Application Case - Delta Electronics

Application Case - Delta Electronics

Application Case - Delta Electronics

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Application</strong> <strong>Case</strong><br />

<strong>Case</strong> <strong>Application</strong> of <strong>Delta</strong>’s AC Servo Drive Products in Extruder<br />

Industrial Automation BU, <strong>Delta</strong> <strong>Electronics</strong>, Inc.<br />

Issued by Solution Center Date February, 2010 Pages 2<br />

Applicable to<br />

DOP Series HMI, DTA Series Temperature Controller, VFD-B Series AC Motor Drive, VFD-E Series<br />

AC Motor Drive, VFD-C2000 Series AC Motor Drive, DVP series PLC<br />

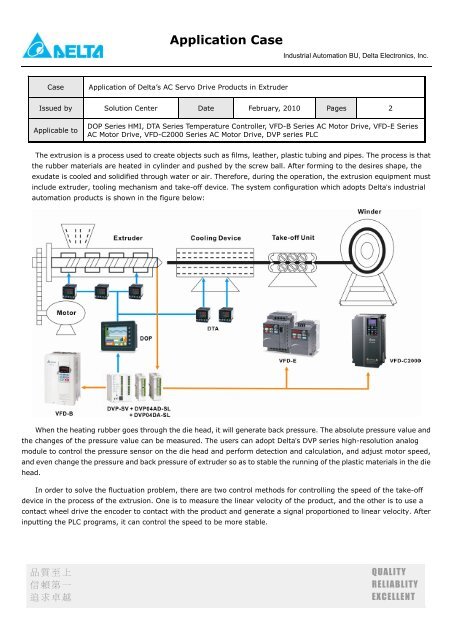

The extrusion is a process used to create objects such as films, leather, plastic tubing and pipes. The process is that<br />

the rubber materials are heated in cylinder and pushed by the screw ball. After forming to the desires shape, the<br />

exudate is cooled and solidified through water or air. Therefore, during the operation, the extrusion equipment must<br />

include extruder, tooling mechanism and take-off device. The system configuration which adopts <strong>Delta</strong>’s industrial<br />

automation products is shown in the figure below:<br />

When the heating rubber goes through the die head, it will generate back pressure. The absolute pressure value and<br />

the changes of the pressure value can be measured. The users can adopt <strong>Delta</strong>’s DVP series high-resolution analog<br />

module to control the pressure sensor on the die head and perform detection and calculation, and adjust motor speed,<br />

and even change the pressure and back pressure of extruder so as to stable the running of the plastic materials in the die<br />

head.<br />

In order to solve the fluctuation problem, there are two control methods for controlling the speed of the take-off<br />

device in the process of the extrusion. One is to measure the linear velocity of the product, and the other is to use a<br />

contact wheel drive the encoder to contact with the product and generate a signal proportioned to linear velocity. After<br />

inputting the PLC programs, it can control the speed to be more stable.<br />

品質至上 QUALITY<br />

信賴第一 RELIABLITY<br />

追求卓越 EXCELLENT

<strong>Application</strong> <strong>Case</strong><br />

Industrial Automation BU, <strong>Delta</strong> <strong>Electronics</strong>, Inc.<br />

When the open-collector type encoder is used, the converter is not needed. The channel of the high-speed counter<br />

of <strong>Delta</strong>’s PLC can be connected directly for detecting the extrusion speed. When <strong>Delta</strong>’s PLC application instruction SPD<br />

is used, the speed detection procedure can be easily recorded. In addition, <strong>Delta</strong>’s DVP-EH2 series or DVP-SV series<br />

PLCs all provide built-in 200K high-speed counter which is able to detect up to 1200rpm speed.<br />

The second controlling method uses the feedback measure system to measure the product size and the<br />

compensation changes. Connecting the analog output signals of thickness gauge or diameter detector which is installed<br />

near the take-off device to Delat’s PLC analog module, DVP04AD-S can feedback the output signals to take-off device and<br />

extruder. Doing this is to compensate the speed of the take-off device and the output changes of extruder.<br />

Regarding the winder equipment, <strong>Delta</strong>’s AC motor drive is used to control the closed-loop vector for constant tension<br />

control and the encoder is used to feedback the signals to the AC motor drive. In the actual application, <strong>Delta</strong>’s AC motor<br />

drive is applied to control the change of the winder diameter. To keep the constant tension, the motor drive will calculate<br />

the winder diameter provided by the system and relevant parameters and and compensate the corresponding motor<br />

torque according to the change of the actual winder diameter.<br />

More information on <strong>Delta</strong>’s industrial automation products, visit our website at:<br />

http://www.delta.com.tw/industrialautomation<br />

品質至上 QUALITY<br />

信賴第一 RELIABLITY<br />

追求卓越 EXCELLENT