Single-Width Centrifugal Fan Performance Supplement - Greenheck

Single-Width Centrifugal Fan Performance Supplement - Greenheck

Single-Width Centrifugal Fan Performance Supplement - Greenheck

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

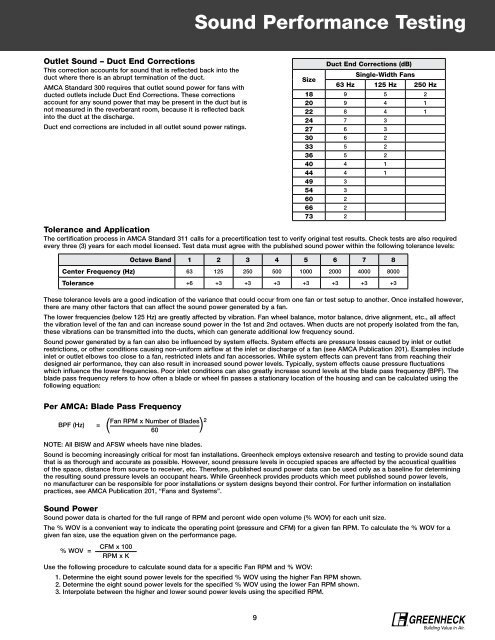

Outlet Sound – Duct End Corrections<br />

This correction accounts for sound that is reflected back into the<br />

duct where there is an abrupt termination of the duct.<br />

AMCA Standard 300 requires that outlet sound power for fans with<br />

ducted outlets include Duct End Corrections. These corrections<br />

account for any sound power that may be present in the duct but is<br />

not measured in the reverberant room, because it is reflected back<br />

into the duct at the discharge.<br />

Duct end corrections are included in all outlet sound power ratings.<br />

Per AMCA: Blade Pass Frequency<br />

BPF (Hz) = ( <strong>Fan</strong> RPM x Number of Blades ) 2<br />

60<br />

Sound <strong>Performance</strong> Testing<br />

Tolerance and Application<br />

The certification process in AMCA Standard 311 calls for a precertification test to verify original test results. Check tests are also required<br />

every three (3) years for each model licensed. Test data must agree with the published sound power within the following tolerance levels:<br />

These tolerance levels are a good indication of the variance that could occur from one fan or test setup to another. Once installed however,<br />

there are many other factors that can affect the sound power generated by a fan.<br />

The lower frequencies (below 125 Hz) are greatly affected by vibration. <strong>Fan</strong> wheel balance, motor balance, drive alignment, etc., all affect<br />

the vibration level of the fan and can increase sound power in the 1st and 2nd octaves. When ducts are not properly isolated from the fan,<br />

these vibrations can be transmitted into the ducts, which can generate additional low frequency sound.<br />

Sound power generated by a fan can also be influenced by system effects. System effects are pressure losses caused by inlet or outlet<br />

restrictions, or other conditions causing non-uniform airflow at the inlet or discharge of a fan (see AMCA Publication 201). Examples include<br />

inlet or outlet elbows too close to a fan, restricted inlets and fan accessories. While system effects can prevent fans from reaching their<br />

designed air performance, they can also result in increased sound power levels. Typically, system effects cause pressure fluctuations<br />

which influence the lower frequencies. Poor inlet conditions can also greatly increase sound levels at the blade pass frequency (BPF). The<br />

blade pass frequency refers to how often a blade or wheel fin passes a stationary location of the housing and can be calculated using the<br />

following equation:<br />

NOTE: All BISW and AFSW wheels have nine blades.<br />

Sound is becoming increasingly critical for most fan installations. <strong>Greenheck</strong> employs extensive research and testing to provide sound data<br />

that is as thorough and accurate as possible. However, sound pressure levels in occupied spaces are affected by the acoustical qualities<br />

of the space, distance from source to receiver, etc. Therefore, published sound power data can be used only as a baseline for determining<br />

the resulting sound pressure levels an occupant hears. While <strong>Greenheck</strong> provides products which meet published sound power levels,<br />

no manufacturer can be responsible for poor installations or system designs beyond their control. For further information on installation<br />

practices, see AMCA Publication 201, “<strong>Fan</strong>s and Systems”.<br />

Sound Power<br />

Sound power data is charted for the full range of RPM and percent wide open volume (% WOV) for each unit size.<br />

The % WOV is a convenient way to indicate the operating point (pressure and CFM) for a given fan RPM. To calculate the % WOV for a<br />

given fan size, use the equation given on the performance page.<br />

% WOV =<br />

CFM x 100<br />

RPM x K<br />

Octave Band 1 2 3 4 5 6 7 8<br />

Center Frequency (Hz) 63 125 250 500 1000 2000 4000 8000<br />

Tolerance +6 +3 +3 +3 +3 +3 +3 +3<br />

Use the following procedure to calculate sound data for a specific <strong>Fan</strong> RPM and % WOV:<br />

1. Determine the eight sound power levels for the specified % WOV using the higher <strong>Fan</strong> RPM shown.<br />

2. Determine the eight sound power levels for the specified % WOV using the lower <strong>Fan</strong> RPM shown.<br />

3. Interpolate between the higher and lower sound power levels using the specified RPM.<br />

9<br />

Size<br />

Duct End Corrections (dB)<br />

<strong>Single</strong>-<strong>Width</strong> <strong>Fan</strong>s<br />

63 Hz 125 Hz 250 Hz<br />

18 9 5 2<br />

20 9 4 1<br />

22 8 4 1<br />

24 7 3<br />

27 6 3<br />

30 6 2<br />

33 5 2<br />

36 5 2<br />

40 4 1<br />

44 4 1<br />

49 3<br />

54 3<br />

60 2<br />

66 2<br />

73 2<br />

®