bravo zulu 1/2008 - GL Group

bravo zulu 1/2008 - GL Group

bravo zulu 1/2008 - GL Group

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

claSSIFIcaTIon<br />

Second naval Submarine in class<br />

The second naval submarine has<br />

been submitted into <strong>GL</strong> class. The<br />

conventional class 209 submarine<br />

of type 1400 MOD for the South African<br />

Navy was built by the German<br />

Submarine Consortium, consisting<br />

of Howaldtswerke Deutsche Werft AG<br />

(HDW), Kiel, Nordseewerke GmbH<br />

(NSWE), Emden, and MAN Ferrostaal<br />

AG, Essen. Delivery took place in November<br />

2006.<br />

The submarine “SAS Charlotte<br />

Maxeke” has received “100 N 6 Submarine”<br />

classification, the machinery<br />

plant was classed as “MC U” in June<br />

<strong>2008</strong>. The sister vessel “SAS ‘Mathatisi”<br />

was successfully classed last year<br />

cUSTomER SERVIcE<br />

network Expanded<br />

In order to provide worldwide navies with<br />

a single point of contact and enhance onsite<br />

customer service, <strong>GL</strong> appointed Naval<br />

Business Development Manager (BDM).<br />

They will interact with <strong>GL</strong>’s local representatives,<br />

all other internal and external<br />

technical and administrative specialists<br />

to carry out naval projects. Headquarters<br />

will prepare proposals, run projects and<br />

support field sales.<br />

The traditional range of services includes<br />

comprehensive classification<br />

services for newbuildings based on <strong>GL</strong><br />

design requirements for surface craft and<br />

submarines, safety consulting for ships in<br />

operation, as well as a wide range of engineering<br />

services such as assessment of the<br />

strength of pressure hulls against buckling,<br />

sufficient fatigue life capacity, resistance<br />

against underwater explosions or vibration<br />

behaviour.<br />

“Much like in commercial shipping,<br />

these surveys are an excellent means of<br />

identifying wear and tear early on, thus<br />

helping to avoid more costly repairs at a<br />

later date,” said Lorenz Petersen, Head of<br />

Navy Projects. For newbuilding projects,<br />

<strong>GL</strong>’s global network of surveyors handles<br />

the full spectrum of construction monitoring<br />

services using modern software tools.<br />

Following the approval of a newly-built naval<br />

vessel, the ship continues to undergo<br />

technical inspections at regular intervals<br />

while in service.<br />

Additionally, <strong>GL</strong> opened a new office in<br />

Berlin. Dietmar Gossel, who is the on-site<br />

Liaison Officer, acts as contact person for<br />

authorities, institutions as well as governmental<br />

agencies and navies in the federal<br />

capital. ■<br />

contact details: Dietmar Gossel, Liasion Officer,<br />

Phone: +49 30 2092-4168,<br />

E-Mail: dietmar.gossel@gl-group.com<br />

as the first naval submarine worldwide.<br />

The South African Navy had<br />

commissioned <strong>GL</strong> with the classification<br />

of a total of three submarines.<br />

The order includes the inspection<br />

of the construction plans as well as<br />

annual technical safety checks. The<br />

third vessel will be inspected at the<br />

end of <strong>2008</strong>. In classifying newly-constructed<br />

submarines, Germanischer<br />

Lloyd’s services include the inspection<br />

of construction drawings, materials,<br />

joining, propulsion and systems<br />

technology, as well as supervision of<br />

construction and testing. <strong>GL</strong> also<br />

tests and certifies fuel cells and other<br />

AIP systems. ■<br />

acoUSTIcS<br />

noise under control<br />

Ships are known to radiate noise<br />

in all frequency bands, with the<br />

highest sound levels at the lowest frequencies.<br />

Reducing the radiated noise<br />

level as far as possible, be it on board<br />

or outside the ship, is one of the <strong>GL</strong><br />

Acoustics department’s main tasks.<br />

For naval vessels in particular, it is of<br />

great advantage to reduce the level<br />

of waterborne noise to make the ship<br />

more difficult to detect.<br />

For very high frequencies (structure-borne<br />

noise), the standard FEA<br />

approach to vibration analyses is impossible<br />

due to excessive computational<br />

requirements. For a typical passenger<br />

vessel for a frequency of 1,000<br />

Hz, a FEA vibration model would lead<br />

to several million degrees of freedom.<br />

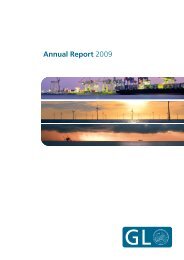

VIRTUal.<br />

gl noiseFEm grid applied on the<br />

validation of radiated noise of a mine-hunter.<br />

noISE and VIBRaTIon – gl’S SERVIcE<br />

If you would like to be informed about<br />

noise and vibration analyses, please contact<br />

Jürgen Jokat, <strong>GL</strong>’s Head of Acoustics.<br />

Cooperation should start as early as possible,<br />

preferably in the conceptual design<br />

stage. If desired, standardized parts of the<br />

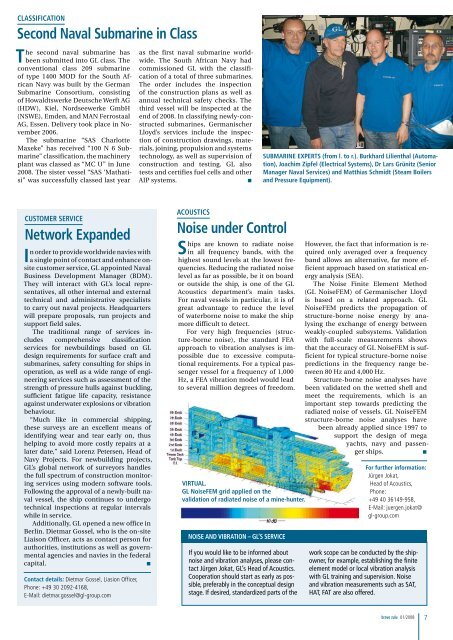

SUBmaRInE EXpERTS (from l. to r.). Burkhard lilienthal (automation),<br />

Joachim Zipfel (Electrical Systems), dr lars grünitz (Senior<br />

manager naval Services) and matthias Schmidt (Steam Boilers<br />

and pressure Equipment).<br />

However, the fact that information is required<br />

only averaged over a frequency<br />

band allows an alternative, far more efficient<br />

approach based on statistical energy<br />

analysis (SEA).<br />

The Noise Finite Element Method<br />

(<strong>GL</strong> NoiseFEM) of Germanischer Lloyd<br />

is based on a related approach. <strong>GL</strong><br />

NoiseFEM predicts the propagation of<br />

structure-borne noise energy by analysing<br />

the exchange of energy between<br />

weakly-coupled subsystems. Validation<br />

with full-scale measurements shows<br />

that the accuracy of <strong>GL</strong> NoiseFEM is sufficient<br />

for typical structure-borne noise<br />

predictions in the frequency range between<br />

80 Hz and 4,000 Hz.<br />

Structure-borne noise analyses have<br />

been validated on the wetted shell and<br />

meet the requirements, which is an<br />

important step towards predicting the<br />

radiated noise of vessels. <strong>GL</strong> NoiseFEM<br />

structure-borne noise analyses have<br />

been already applied since 1997 to<br />

support the design of mega<br />

yachts, navy and passenger<br />

ships. ■<br />

For further information:<br />

Jürgen Jokat,<br />

Head of Acoustics,<br />

Phone:<br />

+49 40 36149-9 8,<br />

E-Mail: juergen.jokat@<br />

gl-group.com<br />

work scope can be conducted by the shipowner,<br />

for example, establishing the finite<br />

element model or local vibration analysis<br />

with <strong>GL</strong> training and supervision. Noise<br />

and vibration measurements such as SAT,<br />

HAT, FAT are also offered.<br />

<strong>bravo</strong> <strong>zulu</strong> 01/<strong>2008</strong> 7