A380: the countdown is on - Orient Aviation

A380: the countdown is on - Orient Aviation

A380: the countdown is on - Orient Aviation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

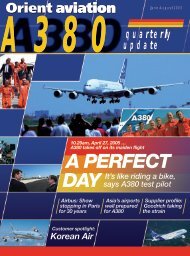

<str<strong>on</strong>g>A380</str<strong>on</strong>g> ASSEMBLY<br />

By Charles Anders<strong>on</strong><br />

It <str<strong>on</strong>g>is</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> sheer size of <str<strong>on</strong>g>the</str<strong>on</strong>g>m that makes<br />

you gasp – three of <str<strong>on</strong>g>the</str<strong>on</strong>g> largest<br />

passenger aircraft ever made sitting<br />

side by side in enormous stati<strong>on</strong>s at<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> open plan final assembly hall in<br />

Toulouse.<br />

Walk above <str<strong>on</strong>g>the</str<strong>on</strong>g>se first <str<strong>on</strong>g>A380</str<strong>on</strong>g>s al<strong>on</strong>g<br />

<strong>on</strong>e of <str<strong>on</strong>g>the</str<strong>on</strong>g> corridors that skirt <str<strong>on</strong>g>the</str<strong>on</strong>g> giant,<br />

purpose-built Jean Luc Lagardère complex<br />

and <str<strong>on</strong>g>the</str<strong>on</strong>g>ir 80-metre wingspan, 73-metre<br />

length and 24-metre height give you a first<br />

idea of what will be lining up at <str<strong>on</strong>g>the</str<strong>on</strong>g> world’s<br />

major airports in <str<strong>on</strong>g>the</str<strong>on</strong>g> coming years.<br />

Step <strong>on</strong> to <str<strong>on</strong>g>the</str<strong>on</strong>g> shop floor and stand next<br />

to <str<strong>on</strong>g>the</str<strong>on</strong>g> lightly painted “green” aircraft and<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g>y are downright intimidating. The wings<br />

appear to arch forever. The fuselage dwarfs<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> workers surrounding it. The tail plane<br />

reaches up towards <str<strong>on</strong>g>the</str<strong>on</strong>g> sky.<br />

But <str<strong>on</strong>g>the</str<strong>on</strong>g>n ever y thing about th<str<strong>on</strong>g>is</str<strong>on</strong>g><br />

assembly process <str<strong>on</strong>g>is</str<strong>on</strong>g> larger than life: from<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> comp<strong>on</strong>ent manufacturing and sub-<br />

assembly programmes in sites across Europe,<br />

through to <str<strong>on</strong>g>the</str<strong>on</strong>g> giant transportati<strong>on</strong> exerc<str<strong>on</strong>g>is</str<strong>on</strong>g>e<br />

that brings <str<strong>on</strong>g>the</str<strong>on</strong>g> various pieces toge<str<strong>on</strong>g>the</str<strong>on</strong>g>r and <strong>on</strong><br />

to <str<strong>on</strong>g>the</str<strong>on</strong>g> complex work that will finally see <str<strong>on</strong>g>the</str<strong>on</strong>g>m<br />

roll out of <str<strong>on</strong>g>the</str<strong>on</strong>g> factory and fly to Hamburg for<br />

final fitting and painting.<br />

At Toulouse, <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> 50-hectare<br />

producti<strong>on</strong> site, <str<strong>on</strong>g>the</str<strong>on</strong>g> three fuselage secti<strong>on</strong>s,<br />

wings, tail plane, empennage, landing gear<br />

and engine pyl<strong>on</strong>s are turned into a single<br />

airplane after arrival by road c<strong>on</strong>voy at<br />

a holding area <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> north side of <str<strong>on</strong>g>the</str<strong>on</strong>g> plant.<br />

The wings, in particular, need special<br />

attenti<strong>on</strong>. Only two-thirds of <str<strong>on</strong>g>the</str<strong>on</strong>g> fin<str<strong>on</strong>g>is</str<strong>on</strong>g>hed<br />

product can be completed at <str<strong>on</strong>g>the</str<strong>on</strong>g> plant in<br />

Brought<strong>on</strong>, North Wales, where <str<strong>on</strong>g>the</str<strong>on</strong>g>y are<br />

first assembled. They are simply too big to<br />

transport as a complete item. The remaining<br />

<strong>on</strong>e-third of <str<strong>on</strong>g>the</str<strong>on</strong>g> work, mainly adding<br />

movable parts, <str<strong>on</strong>g>is</str<strong>on</strong>g> undertaken in Toulouse.<br />

Next <str<strong>on</strong>g>the</str<strong>on</strong>g> wing <str<strong>on</strong>g>is</str<strong>on</strong>g> fixed to <str<strong>on</strong>g>the</str<strong>on</strong>g> central<br />

fuselage secti<strong>on</strong>, before <str<strong>on</strong>g>the</str<strong>on</strong>g> rest of <str<strong>on</strong>g>the</str<strong>on</strong>g> plane<br />

takes shape. Then it <str<strong>on</strong>g>is</str<strong>on</strong>g> pushed back to <strong>on</strong>e<br />

of three interchangeable stati<strong>on</strong>s where<br />

various systems, including <str<strong>on</strong>g>the</str<strong>on</strong>g> flight c<strong>on</strong>trols<br />

and electrical and hydraulic power units, are<br />

installed. Some systems testing takes place in<br />

th<str<strong>on</strong>g>is</str<strong>on</strong>g> stati<strong>on</strong>. Fur<str<strong>on</strong>g>the</str<strong>on</strong>g>r tests will c<strong>on</strong>tinue outside.<br />

The whole final assembly, fin<str<strong>on</strong>g>is</str<strong>on</strong>g>hing and<br />

testing process takes <strong>on</strong>e m<strong>on</strong>th, with each<br />

plane spending a week in <str<strong>on</strong>g>the</str<strong>on</strong>g> first assembly<br />

stati<strong>on</strong> before moving <strong>on</strong>, allowing Airbus<br />

to hit its target producti<strong>on</strong> rate of four<br />

<str<strong>on</strong>g>A380</str<strong>on</strong>g>s a m<strong>on</strong>th, or to handle fewer planes<br />

if necessary.<br />

LARGER<br />

than life<br />

The company has broken with its<br />

normal practice by having final assembly<br />

of <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>A380</str<strong>on</strong>g> in <strong>on</strong>e place, even though<br />

its comp<strong>on</strong>ents are being manufactured<br />

elsewhere and interior furn<str<strong>on</strong>g>is</str<strong>on</strong>g>hing will be<br />

completed in Hamburg. Its single-a<str<strong>on</strong>g>is</str<strong>on</strong>g>le or<br />

l<strong>on</strong>g-range planes are assembled <strong>on</strong> two or<br />

three different sites.<br />

Jean-Claude Schoepf, vice-president,<br />

final assembly and delivery for <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>A380</str<strong>on</strong>g>,<br />

l<str<strong>on</strong>g>is</str<strong>on</strong>g>ts safety, inventory and <str<strong>on</strong>g>the</str<strong>on</strong>g> space<br />

requirements as <str<strong>on</strong>g>the</str<strong>on</strong>g> main reas<strong>on</strong>s. Again,<br />

Assembly process: “it’s working well”<br />

it <str<strong>on</strong>g>is</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> size of <str<strong>on</strong>g>the</str<strong>on</strong>g> plane, and of <str<strong>on</strong>g>the</str<strong>on</strong>g> project<br />

itself, that led to <str<strong>on</strong>g>the</str<strong>on</strong>g> dec<str<strong>on</strong>g>is</str<strong>on</strong>g>i<strong>on</strong>.<br />

On safety: <str<strong>on</strong>g>the</str<strong>on</strong>g> wing and central<br />

fuselage secti<strong>on</strong> al<strong>on</strong>e weigh 100 t<strong>on</strong>nes and<br />

would need transferring by crane after being<br />

joined toge<str<strong>on</strong>g>the</str<strong>on</strong>g>r under <str<strong>on</strong>g>the</str<strong>on</strong>g> traditi<strong>on</strong>al Airbus<br />

assembly system. “We prefer to remove th<str<strong>on</strong>g>is</str<strong>on</strong>g><br />

and avoid <str<strong>on</strong>g>the</str<strong>on</strong>g> r<str<strong>on</strong>g>is</str<strong>on</strong>g>k of an accident,” he said.<br />

On space: each aircraft positi<strong>on</strong> takes<br />

up <strong>on</strong>e hectare, made up of <str<strong>on</strong>g>the</str<strong>on</strong>g> 80 metre by<br />

80 metre size of <str<strong>on</strong>g>the</str<strong>on</strong>g> plane and <str<strong>on</strong>g>the</str<strong>on</strong>g> margins<br />

surrounding it that are necessary for log<str<strong>on</strong>g>is</str<strong>on</strong>g>tic<br />

flows. With four stati<strong>on</strong>s needed, a single<br />

site where land <str<strong>on</strong>g>is</str<strong>on</strong>g> available made more<br />

sense to <str<strong>on</strong>g>the</str<strong>on</strong>g> Airbus planners.<br />

On log<str<strong>on</strong>g>is</str<strong>on</strong>g>tics: to optim<str<strong>on</strong>g>is</str<strong>on</strong>g>e fixed costs<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> U-shaped final assembly line building<br />

has <str<strong>on</strong>g>the</str<strong>on</strong>g> same amount of empty space lying<br />

parallel to <str<strong>on</strong>g>the</str<strong>on</strong>g> present stati<strong>on</strong>s allowing<br />

three more of <str<strong>on</strong>g>the</str<strong>on</strong>g> same to be built if Airbus<br />

really hits <str<strong>on</strong>g>the</str<strong>on</strong>g> jackpot with <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>A380</str<strong>on</strong>g>.<br />

The Jean Luc Lagardère building, named<br />

after <str<strong>on</strong>g>the</str<strong>on</strong>g> former EADS joint president and<br />

French industrial<str<strong>on</strong>g>is</str<strong>on</strong>g>t who died in 2003,<br />

represents a 360 milli<strong>on</strong> euro (US$432<br />

milli<strong>on</strong>) investment <strong>on</strong> Airbus’s behalf.<br />

Work began <strong>on</strong> it in 2001 and at present it<br />

has 500 to 600 staff and 34,000 sq metres<br />

of office space.<br />

Many workers have been transferred<br />

from o<str<strong>on</strong>g>the</str<strong>on</strong>g>r Airbus programmes under a<br />

system that <strong>on</strong>ly allows a certain percentage<br />

to move, so ex<str<strong>on</strong>g>is</str<strong>on</strong>g>ting projects w<strong>on</strong>’t suffer.<br />

The workforce <str<strong>on</strong>g>is</str<strong>on</strong>g> expected to total 1,500<br />

to 2,000 by 2008 with future recruitment<br />

being expanded outside <str<strong>on</strong>g>the</str<strong>on</strong>g> company.<br />

A static test building and general<br />

purpose hangar make up <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>A380</str<strong>on</strong>g> facilities<br />

<strong>on</strong> th<str<strong>on</strong>g>is</str<strong>on</strong>g> Toulouse site. Nearby, at Toulouse<br />

St Martin, a 19,000 square metre building<br />

houses cockpit simulators and <str<strong>on</strong>g>the</str<strong>on</strong>g> “ir<strong>on</strong><br />

bird” test rig being used for systems<br />

integrati<strong>on</strong> simulati<strong>on</strong> and verificati<strong>on</strong>.<br />

All across Europe, producti<strong>on</strong> of <str<strong>on</strong>g>A380</str<strong>on</strong>g><br />

secti<strong>on</strong>s <str<strong>on</strong>g>is</str<strong>on</strong>g> now underway as Airbus gears<br />

up for entry into service.<br />

In Hamburg, forward and aft fuselage<br />

secti<strong>on</strong>s are assembled, toge<str<strong>on</strong>g>the</str<strong>on</strong>g>r with <str<strong>on</strong>g>the</str<strong>on</strong>g>ir<br />

essential flight systems. O<str<strong>on</strong>g>the</str<strong>on</strong>g>r facilities at<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> Major Comp<strong>on</strong>ent Assembly hall which<br />

opened <str<strong>on</strong>g>the</str<strong>on</strong>g>re in May 2003 are an interior<br />

fin<str<strong>on</strong>g>is</str<strong>on</strong>g>hing centre, a delivery facility, paint<br />

shops and a pre-flight hangar.<br />

In Brought<strong>on</strong>, wing assembly <str<strong>on</strong>g>is</str<strong>on</strong>g><br />

carried out in an 83,000 sq. metre “West<br />

Factory”. Stringers for bottom wing skin<br />

panels are also produced <str<strong>on</strong>g>the</str<strong>on</strong>g>re.<br />

In Getafe and Puerto Real, <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

horiz<strong>on</strong>tal tail plane and <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>A380</str<strong>on</strong>g>’s belly<br />

faring are put toge<str<strong>on</strong>g>the</str<strong>on</strong>g>r.<br />

In Nantes, <str<strong>on</strong>g>the</str<strong>on</strong>g> centre wing box <str<strong>on</strong>g>is</str<strong>on</strong>g><br />

manufactured and assembled.<br />

In Saint Nazaire, an extended<br />

fuselage assembly.<br />

Then begins <str<strong>on</strong>g>the</str<strong>on</strong>g> journey to Toulouse for<br />

final assembly.<br />

“If you go anywhere in our plants today,<br />

you will see <str<strong>on</strong>g>the</str<strong>on</strong>g> factories are full of secti<strong>on</strong>s<br />

for <str<strong>on</strong>g>the</str<strong>on</strong>g> next 30 aircraft,” said Charles<br />

Champi<strong>on</strong>, executive vice-president for <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

<str<strong>on</strong>g>A380</str<strong>on</strong>g> programme. “It’s all working well.”<br />

DECEMBER 2004-FEBRUARY 2005 ORIENT AVIATION / <str<strong>on</strong>g>A380</str<strong>on</strong>g> Quarterly Update 15

![OAMag-V7N4-Cover [Converted] - Orient Aviation](https://img.yumpu.com/48598575/1/190x255/oamag-v7n4-cover-converted-orient-aviation.jpg?quality=85)