Two frequently development ways of the induction ... - Kienle + Spiess

Two frequently development ways of the induction ... - Kienle + Spiess

Two frequently development ways of the induction ... - Kienle + Spiess

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

[2] E. F. Brush Jr, S. P. Midson, W. G. Walkington, D. T. Peters, J. G. Cowie, “Porosity Control in Copper<br />

Rotor Die Castings”, NADCA Indianapolis Convention Center, Indianapolis, IN September 15-18, 2003,<br />

T03-046<br />

Presentation Company <strong>Kienle</strong> + <strong>Spiess</strong><br />

One <strong>of</strong> <strong>the</strong> leading manufacturer <strong>of</strong> punched lamination and die-cast rotors<br />

Revenue 2008: 219 Mio. EUR<br />

Employees: 1’150<br />

Manufacturing sides: <strong>Kienle</strong> + <strong>Spiess</strong> GmbH, Sachsenheim, Germany<br />

<strong>Kienle</strong> + <strong>Spiess</strong> GmbH, Vaihingen/ Enz, Germany<br />

<strong>Kienle</strong> + <strong>Spiess</strong> Kft, Tokod, Hungary<br />

<strong>Kienle</strong> + <strong>Spiess</strong> UK, Bilston, Great Britain<br />

Production Area: 45’000 sqm<br />

Steel consumption: 100’000 t<br />

Our products<br />

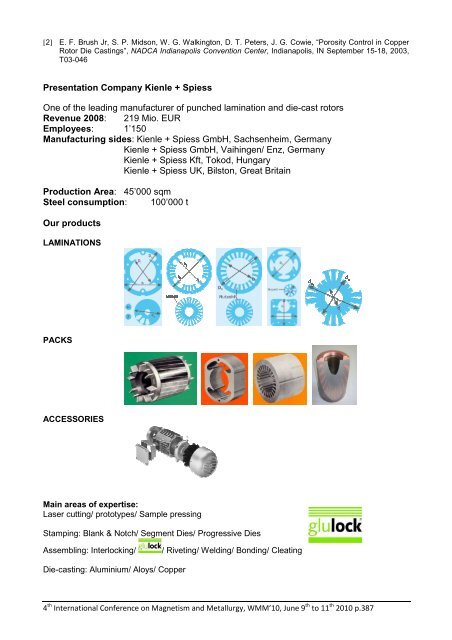

LAMINATIONS<br />

PACKS<br />

ACCESSORIES<br />

Main areas <strong>of</strong> expertise:<br />

Laser cutting/ prototypes/ Sample pressing<br />

Stamping: Blank & Notch/ Segment Dies/ Progressive Dies<br />

Assembling: Interlocking/ / Riveting/ Welding/ Bonding/ Cleating<br />

Die-casting: Aluminium/ Aloys/ Copper<br />

4 th International Conference on Magnetism and Metallurgy, WMM’10, June 9 th to 11 th 2010 p.387