

1. Remove the discharge tube.<br />

2. Apply multipurpose grease to surface shown.<br />

3. Refit discharge tube.<br />

GREASING ROTOR BEARINGS<br />

Both front and rear bearings are sealed and do not need greasing.<br />

ENGINE MANUFACTURER’S HANDBOOK<br />

Refer to your Engine Manufacturer’s Handbook for detailed instructions on the following:<br />

Changing the fuel filter Checking the engine oil Changing the engine oil Changing the engine oil filter<br />

3<br />

2<br />

3<br />

2

WARRANTY 22<br />

ENVIRONMENTAL MANUFACTURING LLP 12 MONTH CHIPPER WARRANTY<br />

WARRANTY PERIOD<br />

The warranty period for the woodchipper commences on the date of sale to the first end user and continues for<br />

a period of 12 months. This guarantee is to the first end user only and is not transferable except when an<br />

authorised Timberwolf Dealer has a woodchipper registered with Environmental Manufacturing LLP as a hire<br />

chipper or long term demonstrator – in these situations they are duly authorised to transfer any remaining<br />

warranty period to their first end user. Any warranty offered by the Timberwolf Dealer beyond the original 12<br />

month period will be wholly covered by said Dealer.<br />

LIABILITY<br />

Our obligation under this warranty is limited to repair at Environmental Manufacturing LLP premises or at our<br />

option an Environmental Manufacturing LLP approved Timberwolf dealer. No liability will be accepted for<br />

special, indirect, incidental, or consequential loss or damages of any kind.<br />

WARRANTY STATEMENT<br />

Environmental Manufacturing LLP warrants to the first end user that;<br />

-Your woodchipper shall be designed, built and equipped, at the point of sale, to meet all current applicable<br />

regulations.<br />

-Your chipper shall be free from manufacturing defects both in materials and workmanship in normal service for<br />

the period mentioned above.<br />

Warranty will not apply to a failure where normal use has exhausted the life of a component.<br />

Engine units are covered independently by their respective manufacturer warranties.<br />

OWNERS WARRANTY RESPONSIBILITIES<br />

As the owner of an Environmental Manufacturing LLP woodchipper you are responsible for the following;<br />

-Operation of the woodchipper in accordance with the Environmental Manufacturing LLP instruction manual.<br />

-Performance of the required maintenance listed in your Environmental Manufacturing LLP instruction manual.<br />

-In the event of a failure the Environmental Manufacturing LLP authorised Timberwolf dealer is to be notified<br />

within 10 days of failure and the equipment is to be made available for unmolested inspection by the dealer<br />

technician.<br />

WARRANTY RESTRICTIONS<br />

The Environmental Manufacturing LLP warranty is restricted to the first end user only and is not transferable<br />

except when an authorised Timberwolf Dealer has a woodchipper registered with Environmental Manufacturing<br />

LLP as a hire chipper or long term demonstrator – in these situations they are duly authorised to transfer any<br />

remaining warranty period to their first end user.<br />

The Environmental Manufacturing LLP warranty may be invalidated if any of the following apply;<br />

-The failed parts or assembly is interfered with in any way.<br />

-Normal maintenance has not been performed.<br />

-Incorrect reassembly of components.<br />

-The machine has undergone modifications not approved in writing by Environmental Manufacturing LLP.<br />

-In the case of tractor driven equipment, use has been on an unapproved tractor.<br />

-Conditions of use can be deemed abnormal.<br />

-The machine has been used to perform tasks contrary to those stated in the Environmental Manufacturing LLP<br />

instruction manual.<br />

WARRANTY SERVICE<br />

To obtain warranty service please contact your nearest Environmental Manufacturing LLP approved Timberwolf<br />

dealer. To obtain details of the nearest facility please contact Environmental Manufacturing LLP at the address<br />

on the front of this manual.<br />

These warranty terms are in addition to and not in substitution for and do not affect any right and remedies which<br />

an owner might have under statute or at common law against the seller of the goods under the contract by which<br />

the owner acquired the goods.

CERTIFICATE OF CONFORMITY 23

IDENTIFICATION PLATES 24<br />

EXAMPLE

!<br />

HOT<br />

EXHAUST<br />

WARNING<br />

FAILURE TO MAINTAIN BRAKE<br />

ADJUSTMENT WILL RESULT IN<br />

DAMPER FAILURE. NO WARRANTY<br />

LIABILITY WILL BE ACCEPTED ON<br />

THIS ITEM.<br />

DANGER<br />

BEWARE OF<br />

SHARP BLADES<br />

WHEN THE<br />

ROTOR HOUSING<br />

IS OPEN.<br />

HIGH<br />

VELOCITY<br />

DISCHARGE<br />

KEEP CLEAR!<br />

0<br />

1<br />

2<br />

Forward<br />

Latch<br />

Engine<br />

Safety<br />

DECALS 25<br />

616 617 670 671 1136 x 2<br />

PUSH TO STOP<br />

!<br />

DO NOT PULL HERE<br />

!<br />

!<br />

DANGER<br />

! !<br />

DANGER<br />

DANGER<br />

DANGER<br />

119 dB<br />

1350KGMAX<br />

GREASE ROLLER<br />

SPINDLE AND<br />

SLIDES<br />

LWA<br />

Last Updated 1st Dec 2010<br />

!<br />

DANGER<br />

!<br />

!<br />

DANGER<br />

DANGER DANGER<br />

SEE NEXT PAGE FOR DETAIL<br />

PUSH TO STOP<br />

PULL TO RESET<br />

92 dB<br />

!! ATTENTION !!<br />

NEW DRIVE BELTS NEED<br />

RE-TENSIONING<br />

WHEN NEW BELTS ARE FITTED CHECK<br />

TENSION EVERY 2-3 HOURS & ADJUST<br />

UNTIL TENSION REMAINS CONSTANT.<br />

TIMBERWOLF<br />

OPERATING INSTRUCTIONS<br />

READ THE INSTRUCTION MANUAL.<br />

THE INSTRUCTION MANUAL WITH THIS MACHINE<br />

CONTAINS IMPORTANT OPERATING, MAINTENANCE AND<br />

HEALTH AND SAFETY INFORMATION.<br />

FAILURE TO FOLLOW THE INFORMATION CONTAINED IN<br />

THE INSTRUCTION MANUAL MAY LEAD TO DEATH OR<br />

SERIOUS INJURY.<br />

1258 1363 1399 1661 1662<br />

! SAFETY NOTE !<br />

LIFTING EYE IS DESIGNED TO LIFT THE<br />

MACHINE’S WEIGHT ONLY.<br />

DO NOT USE HOIST HOOK DIRECTLY ON LIFTING EYE.<br />

USE CORRECTLY RATED SAFETY SHACKLE<br />

ONLY THROUGH LIFTING EYE.<br />

LIFTING EYE TO BE INSPECTED EVERY 6 MONTHS<br />

OR BEFORE EACH USE.<br />

ALWAYS VISUALLY INSPECT LIFTING EYE PRIOR TO<br />

EACH USE. DO NOT USE LIFTING EYE IF DAMAGED.<br />

2440 2800 2801 2802 2949<br />

LAeq<br />

!! ATTENTION !!<br />

CLEAN UNDER BLADES BEFORE<br />

REFITTING OR TURNING<br />

FAILURE TO DO SO MAY RESULT IN<br />

BLADE(S) COMING LOOSE AND DAMAGE<br />

BEING CAUSED TO THE ROTOR HOUSING<br />

2950 2951 2995 2998 3004 3022<br />

WARNING<br />

DO NOT ENGAGE STARTER MOTOR<br />

FOR MORE THAN<br />

20 SECONDS<br />

ALLOW ONE MINUTE BEFORE ATTEMPTING TO START<br />

INVESTIGATE REASONS FOR FAILURE TO START<br />

EXCESSIVE CRANKING WILL RESULT IN STARTER MOTOR FAILURE.<br />

THIS WILL NOT BE COVERED UNDER WARRANTY.<br />

4099 X 2 4310 X 2 17335 18393 19517

DECALS 26<br />

671 - these individual decals are supplied as a set, they may not all apply to your machine.<br />

CAUTION<br />

DANGER<br />

DANGER<br />

WHEN TRANSPORTING<br />

DISCHARGE CLAMPS MAY<br />

WORK LOOSE.<br />

CHECK FREQUENTLY<br />

AUTOFEED SYSTEM FITTED.<br />

ROLLERS MAY TURN WITHOUT<br />

WARNING!<br />

WHEN ENGINE IS SWITCHED OF<br />

THE ROLLERS WILL TURN<br />

DURING THE RUN DOWN<br />

PERIOD<br />

WITHOUT THIS<br />

! !<br />

DO NOT OPERATE<br />

COVER IN PLACE<br />

CAUTION<br />

FUEL HERE<br />

RISK OF FIRE<br />

DANGER<br />

AVOID STANDING DIRECTLY IN<br />

FRONT OF FEED FUNNEL TO<br />

REDUCE EXPOSURE TO NOISE,<br />

DUST AND RISK FROM EJECTED<br />

PARTICLES<br />

ALLOW ENGINE TO COOL FOR<br />

1 MINUTE BEFORE REFUELING.<br />

USE UNLEADED PETROL<br />

DO NOT OPERATE<br />

WITHOUT THIS<br />

COVER IN PLACE<br />

!<br />

DANGER<br />

CAUTION<br />

DANGER<br />

ROTATING<br />

BLADES<br />

!<br />

DO NOT PUT ROAD<br />

SWEEPINGS IN MACHINE<br />

AS GRIT WILL DAMAGE<br />

BLADES<br />

DO NOT OPERATE<br />

WITHOUT THIS<br />

COVER IN PLACE<br />

!<br />

DANGER DANGER<br />

DANGER<br />

DO NOT USE THIS MACHINE<br />

WITHOUT THE DISCHARGE UNIT<br />

FITTED FAILURE TO COMPLY<br />

MAY RESULT IN SERIOUS<br />

INJURY OR DAMAGE<br />

!<br />

STOP ENGINE AND REMOVE<br />

KEY BEFORE REMOVING<br />

DISCHARGE UNIT. ROTATING<br />

BLADES INSIDE.<br />

!<br />

DO NOT OPERATE<br />

WITHOUT THIS<br />

COVER IN PLACE<br />

!

ELECTRICAL DETAIL 27<br />

Date Last Modified: 19th Sept 05

2973<br />

HYDRAULIC LAYOUT 28<br />

BOTTOM<br />

MOTOR<br />

2830<br />

4243<br />

PUMP<br />

TANK<br />

P T<br />

DCV<br />

A B<br />

2885<br />

4244<br />

Date Last Modified: 1st Sept 05<br />

FILTER<br />

TOP<br />

MOTOR<br />

3060<br />

KIT NO: 4245

190 ROAD MACHINES WOULD NOT HAVE THIS SWITCH.<br />

CONNECT "ONLY" THE BLACK/WHITE WIRE TO ONE OF THE BLACK WIRES.<br />

MAIN LOOM 18482<br />

COMPONENT LIST:<br />

MAIN LOOM: 17276/2, FUNNEL LOOM: 1975/3, SAFETY BAR LOOM: 1406/1<br />

NO STRESS SENSOR: 1638/2<br />

POSITIVE BATTERY CABLE: 1375/2, NEGATIVE BATTERY CABLE: 1376/2<br />

ENGINE SPD<br />

SIGNAL (INDUCTIVE)<br />

ENGINE<br />

ROTOR<br />

SWITCH EMERGENCY<br />

HOUR FUEL FUEL<br />

METER<br />

PUMP<br />

SOLENOID<br />

SECURITY<br />

GROUND<br />

ENGINE<br />

GROUND<br />

SWITCH<br />

POINT<br />

N.O./N.C.<br />

N.O./N.C.<br />

13 14<br />

KEY SWITCH<br />

CONTROLLER<br />

H-BOX PCU<br />

C D<br />

21 22<br />

M<br />

B<br />

B<br />

PULL 1 2 HOLD<br />

A B<br />

B B<br />

B/W<br />

START<br />

BL/W<br />

B/R<br />

B<br />

P/W<br />

RUN<br />

R<br />

OFF<br />

ACC<br />

CONFIGURATION T.B.A.<br />

1 IN-<br />

SPEED SIG -<br />

2 IN+<br />

SPEED SIG +<br />

3 EPA OIL PRESSURE SW<br />

4 EPB WATER TEMP SW<br />

5 EPC EMERGENCY/ROTOR SWITCH<br />

6 STT GLOW PLUG I/P<br />

7 RST RESET REVERT TO RESET MODE<br />

FROM SAFETY SWITCH<br />

8 AX1<br />

9 AX1<br />

10 AX2<br />

11 AX2<br />

12 OUT 4 AUTO REVERSE PULSE OUTPUT<br />

13 OUT 5 SOL GND SPEED CONTROLLED<br />

14 GND GND 0v<br />

15 BAT BAT 12 V IGP<br />

16 OUT 1<br />

17 OUT 2 FUEL HOLD SOLENOID<br />

18 OUT 3 GLOW PLUG LAMP<br />

SP<br />

1<br />

P<br />

SP<br />

1<br />

TACHO SIG / ALT<br />

B B/W<br />

U/B<br />

B/R<br />

B<br />

B<br />

BL<br />

BL<br />

Y/BL<br />

Y/BL<br />

Y/R<br />

SP<br />

1<br />

Y/R<br />

SP<br />

1<br />

SP<br />

4<br />

R<br />

BR<br />

B/R<br />

SP<br />

1<br />

SP<br />

4<br />

B/R<br />

G<br />

P/W<br />

P/W BR<br />

ENG GND POINT<br />

PART No. 1376<br />

BATT 25mm<br />

BR<br />

BR<br />

SP<br />

6<br />

SP<br />

1<br />

SP<br />

2<br />

BATTERY<br />

O<br />

O<br />

BATT 25mm<br />

STARTER<br />

R MAIN TERM<br />

PART No. 1375<br />

CIRCUIT DIAGRAM 29<br />

WATER TEMP<br />

SWITCH t<br />

STARTER<br />

SOL TERM<br />

STARTER<br />

MOTOR<br />

W/R<br />

Y/R<br />

P/W<br />

P/W<br />

OIL PRESS<br />

SWITCH<br />

p<br />

W/R<br />

BR/B<br />

SP<br />

4<br />

87a<br />

R<br />

B<br />

BL<br />

SP<br />

1<br />

BL<br />

SP<br />

4<br />

ROTOR<br />

Y/BL<br />

87<br />

30<br />

BL/B<br />

ALTERNATOR<br />

P<br />

BR/R<br />

O/P<br />

R<br />

B/W<br />

86<br />

85<br />

START RELAY<br />

GLOW<br />

PLUGS<br />

35 1mm<br />

FWD REVERSE<br />

SOLENOID SOLENOID<br />

8<br />

.5mm<br />

39 1mm<br />

14<br />

.5mm<br />

18 2mm<br />

SP#1<br />

12 .5mm BLACK 41 1mm<br />

40<br />

1mm<br />

48<br />

3mm<br />

40 1mm<br />

27<br />

1mm<br />

40<br />

1mm<br />

33<br />

1mm<br />

7 1mm 28 1mm<br />

1<br />

1 2<br />

3<br />

2<br />

3<br />

W<br />

BR<br />

BR P/W<br />

FUSE 1<br />

IGP<br />

HEATERS<br />

ON LED<br />

15 1mm<br />

16<br />

1.5mm<br />

LATCH RELAY<br />

FWD SOL<br />

SP<br />

2<br />

G<br />

1-AC 3mm<br />

GREEN<br />

SP#2<br />

P/W<br />

LED<br />

O<br />

B/BR<br />

SP<br />

5<br />

BR/R<br />

B<br />

SP<br />

1<br />

SP<br />

4<br />

BL<br />

1mm<br />

2mm<br />

15<br />

5<br />

POWER ON<br />

LED<br />

B/BR<br />

LINK LEAD<br />

50E 1mm<br />

87a<br />

SP#4 14<br />

0.5<br />

BLUE<br />

8 0.5<br />

40 1mm<br />

40<br />

1mm<br />

BL/G<br />

LED<br />

FUSE 2<br />

AUX<br />

20<br />

1mm<br />

40 1mm<br />

87<br />

30<br />

SP<br />

1<br />

B<br />

SP<br />

4<br />

B BL<br />

SP<br />

1<br />

86<br />

85<br />

LINK LEAD<br />

AUX POWER<br />

CONN<br />

B<br />

Date Last Modified: 8th July 09<br />

SP<br />

2<br />

G<br />

B<br />

SP<br />

1<br />

P/W<br />

SP<br />

1<br />

BL/W<br />

2<br />

1<br />

SPLIT TO FUNNEL LOOM<br />

A B/G<br />

B/G<br />

FWD<br />

N.O.<br />

REV STOP<br />

N.O./N.C.<br />

N.C./N.C.<br />

13 14<br />

A B<br />

21 22<br />

C D<br />

PART No. 1975<br />

P/W<br />

13 14<br />

BL/G<br />

B<br />

BL/G<br />

P/W<br />

C<br />

O<br />

D<br />

BL<br />

E<br />

BL<br />

SP<br />

4<br />

W<br />

F<br />

BL/R<br />

BL<br />

SAFETY SW<br />

N.O./N.C.<br />

PART No. 1406<br />

SPLIT TO SAFETY SWITCH LOOM<br />

KEY TO WIRING<br />

B BLACK<br />

BL BLUE<br />

BR BROWN<br />

R RED<br />

G GREEN<br />

Y YELLOW<br />

P PURPLE<br />

W WHITE<br />

O ORANGE<br />

B/G BLACK WITH GREEN TRACER<br />

BL/R BLUE WITH RED TRACER<br />

O<br />

1<br />

C D<br />

BL/R<br />

2<br />

A B<br />

BL/G BLUE WITH GREEN TRACER<br />

BL/W BLUE WITH WHITE TRACER<br />

B/R BLACK WITH RED TRACER<br />

P/W PURPLE WITH WHITE TRACER<br />

B/BR BLACK WITH BROWN TRACER<br />

BL/B BLUE WITH BLACK TRACER<br />

W/R WHITE WITH RED TRACER<br />

Y/B YELLOW WITH BLUETRACER<br />

O/W ORANGE WITH WHITE TRACER<br />

O/Y ORANGE WITH YELLOW TRACER<br />

BL<br />

3<br />

DOCUMENT No. ISSUE<br />

CIRCUIT DIAGRAM FOR: 190 (T)DHB and 190 (T)FTR (H-BOX) 190-CD<br />

2

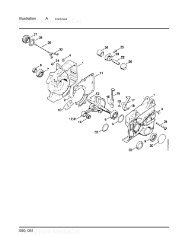

TIMBERWOLF<br />

190TDHB (<strong>Turbo</strong>)<br />

PARTS LISTS<br />

The following illustrations are for parts identification only. The<br />

removal or fitting of these parts may cause a hazard and should<br />

only be carried out by trained personnel.<br />

Page No.<br />

CHASSIS - FIXED TOWHEAD 31<br />

CHASSIS - ADJUSTABLE TOWHEAD 32<br />

CONTROL BOX 33<br />

CONTROL PANEL 34<br />

DECALS See pages 25 - 26<br />

DISCHARGE 35<br />

DRIVE TRAIN 36<br />

ELECTRICAL LAYOUT 37<br />

ENGINE 38<br />

ENGINE BAY 39<br />

FUEL TANK 40<br />

FUNNEL 41<br />

HYDRAULICS 42<br />

ROLLER BOX 43<br />

ROTOR 44<br />

ROTOR HOUSING 45<br />

V- BELT TENSIONING TABLE 46

Date Last Modified: 9th June 11<br />

21<br />

1<br />

20<br />

17<br />

38<br />

29<br />

10<br />

11<br />

49 50<br />

24<br />

16<br />

36<br />

x2<br />

18<br />

2<br />

47<br />

33<br />

12<br />

36<br />

4<br />

CHASSIS - FIXED TOWHEAD 31<br />

20<br />

19<br />

19<br />

14<br />

13<br />

28<br />

39<br />

4<br />

7<br />

10<br />

9<br />

15<br />

6<br />

5<br />

4<br />

10<br />

4<br />

14<br />

3<br />

22<br />

11<br />

46<br />

49 36<br />

25<br />

40<br />

23<br />

36<br />

43<br />

26<br />

41<br />

8<br />

9<br />

30<br />

6<br />

19<br />

4<br />

42<br />

4<br />

4<br />

44<br />

37<br />

34<br />

31<br />

10<br />

4<br />

8<br />

35<br />

11<br />

45<br />

27<br />

28 32<br />

Item Part No Part Name Q’ty<br />

35 1932 Wheel 3<br />

36 0839 M10 C Washer 14<br />

37 0350 M8/25 Bolt 2<br />

38 1036 M10 Brake Adjuster Nut 1<br />

39 1054 Brake Rod 1<br />

40 0382 M10/30 Bolt 4<br />

41 079F Nut Ball 1<br />

42 1501 M10 Plain 1/2 Nut 1<br />

43 0358 Catch Plate 1<br />

44 0067 Pop Rivet 4<br />

45 2963 Catch 1<br />

46 3043FS Outer Beam Handle 2<br />

47 17501 Jockey Wheel Clamp 1<br />

48 0878 M10/20 Bolt 2<br />

49 4345 M10 P Nyloc Nut 6<br />

50 0701 M10 A Washer 12<br />

Item Part No Part Name Q’ty<br />

18 4210 Battery 1<br />

19 0360 M10/25 Bolt 8<br />

20 0313 M12/100 4<br />

21 17478 Jockey Wheel 1<br />

22 17474FB Inner Chassis Beam O/S 1<br />

23 19076FB Outer Chassis Beam O/S 1<br />

24 1520 M10/45 Bolt 2<br />

25 19078F Offside Mudguard 1<br />

26 17522FB Tool Box Lid 1<br />

27 17494 Axle 1<br />

28 0479 M8 P Nyloc Nut 4<br />

29 17493 Tow Head 1<br />

30 0354 M8/60 Bolt 1<br />

31 1682 Threaded Stand Off 1<br />

32 2633 Wind Down Jack Stand 1<br />

33 18035FS Battery Support Bracket 1<br />

34 1683M Plain Stand Off 1<br />

Item Part No Part Name Q’ty<br />

1 19075FB Outer Chassis Beam N/S 1<br />

2 17475FB Inner Chassis Beam N/S 1<br />

3 0352 M8/40 Bolt 2<br />

4 0712 M8 C Washer 24<br />

5 19056 Lightboard 1<br />

6 0346 M8/20 Bolt 5<br />

7 19074FB Lightboard Bracket 1<br />

8 0481 M8 T Nyloc Nut 3<br />

9 0429 M12/35 Bolt 12<br />

10 0704 M12 C Washer 40<br />

11 0644 M12 P Nyloc Nut 12<br />

12 19077FB Nearside Mudguard 1<br />

13 1830FB Cross Beam 1<br />

14 18037 M8/12 Bolt 8<br />

15 1644 AV Mount 4<br />

16 0052 M10 T Nyloc Nut 2<br />

17 18036FB Battery Cover 1

29<br />

21<br />

1<br />

38<br />

x4<br />

20<br />

17<br />

49<br />

16<br />

51<br />

CHASSIS - ADJUSTABLE TOWHEAD 32<br />

47<br />

36<br />

x2<br />

18<br />

2<br />

36<br />

33<br />

12<br />

24<br />

4<br />

52<br />

50<br />

19<br />

14<br />

28<br />

10<br />

13<br />

39<br />

11<br />

4<br />

15<br />

9<br />

7<br />

6<br />

4<br />

22<br />

5<br />

14<br />

10<br />

11<br />

4<br />

3<br />

46<br />

25<br />

40<br />

49 36<br />

23<br />

43<br />

36<br />

26<br />

8<br />

4<br />

19<br />

9<br />

41<br />

30<br />

6<br />

42<br />

44<br />

10<br />

4<br />

4<br />

37<br />

35<br />

11<br />

34<br />

31<br />

4<br />

45<br />

27<br />

8<br />

Date Last Modified: 7th July 11<br />

28 32<br />

Item Part No Part Name Q’ty<br />

37 0350 M8/25 Bolt 2<br />

38 1036 M10 Brake Adjuster Nut 1<br />

39 19585 Brake Rod 1<br />

40 0382 M10/30 Bolt 4<br />

41 079F Nut Ball 1<br />

42 1501 M10 Plain 1/2 Nut 1<br />

43 0358 Catch Plate 1<br />

44 0067 Pop Rivet 4<br />

45 2963 Catch 1<br />

46 3043FS Outer Beam Handle 2<br />

47 17501 Jockey Wheel Clamp 1<br />

48 0878 M10/20 Bolt 2<br />