High Voltage Control Unit Typ HST 01/01 - SCHNIER Elektrostatik ...

High Voltage Control Unit Typ HST 01/01 - SCHNIER Elektrostatik ...

High Voltage Control Unit Typ HST 01/01 - SCHNIER Elektrostatik ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

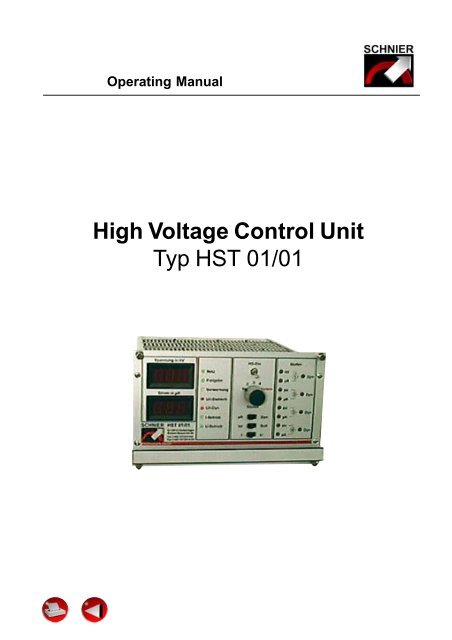

Operating Manual<br />

<strong>High</strong> <strong>Voltage</strong> <strong>Control</strong> <strong>Unit</strong><br />

<strong>Typ</strong> <strong>HST</strong> <strong>01</strong>/<strong>01</strong>

Operating Manual<br />

Inhaltsverzeichnis<br />

1.0 General Information<br />

2.0 Safety<br />

3.0 Technical-<br />

Data<br />

4.0 Design<br />

Description<br />

5.0 Functional<br />

Description<br />

6.0 Busmodule<br />

7.0 Spare Parts and<br />

After Sales Servicet<br />

1.1 Introduction<br />

1.2 Scope of Application<br />

2.1 Labor Protection Symbol<br />

2.2 Warning Label<br />

2.3 General Safety Notes<br />

2.4 Special Safety Notes<br />

3.1 General Notes<br />

3.2 Supply <strong>Voltage</strong>s<br />

3.3 Setting Values<br />

3.4 Inputs<br />

3.5 Outputs<br />

4.1 Subassemblies<br />

4.2 General Notes<br />

4.3 Panel Overview<br />

4.4 Indicating Instruments<br />

4.5 <strong>Control</strong> LED´s<br />

4.6 Switches<br />

4.7 Trim Potentiometers<br />

4.8 <strong>Control</strong> <strong>Unit</strong> Mounting<br />

5.1 Constant <strong>Voltage</strong> Operation<br />

5.2 Constant Current Operation<br />

6.1 Overview<br />

6.2 Mains Supply<br />

6.3 HV Generator Connection<br />

6.4 External Supplies<br />

6.5 Inputs and Outputs<br />

6.6 Earth reversing switch connections<br />

Nr. 81<strong>01</strong>23BE_02/00<br />

Page2 of 17

Operating Manual<br />

1.0 General Information<br />

1.1 Introduction<br />

1.2 Scope of Application<br />

This Operating Manual (in the following called OM) has to be read,<br />

fully understood and observed in all respects by all persons who<br />

are responsible for the devices and the electrostatic installation.<br />

For these reasons the OM should always be available to the<br />

operating, maintenance and service personal.<br />

Only with the knowledge of this OM faults can be avoided and a<br />

trouble-free operation be guarenteed. Therefore it is important<br />

that the OM is known to all persons involved. The company<br />

<strong>SCHNIER</strong> <strong>Elektrostatik</strong> GmbH will not assume any responsibility<br />

resulting from the failure to comply with the OM!<br />

The HV control unit may only be used in electrostatic coating<br />

installations within the temperature range of 10°C to 40°C and a<br />

relative humidity of between 35% to 80%. Furthermore the relevant<br />

safety notes according to points 2.3 and 2.4 of this OM<br />

must be strictly observed.<br />

The HV control unit HS <strong>01</strong>/<strong>01</strong> has to be only operated with the<br />

high voltage generators of the medium frequency types supplied.<br />

by the company <strong>SCHNIER</strong> <strong>Elektrostatik</strong> GmbH.<br />

Nr. 81<strong>01</strong>23BE_02/00<br />

Page 3 of 17

2.0 Safety<br />

Operating Manual<br />

2.1 Labor Protection Symbol<br />

2.2 Warning Label<br />

2.3 Special Safety Notes<br />

2.4 General Safety Notes<br />

This symbol marks all notes which might lead to danger for life<br />

and limb of persons if they are not observed. Please observe<br />

them and be especially careful in these cases.<br />

Apart from the notes in this OM the general valid safety instructions<br />

as well as the regulation for the prevention of accidents must be<br />

adhered to.<br />

Attention!<br />

Nr. 81<strong>01</strong>23BE_02/00<br />

Page 4 of 17<br />

This attention label will be displayed in this OM whenever there is<br />

an important note to be observed in order to avoid damage or<br />

destruction of the device.<br />

The HV control unit may only be used for stationary spraying<br />

installations which fulfill the relevant safety requirements.<br />

The safety notes under point 2.4 are To be observed most stringently,<br />

especially:<br />

EN 50 176<br />

EN 50 177<br />

EN 50 223<br />

EN 50 348<br />

DIN VDE <strong>01</strong>47 SEC. 1<br />

Moreover, the operating instruction of the resp. electrostatic<br />

plant has to be observed!<br />

See data sheet “Vorschriften und Regeln” no. 810002DD<strong>01</strong>.

3.0 Technical Data<br />

3.1 General Notes<br />

3.2 Supply voltages<br />

3.3 Setting Values<br />

Operating Manual<br />

Device designation HV control unit<br />

Model <strong>HST</strong> <strong>01</strong>/<strong>01</strong><br />

Dimensions H/W/L 3 HE/42 TE / 232,5mm<br />

Serial number see label<br />

Year of construction see label<br />

The control unit can be powered in the following two ways:<br />

a) Internal supply module<br />

SEVM 1<strong>01</strong><br />

connection via X1<br />

b) External power<br />

supplies<br />

connection via X3<br />

230 V / 50-60 Hz 150VA<br />

36 V AC + 10% /<br />

50- 60 Hz 120 VA<br />

24 V DC + 10 %/20VA<br />

The following setting values depend on the employed HV generator<br />

a) Constant voltage operation<br />

Static current<br />

disconnection treshold :<br />

<strong>High</strong> voltage: 0- >100 kV, stepless<br />

adjustment<br />

Dynamic current<br />

disconnection (di/dt): 0- >980 µA/s<br />

<strong>High</strong> voltage ramp rate: approx. 3s (fixed)<br />

b)Constant current operation<br />

Nr. 81<strong>01</strong>23BE_02/00<br />

Page 5 of 17<br />

Current limitation: 0- >800 µA, stepless<br />

adjustment<br />

<strong>Voltage</strong> limitation: 0- >100 kV, stepless<br />

adjustment<br />

Dynamic voltage<br />

disconnection (du/dt) 0- >100 kV/s<br />

Static voltage<br />

disconnection treshold 36 kV (fixed)<br />

<strong>High</strong> voltage ramp rate approx. 3s (fixed)

Operating Manual<br />

3.4 Inputs HV on 24 V DC<br />

Stage 1 24 V DC<br />

Stage 2 24 V DC<br />

Stage 3 24 V DC<br />

Stage 4 24 V DC<br />

Stage 5 ( analog ) 24 V DC<br />

I or U operation 24 V DC<br />

3.5 Outputs<br />

Analog outputs for<br />

instruments<br />

Inputs for analog setting of nominal value<br />

U nom<br />

0 ... 10 V DC equals<br />

0 ... 100 kV<br />

I 0 ... 10 V DC equals<br />

nom<br />

0 ... 1 mA<br />

du or di / dt 0 ... 10 V DC equals<br />

0 ... 100 kV/s<br />

or 0 ... 1mA /s<br />

Fault: 24V DC max 100mA<br />

Release: 24V DC max 100mA<br />

Pre-warning: 24V DC max 100mA<br />

HV on 24V DC max 100mA<br />

Earth reversing switch 24V DC max 100 mA,<br />

adjustable disconnection<br />

delay between 0,1and 5s<br />

U act<br />

I act<br />

0 ... 10 VDC equals<br />

0 ... 100kV<br />

(Ri>100kOhm)<br />

0 ... 10 VDC equals<br />

0 ... 1mA<br />

(Ri >100kOhm)<br />

Nr. 81<strong>01</strong>23BE_02/00<br />

Page 6 of 17

Operating Manual<br />

4.0 Design Description<br />

4.1 Subassemblies<br />

4.2 General Notes<br />

Nr. 81<strong>01</strong>23BE_02/00<br />

Page 7 of 17<br />

The HV control unit <strong>HST</strong> <strong>01</strong>/<strong>01</strong> consists of the following<br />

components:<br />

-<strong>Control</strong> module SESM 1<strong>01</strong><br />

-Power module SELM 1<strong>01</strong><br />

-Front module SEFM 1<strong>01</strong><br />

-Bus module SEBM 102<br />

-External supply module SEVM 1<strong>01</strong> (optional)<br />

The high voltage control unit <strong>HST</strong> <strong>01</strong>/<strong>01</strong> is designed for the operation<br />

of HV generators ot the medium frequency types.<br />

According to the selected operation mode (I constant or U constant)<br />

the voltage or the current can be defined in 5 stages and can be<br />

adjusted between 0 and 100% of U nom. or I nom.<br />

For each stage there is a static and a dynamic dis-connection<br />

treshold (for more details see 4.4 and 4.5).

4.3 Übersichtsbild<br />

General<br />

Operating Manual<br />

4<br />

3<br />

2<br />

1<br />

1 Fixing screw<br />

2 Handle bar<br />

Adjustment potentiometers<br />

14 kV adjust stage 1<br />

15 µA adjust stage 1<br />

16 Dynamic adjust stage 1<br />

17 kV adjust stage 2<br />

18 Dynamic adjust stage 2<br />

19 µA adjust stage 2<br />

20 kV adjust stage 3<br />

21 Dynamic adjust stage 3<br />

22 µA adjust stage 3<br />

23 Dynamic adjust stage 4<br />

24 kV adjust stage 4<br />

25 µA adjust stage 4<br />

5 6 7 8 9 10 11 12 13 14 15<br />

28 27 26 25<br />

Visual displays and LED's<br />

3 Display for µA and fordynamic disconnection<br />

4 Display for kV<br />

5 LED for release signal<br />

6 LED for power on<br />

7 LED for warning<br />

8 LED for static disconnection (U or I)<br />

9 LED for dynamic disconnection (U or I)<br />

10 LED for constant current mode<br />

11 LED for constant voltage mode<br />

Switches<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22<br />

23<br />

24<br />

Nr. 81<strong>01</strong>23BE_02/00<br />

Page 8 of 17<br />

12 HV on<br />

13 Set point selection switch<br />

26 Selection of µA or Dyn.<br />

27 Selection of actual or nominal value<br />

28 Selection of current or voltage mode<br />

(only analog step)

4.4 Indicating<br />

Instruments<br />

4.5 <strong>Control</strong> LED's<br />

1. Power on LED (6)<br />

2.Release LED (5)<br />

3.Warning LED (7)<br />

4.U/I static LED (8)<br />

5.U/I dynamic LED (9)<br />

Operating Manual<br />

6.Current mode LED (10)<br />

7.<strong>Voltage</strong> mode LED (11)<br />

4.6 Switches<br />

Nr. 81<strong>01</strong>23BE_02/00<br />

Page 9 of 17<br />

In the HV control unit <strong>HST</strong> <strong>01</strong>/<strong>01</strong>, there are two digital instruments.<br />

The top digital display (4) is for the kV. Dependent on the position<br />

of the Nominal/Actual Value Switch (27) it indicates the exact<br />

nominal or actual value of the output voltage.<br />

The lower digital display (3) is for µA (3). It also indicates the<br />

exact nominal or actual value of the output current, dependent on<br />

the position of the Nominal/Actual Value Switch (27). In addition<br />

the actual values can also externally be evaluated or displayed<br />

via the bus module (for more details see Technical Data, page<br />

11).<br />

With the selection switch (26) in the Dyn. position, the dynamic<br />

disconnection value can be displayed. In this case the nominal<br />

value is indicated in any of the two positions of the selection switch<br />

(27) for nominal or actual value.<br />

The HV control unit <strong>HST</strong> <strong>01</strong>/<strong>01</strong> has seven control LED's which<br />

are as follows:<br />

This LED is on when the internal power supply is functioning<br />

correctly.<br />

This LED is on when 80% of U or I is achieved<br />

nom nom<br />

This LED is on when 80% of the adjusted static disconnection<br />

treshold is reached<br />

This LED is on after triggering of the static current or voltage<br />

disconnection treshold.<br />

This LED is on after triggering of the dynamic current or voltage<br />

disconnection treshold.<br />

This LED is on when the selected stage is in current mode.<br />

This LED is on when the selected stage is in voltage mode.<br />

The HV control unit <strong>HST</strong> <strong>01</strong>/<strong>01</strong> has five function switches on<br />

the front plate.<br />

The switches (26) for µA or Dyn. and (27) for nominal or actual<br />

value are only used for the digital displays as described in 4.4.<br />

The HV on switch (12) serves as master switch.

Operating Manual<br />

Attention!<br />

4.7 Trim Potentiometers<br />

Attention!<br />

fig.1<br />

On the front plate of the HV control unit high voltage cannot be<br />

activated without an additional external release signal (for<br />

instance key switch or PLC signal). Only with the HV-on switch<br />

(12) in the on position and the external HV-on signal present,<br />

high voltage is generated.<br />

The multiple contact switch (13) is for selection of single stages.<br />

The HV control unit has 5 stages. For the stages 1 to 4 the<br />

nominal values for kV, µA and Dyn can be adjusted using the<br />

trim potentiometers located on the unit's front plate. The stage 5<br />

(analog) nominal values for kV, µA and Dyn can be defined<br />

externally using analog voltages (0 ... 10 V DC). Stage 5 cannot<br />

be selected via the multiple contact switch (13), but externally<br />

with the switch (13) in the "External" position.<br />

This works the same way also for the externalselection of the<br />

stages 1 to 4. One of the five stages can only be controlled<br />

externally if the multiple contact switch (13) is in the "External"<br />

position.<br />

As already described in 4.6 the high voltage controller S<strong>HST</strong><br />

100/<strong>01</strong> has 4 internally adjustable stages (stage 1 to 4) whose<br />

nominal values for kV, µA and Dyn can be adjusted via 12 trim<br />

potentiometers (14 to 25). There are 3 trim potentiometers per<br />

stage for specifying values from 0 to 100 kV or from 0 to 800 µA<br />

or from 0 to 100 kV/s or from 0 to 1000 µA/s.<br />

The following assignment have been made:<br />

Trim potentiometers for stage 1:<br />

(14) for kV, (15) for µA and (16) for Dyn<br />

Trim potentiometers for stage 2:<br />

(17) for kV, (19) for µA and (18) for Dyn<br />

Trim potentiometers for stage 3:<br />

(20) for kV, (22) for µA and (21) for Dyn<br />

Trim potentiometers for stage 4:<br />

(24) for kV, (25) for µA and (23) for Dyn<br />

It is important that the corect trim tool (see fig. 1) is used as<br />

the use of any other tool could cause damage to the trim<br />

potentiometers<br />

1 trim tool is supplied with every control unit .<br />

Nevertheless additional trim tools can be ordered by stating:<br />

article designation: SEAS<br />

reference no.: 150<strong>01</strong>8<br />

Nr. 81<strong>01</strong>23BE_02/00<br />

Page 10 of 17

Operating Manual<br />

4.8 <strong>Control</strong> <strong>Unit</strong> Mounting<br />

Attention!<br />

5.0 Functional Description<br />

The HV control unit <strong>HST</strong> <strong>01</strong>/<strong>01</strong> is equipped with four knurled screws<br />

secured against loss for attaching the control module to the rack.<br />

The control module must be fastened with all fixing screws to the<br />

rack in order to guarantee perfect electrical contact between the<br />

plug-in connectors and the bus plate bar.<br />

After loosening the fixing screws the control module may only be<br />

pulled out of the rack using the handle bar (2). Never pull out the<br />

control module using the switches instead of the handle bar.<br />

The HV control unit <strong>HST</strong> <strong>01</strong>/<strong>01</strong> is provided with 5 stages. There<br />

is one trim potentiometer for kV, one for µa and one for Dyn for<br />

each of the stages 1 to 4. By means of the trim potentiometers<br />

nominal values between 0 and 100% cvan be adjusted.<br />

For stage 5 (analog) the nominal values are specified via analog<br />

voltages by the superimposed control system (for more details<br />

refer to Technical Data, page11).<br />

For each stage two operating modes are available:<br />

a) constant voltage (U-mode)<br />

b) constant current (I-mode).<br />

Nr. 81<strong>01</strong>23BE_02/00<br />

Page 11 of 17<br />

For stages 1 to 4 switching over of the operating modes can only<br />

be carried out internally on the control board SESM 1<strong>01</strong> (see<br />

fig.)<br />

For stage 5 (analog) the change-over may be realized either via<br />

the front plate or externally. The device will be in I-mode after<br />

having selected I-mode from the front plate or externally.

Operating Manual<br />

Attention!<br />

Stage 4<br />

U I<br />

< ><br />

Stage 3<br />

U I<br />

< ><br />

Stage 2<br />

U I<br />

< ><br />

Stage 1<br />

U I<br />

< ><br />

5.1 Constant<br />

<strong>Voltage</strong> Mode<br />

Nr. 81<strong>01</strong>23BE_02/00<br />

Page 12 of 17<br />

Only authorised personnel should be allowed to execute the<br />

operation of switching over on the control board as this requires<br />

the opening of the control unit.<br />

In the constant voltage mode the voltage is increased to the<br />

adjusted nominal value and held constant. When reaching approx.<br />

80% of the desired output voltage the "release" signal is output.<br />

When there is load on the HV output, the output voltage is kept<br />

constant, but only within the power range of the connected HV<br />

generator (see characteristic curve of the HV generator).

5.2 Constant<br />

Current Mode<br />

Operating Manual<br />

Nr. 81<strong>01</strong>23BE_02/00<br />

Page 13 of 17<br />

In the constant voltage mode the static current disconnection<br />

treshold can be adjusted between 0 and approx. 820 µA. When<br />

reaching approx. 80% of the adjusted disconnection treshold the<br />

"warning" signal is generated. As soon as the load decreases,<br />

the signal disappears. If the load nevertheless increases the<br />

controller indicates "fault" when the adjusted treshold value is<br />

reached. <strong>High</strong> voltage then will automatically be switched off. In<br />

order to switch the high voltage on again, the "HV on" signal has<br />

to be surpressed during at least one second either by (12) on the<br />

front plate or by means of the external control system.<br />

The dynamic di/dt disconnection treshold can be adjusted<br />

between 0 and approx. 999 µA/s. This part of the controller<br />

continuously monitors in which time a determined current value<br />

is reached, either during current rise or fall (current slope<br />

steepness). If the current slope is steeper than permitted by the<br />

adjusted value, the controller will indicate "fault". The fault reset<br />

procedure is the same as for static disconnection. The dynamic<br />

disconnection is independent of the static disconnection treshold.<br />

This means that a dynamic disconnection may also be triggered<br />

if the current is significantly below the static disconnection value.<br />

On the front plate of the HV control unit the type of disconnection,<br />

either static of dynamic, will be displayed. In addition a collective<br />

fault is output to the external control system.<br />

In constant current mode the operating current can be adjusted.<br />

This value is kept constant by regulating the output voltage. When<br />

reaching approx. 80% of the adjusted current value the "release"<br />

signal is output. By means of the "kV" nominal value the maximum<br />

admissible operating voltage between 40 and 100 kV can be<br />

limited.<br />

In constant current mode the static voltage disconnection treshold<br />

is fixed to approx. 38 kV. When reaching this value the device<br />

switches off and indicates "fault". In order to switch the high voltage<br />

on again, the "HV on" signal has to be surpressed during at least<br />

one second either by the switch (12) on the front plate or by means<br />

of the external control system. Before the controller disconnects<br />

the "warning" signal is generated at appox. 46 kV.

6.0 Bus module<br />

6.1 Overview<br />

Operating Manual<br />

X4<br />

The dynamic du/dt disconnection treshold can be set between 0<br />

and approx. 999 kV/s. This part of the controller continuously<br />

monitors in which time a determined voltage value is achieved,<br />

either during voltage rise or fall (voltage slope steepness). If the<br />

voltage slope is steeper than permitted by the adjustable value<br />

the controller will indicate "fault". The dynamic disconnection is<br />

independent of the static disconnection treshold. This means that<br />

a dynamic disconnection may also be triggered if the voltage is<br />

significantly above the static disconnection value.<br />

On the front plate of the HV control unit the type of disconnection,<br />

either static of dynamic, will be displayed. In addition a collective<br />

fault is output to the external control system.<br />

P1<br />

Nr. 81<strong>01</strong>23BE_02/00<br />

Page 14 of 17<br />

X1<br />

X5<br />

X2<br />

X3

6.2 Main supply<br />

6.3 HV Cascade<br />

Connection<br />

Operating Manual<br />

The power is supplied to connector X1 and is only required with<br />

integrated supply module SEVM 1<strong>01</strong> and is therefore not necessary<br />

in case of external power supply via connector X3.<br />

Pin Designation Signal Function<br />

<strong>01</strong> L1 230V 150VA 50Hz supply voltage<br />

02 N 230V 150VA 50Hz supply voltage<br />

<<br />

03 PE PE<br />

6.4 External Supplies<br />

The HV cascade is connected via connector X2.<br />

Pin Designation Signal Function<br />

<strong>01</strong> R+ 0-36V DC 120 VA supply<br />

02 PEGND 0 ground<br />

03 E+ 17V DC 10VA auxiliary voltage<br />

04 I-Ist 0-10V DC current actual value<br />

05 U-Ist 0-10V DC voltage actual value<br />

Attention!<br />

The external power supply is realized via connector X3 and will<br />

only be required without a supply module integrated, for instance<br />

if various controllers are supplied by a single power supply.<br />

<<br />

<<br />

<<br />

Pin 02 (GND) must be connected to ground.<br />

Pin 03 or 04 (36VAC) must not be grounded.<br />

Pin Designation Signal Function<br />

<strong>01</strong> 24V DC 24V DC 20 VA Steuerspannung<br />

02 GND 0 Masse<br />

03 36V AC2 36V 120VA 50Hz Versorgung HS-Erzeuger<br />

04 36V AC1 36V 120VA 50Hz Versorgung HS-Erzeuger<br />

<<br />

6.4 Inputs and Outputs<br />

6.6 Earth Reversing<br />

Switch Connector X5<br />

Operating Manual<br />

Via connector X4 different inputs and outputs are available.<br />

Pin Bezeichnung Signal Funktion<br />

<strong>01</strong> PEGND 0 Ground<br />

02 U-Ist-Ext 0-10V DC 0,1mA Actual value output<br />

03 I-Ist-Ext 0-10V DC 0,1mA Actual value output<br />

04 HV-On 24V DC 100mA Output<br />

05 Fault 24V DC 100mA Output<br />

06 Relase 24V DC 100mA Output<br />

07 Warning 24V DC 100mA Output<br />

08 DX/DT 0-10V DC Analog nom. value input Dyn.<br />

09 U-Nom. 0-10V DC Analog nom. value input voltage<br />

10 I-Nom. 0-10V DC Analog nom. value input current<br />

11 HV-On 24V DC <strong>Control</strong> signal HV on<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

Stage 1<br />

Stage 2<br />

Stage 3<br />

Stage 4<br />

Analog Stage<br />

I-Mode<br />

24V DC<br />

24V DC<br />

24V DC<br />

24V DC<br />

24V DC<br />

24V DC<br />

<<br />

Operating Manual<br />

Pin Designation Signal Function<br />

<strong>01</strong> ES 24V DC 100mA Triggering of earth reversing switch<br />

02 GND 0 Ground<br />

03 24V DC 24V DC Supply for feedback signal<br />

04 Feedback. 24V DC Feedback from earth revers. switch<br />

Spare parts and<br />

Service<br />

No guarantee whatsoever is valid, if no original parts are used!<br />

Our address:<br />

<<br />

Schnier <strong>Elektrostatik</strong> GmbH<br />

Robert-Bosch-Straße 60<br />

72810 Gomaringen, Germany<br />

Tel.: +49 (0) 70 72 / 91 43 -0<br />

Fax: +49 (0) 70 72 / 91 43 -20<br />

<<br />

Nr. 81<strong>01</strong>23BE_02/00<br />

Page 17 of 17