Download Newsletter 33_2012 - Towingline.com

Download Newsletter 33_2012 - Towingline.com

Download Newsletter 33_2012 - Towingline.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

13 TH VOLUME, NO. <strong>33</strong> DATED 19 AUGUST <strong>2012</strong><br />

BUYING, SALES, NEW BUILDING, RENAMING AND OTHER TUGS TOWING & OFFSHORE INDUSTRY NEWS<br />

TUGS & TOWING NEWS<br />

NEW RAMPARTS 3200-W CLASS TUG FOR SAUDI PORTS AUTHORITY<br />

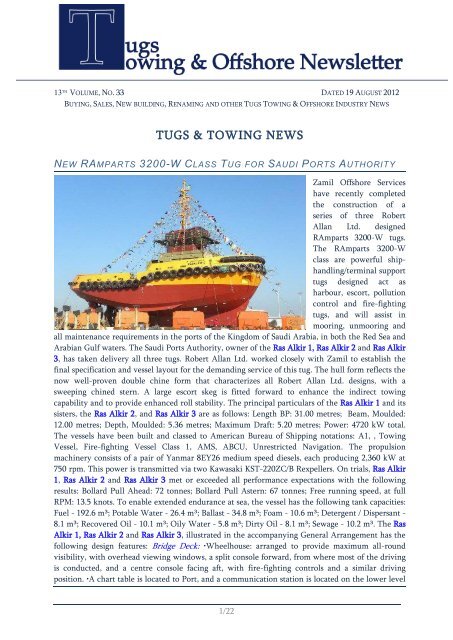

Zamil Offshore Services<br />

have recently <strong>com</strong>pleted<br />

the construction of a<br />

series of three Robert<br />

Allan Ltd. designed<br />

RAmparts 3200-W tugs.<br />

The RAmparts 3200-W<br />

class are powerful shiphandling/terminal<br />

support<br />

tugs designed act as<br />

harbour, escort, pollution<br />

control and fire-fighting<br />

tugs, and will assist in<br />

mooring, unmooring and<br />

all maintenance requirements in the ports of the Kingdom of Saudi Arabia, in both the Red Sea and<br />

Arabian Gulf waters. The Saudi Ports Authority, owner of the Ras Alkir 1, Ras Alkir 2 and Ras Alkir<br />

3, has taken delivery all three tugs. Robert Allan Ltd. worked closely with Zamil to establish the<br />

final specification and vessel layout for the demanding service of this tug. The hull form reflects the<br />

now well-proven double chine form that characterizes all Robert Allan Ltd. designs, with a<br />

sweeping chined stern. A large escort skeg is fitted forward to enhance the indirect towing<br />

capability and to provide enhanced roll stability. The principal particulars of the Ras Alkir 1 and its<br />

sisters, the Ras Alkir 2, and Ras Alkir 3 are as follows: Length BP: 31.00 metres; Beam, Moulded:<br />

12.00 metres; Depth, Moulded: 5.36 metres; Maximum Draft: 5.20 metres; Power: 4720 kW total.<br />

The vessels have been built and classed to American Bureau of Shipping notations: A1, , Towing<br />

Vessel, Fire-fighting Vessel Class 1, AMS, ABCU, Unrestricted Navigation. The propulsion<br />

machinery consists of a pair of Yanmar 8EY26 medium speed diesels, each producing 2,360 kW at<br />

750 rpm. This power is transmitted via two Kawasaki KST-220ZC/B Rexpellers. On trials, Ras Alkir<br />

1, Ras Alkir 2 and Ras Alkir 3 met or exceeded all performance expectations with the following<br />

results: Bollard Pull Ahead: 72 tonnes; Bollard Pull Astern: 67 tonnes; Free running speed, at full<br />

RPM: 13.5 knots. To enable extended endurance at sea, the vessel has the following tank capacities:<br />

Fuel - 192.6 m³; Potable Water - 26.4 m³; Ballast - 34.8 m³; Foam - 10.6 m³; Detergent / Dispersant -<br />

8.1 m³; Recovered Oil - 10.1 m³; Oily Water - 5.8 m³; Dirty Oil - 8.1 m³; Sewage - 10.2 m³. The Ras<br />

Alkir 1, Ras Alkir 2 and Ras Alkir 3, illustrated in the ac<strong>com</strong>panying General Arrangement has the<br />

following design features: Bridge Deck: •Wheelhouse: arranged to provide maximum all-round<br />

visibility, with overhead viewing windows, a split console forward, from where most of the driving<br />

is conducted, and a centre console facing aft, with fire-fighting controls and a similar driving<br />

position. •A chart table is located to Port, and a <strong>com</strong>munication station is located on the lower level<br />

1/22

13 TH VOLUME, NO. <strong>33</strong> DATED 19 AUGUST <strong>2012</strong><br />

of the wheelhouse, similarly to Port. Main Deck: •Deck locker: outfitted with shelving to store<br />

hoses, fittings, rescue equipment, SCBA air-packs, etc. <strong>com</strong>mensurate with Class notation of FiFi 1.<br />

•Mess / Lounge / Galley: <strong>com</strong>fortable seating area with television and an area for the crew to enjoy a<br />

meal between shifts. •Flush-mounted, machinery access/removal flush hatch. •Ac<strong>com</strong>modation:<br />

cabins for Master and Chief Engineer, with private facilities. Below Main Deck: •Ac<strong>com</strong>modation:<br />

lavatory facilities suitable for the crew of 6, a laundry, HVAC Room and access to the Engine<br />

Control Room and then to the Engine Room. •Owners Stateroom: a <strong>com</strong>fortable single berth cabin,<br />

with ensuite, specifically set aside for an Owners representative The RAmparts 3200-W is designed<br />

for maximum efficiency in the performance of ship-handling, escort, and related terminal support<br />

activity services. The vessel is equipped with a hawser winch, towing hook, forward, with heavy<br />

bow fendering for ship-assist and escort work. A towing hook and capstan are fitted aft for<br />

secondary towline duties. The RAmparts Class tugs are a proven, standardized Z-drive tug design.<br />

Each design is developed from a successful prototype vessel or series of vessels, and refined to<br />

emphasize ease of construction, and the Owners specific requirements. These RAmparts 3200-W<br />

tugs are designed to perform a wide variety of tasks such as: •Ship-handling; •Escort; •Anchor<br />

handling operations; •Diving support; •ROV support; •Offshore personnel transfer; •Safety or standby<br />

support; •Rescue and salvage towing operations; •Oil spill response; •Off-Ship fire-fighting<br />

operations; •Delivery of cargo to offshore drilling and production rigs that can include containers,<br />

various type of deck cargo, fuel oil, drilling water and potable water. (Source: Robert Allan)<br />

TEMPEST SOLD<br />

Advertisement<br />

Last week International Transport<br />

Contractors (ITC) has sold her 1977 built<br />

Dutch registered with call sign PHXV tug<br />

Tempest (Imo 7515377) to Indus<br />

Shipping & Trading Company. It is<br />

reported that the tug has received the<br />

new name Indus temporarily and that she<br />

will be dry docked and brought back in<br />

class first by the new owner. The tug has<br />

a rich history. She is built on the<br />

Scheepswerf Van der Giessen-De Noord<br />

BV – Alblasserdam; Netherlands under<br />

number 908 and is the sister of the Typhoon. On 16 February 1977 delivered to Bureau Wijsmuller<br />

Ijmuiden and managed by Wijsmuller Salvage BV. In 1991 transferred to SmitWijs Towage CV, a<br />

2/22

13 TH VOLUME, NO. <strong>33</strong> DATED 19 AUGUST <strong>2012</strong><br />

joint venture between Wijsmuller and Smit Internationale - Rotterdam and managed by CW<br />

Marine Services. In 1999 transferred to Smitwijs Scheepsholding BV and managed by Wijsmuller<br />

Marine Services BV – Ijmuiden and renamed Smitwijs Tempest. On 30 th December 2005 sold to ITC<br />

- International Transport Contractors; Netherlands and managed by Tempest International BV -<br />

Heemstede for service in the Far East and re-renamed Tempest. Her two Stork Werkspoor 6TM410<br />

diesel engine delivers an total output of 8,500 bhp, with a speed of 14.5 knots and a bollard pull of<br />

120 tons. We wish her following wind and fair seas. (Photo: Willem Koper)<br />

GRANDWELD DELIVERS TWO 55 TONS BOLLARD PULL ESCORT<br />

TUGBOATS TO ABU DHABI PORTS COMPANY<br />

Grandweld Shipyards has <strong>com</strong>memorated<br />

the delivery of the two new 55 Tons<br />

Bollard Pull Escort Tugboats in a special<br />

ceremony held at Khalifa Port on August 6,<br />

<strong>2012</strong>. The new tugboats are specially<br />

designed to assist in marine and Harbour<br />

operation at Khalifa Port including<br />

escorting & towing, mooring/unmooring,<br />

and fire fighting operations. The vessels are<br />

also equipped with state of the art<br />

machinery including 4700 BHP medium<br />

speed engines, a forward escort winch, and<br />

2xAzimuthing stern propulsion system to<br />

achieve 55 ton bollard pull of towing<br />

capacity. This will allow the vessels to handle the large vessels and container ships operating at<br />

Khalifa Port. Jamal Abki, General Manager of Grandweld Shipyards <strong>com</strong>mented: “We wish to thank<br />

Abu Dhabi Ports Company (ADPC) for giving us the opportunity to build their first tugs for Khalifa<br />

Port. We at Grandweld understood the requirement of ADPC for high standard and top quality tugs.<br />

Therefore, these tugs were built to the most advanced design and fitted with the highest quality<br />

equipments that will ensure reliability and mission readiness for heavy duty operations at the Port.<br />

We are proud to advise that both, Al Fenci and Al Durrah have successfully passed stringent testing<br />

requirements during extensive sea trials that was attended and certified by the American Bureau of<br />

Shipping (ABS Class). Both vessels over performed on speed and bollard pull figures, which<br />

categorize the capabilities and value of the tugs” In addition to that, the vessels are designed for<br />

premium standard of crew <strong>com</strong>fort (ABS Class “HAB” notation). (Source: Grandweld)<br />

TEEKAY - KOTUG JOINT VENTURE TO PURSUE OPPORTUNITIES IN<br />

AUSTRALIAN TOWAGE MARKET<br />

Sydney, Australia/Rotterdam, The Netherlands, August 15, <strong>2012</strong>: Teekay Shipping Australia Pty Ltd.<br />

(Teekay) and KOTUG International B.V. The Netherlands (KOTUG) today announced the<br />

establishment of a new Joint Venture (JV) <strong>com</strong>pany, called KT Maritime Services Australia Pty Ltd,<br />

to pursue new business opportunities in the Australian towage market. "We believe there are new<br />

opportunities for trusted and experienced <strong>com</strong>panies like Teekay and KOTUG to provide superior<br />

towage services at existing and greenfield terminal developments," <strong>com</strong>mented Ard-Jan Kooren,<br />

CEO of KOTUG. "The JV between Teekay and KOTUG will bring together <strong>com</strong>plementary skills<br />

from each partner. At KOTUG, we have many years of practical and technical experience in the<br />

3/22

13 TH VOLUME, NO. <strong>33</strong> DATED 19 AUGUST <strong>2012</strong><br />

towage field, including the<br />

deployment of our highly<br />

maneuverable RotorTug<br />

technology. Combined with<br />

Teekay’s worldwide reputation<br />

for operational leadership and<br />

deep knowledge and expertise in<br />

the Australian crewing and ship<br />

management markets, this results<br />

in a strong partnership to pursue<br />

new business." "The Australian<br />

market for towage services is<br />

growing as new LNG projects<br />

begin production, adding to the<br />

ongoing growth in Australian coal and iron ore export shipments," <strong>com</strong>mented David Parmeter,<br />

Managing Director, Teekay Shipping Australia Pty Ltd. "Since 2002, Teekay has operated in the<br />

Australian towage market at both Hay Point and Port Hedland where we currently manage 12 tugs<br />

and have experience with several KOTUG RotorTug vessels. With our new JV <strong>com</strong>pany, we are<br />

formalizing a partnership that will deliver top tier towage services for the Australian market."<br />

Under the terms of the JV agreement, Teekay and KOTUG will both continue to separately manage<br />

respective existing operations in various Australian ports. KT Maritime Services Australia Pty Ltd<br />

will be located in Perth, Australia. Jamie Anderson, Business Development Manager for KT<br />

Maritime Services Australia, will be responsible for developing new business with potential<br />

customers. (Press Release Kotug)<br />

Advertisement<br />

THE FIRST OF FOUR NEW TRACTORS ARRIVE IN ANTWERP<br />

At the end of June the first of four new Voith propelled tractor tugs ordered by the Antwerp Port<br />

Authority arrived from the Union Naval Valencia (UNV) shipyard in Spain. The Port of Antwerp<br />

continues to operate a long standing ‘all Voith tractor policy’ for their extensive tug fleet used<br />

exclusively for shiphandling within the enclosed dock systems. The tugs are traditionally un-named<br />

and identified by a serial number. This latest addition to the fleet is ‘40’ The design follows a well<br />

established concept, changed only to satisfy the increasing demand for more bollard pull as ships<br />

be<strong>com</strong>e larger. ‘40’ and its three sister ships, ‘41’, ‘42’ and ’43’, was designed by SENER Ingenieria y<br />

Sistemas, working closely with UNV and the client. The resulting vessel is 29.50m in length overall,<br />

4/22

13 TH VOLUME, NO. <strong>33</strong> DATED 19 AUGUST <strong>2012</strong><br />

12.50m beam, 4.50m depth to the main<br />

deck and a maximum draft of 3.80m.<br />

Design and construction meets the class<br />

requirements of Bureau Veritas;<br />

1+Hull,+ Mach,Tug Coastal Area,+AUT-<br />

UMS, Comf-Noise 3. In plan view the<br />

hull is almost oval and well fendered<br />

fore and aft. The hull has a pronounced<br />

shear and incorporates a sizeable skeg<br />

and the usual docking/nozzle plate<br />

beneath each propeller. Achieving the<br />

required performance with such a<br />

relatively shallow draft may well have<br />

been an important requirement for the<br />

client but a challenge for the naval architects. Tank capacities quoted are 142 cu/m of fuel, 18 cu/m<br />

of fresh water, 7 cu/m of lubricating oil and 90 cu/m of ballast. To achieve the required bollard pull<br />

of 70 tonnes, two ABC DZC 12 cylinder main engines are fitted, each developing 2,640kW at 1000<br />

rpm (total approximately 7,080 bhp). Power is transmitted to a pair of Voith Schneider Type<br />

32R5/265-2 propulsion units. This <strong>com</strong>bination produces the required bollard pull performance and<br />

a maximum free running speed of 13 knots. Electrical power aboard this class of tug is supplied by<br />

two Scania (type D1 12 62M) powered generating sets, each rated at 199kW at 1500rev/min –<br />

225kVA, 50 Hz. Deck equipment supplied by Brusselle includes a conventional anchor windlass and<br />

two anchors in the bow. Two towing winches are fitted in a rather unusual configuration on the<br />

after deck. A Brusselle type HSL 150-50/1-0 single drum main towing winch with a 75-5kN line<br />

pull is mounted on the centerline. A similar auxiliary winch is placed diagonally on the port side.<br />

When in use either winch can deploy a towline via the same deck mounted ‘staple’.<br />

Ac<strong>com</strong>modation is provided for a maximum crew of six persons, with the usual mess room, galley,<br />

stowage and sanitary facilities. (Source: Maritime Journal; Photo: Mercator Media)<br />

ICE-CLASS TUGBOAT LAUNCHED IN ARCHANGEL SHIPYARD<br />

Laysky Shipyard in Archangel,<br />

Russia, launches the 'Iskander'<br />

tugboat for delivery to Ecotek-<br />

Bunker after sea trials. The new<br />

tugboat will transport barges laden<br />

with coal, firewood, construction<br />

materials to remote areas of the<br />

Arkhangelsk region: Mezen,<br />

Kamenka, Onega, and to the Nenets<br />

Autonomous District. This is the<br />

second ice-class tug launched at<br />

Laysky Shipyard in the past eighteen<br />

months. The Laysky Shipyard is<br />

located in the Lay River estuary, a tributary of the Northern Dvina. The shipyard has a 14,000 cmb<br />

dry dock, for construction of both flat and keeled vessels of dock weight of 2,500 ton, with 115-mlong<br />

keel track cribbing. The dock crane’s lifting capacity is 20 tons. (Press Release Laysky Shipyard)<br />

5/22

13 TH VOLUME, NO. <strong>33</strong> DATED 19 AUGUST <strong>2012</strong><br />

HINDUSTHAN SHIPYARD DELIVERS BOLLARD PULL TUG TO VIZAG PORT<br />

The Hindusthan Shipyard Ltd delivered a 50-tonne<br />

bollard pull tug to the Visakhapatnam port trust here<br />

on Friday 10 th August <strong>2012</strong>, in the presence of Vizag<br />

port chairman Ajeya Kallam, according to a press<br />

release. Col. H. Cartwright Reid was the sixth tug<br />

delivered by Hindusthan Shipyard to the Vizag port,<br />

enabling the latter to handle more vessels.<br />

Hindusthan Shipyard has so far delivered 168 vessels<br />

of various types. The tug has a steerable rudder<br />

propulsion system for better navigation. It is <strong>33</strong>.50<br />

metres in length, 10.80 metres in breadth and 3.90<br />

metres in depth. It has a speed of 11 knots and<br />

<strong>com</strong>plement of 14. It has been built to Indian<br />

Register of Shipping classification, according to the<br />

release. The function was attended by the CMD and senior officials of Hindusthan Shipyard. (Press<br />

Release: The Hindu)<br />

KEVERNE IN BRAEFOOT BAY<br />

An unusual assignment for J P Knight<br />

(Caledonian) Ltd's Keverne (Imo<br />

9381794), 393 gt, 2006, ex Azuma Maru<br />

was as standby tug at Braefoot Bay, Firth<br />

of Forth, 12th August <strong>2012</strong>. She took<br />

over from the usual tug, Fidra (Imo<br />

9108491) Forth Estuary Towage, Leith,<br />

1995, 276 dwt, mid-morning when the<br />

latter went to Rosyth. Braefoot exports<br />

products produced at the Mossmoran<br />

Plant in Fife with two jetties, the larger<br />

one operated by Shell and a smaller one<br />

operated by Exxon. In the background is Bastogne (Imo 9237747) LPG Tanker, 22,902 gt, 26,616<br />

dwt, Exmar Marine NV, built: 2002. Renamed 2011, ex- BW Hugin (2007), Berge Hugin (2005),<br />

Lancashire (2002), on the larger west jetty operated by Shell. (Photo: Iain McGeachy)<br />

Advertisement<br />

6/22

13 TH VOLUME, NO. <strong>33</strong> DATED 19 AUGUST <strong>2012</strong><br />

WÄRTSILÄ TO POWER FOUR SVITZER TUGBOATS<br />

Wärtsilä contracted to supply power systems<br />

of four modern diesel-electric tugs building<br />

for Australian owner Svitzer. The vessels are<br />

being built at the ASL shipyard in Singapore<br />

and are scheduled to be in operation by early<br />

2014. Each of the four 80 Ton Bollard Pull<br />

(TBP) harbour tugs will be fitted with two 9cylinder<br />

and one 8-cylinder in-line Wärtsilä<br />

20 engines. The use of the Wärtsilä 20<br />

engines as diesel-electric generating sets is a<br />

new development in the tugs market. The<br />

engines will operate on Marine Gas Oil<br />

(MGO) and the tugs will be equipped with batteries that allow power from the Wärtsilä generating<br />

sets to be stored for later use. “Modern tugs need to feature both fuel efficiency and environmental<br />

sustainability, as well as lifecycle reliability. This contract represents further evidence of Wärtsilä’s<br />

strength in meeting these demands, and further emphasises our ability to offer sophisticated dieselelectric<br />

machinery solutions for this particular sector of the marine industry,” says Aaron<br />

Bresnahan, Vice President, Wärtsilä Ship Power Specials. “By selecting Wärtsilä 20 engines for the<br />

diesel-electric generating sets, the owner will benefit from their robustness and reliability, which<br />

has been proven by the fact that more than 4000 of the engines have been delivered since this<br />

model was introduced to the market in the early 1990s. The Wärtsilä 20 offers low exhaust gas<br />

emissions, low operating costs, fuel economy across the entire engine operation range, and high<br />

redundancy,” says Bresnahan. Wärtsilä has earlier supplied integrated propulsion solutions for two<br />

Svitzer Tier III <strong>com</strong>pliant ECOtug(s). (Press Release Wartsila)<br />

TUGS OF BOLUDA TOWAGE AND SALVAGE IN THE GREAT RACE OF<br />

CÁDIZ <strong>2012</strong><br />

The tugs VB Cádiz y VB<br />

Jerez from the fleet of<br />

Boluda Towage and<br />

Salvage, took part on the<br />

manoeuvres of docking and<br />

exit of the two big school<br />

ship from the Spanish and<br />

Italian navy, Juan Sebastián<br />

el Cano and Américo<br />

Vespucci respectively, in<br />

occasion of the bicentenary<br />

of the Spanish<br />

Constitution, have<br />

participate in the Great<br />

Race, that took place in the<br />

waters of Cadiz. Nearly half hundreds of big ships have participated in the <strong>com</strong>petition that due to<br />

its spectacular way, have concentrated thousands of spectators in the bay of Cádiz. The sailing ships<br />

left Cadiz on the 5 th August to La Coruña. (Source: Boluda)<br />

7/22

13 TH VOLUME, NO. <strong>33</strong> DATED 19 AUGUST <strong>2012</strong><br />

SVITZER SOLD FLYING SPINDRIFT<br />

Advertisement<br />

Svitzer has sold the ASD tug Flying<br />

Spindrift to FFS-A/S of Farsund in<br />

Norway. The 30m vessel was built in<br />

1986 by Richard Dunston at Hessle<br />

and was the only tug with an<br />

azimuthing propulsion system to be<br />

constructed for the Clyde Shipping<br />

Company prior to the subsequent<br />

takeovers. Flying Spindrift is powered<br />

by two Ruston 6RKCM diesels of<br />

3,188bhp (total), giving it a bollard<br />

pull of 40 tonnes. The tug has been<br />

renamed FFS Atlas and joins two other<br />

former British tugs the Voith tractor<br />

FFS Achilles (ex; Svitzer Stephanie) and FFS Khan (ex; Alfred Lamey/Coburg). The sale was made<br />

via the services of broker Michael Vincent. (Source: Maritime Journal; Photo: W. Keough)<br />

EN AVANT 10 COMMENCED TRAILS<br />

Last week was seen the 2002 built Dutch<br />

registered with call sign PCPP tug En<br />

Avant 10 (Imo 9264386) during her<br />

technical trails in the Rotterdam<br />

Europoort. The tug is owned and<br />

managed by T.Muller Rederij –<br />

Dordrecht; Netherlands. The tug is built<br />

as Dhoce at the Astilleros Armon SA –<br />

Navia; Spain under number 553 for<br />

Remolques Unidos SA – Santander. In<br />

2004 sold to Zaklad Uglug Zeglugowych<br />

– Szczecin; Poland and renamed Tryton.<br />

In <strong>2012</strong> taken over by T.Muller and renamed En Avant 10. She has a length of 30.00 mtrs a beam of<br />

9.85 mtrs and a depth of 5.40 mtrs. The tug has two Caterpillar 3516B with a total output of 2,942<br />

kW a speed of 12 knots and a bollard pull of 50 tons. (Photo: Ruud Zegwaard)<br />

8/22

13 TH VOLUME, NO. <strong>33</strong> DATED 19 AUGUST <strong>2012</strong><br />

STEAM TUG KERSE<br />

YESTERYEAR<br />

By Iain Forsyth<br />

I sailed on the Kerse<br />

1/3/1974 as a passenger,<br />

She was under the<br />

<strong>com</strong>mand of Tugmaster<br />

Alex Gourlay Snr, We<br />

sailed from her berth in<br />

the Old Dock<br />

Grangemouth, through<br />

the Carron Dock, passing<br />

the Grange Dock to the<br />

Oil Basin where we were<br />

to be head tug on the<br />

sailing of British Poplar<br />

from Jetty 2 after making<br />

fast we successfully guided<br />

the tanker into the Lock, Pilot Capt Bob Hardie let us go in the Lock and we headed back to our<br />

berth, at this point I was invited down the hole into the Engine Space, where I met "Wee Willie"<br />

the Stoker, he asked me if I would like to coal the boiler, so shovel in hand one back left, one back<br />

right, one front left, one front right, and one in the middle for luck, I repeated this several times on<br />

the way back to the berth, at one point "Wheeee" from the blower and a Voice said where,s all this<br />

steam <strong>com</strong>ing from the safety valve is lifting, When we reached the berth I realised I had had the<br />

mickey taken out of me, and I was presented with a handmade certificate declaring me an Honorary<br />

Stoker of the ST Kerse. ST Kerse. built by J Cran & Somerville Ltd Leith 1923, Yrd No 131 for<br />

Grangemouth & Forth Towing Company Ltd. 110 ft Loa 24ft beam 12ft draught, 213grt, Speed 9kts.<br />

The 2cyl engine was manufactured by the builders 92Nhp seven and a half tons bollard pull. After<br />

50 years’ service she left Grangemouth for the last time on Wednesday 6th March 1974 for the<br />

shipbreakers at Bo`ness, Fifty years down the line and there was heated debate in the Boardroom as<br />

to whether she should have electric light and hot water radiators when being built. (Image from the<br />

Forth Tugs Library).<br />

Advertisement<br />

ACCIDENTS – SALVAGE NEWS<br />

9/22

13 TH VOLUME, NO. <strong>33</strong> DATED 19 AUGUST <strong>2012</strong><br />

TANKER GROUNDED OFF WANGEROOGE<br />

Last week the "Katja" ran aground<br />

off the island Minsener Oog, two<br />

km southeast of Wangerooge, in<br />

the Frisian Community with a<br />

cargo of 87.000 tons crude oil in<br />

the night of Aug 14, <strong>2012</strong>, arund<br />

1 a.m. The ship developed a list of<br />

1,5 degrees. The tugs "Bugsier 1“<br />

and "Wilhelmshaven“, the<br />

"Mellum“ of the WSA<br />

Wilhelmshaven, the antipollution<br />

ship "Neuwerk“ and the<br />

emergency tug "Nordic" were<br />

among the vessels which responded. At 6.15 the vessel could be refloated with tug assistance when<br />

the tide rised. Escorted by two tugs it proceeded to Wilhelmshaven where it berthed at 8.30 a.m.<br />

Here the cargo which came from Hound Pt. was to be unloaded and the hull will undergo surveys.<br />

(Source: Vesseltracker; Photo: Havariekommando)<br />

HELICOPTERS TO REMOVE PIECES OF RENA WRECK<br />

US salvors, Resolve, have been<br />

appointed to reduce the size of the<br />

bow of the wreck of the Rena, using<br />

helicopters to lift sections as they are<br />

cut. Captain John Owen, senior<br />

claims manager with Rena insurer<br />

The Swedish Club, said Resolve's plan<br />

would allow the wreck to be reduced<br />

in a controlled and safe way. "This is<br />

a very difficult and potentially<br />

dangerous location to conduct<br />

operations," he said. The appointment<br />

of Resolve was announced today<br />

during a trip to Motiti Island by Athens-based Konstantinos Zacharatos, a director and legal counsel<br />

for Greek-owned <strong>com</strong>pany Costamare whose subsidiary Daina Shipping owned the Rena. "The<br />

appointment of Resolve is the next important step in dealing with the issues arising from this<br />

regrettable incident," Zacharatos said. "After the grounding in October last year we have been<br />

closely managing the work of our environmental agents (Braemar Howells) and salvors (Svitzer)."<br />

Rena, a 236-metre-long Liberian-flagged cargo vessel, caused an environmental disaster after it<br />

struck Astrolabe Reef off Tauranga while travelling from Napier to Tauranga. The condition of the<br />

wreck deteriorated, and on January 10 the position of the stern section of the Rena began to change<br />

significantly. Within about 90 minutes about 75 per cent of the stern was under water. A<br />

spokesperson for the owners and insurers said Resolve already had people in the area, and the work<br />

of reducing the bow was expected to start in the next couple of weeks. That job, cutting the bow<br />

section down to one-metre below the low tide mark, was expected to take six months, depending on<br />

factors such as the weather. At the same time as work was under way on the bow, investigations<br />

10/22

13 TH VOLUME, NO. <strong>33</strong> DATED 19 AUGUST <strong>2012</strong><br />

would be carried out to determine what should be done with the rest of the ship, the spokesperson<br />

said. On Monday, Zacharatos apologised for the disaster in a series of meetings involving Maori and<br />

officials and representatives from the Bay of Plenty. It was also revealed the ship's owners and<br />

insurers had so far spent $200 million on the salvage operation, of which $70 million had been spent<br />

in the local economy. (Source: Stuff.co.nz)<br />

WRECK REMOVAL DUE TO START<br />

Advertisement<br />

11/22<br />

The salvage <strong>com</strong>pany Buksér og Berging has<br />

been contracted to remove the wreck of the<br />

"Ramnfjord" which has been on the<br />

Hakaskjæret at Hustadvika since it ran aground<br />

on Apr 12. The <strong>com</strong>pany has previously been<br />

involved in clearing the casualty for diesel and<br />

machine oil, and was to start wreck removal on<br />

Aug 14. After the "Ramnfjord" is removed from<br />

the reef, it is to be towed to Stokksund in Sør-<br />

Trøndelag for scrapping. (Source: Vesseltracker<br />

& Tidens Krav; Photo: Buksér og Berging)<br />

COSTA CONCORDIA UPDATE: SALVAGE TIMELINE ALTERED, WRECK<br />

SITE PROVIDES LOCAL TOURISM BOOM<br />

The refloating of the wrecked Costa<br />

Concordia cruise ship is expected to be<br />

delayed until the spring of 2013. Project<br />

officials had expected to upright the<br />

semi-submerged vessel around mid-<br />

January, but now that's not likely to<br />

happen until March or April 2013. The<br />

salvage plan has to be constantly updated<br />

as different technologies and operational<br />

solutions are tested to ensure feasibility<br />

and effectiveness. Drilling techniques<br />

have been revised based on seabed<br />

mapping to minimize environmental impact. Engineering and construction elements for the

13 TH VOLUME, NO. <strong>33</strong> DATED 19 AUGUST <strong>2012</strong><br />

installation of underwater platforms also were updated, reports the Sun-Sentinel newspaper. Titan<br />

Salvage, along with Italian firm Micoperi, is handling the Concordia salvage contract and is expected<br />

to refloat and remove the luxury liner in one piece to avoid environmental damage. The refloating<br />

still requires watertight chambers to be attached to the ship's side that's above water, and cranes<br />

attached to the platform will then pull the ship upright, helped by the water-filled chambers. Once<br />

on the platform, more chambers will be attached to the other side of its hull, and then the chambers<br />

will be drained and filled with air. When upright, the Concordia will be towed to an Italian port.<br />

More recently, tourists and onlookers can pay about US$12 and take a daytrip to view the wreck.<br />

Ferries pass within meters of the capsized ship. Ironically, the disaster that took over 30 lives has<br />

ignited a boom for Giglio’s tourism industry. Officials on the island want the wreck removed as soon<br />

as possible and prefer recognition for their landscape and environment. Lastly, the formal<br />

investigation into the incident is ongoing. Costa Crociere, the cruise ship’s operator, and the<br />

Concordia’s captain are being probed. People want to know why the ship was sailing so close to the<br />

island at high speed, and why the evacuation was delayed for more than an hour after the crash<br />

when the vessel was already listing badly. No trial is expected before 2013. (Source: The Maritime<br />

Executive)<br />

OCEAN BREEZE ON SAN ANTONIA BEACH<br />

Coming from Arica, the<br />

"Ocean Breeze" was pushed<br />

on the beach off the port of<br />

San Antonio, Chile, in the<br />

early morning of Aug 16,<br />

<strong>2012</strong>. Heavy swells caused<br />

the ship, which had been<br />

anchoring two days off the<br />

port, to go adrift until the<br />

ship was washed up on the<br />

beach, where it was<br />

pounded by the surf. Its 24<br />

crew members were<br />

rescued. A helicopter hoisted them off the casualty. (Source: Vesseltracker; Photo: J.Carlos C)<br />

OFFSHORE NEWS<br />

NEW VESSELS AND CHARTERS FOR TOPAZ<br />

Topaz Energy and Marine (“Topaz”), a UAE-based oil field services <strong>com</strong>pany, has been awarded two<br />

new long term charters, totalling over $65 million, in the GCC and the Caspian Sea, two of the<br />

<strong>com</strong>pany’s major operating areas. It also confirms the acquisition of Topaz Rayyan and Caspian<br />

Reliance, two Anchor Handling Tug Supply Vessel (AHTS). Topaz Rayyan, will be deployed in<br />

Qatar on a seven-year, $50 million charter, for an international oil <strong>com</strong>pany (“IOC”). The vessel was<br />

built in 2006 and was previously owned by Sanko Steamship Co Ltd in Japan. The second AHTS,<br />

Caspian Reliance, is to be deployed in the Caspian Sea with a firm contract value of $13.9 million. It<br />

is a new, untraded vessel formerly owned by Boluda Ltd. The vessels are 100-T DP-2 Anchor<br />

Handling Tug Supply Vessels (AHTS) and both will undergo a $2 million upgrade to meet client<br />

specific requirements. Advanced DP-2 is a standard required increasingly by IOCs, which allows<br />

12/22

13 TH VOLUME, NO. <strong>33</strong> DATED 19 AUGUST <strong>2012</strong><br />

vessels to remain accurately in position for<br />

long durations. Roy Donaldson, COO of<br />

Topaz Marine & Energy said: “The<br />

addition of these two vessels increases the<br />

number of more technologically advanced<br />

DP-2 vessels in our fleet. Our strategic<br />

focus on modern technology ensures our<br />

vessels meet the standards required<br />

increasingly by our major international oil<br />

clients. These acquisitions ensure that<br />

Topaz’s fleet remains one of the youngest<br />

operators in the world.” Topaz has been<br />

operating under long-term contracts in<br />

Qatar for the past five years. The Topaz Rayyan will be joining their 35 existing vessels in<br />

supporting their operations in the Middle East. Earlier in the year, Topaz Marine Saudi Arabia, a<br />

joint-venture with Saudi-based GENTAS, was awarded a three-year, $88 million charter for the six<br />

AHTS vessels by Saudi Aramco. Within the Caspian Sea, Topaz has been present in Azerbaijan since<br />

the acquisition of BUE Marine in 2005 and currently operates 25 vessels supporting oil<br />

majors.Furthermore, Topaz is also <strong>com</strong>pleting the delivery of two AHTS vessels, Topaz Dignity on<br />

behalf of BP Azerbaijan and the Topaz Triumph on behalf of West African clients. Both are due to<br />

be deployed on long-term contracts. (Source: Press Release; Photo vesseltracker)<br />

Advertisement<br />

13/22

13 TH VOLUME, NO. <strong>33</strong> DATED 19 AUGUST <strong>2012</strong><br />

CONTRACT AWARD FOR NOR TIGERFISH<br />

Solstad Offshore ASA (SOFF) has been<br />

awarded a contract with a large oil <strong>com</strong>pany<br />

for the 5,500 bhp AHTS «Nor Tigerfish». The<br />

duration of the contract is 1 year firm and with<br />

2x3 months options. The new contract will<br />

<strong>com</strong>mence during August -12. Total value for<br />

the firm contract is approximatly USD 9,5<br />

million. (Source: Solstad Offshore)<br />

HARVEY GULF BECOMES FIRST U.S. COMPANY TO CONTRACT LNG-<br />

POWERED OSVS<br />

Harvey Gulf International Marine<br />

announced that it has signed long<br />

term charters for 3 of its LNG<br />

powered Offshore Supply Vessels,<br />

making Harvey Gulf the first<br />

<strong>com</strong>pany to build and contract<br />

Liquefied Natural Gas powered<br />

Offshore Support Vessels for<br />

Deepwater Exploration and<br />

Production in America. The Harvey<br />

Energy, Harvey Power and Harvey<br />

Liberty will begin providing<br />

deepwater OSV services immediately<br />

upon delivery in 2013 and 2014. Harvey Gulf also announced that it took delivery of its final Tiger-<br />

Shark Class 300’ Offshore Supply Vessel, the Harvey Champion, on August 8, <strong>2012</strong>. Immediately<br />

following delivery, the Champion began a multi-year charter for operation in the U.S. Gulf of<br />

Mexico. Harvey Gulf's CEO, Shane Guidry, says that he was able to appreciate, years before his<br />

<strong>com</strong>petitors, the advantage of using LNG for his Vessels’ fuel source. According to Mr. Guidry “The<br />

operations savings, coupled the stringent emissions rules that begin in August and will increase over<br />

the <strong>com</strong>ing years, will put our customers in the best possible position to operate. In additional<br />

running on cleaner and cheaper natural gas, customers will not have to depend on Scrubber Systems<br />

using particulate filters and Urea, which can increase the cost of fuel by as much as 30 percent. Mr.<br />

Guidry also believes that LNG Vessels will assist in making it possible customers to drill in the<br />

Eastern Gulf in the near future, where permitting is likely to require the best available technology<br />

and practices for containment of emissions. Harvey Gulf also announced that it contracted with a<br />

shipyard to construct a dry-dock measuring 320' x 120' x 12', with 9000 Long tons of lifting capacity.<br />

Mr. Guidry <strong>com</strong>mented “with a fleet of 32 deepwater vessels and 6 additional ones on the drawing<br />

board, the dock will lower our maintenance and repair costs and reduce vessel downtime by<br />

eliminating delays from limited availability of dry-docks for high deadweight capacity vessels.”<br />

When the dock delivers in 2013, it will be placed at one of the two terminals the <strong>com</strong>pany is<br />

building in Port Fourchon, Louisiana. Harvey Gulf will also provide dry-dock related services to<br />

other vessel operators. (Source: Harvey Gulf International Marine)<br />

14/22

13 TH VOLUME, NO. <strong>33</strong> DATED 19 AUGUST <strong>2012</strong><br />

Advertisement<br />

SCI TAKES DELIVERY OF NEW PSV FROM COCHIN SHIPYARD<br />

Today, Cochin Shipyard<br />

Limited delivered the new<br />

high-tech Rolls Royce<br />

Platform Supply Vessel of UT<br />

755 CD design. The ship “SCI<br />

Nalanda’ was delivered to<br />

Shipping Corporation of India<br />

in the presence of the CMD,<br />

SCI, Shri S Hajara and CMD,<br />

CSL, Cmde K Subramaniam.<br />

The Protocol documents of<br />

the ship were signed in the<br />

yard by Capt. R S Sundar,<br />

Director (Operations) on<br />

behalf of CSL and Capt. K<br />

Devadas, Senior Vice President (T&OS), on behalf of SCI Symbolizing the acquisition of the new<br />

vessel Capt. VSM Nair, Master designate of the vessel received the registration documents of the<br />

vessel from Shri S Hajara. This is the first in the series of two high technology offshore vessels being<br />

built by CSL for SCI and is based on the UT 755 CD design of Rolls Royce. With the delivery of this<br />

high end, high performance vessel, Cochin Shipyard enters the league of select international yards<br />

capable of building such vessels. The vessel is dually classed under the Rules and Regulations of Det<br />

Norske Veritas (DNV) and Indian Register of Shipping (IRS) and registered under the Indian flag<br />

with Mumbai as the homeport. This 79 x 16 Metre vessel is a high end Diesel Electric PSV with 4<br />

Nos 994 KW Diesel gensets and 2 Nos 1470 KW Azimuth thrusters. The vessel with redundant<br />

dynamic positioning (DP2) system features has been assigned the ‘CLEAN DESIGN’ notation by<br />

DNV signifying the highest levels of environmental <strong>com</strong>pliance. The vessel <strong>com</strong>plies with the<br />

highest levels of Comfort class COMF-V(3)C(3) requirement which signifies extremely low noise<br />

and vibration level as also high degree of human <strong>com</strong>fort in the ac<strong>com</strong>modation. The NAUT OSV<br />

(A) notation on the vessel means that the vessel’s bridge systems are laid down meeting stringent<br />

ergonomic and safety requirements. The vessel is also equipped with external fire fighting (FiFi-1)<br />

equipment, inerted stainless steel tanks for carriage of low flash liquids like methanol and is fully<br />

outfitted to meet UKOOA type-C requirements for emergency rescue and recovery functions for up<br />

to 20 rescues. The above features mean that the vessel is in the highest grade of PSVs which can<br />

meet the most demanding requirements of all global oil majors. The second & last vessel in the series<br />

is expected to be delivered next month to SCI. Cochin Shipyard is presently constructing 28 ships –<br />

15/22

13 TH VOLUME, NO. <strong>33</strong> DATED 19 AUGUST <strong>2012</strong><br />

20 Fast Patrol Vessels for Coast Guard, 7 Offshore Support ships to Indian and Foreign owners and<br />

the prestigious Aircraft Carrier for the Indian Navy. The yard had <strong>com</strong>pleted the technical float out<br />

of the Aircraft Carrier in Dec 2011 after <strong>com</strong>pleting a record 15000 Tons of work in 3 years. The<br />

yard continued to post good financial performance even in the aftermath of the withdrawal of<br />

shipbuilding subsidy by GOI. (Source: CochinShipyard)<br />

SIEM SWORDFISH SALE COMPLETED<br />

Siem Offshore says the sale and delivery of Siem Swordfish was concluded on 31 July in line with<br />

the charterer’s purchase option, which was exercised in December 2009. The gross sales proceeds<br />

amounted to US$54 million. The proceeds will be used to repay bank debt and to strengthen<br />

working capital by US$16 million in order to support the <strong>com</strong>pany’s newbuilding program. (Source:<br />

OSO)<br />

DOF WINS FPSO MOORING CONTRACT IN INDIA<br />

DOF Subsea Asia Pacific, a<br />

subsidiary of DOF ASA has<br />

received a Letter of Award for<br />

the installation of a FPSO<br />

mooring system in India and the<br />

project management and<br />

engineering associated with the<br />

hookup and <strong>com</strong>missioning of<br />

the FPSO. The work will be<br />

executed in Q4 <strong>2012</strong> and is<br />

valued at USD 16m. Steve<br />

Brown, EVP, Asia Pacific said<br />

"this, and other recent awards,<br />

build on the excellent track<br />

record that DOF Subsea has in the region. Our Project Management and Engineering capability<br />

along with our regional fleet the Skandi Hercules, Skandi Singapore and Skandi Hawk are central to<br />

our drive to achieve ever higher standards of safety, quality and reliability. We look forward to<br />

working with our clients to deliver safe and successful projects." Skandi Hercules, the vessel to be<br />

used for the operation is a versatile multipurpose Construction Anchor Handling Vessel, ideally<br />

suited to deepwater mooring and field installation operations. Built to meet future environmental<br />

standards, the vessel is fuel efficient and clean class, thus having the capability to work in most of<br />

the world’s offshore| oil & gas precincts. At 108 m long, operating capabilities include a working<br />

moonpool, a 1401 Offshore Crane, "Safe Deck" manipulator crane system, a main winch capacity of<br />

500 t and secondary of 170 t and a bollard pull of 3501. (Source: DOF Subsea)<br />

PERDANA PETROLEUM LOOKING TO EXPAND<br />

Perdana Petroleum Bhd is looking into the possibility of buying more vessels as it feels that the<br />

market is now slowly moving into the right direction, said its managing director, Shamsul Saad. The<br />

<strong>com</strong>pany presently has 14 vessels which <strong>com</strong>prises of eight units of anchor handling tug supply<br />

(AHTS) vessels, two 5,000 BHP AHTS, six mid-size AHTS between 10,000 and 12,000 BHP and six<br />

maintenance & hook-up work vessels being four work barges and two workboats. "We are working<br />

16/22

13 TH VOLUME, NO. <strong>33</strong> DATED 19 AUGUST <strong>2012</strong><br />

closely with Dayang Enterprise Bhd for our long term business model. We are aiming to participate<br />

in more long term charters towards the year end," said Shamsul. Dayang is Perdana Petroleum's<br />

strategic shareholder with a 14.88% stake. While Perdana Petroleum has been in the red over the<br />

last two years, Shamsul is cautiously optimistic over the <strong>com</strong>pany's prospects this year, as most of<br />

the aggressive writedown on its old vessels have been <strong>com</strong>pleted. Meanwhile, Perdana received<br />

99.99% shareholder approval yesterday, for its proposed divestment of its 57.7 million shares of a<br />

26.9% stake in Petra Energy, amounting to RM96.94mil or RM1.68 per share. The block is being<br />

sold to Wah Seong Corp Bhd. When the proposed divestment was first announced on April 26,<br />

Petra Energy was trading at the RM1.06 range. Since then, it has been rocketing up. It closed<br />

Thursday, up 10 sen to RM1.79 on volume of 1.9 million shares. (Source: The Star)<br />

SKANDI CHIEFTAIN RSV REMAINS WITH PETROBRAS<br />

Norskan / DOF Subsea Brazil<br />

have agreed with Petrobras a<br />

2 year extension for Skandi<br />

Chieftain RSV. The contract<br />

will <strong>com</strong>mence in 3Q <strong>2012</strong>.<br />

Skandi Chieftain, equipped<br />

with Kongsberg Simrad DP1<br />

dynamic positioning system,<br />

is a ROV Support Vessel with<br />

ROVs and various deck<br />

mounted subsea equipment.<br />

The vessel built in 2005 has<br />

been working for the<br />

Brazilian oil giant since 2009.<br />

Skandi Chieftain, powered<br />

by 4 Mitsubishi engines (each 1190kW/ 1618 bhp, 1800 rpm), can ac<strong>com</strong>modate 22 persons. Also,<br />

Helix Well Ops, a business unit of international offshore energy <strong>com</strong>pany Helix Energy Solutions<br />

Group (Helix ESG), yesterday reported it had chartered DOF’s Skandi Constructor vessel. DOF has<br />

revealed that total contract values for the firm periods are approximately NOK 825 million ($138.7<br />

million). (Source: Offshore Energy Today; Photo: Jan Plug)<br />

MICLYN EXPRESS OFFSHORE TAKES DELIVERY OF MSV<br />

17/22<br />

Miclyn Express Offshore takes delivery of 2011<br />

built 70m Maintenance Support Vessel,<br />

renamed “MEO Galaxy”. Headquartered in<br />

Singapore Miclyn Express Offshore group of<br />

<strong>com</strong>panies is a leading provider of service<br />

vessels to the expanding offshore oil and gas<br />

industry, across South East Asia, Australia and<br />

the Middle East. MEO Galaxy is an ideal vessel<br />

to provide support for platform maintenance,<br />

as well as HUC operations. The fully SPS<br />

<strong>com</strong>pliant vessel is capable of carrying 150<br />

persons and is fitted with a 4 point mooring

13 TH VOLUME, NO. <strong>33</strong> DATED 19 AUGUST <strong>2012</strong><br />

system, <strong>com</strong>bined with a clear deck area of in excess of 600m2 and a 25tonne deck crane. The vessel<br />

has a service speed of 12 knots with twin 1750bhp main engines. The first deployment will see the<br />

vessel operating in Malaysia in the medium term, however strong demand both within South East<br />

Asia and the Middle East looks to provide a strong future for the vessel elsewhere. (Press Release<br />

MEO)<br />

Advertisement<br />

HELIX WELL OPS CHARTERS SKANDI CONSTRUCTOR<br />

Aberdeen-based Helix Well Ops UK<br />

(Well Ops), a business unit of<br />

international offshore energy <strong>com</strong>pany<br />

Helix Energy Solutions Group (Helix<br />

ESG), is expanding its Europe and Africa<br />

well intervention fleet with an<br />

investment that will create 60 jobs. A<br />

leading global provider of subsea well<br />

intervention, Well Ops will take control<br />

of the mono-hull well intervention vessel<br />

Skandi Constructor in spring 2013, after<br />

agreeing a three-year charter with DOF<br />

Subsea. The move to strengthen Well Ops’ regional fleet, which currently includes the 132-metre<br />

(4<strong>33</strong>ft) long Well Enhancer and the 114-metre (374ft) long MSV Seawell, will lead to the creation of<br />

approximately 50 jobs offshore and a further 10 onshore over the next nine months. At the moment<br />

the firm employs 70 staff in Aberdeen and a further 300 offshore. Launched in 2009, Skandi<br />

Constructor is a 120-metre (393ft) long Ulstein SX121 DP3 mono-hull well intervention vessel that<br />

features the new X-bow design. The 8,500-tonne vessel ac<strong>com</strong>modates up to 100 personnel and is<br />

capable of working in depths of up to 3,000 metres (9,842ft). It has a deck capacity of 1,470 square<br />

metres (15,822 sq ft) and features an 8m x 8m (27ft x 27ft) moon-pool, a 150-tonne crane, a multipurpose<br />

tower with 140-tonne lift capability and two work class ROVs. Well Ops will build and test,<br />

ready for use, a specially designed version of its 7⅜” subsea intervention lubricator (SIL) to enable<br />

subsea well interventions to be undertaken from Skandi Constructor. The SIL is a single trip well<br />

intervention system that provides well access, while managing containment when the well is ‘live’<br />

and under pressure. The SIL is configured to undertake work through all types of subsea xmas trees.<br />

The vessel and SIL will allow Well Ops to provide its regional clients with a solution for deeper<br />

water wells and well interventions, which to date has been limited within the mono-hull vessel<br />

market. (Press Release Helix)<br />

18/22

13 TH VOLUME, NO. <strong>33</strong> DATED 19 AUGUST <strong>2012</strong><br />

DUTCH OPERATOR HIRES SEASAFE SUPPORTER FOR GABON OPS<br />

Otto Marine Limited, a leading offshore<br />

marine <strong>com</strong>pany which specializes in<br />

building <strong>com</strong>plex offshore support<br />

vessels, ship chartering and offers<br />

specialized offshore services, has<br />

secured a time-charter contract for its<br />

Maintenance and<br />

Construction/Ac<strong>com</strong>modation support<br />

vessel, Seasafe Supporter, for a firm 500<br />

days with an option to extend for 2<br />

months. Seasafe Supporter is an ABSclassed<br />

support vessel capable of<br />

ac<strong>com</strong>modating 90 men. It is fully<br />

equipped with 4-point mooring system, 45 Tonne Deck Pedestal crane with 120 foot boom and is<br />

also DP zero /DP1 capable. The Group’s wholly-owned subsidiary, Global Workboats, will charter<br />

Seasafe Supporter to a Dutch operator who will in-turn deploy this vessel to support offshore works<br />

in Gabon, west coast of Africa. (Press Release: Otto Marine)<br />

SUPER AMPELMANN ONBOARD REM STAR<br />

This month, the platform supply vessel<br />

Rem Star is equipped with a Super<br />

Ampelmann Walk-to-Work system. It<br />

concerns a system (E-type), one and a<br />

half times as large as the standard<br />

Ampelmann Walk-to-Work systems.<br />

The new system is not only equipped<br />

with a telescopic gangway, but also<br />

with a telescopic crane. The Rem Star is<br />

part of the Southern North Sea (SNS)<br />

Pool, managed by Peterson SBS from<br />

Den Helder, the Netherlands, and is<br />

deployed by NAM/Shell for<br />

maintenance work on fixed platforms<br />

in the southern part of the North Sea. (Source and photo Paul Schaap)<br />

NEW CTRUK VIDEO CASE STUDY<br />

WINDFARM NEWS<br />

Herewith just wanted to let you know that CTruk have released a new video case study,<br />

demonstrating the effectiveness of our 20T MPC design for Offshore Turbine Services. OTS have<br />

two 20Ts in operation, with a third due to launch later this month. You can watch the short video<br />

here (Source: CTruk Boats Ltd.)<br />

19/22

13 TH VOLUME, NO. <strong>33</strong> DATED 19 AUGUST <strong>2012</strong><br />

HGO TAKES DELIVERY OF HEAVY LIFT JACK-UP VESSEL IN POLAND<br />

Overdick has announced that the<br />

Heavy Lift Jack-Up Vessel<br />

“Innovation” has successful<br />

<strong>com</strong>pleted sea and jacking trials and<br />

has been delivered to their clients of<br />

HGO Infra Sea Solutions<br />

(HOCHTIEF Solutions and GeoSea)<br />

by the shipyard Crist in Gdynia. The<br />

HLJV “Innovation” has been designed<br />

by Overdick with the support of<br />

Wärtsilä Ship Design. Overdick has<br />

described the vessel as “the most<br />

capable Jack-Up Crane unit in the<br />

world.” The vessel will be used to<br />

build and maintain offshore wind farms as well as offshore oil and gas facilities. (Source: Offshore<br />

Energy Today)<br />

ALICAT WORKBOATS SELLS CREW TRANSFER VESSEL TO DALBY<br />

OFFSHORE RENEWABLES<br />

Dalby Offshore Renewables purchased<br />

Boat 12 from Alicat Workboats of<br />

Great Yarmouth, after it bought two<br />

crew transfer vessels from the Great<br />

Yarmouth’s <strong>com</strong>pany earlier this year.<br />

Prior to purchasing the two crew<br />

transfer vessels, Dalby put the Alicat<br />

through its paces with various sea trials<br />

and an exhaustive evaluation process,<br />

however the vessel passed with flying<br />

colours and stood out as a superior<br />

vessel. The <strong>com</strong>pany was impressed<br />

with the first two vessels so it<br />

purchased Alicat Boat 12 directly from<br />

the production line, further strengthening the relationship between the two organisations. (Source:<br />

Alicat Workboats)<br />

YARD NEWS<br />

ARCTECH VESSEL DELIVERED IN ADVANCE<br />

The offshore supply vessel ‘Vitus Bering’, being built by Arctech Helsinki Shipyard, will be finalised<br />

and delivered four months in advance of its initial delivery date. The vessel is one of two being built<br />

by Helsinki Shipyard – a joint venture owned by STX Finland and United Shipbuilding Corporation<br />

– for Russian shipping group Sov<strong>com</strong>flot (SCF Group). The vessels will supply Exxon Neftegas<br />

20/22

13 TH VOLUME, NO. <strong>33</strong> DATED 19 AUGUST <strong>2012</strong><br />

Limited’s oil and gas<br />

production platform in the<br />

Arkutun-Dagi field in the<br />

fast developing Sakhalin<br />

area of Far East Russia.<br />

Esko Mustamäki,<br />

managing director,<br />

Arctech Helsinki<br />

Shipyard, said: "Modern<br />

design and long term<br />

shipbuilding experience<br />

are <strong>com</strong>bined in these<br />

projects. The finalising of<br />

the vessels four months in<br />

advance has required<br />

excellent cooperation and team spirit. I’m sure that they are a good start for prospective projects<br />

with participation of Russian United Shipbuilding Corporation and Sov<strong>com</strong>flot for future work in<br />

the Russian Arctic." The vessels, which measure 99.9m in length and 21.7m in breadth, have been<br />

specially designed for extreme environmental conditions. With a total power of 18,000kW, the<br />

vessels will be capable of drifting through ice in temperatures as cold as minus 35°C. Independently,<br />

the vessels will operate in 1.7m thick ice and will carry various types of cargo. (Source: The<br />

Motorship; Photo: J. Koskimies)<br />

NEW BARGE FOR SOUTH PARS JACKETS TRANSPORTATION<br />

Sadra Shipbuilding Plant in<br />

Busher has launched its<br />

second barge for<br />

transportation of platform<br />

jackets for the offshore<br />

South Pars field<br />

developments, Pars Oil and<br />

Gas <strong>com</strong>pany reports.<br />

Mahdis II, a 1,500-metric<br />

ton (1,654-ton) vessel, is 84<br />

m (275 ft) long, with a<br />

breadth of 27 m (88 ft),<br />

height of 6 m (19 ft), and<br />

draft of 4.7 m (15 ft). Its<br />

loading capacity is 7,000 metric tons (7,716 tons). The vessel was built in six months. This vessel and<br />

its forerunner Mahdis I, launched last year, will transport jackets for South Pars phases 13 and 22.<br />

Previously, Iran used foreign chartered vessels for transportation programs. The second 2,000-metric<br />

ton (2,205-ton) jacket for the South Pars A-19 platform has been installed at its offshore location. A<br />

second drilling derrick, designed to drill five wells, should head offshore shortly. The C-19 derrick is<br />

deployed at the South Pars 19 site. Phase 19 calls for drilling 21 wells. Petropars and Iranian<br />

Offshore Engineering and Construction Co. are responsible for the development, designed to deliver<br />

50 MMcm/d (1.76 bcf/d) of sweet gas, 75,000 b/d of gas condensates, 400 tons of sulfur, and annual<br />

production of 1.05 MM tons of liquefied gas and 1 MM tons of ethane. (Source: South Pars)<br />

21/22

13 TH VOLUME, NO. <strong>33</strong> DATED 19 AUGUST <strong>2012</strong><br />

WEBSITE NEWS<br />

HTTP://WWW.TOWINGLINE.COM<br />

ARE YOU ALSO INTERES T ED IN THIS FREE TUGS TOW ING & OFFSHO RE NEWSLETTER.<br />

PLEASE VIS IT THE WEBS ITE WWW.TO W I N G L I N E . C O M AND S UBSCRIBE YOURSE LF FOR FREE<br />

Last week there have been new updates posted:<br />

1. Several updates on the News page posted last week:<br />

Marcon International Brokering Tarsiut Island Caissons in Arctic<br />

Still no permission for MSC FLAMINIA to enter a sheltered area<br />

Record revenue and order book Boskalis first half <strong>2012</strong><br />

Teekay – KOTUG Joint Venture to Pursue Opportunities In Australian Towage<br />

Market<br />

Another eight containers recovered from the RENA<br />

New RAmparts 3200-W Class Tug for Saudi Ports Authority<br />

Salvors MSC Flaminia stabilize the vessel<br />

U.S. destroyer collides with oil tanker at entrance to Gulf<br />

mailto:Please note that my e-mail address has changed into jvds@towingline.<strong>com</strong><br />

This site is intended to be collective exchange of information. Information on this site has been pulled from many sources; we have<br />

attempted to credit these sources. But due to the multitude of sources sometimes we are unable to note all the sources. If you feel that<br />

material that is posted here is of your authorship and you have not been credited properly please alert us and I will correct the credit or<br />

remove it in accordance to the author's wishes.<br />

DISCLAIMER<br />

The <strong>com</strong>piler of the Tugs Towing & Offshore <strong>Newsletter</strong> disclaim all liability for any loss, damage or expense however caused, arising<br />

from the sending, receipt, or use of this e-mail <strong>com</strong>munication and on any reliance placed upon the information provided through this<br />

free service and does not guarantee the <strong>com</strong>pleteness or accuracy of the information. For more information about advertising,<br />

subscription, preferences and un-subscription visit the website: http://www.towingline.<strong>com</strong> The Tugs Towing & Offshore <strong>Newsletter</strong> is a<br />

::JVDS-MARCOL:: Archive Production.<br />

22/22