Application Case - Delta Electronics

Application Case - Delta Electronics

Application Case - Delta Electronics

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Application</strong> <strong>Case</strong><br />

- 1 -<br />

Industrial Automation BU, <strong>Delta</strong> <strong>Electronics</strong>, Inc.<br />

<strong>Case</strong> <strong>Application</strong> of <strong>Delta</strong>’s PLC in Liquid Filler with Measuring and Weighing Functions<br />

Issued by Solution Center Date August, 2010 Pages 2<br />

Applicable to<br />

DVP-SX2 series PLC, DVP02LC-SL load cell module, DOP-B series human machine interface, VFD<br />

series AC motor drive<br />

Key word Liquid filling, I/O, high efficiency<br />

The Trend<br />

Liquid fillers with weighing function have already been widely applied in the liquid filling industry. Most liquid<br />

filling equipment measures or weighs to decide the volume of the liquid and either way has its pros and cons. Some<br />

liquid fillers measure and weigh to obtain more flexible and accurate filling. The measuring type liquid filler is<br />

applicable in the packaging of less condensed, thiner and small-volume drink, e.g. bottled mineral water, tea, coffee,<br />

diluted juice, flavored milk, etc. while the weighing type liquid filler fits the packaging of more condensed, thicker and<br />

large-volume products, e.g. jam, honey, yoghurt, peanut butter, ice-cream, butter, chocolate paste and so on.<br />

The traditional artificial filling method is no longer suitable for the packaging of the products listed above since the<br />

filling of these products has to take the filling efficiency, control of volume and hygiene into consideration. Therefore,<br />

filling liquid food by automation equipment has become an inevitable trend.<br />

DVP-SX2 for Liquid Filler<br />

The entire liquid filling process requires a high-speed and highly efficient host controller to trigger and activate<br />

every step of action. <strong>Delta</strong>’s new DVP-SX2 series PLC is equipped with bountiful command, strong functions, built-in<br />

with max. 2 axes of 100kHz high-speed pulse output and many 100kHz high-speed counters. Its new left-side<br />

high-speed extension port is extendable to the new DVP series left-side analog modules, e.g. DVP04AD-SL,<br />

DVP04DA-SL and DVP02LC-SL. The new positioning and special motion control commands answer different motion<br />

control demands. DVP-SX2 series PLC is built-in with 4 channels of 12-bit analog input and 2 channels of analog<br />

output and is the best fit for machines or equipment requiring small number of control points.<br />

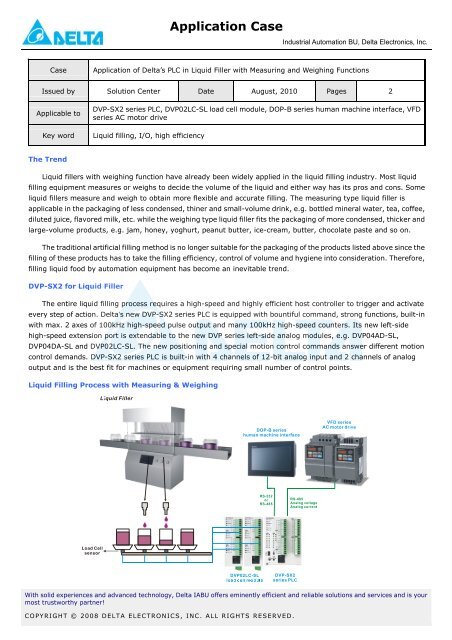

Liquid Filling Process with Measuring & Weighing<br />

With solid experiences and advanced technology, <strong>Delta</strong> IABU offers eminently efficient and reliable solutions and services and is your<br />

most trustworthy partner!<br />

COPYRIGHT © 2008 DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED.

Bottle In Positioning<br />

<strong>Application</strong> <strong>Case</strong><br />

- 2 -<br />

Measuring<br />

Industrial Automation BU, <strong>Delta</strong> <strong>Electronics</strong>, Inc.<br />

Filling Bottle Out<br />

Weighing<br />

The weighing process in the filling adopts <strong>Delta</strong>’s DVP02LC-SL load cell left-side extension module to weigh the<br />

filled bottle. The 12-bit analog output in DVP-SX2 PLC is responsible for the bottle in and out process and VFD series<br />

AC motor drive in charge of transporting empty bottles on the conveyer belt. The entire filling process can also be<br />

realized by pneumatic cylinder, pushing the empty bottle to a certain position for filling and to the next stop for the<br />

next process. The operation of the pneumatic cylinder relies on the I/O control from the PLC. DVP-SX2 series PLC is<br />

extendable to max. 494 points, which is capable enough of handling the I/O control on most of the liquid fillers.<br />

With solid experiences and advanced technology, <strong>Delta</strong> IABU offers eminently efficient and reliable solutions and services and is your<br />

most trustworthy partner!<br />

COPYRIGHT © 2008 DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED.