KUKA YOUR IDEAS - KUKA Roboter

KUKA YOUR IDEAS - KUKA Roboter

KUKA YOUR IDEAS - KUKA Roboter

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PF0067/E/1/0111<br />

»The <strong>KUKA</strong> RoboT GRoUp: YoUR sTRonG pARTneR<br />

Quality made in Germany, creativity and the utmost commitment<br />

to customers and business partners: these form<br />

the basis on which <strong>KUKA</strong> develops the best possible<br />

technologies and thus the optimal automation concepts.<br />

The result is that you receive custom-tailored solutions and<br />

benefit from decisive process optimization.<br />

Genuine passion for the fascination of robotics is reflected<br />

in our slogan “<strong>KUKA</strong> <strong>YOUR</strong> <strong>IDEAS</strong>”, which is also our<br />

promise to you: Whatever you want to do, and however<br />

unusual your idea may be, with us you can implement<br />

anything – irrespective of the specific branch of industry<br />

and irrespective of whether or not a similar application<br />

has existed before.<br />

Whatever task you give us, <strong>KUKA</strong> has the required specialists.<br />

In close cooperation with experienced system partners<br />

with competence in their respective industries, we do everything<br />

in our power to implement your ideas. Let us work on<br />

them together.<br />

»<strong>KUKA</strong> seRvices: AlwAYs TheRe foR YoU<br />

You can rely on us to stand by you in every phase of a project:<br />

from planning and commissioning to maintenance<br />

and conversion. 24 hours a day. 365 days a year. The highdensity<br />

<strong>KUKA</strong> service network ensures that we are always<br />

in your vicinity and can start your production in record time.<br />

<strong>KUKA</strong> <strong>YOUR</strong> <strong>IDEAS</strong><br />

<strong>KUKA</strong> RoboTeR GMbh<br />

Global Sales Center<br />

Hery-Park 3000<br />

86368 Gersthofen<br />

Germany<br />

Tel. +49 821 4533-0<br />

Fax +49 821 4533-1616<br />

info@kuka-roboter.de<br />

Additional contact addresses:<br />

www.kuka-robotics.com<br />

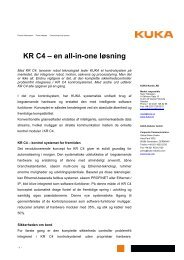

<strong>KUKA</strong>.workvisual<br />

integrated, efficient<br />

methods and tools.<br />

consistent throughout the software life cycle.<br />

<strong>KUKA</strong> engineering environment<br />

<strong>KUKA</strong>.workvisual

<strong>KUKA</strong>.workvisual <strong>KUKA</strong>.workvisual<br />

»woRK MoRe efficienTlY ThRoUGhoUT The sofTwARe life cYcle in AUToMATion.<br />

Programming. Configuration. Loading. Testing. Diagnosis. Modifying. Archiving. <strong>KUKA</strong>.WorkVisual groups<br />

all the steps of a project together in a homogenous offline development, online diagnosis and maintenance<br />

environment. With the highest degree of consistency and seamless integration based on catalogs and<br />

project data that are not program-specific. All steps thus fit seamlessly together without contradiction.<br />

For every subtask, right through to the operable solution.<br />

»<strong>KUKA</strong>.workvisual – The feATURes AT A GlAnce:<br />

A homogenous, project-oriented development environment<br />

throughout the software life cycle<br />

Uniform, standard-oriented user interface<br />

Establishment of a compact and consistent project data<br />

storage facility; advantage: e.g. avoidance of error-prone<br />

multiple entry of the same data<br />

Network administration of all KR C4 controllers:<br />

status monitoring, upload/download, archiving, etc.<br />

Integrated diagnostic concept<br />

Integrated, uniform field bus I/O configuration, mapping and<br />

diagnosis on the robot controller and between the robot<br />

controller and SoftPLC<br />

Supported field buses: PROFINET, PROFIBUS, INTERBUS,<br />

EtherCAT; later also Ethernet/IP and DeviceNet<br />

Integrated drag & drop configuration and menu-guided<br />

parameterization for RoboTeam SafeRobot3.0 and external<br />

axis modules, e.g. linear axes and positioners<br />

»program life cycle in the <strong>KUKA</strong>.workvisual development environment.<br />

Multiprog. 5.0<br />

Coupler<br />

eXtended Motion<br />

VisualKRL<br />

+<br />

WorkVisual Sim VisualProcess<br />

Visual<br />

Project<br />

Visual<br />

Config<br />

Online Services/ Roundload<br />

Visual<br />

Assistance<br />

Network Scan Connect Download/Upload Diagnosis<br />

Efficient, ergonomically optimized editors for text-based and/or<br />

graphical programming of cell components<br />

Creation of 3D simulations using the standard <strong>KUKA</strong> library<br />

Simple importing of CAD data for workpieces and tools<br />

Virtual positioning of components, e.g. for testing<br />

accessibility and reachability<br />

Simple generation of process paths in the 3D editor, e.g.<br />

based on automatic edge detection<br />

Programming of the process device control via the<br />

graphics-based process value editor<br />

Virtual process optimization with subsequent download<br />

change in the real cell<br />

Catalog<br />

& Projects<br />

visualproject: Project definition and<br />

project setup<br />

visualconfig: Configuration of the cell<br />

hardware including communication<br />

visualconfig: Mapping editor for<br />

interfacing devices and software<br />

visualKRl: Editor for text-based<br />

programming<br />

visualprocess: Graphics-oriented<br />

programming and simulation<br />

visualprocess: For programming of the<br />

path-dependent behavior of the process<br />

devices<br />

visualproject: Online manager for<br />

uploading programs or downloading<br />

online modifications via the network<br />

visualAssistance: For action-oriented<br />

diagnosis<br />

woRKflow exAMple:<br />

Office Shop Floor<br />

Planning &<br />

configuration with<br />

<strong>KUKA</strong>.WorkVisual<br />

Configuration in<br />

3D cell with<br />

<strong>KUKA</strong>.WorkVisual<br />

Shop floor diagnosis,<br />

maintenance &<br />

optimization with<br />

<strong>KUKA</strong>.WorkVisual<br />

Roundload &<br />

online diagnosis<br />

Mapping editor. Quick and easy i/o configuration with drag & drop.<br />

Start-up & operator<br />

control of robotic cell<br />

with smartPAD<br />

Graphical programming in the virtual<br />

cell with visualprocess. process<br />

programming with the process value<br />

editor to link the robot path with<br />

process commands.