ALJOIN Final Technical Report - Transport Research & Innovation ...

ALJOIN Final Technical Report - Transport Research & Innovation ...

ALJOIN Final Technical Report - Transport Research & Innovation ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Contract N° G3RD-CT-2002-00829<br />

<strong>Final</strong> <strong>Technical</strong> <strong>Report</strong> – draft 1<br />

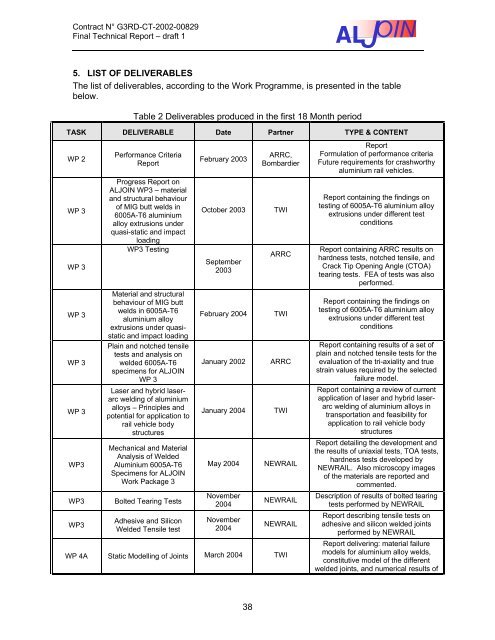

<strong>ALJOIN</strong> 5. LIST OF DELIVERABLES<br />

The list of deliverables, according to the Work Programme, is presented in the table<br />

below.<br />

Table 2 Deliverables produced in the first 18 Month period<br />

TASK DELIVERABLE Date Partner TYPE & CONTENT<br />

WP 2<br />

WP 3<br />

WP 3<br />

WP 3<br />

WP 3<br />

WP 3<br />

WP3<br />

Performance Criteria<br />

<strong>Report</strong><br />

Progress <strong>Report</strong> on<br />

<strong>ALJOIN</strong> WP3 – material<br />

and structural behaviour<br />

of MIG butt welds in<br />

6005A-T6 aluminium<br />

alloy extrusions under<br />

quasi-static and impact<br />

loading<br />

WP3 Testing<br />

Material and structural<br />

behaviour of MIG butt<br />

welds in 6005A-T6<br />

aluminium alloy<br />

extrusions under quasistatic<br />

and impact loading<br />

Plain and notched tensile<br />

tests and analysis on<br />

welded 6005A-T6<br />

specimens for <strong>ALJOIN</strong><br />

WP 3<br />

Laser and hybrid laserarc<br />

welding of aluminium<br />

alloys – Principles and<br />

potential for application to<br />

rail vehicle body<br />

structures<br />

Mechanical and Material<br />

Analysis of Welded<br />

Aluminium 6005A-T6<br />

Specimens for <strong>ALJOIN</strong><br />

Work Package 3<br />

WP3 Bolted Tearing Tests<br />

WP3<br />

Adhesive and Silicon<br />

Welded Tensile test<br />

February 2003<br />

ARRC,<br />

Bombardier<br />

October 2003 TWI<br />

September<br />

2003<br />

ARRC<br />

February 2004 TWI<br />

January 2002 ARRC<br />

January 2004 TWI<br />

May 2004 NEWRAIL<br />

November<br />

2004<br />

November<br />

2004<br />

NEWRAIL<br />

NEWRAIL<br />

WP 4A Static Modelling of Joints March 2004 TWI<br />

38<br />

<strong>Report</strong><br />

Formulation of performance criteria<br />

Future requirements for crashworthy<br />

aluminium rail vehicles.<br />

<strong>Report</strong> containing the findings on<br />

testing of 6005A-T6 aluminium alloy<br />

extrusions under different test<br />

conditions<br />

<strong>Report</strong> containing ARRC results on<br />

hardness tests, notched tensile, and<br />

Crack Tip Opening Angle (CTOA)<br />

tearing tests. FEA of tests was also<br />

performed.<br />

<strong>Report</strong> containing the findings on<br />

testing of 6005A-T6 aluminium alloy<br />

extrusions under different test<br />

conditions<br />

<strong>Report</strong> containing results of a set of<br />

plain and notched tensile tests for the<br />

evaluation of the tri-axiality and true<br />

strain values required by the selected<br />

failure model.<br />

<strong>Report</strong> containing a review of current<br />

application of laser and hybrid laserarc<br />

welding of aluminium alloys in<br />

transportation and feasibility for<br />

application to rail vehicle body<br />

structures<br />

<strong>Report</strong> detailing the development and<br />

the results of uniaxial tests, TOA tests,<br />

hardness tests developed by<br />

NEWRAIL. Also microscopy images<br />

of the materials are reported and<br />

commented.<br />

Description of results of bolted tearing<br />

tests performed by NEWRAIL<br />

<strong>Report</strong> describing tensile tests on<br />

adhesive and silicon welded joints<br />

performed by NEWRAIL<br />

<strong>Report</strong> delivering: material failure<br />

models for aluminium alloy welds,<br />

constitutive model of the different<br />

welded joints, and numerical results of