Download Newsletter 48 2011 - Towingline.com

Download Newsletter 48 2011 - Towingline.com

Download Newsletter 48 2011 - Towingline.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

12 TH VOLUME, NO. <strong>48</strong> DATED 04 DECEMBER <strong>2011</strong><br />

BUYING, SALES, NEW BUILDING, RENAMING AND OTHER TUGS TOWING & OFFSHORE INDUSTRY NEWS<br />

TUGS & TOWING NEWS<br />

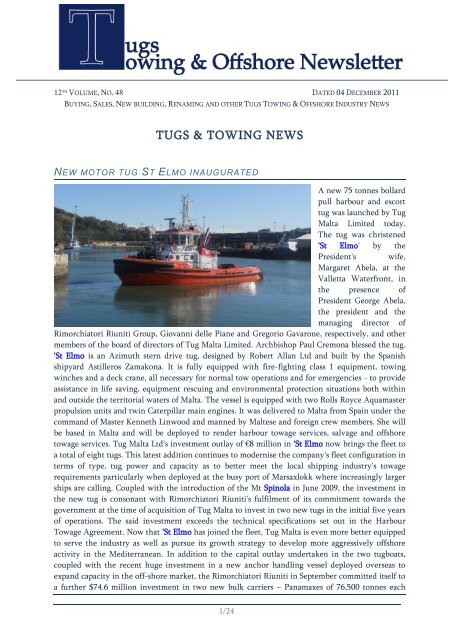

NEW MOTOR TUG ST ELMO INAUGURATED<br />

A new 75 tonnes bollard<br />

pull harbour and escort<br />

tug was launched by Tug<br />

Malta Limited today.<br />

The tug was christened<br />

'St Elmo' by the<br />

President's wife,<br />

Margaret Abela, at the<br />

Valletta Waterfront, in<br />

the presence of<br />

President George Abela,<br />

the president and the<br />

managing director of<br />

Rimorchiatori Riuniti Group, Giovanni delle Piane and Gregorio Gavarone, respectively, and other<br />

members of the board of directors of Tug Malta Limited. Archbishop Paul Cremona blessed the tug.<br />

'St Elmo is an Azimuth stern drive tug, designed by Robert Allan Ltd and built by the Spanish<br />

shipyard Astilleros Zamakona. It is fully equipped with fire-fighting class 1 equipment, towing<br />

winches and a deck crane, all necessary for normal tow operations and for emergencies - to provide<br />

assistance in life saving, equipment rescuing and environmental protection situations both within<br />

and outside the territorial waters of Malta. The vessel is equipped with two Rolls Royce Aquamaster<br />

propulsion units and twin Caterpillar main engines. It was delivered to Malta from Spain under the<br />

<strong>com</strong>mand of Master Kenneth Linwood and manned by Maltese and foreign crew members. She will<br />

be based in Malta and will be deployed to render harbour towage services, salvage and offshore<br />

towage services. Tug Malta Ltd's investment outlay of €8 million in 'St Elmo now brings the fleet to<br />

a total of eight tugs. This latest addition continues to modernise the <strong>com</strong>pany's fleet configuration in<br />

terms of type, tug power and capacity as to better meet the local shipping industry's towage<br />

requirements particularly when deployed at the busy port of Marsaxlokk where increasingly larger<br />

ships are calling. Coupled with the introduction of the Mt Spinola in June 2009, the investment in<br />

the new tug is consonant with Rimorchiatori Riuniti's fulfilment of its <strong>com</strong>mitment towards the<br />

government at the time of acquisition of Tug Malta to invest in two new tugs in the initial five years<br />

of operations. The said investment exceeds the technical specifications set out in the Harbour<br />

Towage Agreement. Now that 'St Elmo has joined the fleet, Tug Malta is even more better equipped<br />

to serve the industry as well as pursue its growth strategy to develop more aggressively offshore<br />

activity in the Mediterranean. In addition to the capital outlay undertaken in the two tugboats,<br />

coupled with the recent huge investment in a new anchor handling vessel deployed overseas to<br />

expand capacity in the off-shore market, the Rimorchiatori Riuniti in September <strong>com</strong>mitted itself to<br />

a further $74.6 million investment in two new bulk carriers – Panamaxes of 76,500 tonnes each<br />

1/24

12 TH VOLUME, NO. <strong>48</strong> DATED 04 DECEMBER 2010<br />

currently being built in South Korea by SPP Plant & Shipbuilding Co Ltd. The investment is to be<br />

undertaken by Bulk Malta Ltd, a newly formed Maltese subsidiary <strong>com</strong>pany of the group. The first<br />

of these vessels is expected to be delivered in 2013 and the second will be due in early 2014. Both<br />

Panamaxes will be deployed to carry any type of dry cargo anywhere in the world. Bulk Malta Ltd<br />

will ultimately own and operate the said bulk carriers. (Source & Photo: Times of Malta)<br />

Advertisement<br />

HISTORICAL MEETING ON HIGH SEAS<br />

This watercolor made by Hans Breeman shows an historical meeting on highseas of two impressive<br />

ships, known in Dutch Maritime History. The largest "Zwarte Zee", the last one carrying this famous<br />

name as part of the fleet of Smit Internationale, meets the ss Rotterdam, largest historical Dutch<br />

passenger ship of the Dutch merchant navy in those days. www.hansbreeman.nl As of from<br />

2/24

12 TH VOLUME, NO. <strong>48</strong> DATED 04 DECEMBER 2010<br />

December 17th next, there will be a maritime painting exhibition available to see in Gallerie R, van<br />

van Beethovenlaan 60, 3055JD Rdam, showing about 55 paintings from Frans Romeijnsen and Hans<br />

Breeman. Opening will be on december 17 th at 15.30 hrs, admission is free. (Source: Hans<br />

Breeman)<br />

SVITZER'S SINGAPORE<br />

We are making good progress with<br />

our tow the Smit Borneo, and our<br />

ETA is unchanged. The picture was<br />

after passing Torres Strait, which took<br />

us 12 hours to get through this narrow<br />

passage under pilotage, sailing through<br />

the Coral Sea, is in the Pacific. It is a<br />

little bit bumpy but then you realize<br />

you are on a ship. The ETA for the<br />

Rena is tomorrow 5 th December <strong>2011</strong>.<br />

(Greetings Marc Biemans o/b<br />

Singapore)<br />

Advertisement<br />

SMIT AMANDLA MARINE STRENGTHENS ITS FOOTHOLD IN MOZAMBIQUE<br />

– CONSOLIDATES POSITION WITH PETROSA<br />

Specialist marine services <strong>com</strong>pany SMIT Amandla Marine has strengthened its presence and<br />

foothold in Mozambique with several useful contracts as it seeks to position itself in that southern<br />

African country. The black empowered <strong>com</strong>pany based in Cape Town and with offices and<br />

workshops in Durban and Mossel Bay, has landed several new and interesting contracts in<br />

Mozambique. These include securing a key harbour towage contract in the port of Beira, as well as a<br />

more recent success with a contract signed with Brazilian mining group Vale to provide two vessels<br />

at Beira in support of a new offshore coal terminal out of Beira. To service this contract two tugs are<br />

being provided, a newbuild Damen Stan tug and the Pentow Service, the latter being the former<br />

Durban offshore single buoy mooring service tug. Managing Director Paul Maclons said that in the<br />

last 24 months SMIT Amandla Marine has secured a good foothold in Mozambique with the Port of<br />

Beira contract and the more recent marine services contract signed with Vale. “This is for two<br />

vessels, marine services and the provision of an offshore terminal out of Beira,” he explained.<br />

3/24

12 TH VOLUME, NO. <strong>48</strong> DATED 04 DECEMBER 2010<br />

Maclons said that SMIT<br />

Amandla Marine was awaiting<br />

the “imminent out<strong>com</strong>e of a<br />

tender submitted to Kenmare for<br />

vessel management services out<br />

of Moma in Mozambique.” The<br />

<strong>com</strong>pany also assisted Kenmare<br />

with the drydocking of the<br />

general cargo vessel Sofia III<br />

(2136-gt, built 1978) in Durban.<br />

He added that SMIT Amandla<br />

Marine has been actively<br />

pursuing growth opportunities<br />

in Namibia, Madagascar and<br />

Mauritius, “supported by a<br />

proven logistics chain and ability<br />

to transfer skills and <strong>com</strong>petencies in our chosen markets,’ he said. Maclons explained that the<br />

<strong>com</strong>pany had tabled a growth strategy at the end of 2009 which outlined its intent to pursue<br />

business opportunities in Southern and East Africa and the Indian Ocean Islands, whilst maintaining<br />

key contracts in South Africa. The strategy was intended to address the risk of possible loss of South<br />

African Government contracts – identified as a concern as early as 2008 – and ensure sustainability.<br />

In respect of SMIT Amandla Marine’s continued presence in South Africa, the <strong>com</strong>pany successfully<br />

tendered for two significant PetroSA contracts. These are for the provision of a South Africanmanned<br />

DP II vessel for PetroSA’s F-O Field Development Operations in 2012 offshore of Mossel<br />

Bay, and for the management of PetroSA’s Marine Loading Facility and E-BT terminal at Mossel<br />

Bay. The DP-II vessel will be the offshore tug and supply ship Peridot (2,464-gt, built 2010), with a<br />

contract <strong>com</strong>mencing in 2012. She will be manned by a fully South African crew. In addition in<br />

November the Level 3 BBBEE <strong>com</strong>pany introduced a new vessel into its terminal operation in<br />

Durban for its client Sapref. The SMIT Amandla pusher tug Siyakhulu (469-gt, built 2009), joined<br />

the Smit Siyunda in early November in support of operations at the SBM offshore of Durban. SMIT<br />

Amandla Marine was more recently in the news in September after successfully refloating the<br />

grounded tanker Phoenix off Sheffield Beach near Durban on behalf of the South African Maritime<br />

Safety Authority and the National Department of Transport – for whom it is an official service<br />

provider. Vessel chartering and offshore support activities were buoyed this year by significant<br />

contracts with WesternGeco, Namibian Marine Phosphate and provision of services to Total’s FPSO<br />

USAN. The <strong>com</strong>pany holds the <strong>2011</strong> National Business Award for ‘Diversity in the Work Place’ –<br />

backed up by its position as the leading employer of black South African seafarers with a diverse and<br />

representative workforce. Permanent employees are shareholders in the business through an<br />

Employee Trust which owns 12% of the <strong>com</strong>pany and realised dividends in April <strong>2011</strong> with a<br />

payout to all beneficiaries. “Despite a global economic recession, we have been able to maintain a<br />

steady investment in our people and the <strong>com</strong>munities in which we operate and have successfully<br />

established a talent pipeline to ensure sustainability in <strong>com</strong>petence and skill,” said Maclons. “The<br />

pursuit of safe operations and continued service excellence remain key drivers, as is the continued<br />

development of a sustainable pool of SMME and black owned suppliers. We are well positioned for<br />

the future and for whatever challenges may <strong>com</strong>e our way into 2012 and have achieved success in<br />

addressing business risk,” he said. (Source: Ports & Ships Maritime News; Photo: Terry Hutson)<br />

4/24

12 TH VOLUME, NO. <strong>48</strong> DATED 04 DECEMBER 2010<br />

DOCKMAN THAMES TOWAGE<br />

One week ago the 19<strong>48</strong> built at the<br />

Henry Scarr Ltd. – Hessle under<br />

number 618 tug Dockman departed<br />

from Stellendam; Netherlands with<br />

a small barge. The Dockman was<br />

built as Stamford Brook for River<br />

Lighterage Co. Ltd. – London. In<br />

1963 sold to United Towing Co Ltd<br />

– Hull and renamed Dockman. In<br />

1973 sold to Cory Lighterage Ltd –<br />

London. In 198? Sold to Bailey &<br />

Boynton – Hull. In 198? sold to<br />

Humber Tugs. In 1989 sold to Tyne<br />

Towage – Gateshead and rebuilt, reengined<br />

diesel 2t British Polar type<br />

M471, 520bhp-388kW. In 1992 sold to Survey & Supply (I.B. Harvey) – Grimsby. In 1993 rebuilt,<br />

re-engined GM Detroit, 650bhp, renamed Alkelda. In 1998 sold to Tyne Towage – Hebburn and<br />

renamed Dockman. In 200? rebuilt wheelhouse, pushknee, re-engined diesel Dorman type 312. In<br />

2009 to Thames Towage – London. (Photo: Jacco van Nieuwenhuyzen; History: Piet van Dammen)<br />

RT SAMBA & RT TANGO SOLD<br />

Advertisement<br />

At the ASL shipyard in Singapore yesterday the<br />

85 ton BP Rotortug ® RT Tango was lifted out of<br />

the water in preparation for the departure to<br />

Western Europe, the tug is sold to an<br />

"undisclosed buyer" and will be renamed Smit<br />

Emu for use in the port of Zeebrugge. The<br />

Rotortug ® RT Samba , sistership of the RT<br />

Tango, seen 26 th November "dry" at the ASL yard<br />

in Singapore for cleaning and inspection prior<br />

departure for Western Europe, to be used in the<br />

port of Zeebrugge. Achieving a bollard pull in<br />

excess of 86 tons ahead and astern in a hull with an overall length of only 28 meter length and a<br />

5/24

12 TH VOLUME, NO. <strong>48</strong> DATED 04 DECEMBER 2010<br />

beam of 12 meter, <strong>com</strong>bined with the unique capabilities of a Rotortugs such as towing in all<br />

directions, the tugs are considered being amongst the worlds most powerful harbor tugs. The tugs<br />

are equipped with three ABC 8DZC engines of over 1800kW each driving 3 Schottel SRP1215<br />

controlable pitch azimuth thrusters. The classification is Bureau Veritas and the notation further<br />

mentions Ice Class and Fire Fighting 1. Delivery is planned the first or second week of December,<br />

the tug RT Samba will be renamed in Smit Kiwi prior departure. (Source & Photo: Piet Sinke -<br />

www.maasmondmaritime.<strong>com</strong>)<br />

BEAMER SOLD<br />

The 1983 Built at the McTay Marine Ltd – Bromborough under number <strong>48</strong>, Leith tug Beamer (Imo<br />

8208830), which has been laid up since 11 th October <strong>2011</strong>, with the redundancy of 5 crew members,<br />

has been sold. Rumoured that she remain in the U.K. East Coast. Name of the buyer, as yet,<br />

unknown. The tug was delivered 1983 to City Leasing Ltd. with managers Forth Estuary Towage<br />

Ltd. a subsidiary of Forth ports Authority – Leith. In 1992 the <strong>com</strong>pany restyled Forth Ports PLC –<br />

Edinburgh. She has a 4 stroke 6 cylinder Allen type 6BPCS12-F main diesel engine with an output<br />

of 1,824 bhp. She has a speed of 11.7 knots and a bollard pull of 20 tons. (Source: Ian Duff)<br />

OSD TO DESIGN LOW-EMISSION TUG FOR ISKES<br />

Offshore Ship Designers has been<br />

contracted to develop the design of<br />

a low-emission diesel-electric<br />

harbour tug for IJmuiden-based<br />

Iskes Towage & Salvage. The 32metre<br />

loa tug will have a bollard<br />

pull of 70 tonnes and will be<br />

powered by three diesel gensets<br />

driving electric motors mounted<br />

over azimuthing propellers aft and<br />

a Voith in-line thruster forward.<br />

The Azistern 3270 tug is a further<br />

development of the low-emission<br />

Azistern series developed by OSD.<br />

It is expected to reduce emissions by 30 per cent <strong>com</strong>pared to conventional, similar-sized harbour<br />

tugs now in service. Michiel Wijsmuller, managing director of OSD, says, “The design and demand<br />

for this low-emission tug stems from our successful work developing the zero-emission Green Tug<br />

design. Iskes was one of the key partners in that project. We can see the market is not yet ready for<br />

fuel cell power for harbor tugs, but we can take from the development work other aspects of the<br />

design which minimise emissions. This vessel will have a very refined and efficient hull form and a<br />

sophisticated power management system which will ensure that the gensets work always at their<br />

best efficiency.” Key points of the design brief are a relatively large deck crane to enable the tug to<br />

do maintenance work for wind farms at sea, electrical winches, low resistance and low-wash hull<br />

form and ac<strong>com</strong>modation for seven crew. (Press Release Merlinco; Image: OSD)<br />

KVICHAK LANDS SEATTLE PUSH-BOAT ORDER<br />

Seattle City Light has awarded a contract to Kvichak Marine Industries to design and build a push-<br />

6/24

12 TH VOLUME, NO. <strong>48</strong> DATED 04 DECEMBER 2010<br />

boat to operate at the Ross Lake dam in the<br />

North Cascades. The push-boat will be used for<br />

large debris removal to ensure continuous power<br />

generation through the dam. The vessel will<br />

feature a removable pilothouse to ease delivery<br />

on the route to Ross Lake. Kvichak delivered a<br />

similar vessel to Seattle City Light in April,<br />

which services Diablo Lake. The boat will<br />

measure 7.85 metres in length, with a beam of<br />

3.66 metres and a draft of 1.04 metres. Weighing<br />

7.8 tonnes, the hull and superstructure will be<br />

constructed of marine grade aluminum alloy<br />

plate and extrusions. Two vertical push knees<br />

will be located at the bow, padded by a 15-centimetre rubber D-section. The push boat will be<br />

powered by a John Deere 224kW turbocharged diesel engine with a stainless steel prop in a 37<br />

nozzle, delivering a bollard pull of 2,331 kilograms. The vessel is designed for a crew of three, with<br />

fuel capacity of 908 litres. Delivery is scheduled for September 2012. (Source: Baird)<br />

TUGBOAT MODEL AHTI<br />

The very fine tugboat model AHTI<br />

has been sold to Sweden. The 1:20<br />

scale scratched model tugboat<br />

AHTI is seen just before sending to<br />

her new Swedish owner. The<br />

model is built from scratch with<br />

the help from Neste Oil / Finland.<br />

She is 1.7m long and 0.65m wide.<br />

She is sold as a display model, but<br />

she was planned as a working RCmodel.<br />

(Source & Photo of the<br />

builder Stefan Thienel)<br />

Advertisement<br />

7/24

12 TH VOLUME, NO. <strong>48</strong> DATED 04 DECEMBER 2010<br />

CARIBEAN TUG<br />

8/24<br />

Remember the last photo of this laid up<br />

Dominican Republic tug Caribean tug<br />

(KAS). She was abandoned with a hole<br />

in the engine room and left by her<br />

owner, never paid I think. She is now<br />

starting a new life as tugboat for the<br />

local ship yard, Ciramar. (Photo: Rinus<br />

Koppenhol)<br />

TAIKOO - LATEST DELIVERY OF POPULAR RAMPARTS 3000 CLASS TUG<br />

FOR HONG KONG UNITED DOCKYARDS<br />

In October, <strong>2011</strong> Cheoy Lee Shipyards handed over the first in a series of four RAmparts 3000 tugs<br />

designed by Robert Allan Ltd. to its proud owners; Hong Kong United Dockyards (HUD). The<br />

Taikoo is the latest edition of this widely accepted RAmparts class design from Robert Allan Ltd.,<br />

and derives its name from a historic dockyard in Hong Kong operated by Butterfield and Swire<br />

beginning in 1907. The yard was responsible for building some of the largest ships in the world<br />

during the early 1900's. It was closed in the '70's to be developed into private housing. The<br />

operation eventually merged with Whampoa Dockyard to be<strong>com</strong>e Hong Kong United Dockyards.<br />

The RAmparts 3000 Class Terminal Support Tug is a 30 metre Azimuth Stern Drive (ASD) tug,<br />

specifically designed for ship assist and coastal towing operations. This vessel is designed to meet the<br />

requirements of HUD for operations in and around Hong Kong. This particular version has an<br />

extended deckhouse with additional ac<strong>com</strong>modation for the crew and cadets that will be aboard the<br />

vessel. Particulars of Taikoo are as follows: Length Overall - 30.00 metres; Beam, moulded, extreme<br />

- 11.60 metres; Depth, Moulded (hull) - 5.10 metres; Maximum draft (DWL) - 5.08 metres; Loadline

12 TH VOLUME, NO. <strong>48</strong> DATED 04 DECEMBER 2010<br />

draft - 4.2 m above base line. The tug is classed by Lloyd's register of Shipping - 100A1 Tug; LMC,<br />

TUG, Unrestricted Service. Tank Capacities are as follows: Fuel Oil - 164 m³; Fresh Water - 29 m³;<br />

On trials, Taikoo met or exceeded all performance expectations, with the following results: Bollard<br />

Pull, ahead - 74 tonnes; Bollard Pull, astern - 67 tonnes; Free running speed, ahead - 13.0 knots. The<br />

vessel has been outfitted to the highest standards for a crew of up to twelve (12) people, although<br />

the normal operating crew is five (5). The deck machinery <strong>com</strong>prises a Plimsoll HAETW/GDG-22-<br />

65/150 Hawser Winch at the bow, a Plimsoll HTW/SD-20/150 Towing Winch on the aft deck, and a<br />

Palfinger PK32002M knuckle-boom crane. The large main deckhouse contains a spacious galley and<br />

mess, three (3) double-cabins, a provisions store room, and a <strong>com</strong>mon washroom. The lower deck<br />

contains one (1) double cabin, one (1) quadruple cabin, a stores locker, laundry, and a <strong>com</strong>mon<br />

washroom. The wheelhouse is designed for maximum all-round visibility with forward and aft<br />

control stations providing maximum visibility to both fore and aft deck working areas. Main<br />

propulsion for each tug <strong>com</strong>prises a pair of Niigata 6L28HX diesel engines, each rated 1,838 kW at<br />

750 rpm, and each driving a Niigata Model ZP 41 Fixed pitch Z-drive unit, in ASD configuration.<br />

The electrical plant <strong>com</strong>prises two (2) identical diesel gen-sets, each with power output of 80 kW<br />

380V, 50Hz, 3-phase. Ship-handling fenders at the bow <strong>com</strong>prises two rows of 800 x 450 cylindrical<br />

fenders. A 350 x 350 hollow "D" fender provides protection at the main and foc'sle deck sheer lines,<br />

and 300 mm "W" block type fendering is used at the stern. (Source & Photo: Robert Allan Ltd)<br />

LAUNCHING A.H.T.S. MAASSTROOM<br />

On Tuesday 15th November<br />

<strong>2011</strong>, our tug / workboat<br />

“Maasstroom” is transported<br />

from the manufacturing hall<br />

Hardinxveld-Giessendam to the<br />

riverside, by using a heavy<br />

transport vehicle. Owned by<br />

Mammoet Heavy Lifting &<br />

Transport <strong>com</strong>pany from<br />

Schiedam. By using of two local<br />

floating sheerlegs the hull was<br />

lifted from the trailer and put<br />

into the water of the river<br />

Merwede. On Thursday 17th<br />

November, after performing some necessary work, the “Maasstroom” was transported to Aalst, by<br />

using the push / tug “Vliestroom”. Over there will take place the further outfitting. The AHTS type<br />

Euro Tug 2300 is built under yard number NP401 at the Neptune Shipyard B.V. – Aalst;<br />

Netherlands. The delivery of the vessel is scheduled for the end of March 2012. (Source: Van<br />

Wijngaarden Marine Services)<br />

ACCIDENTS – SALVAGE NEWS<br />

FAIRMOUNT ALPINE ASSISTS DRIFTING VESSEL OFF CUBA<br />

Fairmount Marine’s powerful tug Fairmount Alpine played an important role by avoiding a<br />

9/24

12 TH VOLUME, NO. <strong>48</strong> DATED 04 DECEMBER 2010<br />

shipping disaster on the coast of Cuba. The crew of the Fairmount Alpine managed to connect with<br />

the drifting cargo vessel off Cuba and managed to tow the distressed vessel into safe waters. The<br />

cargo vessel was reported drifting off Cuba with main engine trouble. Fairmount Alpine was asked<br />

to proceed full speed towards Cuba, to render assistance to the vessel that was drifting dangerously<br />

towards the northeastern Cuban coast. It was estimated that the vessel would hit the rocks of Punta<br />

Brava before the Fairmount Alpine was due to arrive. With a speed of close to 16 knots Fairmount<br />

Alpine arrived at the rendezvous position very fast and radio contact was established between the<br />

masters of Fairmount Alpine and of the drifting vessel. At that moment the vessel was very close to<br />

the Cuban coast already. The vessels crew finally managed to start the main engine with its broken<br />

crankshaft and on three of its six cylinders. Consequently the vessel was able to stay away from the<br />

coast. Shortly afterwards the Fairmount Alpine was in position to establish an emergency towing<br />

connection in order to keep the distressed vessel under control and to tow her towards Kingston,<br />

Jamaica. After a little over two and a half days of slow steaming Kingston was reached. With the<br />

assistance of two pilots and a Kingston harbor tug, the vessel was safely anchored at the Port Royal<br />

anchorage off Kingston. After the safe delivery on the inner anchorage, Fairmount Alpine was<br />

released from her duties. Fairmount Marine is a marine contractor for ocean towage and heavy lift<br />

transportation, headquartered in Rotterdam, the Netherlands. Fairmount’s fleet of tugs consists of<br />

five modern super tugs of 205 tons bollard pull each, especially designed for long distance towing.<br />

(Press Release Fairmount)<br />

Advertisement<br />

TIRED TUG BOAT CREWMAN AIDED BY HARWICH LIFEBOAT<br />

10/24<br />

A tired tug boat crewman who had been at<br />

the wheel for 14 hours was assisted by the<br />

Harwich lifeboat last Friday. Thames<br />

Coastguard received a call at 3.36am from<br />

the Dockman reporting that all of the four<br />

crew were fatigued and seasick because of<br />

adverse conditions. To add to their woes<br />

the engine on the tug, which was pulling a<br />

50m tow 15 miles out at sea, had failed and<br />

the boat was drifting towards a Felixstowe<br />

windfarm. Only one of the crew was left<br />

able to work, and had been navigating the<br />

boat for 14 hours. The Harwich lifeboat

12 TH VOLUME, NO. <strong>48</strong> DATED 04 DECEMBER 2010<br />

team stood-by while the tug got its engine restarted, and then escorted it to safe waters. The tug was<br />

then able to carry on its journey later in the morning. (Source : Clacton Gazette; Photo: Jacco van<br />

Nieuwenhuyzen; see report of departure above also)<br />

DURBAN PILOT BOAT MISSES PORT ENTRANCE, GOES AGROUND<br />

At around midnight on Sunday night the<br />

Durban port pilot boat Lufafa, returning<br />

to port after placing a marine pilot on<br />

board a ship waiting to enter harbour,<br />

somehow missed the now widened<br />

entrance channel and ran aground after<br />

colliding with an old disused concrete<br />

pier on the seaward side of the South<br />

Pier breakwater. The five crew on board<br />

were not injured and all were airlifted to<br />

safety by the Transnet National Ports<br />

Authority (TNPA) pilot helicopter.<br />

According to the TNPA the Lufafa has<br />

suffered only minor damage and was<br />

later refloated and taken safely back into harbor In a statement the TNPA said the Lufafa ran<br />

aground due to “challenging weather conditions, which included extreme swell and poor visibility.”<br />

Durban did experience a heavy electrical storm with lots of rain on Sunday night. On Monday a<br />

team of experts was assembled to refloat the vessel, using the late afternoon high tide to successfully<br />

ac<strong>com</strong>plish the task. On Tuesday marine personnel under the leadership of Captain Mogamat<br />

Plaatjes, deputy harbour master and acting in the absence of Capt. Dennis Mqadi who is overseas,<br />

was locked in meetings for most of the day enquiring into the casualty. The port of Durban uses a<br />

dual pilotage system <strong>com</strong>prising pilot boats (two) and helicopters (two) and as a result port<br />

operations have not been affected. (Source & Photo: Ports and Ships)<br />

MALTA NEWS<br />

By Capt. Lawrence Dalli<br />

SPARROW HAWK FORMER KEEN EXPRESS<br />

11/24<br />

Last week was seen the 1976 built SLE flag<br />

offshore tug/supply ship Sparrow Hawk<br />

offshore Malta during her delivery voyage on<br />

Monday 28th November, <strong>2011</strong>. She’s the<br />

former Keen Express of Vroon Offshore<br />

Services(VOS). (Source & Photo: Cpt.<br />

Lawrence Dalli - www.maltashipphotos.<strong>com</strong>)

12 TH VOLUME, NO. <strong>48</strong> DATED 04 DECEMBER 2010<br />

OFFSHORE NEWS<br />

MICLYN EXPRESS OFFSHORE WINS FIVE YEAR CONTRACTS FOR TWO<br />

OSVS IN SAUDI ARABIA<br />

Miclyn Express Offshore (“MIO”)<br />

announces that two Offshore<br />

Support Vessels (“OSVs”), the<br />

Miclyn Grace and Miclyn Grand,<br />

have been awarded five year<br />

contracts to act as Multipurpose<br />

Vessels for Saudi Aramco in Saudi<br />

Arabia. The vessels are currently<br />

serving out their existing charter<br />

contracts in Thailand and Qatar<br />

respectively and will <strong>com</strong>mence<br />

the new charters in early 2012 on<br />

stronger day rates. The aggregate<br />

value of the two contracts is<br />

US$33 million. CEO Diederik de<br />

Boer said “Miclyn has been providing Crew/Utility Vessel services to Saudi Aramco for some time<br />

and we are delighted to extend this important relationship into OSV services. This long term<br />

contract supports our overall fleet strategy of maximising utilisation”. (Source: Miclyn Int. Offshore)<br />

ROLLS-ROYCE TO DESIGN PSVS<br />

Advertisement<br />

Rolls-Royce received an order from Singapore-based offshore <strong>com</strong>pany, PaxOcean, to design and<br />

equip two oil platform supply vessels. The vessels are to be built at PaxOcean Engineering's ship<br />

yard in Zhuhai, China. The £10 million contract includes vessel design, a fully integrated Rolls-<br />

Royce diesel electric propulsion system and deck machinery. Ronny Pål Kvalsvik, Rolls-Royce,<br />

Sales Manager, Ship Technology - Offshore, said: "We are delighted to continue our strong<br />

relationship with PaxOcean Engineering and to add to their fleet of Rolls-Royce designed ships.<br />

These vessels <strong>com</strong>bine a proven Rolls-Royce design with a range of mission-critical onboard<br />

technology, enabling safe and efficient operation in the challenging environments of offshore oil<br />

and gas fields." YK Tang, Director Group Marketing, PaxOcean Engineering added: "We are very<br />

12/24

12 TH VOLUME, NO. <strong>48</strong> DATED 04 DECEMBER 2010<br />

pleased to announce provision of these UT<br />

755CD vessels as part of our continued effort to<br />

provide our customers with the latest<br />

technology in offshore support vessels, forthe<br />

demanding worldwide deepwater oil and gas<br />

market." The two platform supply vessels will<br />

have an overall length of 78.7m, a 16m beam<br />

and a deck cargo area of 670sq. m. They will be<br />

built in accordance with clean design<br />

regulations and be equipped for firefighting<br />

and oil recovery. Planned delivery of the<br />

vessels is in the first half of 2013. The Rolls-Royce UT 755 CD design is a development of the<br />

popular UT 755 series vessel, designed specifically for supplying equipment to oil and gas platforms.<br />

Since the first UT 755 was delivered in 1996, more than 180 vessels of this design have gone into<br />

service or are on order worldwide. (Source; MarineLink; Image: Rolls Royce)<br />

STX CONFIRMS TWO PLATFORM SUPPLY VESSELS CONTRACTS FROM<br />

ISLAND OFFSHORE<br />

STX OSV, one of the major global designers and<br />

shipbuilders of offshore and specialized vessels,<br />

reported that contracts for two Platform Supply<br />

Vessels (PSV) with Island Offshore have been<br />

confirmed. The contracts had originally been<br />

announced on 30 October <strong>2011</strong>, subject to<br />

financing approvals. All subjects have now been<br />

lifted and the contracts have been made<br />

effective. In an e-mailed statement to Offshore<br />

Energy Today, Island Offshore confirmed the<br />

deal and said “this newbuilding order is a part<br />

of Island Offshore’s strategic growth in this<br />

segment.” The estimated contract value is $85 million (NOK 500 million). The vessels will be of<br />

Rolls Royce’s UT 717 CD design. The overall length of each vessel will be 84.3 meters with a beam<br />

of 17 meters, and the deadweight will be approximately 3800 DWT. Deliveries are scheduled from<br />

STX OSV Brevik in Norway in the third and fourth quarter 2013. (Source & Photo: STX OSV)<br />

SWIRE PACIFIC OFFSHORE RECEIVES ORDER FOR 4 PSV’S<br />

Swire Pacific Offshore Operations (Pte) Limited<br />

has receives an order for 4 Platform Supply<br />

Vessels. The vessels will be built by Universal<br />

Shipbuilding Corporation in Japan. The 5,000<br />

DWT vessels will be classed with DP2 capability<br />

and have diesel electric propulsion systems. The<br />

vessels will be delivered progressively from early<br />

2014. This order follows on from an order earlier<br />

in the year for 4 sister vessels from the EISA<br />

shipyard in Brazil. Neil Glenn, Managing Director<br />

13/24

12 TH VOLUME, NO. <strong>48</strong> DATED 04 DECEMBER 2010<br />

of Swire Pacific Offshore, said, “We are excited to announce the orders for our H Class series of<br />

large PSVs. We see large PSVs as an important market segment moving forward which will meet<br />

with the requirements of our key customers.” (Source: Offshore Energy Today)<br />

NAMING CEREMONY FOR ULSTEIN DESIGN PSV<br />

The first platform supply vessel (PSV) of the<br />

PX106 design from ULSTEIN® ever built,<br />

was named in a formal ceremony in Rio de<br />

Janeiro, Brazil on 24 November. The vessel,<br />

CBO Atlântico, is the first in a series of six<br />

PSVs with X-BOW® hull line design from<br />

ULSTEIN, to be constructed at Estaleiro<br />

Alianca shipyard for Brazilian shipowner<br />

CBO (Companhia Brasileira de Offshore).<br />

CBO, which already has two PSVs of P106<br />

design from ULSTEIN in its fleet, is the first<br />

shipowner who has ordered X-BOW vessels<br />

in Brazil. “CBO’s requirements for standard<br />

of documentation has put ULSTEIN’s engineering team to the test in this project, but we have<br />

worked extremely well with both Estaleiro Alianca and CBO, and the end result is very<br />

satisfactory.” says Project Manager Brazil in ULSTEIN, Mr. Ingar Kaldhol, and adds that the good<br />

cooperation has brought ULSTEIN new knowledge and increased <strong>com</strong>petence that will be put to<br />

good use in future projects. CBO ordered two PX106 and two PX105 designs from ULSTEIN at the<br />

end of 2009, and an additional two PX105 designs in April <strong>2011</strong>. The contracts include delivery of<br />

design, engineering, main equipment and building follow-up. The second PX106 is to be delivered<br />

at the beginning of 2012 and four PSVs of PX105 design will be delivered during 2012 – 2013. CBO<br />

Atlântico will enter into an 8-year contract with Brazilian state oil <strong>com</strong>pany Petrobras in<br />

December. (Source: Ulstein)<br />

Advertisement<br />

SEISMIC ACQUISITION COMMENCED OFFSHORE MALTA<br />

Mediterranean O&G announced that the Company, through its wholly owned subsidiary Malta Oil<br />

Pty Ltd, has now entered into a contract with Fugro-Geoteam Pty Ltd ("Fugro-Geoteam"), who will<br />

undertake the acquisition of 1,000 square kilometers of long offset 3D seismic exploration data on<br />

behalf of the Company, in relation to its license <strong>com</strong>mitment at Area 4 Offshore Malta. Fugro-<br />

14/24

12 TH VOLUME, NO. <strong>48</strong> DATED 04 DECEMBER 2010<br />

Geoteam's vessel, R/V Geo Barents,<br />

has <strong>com</strong>menced mobilization and the<br />

Company expects 3D seismic<br />

acquisition to <strong>com</strong>mence on or about<br />

Wednesday, November 16, <strong>2011</strong>.<br />

The estimated duration of the survey<br />

is about 30 days. Processing of 3D<br />

data will start immediately after the<br />

<strong>com</strong>pletion of the survey, with the<br />

objective of obtaining the results<br />

towards the end of 1Q 2012. Sergio<br />

Morandi, Chief Executive Officer of<br />

Mediterranean Oil and Gas,<br />

<strong>com</strong>mented, "We are extremely<br />

pleased to have entered the 3D seismic acquisition contract with Fugro- Geoteam, a world class<br />

operator. This new 3D seismic data should allow the <strong>com</strong>pany to <strong>com</strong>plete the assessment of the<br />

exploration potential of Area 4 Offshore Malta. We are hopeful that the seismic survey will identify<br />

further prospects in the area and make the drilling of an exploration more attractive." (Source &<br />

Photo: Cpt. Lawrence Dalli - www.maltashipphotos.<strong>com</strong>)<br />

ISLAND CRUSADER IN TOW<br />

On the 1 st December, on a foggy<br />

morning, the 1971 built Panama<br />

flag with call sign HO4409 tug<br />

Pantodynamos (Imo 7038642)<br />

departed from Braila; Romania<br />

with in tow the new building<br />

hull type UT776 CDG Island<br />

Crusader. The picture is taken<br />

when passing Galati on the<br />

Danube River underway to<br />

Sulina at the Black Sea. (Photo:<br />

Huib Lievense)<br />

EMAS MARINE SECURES CHARTERS FOR FOUR AHTS VESSELS<br />

15/24<br />

Ezra Holdings Limited, a global offshore<br />

contractor and provider of integrated<br />

offshore solutions to the oil and gas<br />

industry, announced its offshore support<br />

services division (EMAS Marine) has been<br />

awarded a new charter and charter renewals<br />

for four Offshore Support Vessels (OSV).<br />

These awards worth approximately US$231<br />

million in total were from national oil<br />

<strong>com</strong>panies and an oil major. The charters<br />

are for an average period of 4.25 years

12 TH VOLUME, NO. <strong>48</strong> DATED 04 DECEMBER 2010<br />

(including option periods) for four Anchor, Handling, Tug and Supply (AHTS) vessels that will be<br />

deployed in South America and various regions in the Asia Pacific. Captain Adarash Kumar, CEO,<br />

EMAS Marine, stated, “As an offshore operator <strong>com</strong>mitted to support the world’s deepwater<br />

developments, these contracts are significant as it reaffirms our ability to deliver highly responsive<br />

and reliable services to our oilfield clients globally.” Mr Lionel Lee, EMAS’s Managing Director,<br />

said, “This is an important milestone for us as we further solidify our capabilities in Asia-Pacific and<br />

break new ground in South America, reaffirming our growing presence as a global leader in marine<br />

and offshore support.” “Brazil in particular will be investing heavily in offshore oil and gas<br />

infrastructure and services over the next few years in order to achieve its goal of being one of the<br />

world’s top oil producers. This creates significant opportunities for us for both offshore support and<br />

construction services.” Mr Lee added. The Group recently announced in October <strong>2011</strong> that its<br />

subsea orderbook reached US$745 million and that the Group’s orderbook exceeded US$1.2 billion<br />

for the first time. (Source: EMAS Marine)<br />

DELIVERY OF 2 UNITS ANCHOR HANDLING TUG SUPPLY VESSELS IN<br />

GSHI<br />

October 12, <strong>2011</strong>, Tidewater<br />

Marine, L.L.C., the world leader in<br />

offshore support services, took<br />

successfully delivery of Boutros<br />

Tide, the second in a series of four<br />

newbuild AHTS vessels from<br />

Guangxin Shipbuilding & Heavy<br />

Industry Co., Ltd. in South China.<br />

Five days later, October 17th,<br />

Chayaride Tide, the third AHTS<br />

was delivered in GSHI. The vessels<br />

are flagged of Vanuatu. The last<br />

vessel in the series, Mossalem Tide,<br />

is expected to be delivered in December, <strong>2011</strong>. Guangxin Shipbuilding & Heavy Industry Co., Ltd.<br />

(GSHI) has signed contract with Tidewater for construction of 4 vessels at the time when this new<br />

shipyard set up. It is a Chinese-foreign joint venture specializing in the research and manufacture of<br />

marine engineering equipments and special-purpose vessels. GSHI focuses on the development of<br />

high added-value deep-sea<br />

service vessels, offshore drilling<br />

platforms and supporting vessels,<br />

special marine engineering<br />

vessels and offshore <strong>com</strong>plexes.<br />

The vessel series is specifically<br />

designed to meet demands for<br />

efficient and safe management in<br />

growing offshore oil and gas field<br />

development in Middle East. The<br />

series vessel is a KCM design<br />

58.7M series DP-2 vessel with<br />

AH+ Towing notation in the<br />

world, which is equipped with<br />

16/24

12 TH VOLUME, NO. <strong>48</strong> DATED 04 DECEMBER 2010<br />

3x10 tons side thrusters. She has a suite of multifunction of firefighting, anchoring, towing,<br />

supplying. The 58.7M AHT has an overall length of 58.7 metres on a beam 14.6 metres and a<br />

draught of 4.75 metres. She is powered by two unit caterpillar 3516B Main Engine, rated at<br />

2575bhp@1600rpm, driving two four-bladed controllable pitch propeller. She has a trial speed of<br />

13.50 knots and designed Bollard Pull 65 tons. (Source & Photo: GSHI)<br />

WINDFARM NEWS<br />

Advertisement<br />

ESTONIAN SHIPYARD TO BUILD FOUR WIND FARM SERVICE<br />

CATAMARANS<br />

Estonian shipyard BLRT Marketex is to build four wind farm service catamarans for Sure Wind<br />

Marine of Hexham, Northumberland, U.K. Designed by Incat Crowther, the catamarans will be<br />

available for projects throughout Europe and built to DNV class and dual U.K. MCA and German<br />

Stability rules to ensure full flexibility. "This is first major contract for BLRT Marketex in wind farm<br />

service industry, which marks a new stage in development of our <strong>com</strong>pany," said Vladislav Markin,<br />

head of BLRT Marketex shipbuilding division. "Our extensive experience in small vessel building<br />

gives us the strong confidence in success of this project. We strongly believe in potential of this<br />

growing industry and are proud to build boats in close cooperation with experienced operators and<br />

designers to achieve best performance. Dominic Abraham, managing director of Sure Wind Marine<br />

said: "We are very pleased to be building vessels at such a well-equipped yard with an experienced<br />

team. The team has developed a flexible vessel capable of working throughout Europe in a range of<br />

conditions and roles. The vessels are designed with proven technologies emphasizing reliability,<br />

17/24

12 TH VOLUME, NO. <strong>48</strong> DATED 04 DECEMBER 2010<br />

efficiency and operational range and rely heavily on Incat Crowther's experience from earlier<br />

designs. The increased size over previous Incat Crowther designs allows for extra passenger <strong>com</strong>fort<br />

and space as well as 14 tonnes of cargo capacity." The vessels have been designed by Incat Crowther<br />

in accordance with Det Norske Veritas/+1A1-HSLC-R2 Wind Farm service 1 rules, UK MCA SCV,<br />

Category 2 and are <strong>com</strong>pliant with German Flag State requirements. The vessels will be equipped<br />

with twin MTU 8V2000 M72 engines (720 kW each), which will allow them to reach a maximum<br />

speed of 31 knots and a service speed of 26,5 knots at 85 percent MCR. The first boat will be<br />

delivered early May 2012 with each subsequent vessel delivering at 1.5 month intervals. The BLRT<br />

Marketex shipyardoffers advanced solutions for small vessels building as well as for large sized<br />

projects in steel, stainless steel and aluminum. The <strong>com</strong>pany has more than 10 years of experience in<br />

manufacturing of feeding barges for fish industry, service catamarans, <strong>com</strong>plex <strong>com</strong>ponents for the<br />

offshore oil and gas production sector and offshore wind industry. BLRT Marketex is a subsidiary of<br />

Estonia's BLRT Grupp. (Source: MarineLog)<br />

NORWIND, ULSTEIN TO DEVELOP NEW INSTALLATION VESSEL FOR<br />

OFFSHORE WIND INDUSTRY<br />

Norwegian based NorWind Installer<br />

contracted the ULSTEIN Dutch design<br />

offices Ulstein Sea of Solutions and<br />

Ulstein IDEA Equipment Solutions as<br />

their design partners for a new<br />

foundation installation vessel for the<br />

offshore wind industry. The vessel is a<br />

customized version of the Deepwater<br />

Enabler design from ULSTEIN. The DP<br />

vessel is designed for world-wide<br />

operations with a focus on pre-piling<br />

and jacket/tripod/transition piece<br />

installation for the offshore wind<br />

industry in North Europe. Different<br />

deck layouts, based upon NorWind Installer’s installation experience from Alpha Ventus, have been<br />

developed for the various installation modes on top of the generic vessel platform provided by<br />

ULSTEIN. The approach for this design has been unique in the sense that NorWind Installer and<br />

ULSTEIN started this project by going through the ULSTEIN Accelerated Business Development<br />

process. Technical and operational options from both NorWind Installer and ULSTEIN were<br />

discussed in a transparent process resulting in the most viable option, which met NorWind<br />

Installer’s business model and requirements. ”We are pleased with the concept as it is definitely in<br />

line with our vision of <strong>com</strong>bining state-of-the-art technical solutions with the speed and seakeeping<br />

capacity of DP vessels. It gives us the opportunity to provide our installation services all-year around<br />

in up to 2.5m Hs, as well as meeting our client’s cost targets”, states Thorbjørn Hansen, VP Product<br />

Development at NorWind Installer. The vessel is designed aiming for maximum efficiency and cost<br />

effectiveness and features an 800t heave <strong>com</strong>pensated offshore crane on starboard side, while a prepiling<br />

template can be located on a support structure at the stern. The vessel can carry four jackets,<br />

alternatively at least 24 piles or up to 12 transition pieces on the large open aft deck. To enhance<br />

vessel operability, the anti-heeling system has been designed in such a way that the main crane can<br />

revolve over 180o with a full load in its main hook within 5 minutes, which is very favourable<br />

having a large jacket in the crane hook. When operating in the pre-piling mode, the pre-piling<br />

18/24

12 TH VOLUME, NO. <strong>48</strong> DATED 04 DECEMBER 2010<br />

template is positioned on the seabed by the main crane, in parallell a pile is picked up by a gantry<br />

crane, put in the upending frame on starboard side and upended. The main crane has been modified<br />

by ULSTEIN in such a way that it can first pick-up the piling hammer with its main hook and then<br />

connect to the upended pile with its auxiliary hook. When the hammer is working on driving the<br />

pile into the seabed, the next pile is upended by the upending frame and made ready for crane lift<br />

out. The large aft deck and AHC crane provide flexibility for serving alternative subsea and offshore<br />

markets in the future, which is further increased by the two large holds suitable for carroussels<br />

located below main deck. A deck layout version of the vessel has also been developed for tidal<br />

turbine installations. Voith Schneider propellers of 3,900 kW each will allow for a cruising speed of<br />

13 knots and enhance the DP capabilities of the vessel. To minimize the environmental footprint an<br />

NOx reduction system is installed in the exhaust lines. “After working closely with NorWind<br />

Installer in the ABD process, ULSTEIN started developing the integrated concept for mission<br />

equipment and vessel. This project shows the <strong>com</strong>bined strength we can offer to support our clients<br />

in realizing their visions”, says Edwin van Leeuwen, project manager at ULSTEIN. (Source: Ulstein)<br />

SEAZIP OFFSHORE SERVICE SIGNS CONTRACT TODAY FOR 2 DAMEN<br />

TWIN AXES FOR OFFSHORE WIND FARM MAINTENANCE<br />

Damen Shipyards and SeaZip<br />

Offshore Service will sign a contract<br />

at the EWEA conference (14:30 hrs,<br />

stand 11020, Amsterdam, The<br />

Netherlands,). SeaZip has ordered two<br />

Fast Crew Suppliers of the 2610-type.<br />

The first ever FCS 2610 was delivered<br />

early <strong>2011</strong> and offers reduced peak<br />

accelerations of up to 75%, reduced<br />

added resistance in waves of up to<br />

60% and has already transferred<br />

maintenance crew to turbines in wave<br />

heights of 1.9 m. Jan Reier Arends,<br />

one of Seazip’s Managing Directors, will sign the contract with Roel van Eijle, Sales Manager<br />

Benelux, on the first day of the <strong>2011</strong> Offshore conference of the European Wind Energy<br />

Association. The vessels will be built at Damen Shipyards Singapore and delivery is set for the third<br />

quarter of 2012. Safe access to offshore sites: Offshore wind is rapidly be<strong>com</strong>ing a highly a<br />

specialized field in offshore operations. As the need for specialized services grows, there’s a need for<br />

fit-for-purpose service vessels. That’s why Mr Arends and Mr Sander Schakelaar, managing owners<br />

of the established (container) transport <strong>com</strong>pany JR Shipping, founded SeaZip Offshore Service in<br />

2010. SeaZip will draw on the 18 years of experience and services of JR Shipping, including vessel<br />

development and management. The two entrepreneurs have a clear goal: to provide service vessels<br />

for fast and safe access to offshore sites. In their effort to deliver “outstanding and safe performance<br />

in even the most challenging of circumstances” (SeaZip’s mission statement), they teamed-up with<br />

Damen Shipyards. The FCS 2610, already in use at offshore wind farms, matched Seazip´s<br />

requirements as to safety, transport capacity, <strong>com</strong>fort, and performance levels in harsh weather<br />

conditions. Another argument is that offshore wind farms are being built at ever-increasing<br />

distances from the shore, impairing continuity in operations and maintenance. The FCS 2610 can<br />

over<strong>com</strong>e these challenges as it has a range over 1000 nm, a 20,000 litre fuel tank (for sailing and<br />

transferring purposes) and there’s ac<strong>com</strong>modation for 4 crew and 12 industrial personnel. According<br />

19/24

12 TH VOLUME, NO. <strong>48</strong> DATED 04 DECEMBER 2010<br />

to Mr Arends the Twin Axe catamaran is “an excellent design, especially for staying out at sea for<br />

longer periods, while not <strong>com</strong>promising crew <strong>com</strong>fort.” (Source: Damen)<br />

ALNMARITEC WINS CONTRACT FOR TWO WAVE MASTER CLASS WFSV<br />

Alnmaritec, the specialist aluminium boat<br />

builder based in the North East of the UK,<br />

announced today at the EWEA Offshore<br />

<strong>2011</strong> exhibition that it has been awarded a<br />

contract for two of it’s new Wave Master<br />

class of wind farm support vessels. The<br />

new order was placed by North Sea<br />

Logistics one of the UK’s leading and most<br />

experienced offshore service providers who<br />

currently operate fifteen vessels in the<br />

market and have already <strong>com</strong>pleted over<br />

one million turbine transfers. The vessels<br />

are the fifth and sixth in line of this highly<br />

successful class from Alnmaritec two of which are already in service and have generally been<br />

accepted to be amongst the top performing boats in the market. The <strong>com</strong>pany in fact built the very<br />

first wind farm service vessel in the UK for the same operator and it has been at the forefront of the<br />

development of this type of vessel for the last decade delivering over twenty such craft to the<br />

industry. This particular order also establishes a further landmark for Alnmaritec being the 150th<br />

vessel built by the yard. The new boats will be 19m x 7m and fitted with fixed pitch propellers<br />

giving a top speed of 27.5 knots. Commenting on the new order from the show Alnmaritec<br />

Managing Director Chris Millman said “We are delighted to have secured this order from North Sea<br />

Logistics. This demonstrates the <strong>com</strong>mitment the owner Dave Armstrong has to developing their<br />

fleet in order to maintain their position as an industry leader. We are sure that the new boats will<br />

further enhance their capabilities and we appreciate their continued support and their confidence in<br />

our boats”. (Source: Alnmaritec)<br />

FASTNET SHIPPING IS DELIGHTED TO ANNOUNCE TWO NEW BUILD WIND<br />

FARM VESSELS<br />

Fastnet Shipping is delighted to announce our two new build Wind farm Service Vessels the Fastnet<br />

Skua and Fastnet Puffin, due for launch in March and April 2012 respectively. When launched the<br />

Fastnet Skua and Fastnet Puffin will join our two existing WSV’s the Fastnet Swift and Fastnet Tern<br />

and will in turn bring our total fleet of Tugs , Wind-cats , Jack Ups , Barges and other floating plant<br />

to over 21 different Vessels. (Source: Fastnet)<br />

YARD NEWS<br />

DAMEN SHIPYARDS HARDINXVELD SIGNES CONTRACT WITH ISKES AND<br />

OSD FOR TWO GREEN TUGS<br />

In November <strong>2011</strong> Iskes Towage & Salvage took its first Damen tug into operation: the ASD 2810<br />

‘Argus’. Pleased with its capabilities, Iskes decided to have Damen Shipyards Hardinxveld build a<br />

20/24

12 TH VOLUME, NO. <strong>48</strong> DATED 04 DECEMBER 2010<br />

further two harbour tugs: the<br />

revolutionary ASD 3212 ‘Green<br />

Tug’, designed by Iskes and<br />

Offshore Ship Designers to reduce<br />

CO2, SOx and NOx emissions by<br />

30%. The first contract was signed<br />

at Europort <strong>2011</strong> (Rotterdam) by<br />

managing directors Jos van<br />

Woerkum (DSHa), Jim Iskes and<br />

Michiel Wijsmuller (OSD). The<br />

tugs will be delivered by mid-<br />

2013. Since 2009, Iskes strives to<br />

reduce CO2, SOx and NOx<br />

particles, the ultimate goal being<br />

zero emissions. Triggered by the <strong>com</strong>mitment of the ports of Rotterdam and Amsterdam to the<br />

World Ports Climate Initiative, Iskes teamed up with Offshore Ship Designers to develop a tug with<br />

30% emission reduction. Other stakeholders included research centre MARIN and tug operator<br />

SMIT. Currently, the Green Tug Project is in the final, detailed design stage. This is carried out in<br />

close cooperation with Damen Shipyards Hardinxveld and Damen Research, especially when it<br />

<strong>com</strong>es to propulsion and bollard pull. Environmental economy: DSHa’s Jos van Woerkum says: “The<br />

Green Tug has several similarities with our Damen E3 project, that aims for environmentally<br />

friendly, economically viable and efficiently operating ships. Secondly, this is the first time Damen<br />

is building a vessel that it has not designed in-house. DSHa is known for its Multi Cats, Shoalbusters<br />

and Patrol Vessels. However, the Damen ASD 3212 design neatly fits within the OSD-Iskes format<br />

of the Azistern 3270. In addition, we work in an ‘open calculation’ format. Cost control is important<br />

if this design is to be a <strong>com</strong>mercial success. However, with this project there’s no fixed price! The<br />

Green Tug’s development is more important.” Characteristics The Green Tug’s azimuth thrusters,<br />

bow thrusters and winches use diesel-electric propulsion. In order to reduce emissions while<br />

mobilising to a job the tug will sail on battery power. The energy management system ensures that<br />

the master of the tug always gets the power he needs regardless if the power <strong>com</strong>es from batteries or<br />

from one or more diesel generators. When sailing at cruising speed only one generator is used, this<br />

cuts down on fuel consumption and maintenance. The vessel will have 70 t bollard pull and is<br />

equipped with a double drum, creating an independently controlled forward winch system. The<br />

idea is to pay out two tow-wires at the same time and control each wire independently. This is very<br />

practical when manoeuvring in narrow spaces. ‘Jos and Jim’ “Although Jim and I never did business<br />

before, we’ve known each other quite well for a long time and understand each other’s’ needs”, says<br />

Jos van Woerkum. “A man, and a client, like Jim Iskes goes well with our type of organisation. He’s<br />

very straightforward, knows what he wants and is not afraid of participating in new developments.<br />

He’s an experienced captain and as a ship-owner he’s bursting with ideas. In short, a real<br />

entrepreneur. Our own experience is added to his. With every new vessel we try to improve our<br />

standards. We sail along when the vessels is doing its job and evaluate if it does what we designed it<br />

to do. We always try to put our knowledge of clients and ships into our design and production<br />

standards. Standardization is of course one of Damen’s basic strengths. So, why did we decide to<br />

build the Green Tug, this non-standard project? Because it’s a real innovation, a chance to co-create<br />

a future standard and, of course, because it’s work for our shipyard. My message is: Damen can build<br />

more than standard vessels and at the same time deliver added value because of our standards. We’re<br />

proud to participate in Iskes’ project.” (Press Release Damen Shipyards Group)<br />

21/24

12 TH VOLUME, NO. <strong>48</strong> DATED 04 DECEMBER 2010<br />

Advertisement<br />

STX MARINE SECURES OSVS DESIGN CONTRACT<br />

STX Marine (STXM) congratulated Eastern<br />

Shipbuilding Group on the award by<br />

Hornbeck Offshore Services Inc. for the<br />

design and construction of eight STXM<br />

designed offshore support vessels. The<br />

SV300 and SV310 series vessels are derived<br />

from well proven designs recently<br />

delivered to the US Gulf Coast and they<br />

will have a deadweight of approximately<br />

5500 LT and 6070 LT respectively. The<br />

vessels shall be designed to meet the<br />

requirements of the DP2, FiFi 1 and<br />

ENVIRO notations from ABS as well as be<br />

in accordance with the latest applicable Marpol and IMO regulations. This contract signifies another<br />

example of the successful relationship between STX Marine and Eastern Shipbuilding Group in<br />

bringing state of the art offshore support vessels to the US offshore market sad STX Marine. (Source:<br />

STX Marine)<br />

SHIPPING COMPANY GROEN ORDERS TWO SEISMIC RESEARCH<br />

SUPPORT VESSELS WITH MAASKANT SHIPYARDS<br />

Dutch Shipping Company<br />

Groen has ordered two<br />

Seismic Research & Support<br />

Vessels (SRSV’s) with<br />

Maaskant Shipyards<br />

Stellendam (Netherlands),<br />

part of the Damen Shipyards<br />

Group. Maaskant has broad<br />

experience in maintenance<br />

and repair of Offshore<br />

Support Vessels. However, an order for SRSV-newbuilds is a first. Director Frits van Dongen says:<br />

“The Groen orders are a result of our approach towards offshore vessel design and construction and<br />

we are very proud indeed.” The vessels have been designed in cooperation with Saltwater<br />

Engineering (Netherlands) to meet the needs and experiences of Shipping Company Groen. The<br />

22/24

12 TH VOLUME, NO. <strong>48</strong> DATED 04 DECEMBER 2010<br />

vessels’ all-weather chase and support tasks will focus on seismic activity research. Characteristics:<br />

Both SRSV’s will be 40 m long with a 9.30 m beam. Two Caterpillar propulsion units of in total<br />

1940kw (2640pk) will give the vessels a design speed of 14 knots. They can be deployed worldwide<br />

and have ac<strong>com</strong>modation for 14 people. Experience: Maaskant Shipyards serves dozens of ships,<br />

often owned and operated by long-time clients. The shipyard handles maintenance and repair of<br />

Offshore Support Vessels, Fishing Vessels, Guard Vessels and Standby Vessels. Recently, a 44 m<br />

beam-trawler fishing vessel, built by Maaskant in 1994, was converted to an OSV. The new seismic<br />

research support vessels will be delivered in the first quarter of 2013. (Source: Damen)<br />

GRANDWELD SHIPYARDS SIGNS NEW CONTRACT<br />

Grandweld Shipyards announced a contract award to design, build and deliver two 21.3M<br />

service/crew boats for Kuwait Oil Tanker Company. Contract signing was held today November 29,<br />

<strong>2011</strong> at Grandweld Shipyards facilities in Al Jadaf, Dubai, and the contract was signed between Mr.<br />

Jamal Abki, Grandweld General Manager, and Mr. Faisal Ali, KOTC Deputy Managing Director.<br />

The 21.3M vessels will be powered via twin waterjet installation to ensure high speed and<br />

maneuvering capabilities which will be utilized by KOTC Marine Agency Branch to safely transport<br />

passengers and cargo to and from tankers calling Kuwaiti Oil Terminals. Delivery of the two vessels<br />

is scheduled in the last quarter of 2012. (Source: MarineLink)<br />

BORCOS SHIPPING ORDERS TWO CREW BOATS FROM STRATEGIC<br />

MARINE<br />

Australian ship builder Strategic<br />

Marine has confirmed its position<br />

as a major supplier of vessels to the<br />

Malaysian offshore oil and gas<br />

sector, securing a contract to build<br />

two 40 metre crew boats for<br />

Syarikat Borcos Shipping Sdn Bhd.<br />

On delivery of the vessels mid next year, Borcos Shipping will boast 11 Strategic Marine crew boats<br />

in its fleet, the first one launched in 2005. Strategic Marine Marketing Manager Terry O’Connor<br />

said this contract further established the ship builder as a world-leading manufacturer of crew boats,<br />

especially in the Asia Pacific region. “Our ability to construct hulls in Vietnam and <strong>com</strong>plete them<br />

at our Singapore shipyard has provided the market with an extremely <strong>com</strong>petitive option in<br />

purchasing new crew boats, during such a challenging period in the market,” Mr O’Connor said.<br />

“Strategic Marine has now delivered 35 vessels into the South East Asia region over the past five<br />

years, the majority of which are servicing the local offshore oil and gas sector.” Mr O’Connor said<br />

that Strategic Marine’s reputation in the crew boat market has allowed the <strong>com</strong>pany to fast-track its<br />

shipbuilding diversification plans and establish regional operations in WA’s North West and<br />

Queensland. “In the past few weeks we have finalised plans to expand our fast-response repair and<br />

servicing operation in Karratha and secured a contract for fabrication and design work for John<br />

Holland’s mining construction works in Gladstone, Australia. “Our ship building operations now<br />

include a vast range of vessel designs, including platform supply vessels, anchor handling vessels,<br />

dive / ROV support vessels, tug boats, wind farm maintenance vessels and passenger vessels,” he<br />

said. The Borcos Shipping crew boats can transfer up to 58 oil rig personnel and carry 44 tonnes of<br />

cargo. “These vessels have been tried and tested in the Malaysian market and their continued<br />

success is testament to their superior operability, unrivalled passenger <strong>com</strong>fort and – very<br />

23/24

12 TH VOLUME, NO. <strong>48</strong> DATED 04 DECEMBER 2010<br />

importantly – their economical hull form,” Mr O’Connor said. Borcos Shipping is an established<br />

Malaysian shipping <strong>com</strong>pany formed in early 1980. Its registered office is in Miri, Sarawak with<br />

branch offices in Labuan, Kota Kinabalu and Terengganu. (Source: Strategic Marine)<br />

WEBSITE NEWS<br />

HTTP://WWW.TOWINGLINE.COM<br />

ARE YOU ALSO INTERES T ED IN THIS FREE TUGS TOW ING & OFFSHO RE NEWSLETTER.<br />

PLEASE VIS IT THE WEBS ITE WW W.TO W I N G L I N E . C O M AND S UBSCRIBE YOURSE LF FOR FREE<br />

Last week there have been new updates posted:<br />

1. Several updates on the News page posted last week:<br />

Fairmount Alpine assists drifting vessel off Cuba<br />

Tug Singapore underway with Smit Borneo to Rena<br />

Taikoo – Latest delivery of popular RAmparts 3000 for HUD<br />

SeaZip Offshore Service signs contract today for 2 Damen Twin Axes<br />

Damen Shipyards Hardinxveld signes contract with Iskes and OSD for two Green<br />

Tugs<br />

OSD to design low emission tug for Iskes<br />

CBMM restores 1931 Potomac River Dory Boat<br />

CBMM breaks ground on restoration of Navy Point bulkhead in St. Michaels<br />

Sleepvaartmuseum ontvangt uniek schilderij<br />

Stranded tugboat pulled out from Miramar beach<br />

mailto:Please note that my e-mail address has changed into jvds@towingline.<strong>com</strong><br />

This site is intended to be collective exchange of information. Information on this site has been pulled from many sources; we have<br />

attempted to credit these sources. But due to the multitude of sources sometimes we are unable to note all the sources. If you feel that<br />

material that is posted here is of your authorship and you have not been credited properly please alert us and I will correct the credit or<br />

remove it in accordance to the author's wishes.<br />

DISCLAIMER<br />

The <strong>com</strong>piler of the Tugs Towing & Offshore <strong>Newsletter</strong> disclaim all liability for any loss, damage or expense however caused, arising<br />

from the sending, receipt, or use of this e-mail <strong>com</strong>munication and on any reliance placed upon the information provided through this<br />

free service and does not guarantee the <strong>com</strong>pleteness or accuracy of the information. For more information about advertising,<br />

subscription, preferences and un-subscription visit the website: http://www.towingline.<strong>com</strong> The Tugs Towing & Offshore <strong>Newsletter</strong> is a<br />

::JVDS-MARCOL:: Archive Production.<br />

24/24