Cal Stadium Renovation - Trimble

Cal Stadium Renovation - Trimble

Cal Stadium Renovation - Trimble

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Pre-Surveying<br />

Helps Keep<br />

Railroads on<br />

Track<br />

The need for speed and ride comfort for both passenger<br />

and freight operations puts high demands on the<br />

fundamental elements of railway infrastructure—the<br />

roadbed and tracks. Roadbed and track quality must be<br />

established during initial construction and maintained over<br />

time. This involves proper ballast laying and grading, sleepers<br />

(ties) positioning, and, especially, ballast tamping and<br />

compressing for exact rail positioning. Since much of the<br />

work—whether new construction or routine maintenance—<br />

depends upon accurately establishing or verifying the track<br />

position, high-accuracy survey technology is critical.<br />

Track Renewal in Central Germany<br />

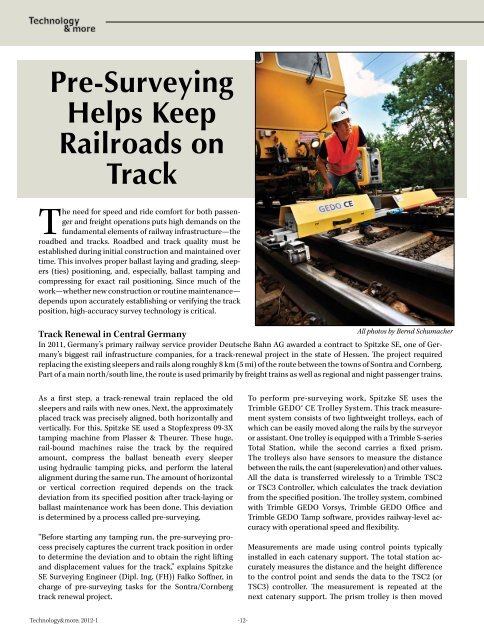

All photos by Bernd Schumacher<br />

In 2011, Germany’s primary railway service provider Deutsche Bahn AG awarded a contract to Spitzke SE, one of Germany’s<br />

biggest rail infrastructure companies, for a track-renewal project in the state of Hessen. The project required<br />

replacing the existing sleepers and rails along roughly 8 km (5 mi) of the route between the towns of Sontra and Cornberg.<br />

Part of a main north/south line, the route is used primarily by freight trains as well as regional and night passenger trains.<br />

As a first step, a track-renewal train replaced the old<br />

sleepers and rails with new ones. Next, the approximately<br />

placed track was precisely aligned, both horizontally and<br />

vertically. For this, Spitzke SE used a Stopfexpress 09-3X<br />

tamping machine from Plasser & Theurer. These huge,<br />

rail-bound machines raise the track by the required<br />

amount, compress the ballast beneath every sleeper<br />

using hydraulic tamping picks, and perform the lateral<br />

alignment during the same run. The amount of horizontal<br />

or vertical correction required depends on the track<br />

deviation from its specified position after track-laying or<br />

ballast maintenance work has been done. This deviation<br />

is determined by a process called pre-surveying.<br />

“Before starting any tamping run, the pre-surveying process<br />

precisely captures the current track position in order<br />

to determine the deviation and to obtain the right lifting<br />

and displacement values for the track,” explains Spitzke<br />

SE Surveying Engineer (Dipl. Ing. (FH)) Falko Soffner, in<br />

charge of pre-surveying tasks for the Sontra/Cornberg<br />

track renewal project.<br />

Technology&more; 2012-1<br />

-12-<br />

To perform pre-surveying work, Spitzke SE uses the<br />

<strong>Trimble</strong> GEDO® CE Trolley System. This track measurement<br />

system consists of two lightweight trolleys, each of<br />

which can be easily moved along the rails by the surveyor<br />

or assistant. One trolley is equipped with a <strong>Trimble</strong> S-series<br />

Total Station, while the second carries a fixed prism.<br />

The trolleys also have sensors to measure the distance<br />

between the rails, the cant (superelevation) and other values.<br />

All the data is transferred wirelessly to a <strong>Trimble</strong> TSC2<br />

or TSC3 Controller, which calculates the track deviation<br />

from the specified position. The trolley system, combined<br />

with <strong>Trimble</strong> GEDO Vorsys, <strong>Trimble</strong> GEDO Office and<br />

<strong>Trimble</strong> GEDO Tamp software, provides railway-level accuracy<br />

with operational speed and flexibility.<br />

Measurements are made using control points typically<br />

installed in each catenary support. The total station accurately<br />

measures the distance and the height difference<br />

to the control point and sends the data to the TSC2 (or<br />

TSC3) controller. The measurement is repeated at the<br />

next catenary support. The prism trolley is then moved