Technical Information The Integro

Technical Information The Integro

Technical Information The Integro

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Technical</strong> <strong>Information</strong> <strong>The</strong> <strong>Integro</strong>

Model<br />

<strong>Integro</strong> (633.001)<br />

<strong>Integro</strong> M (633.002)<br />

<strong>Integro</strong> L (633.004)<br />

3

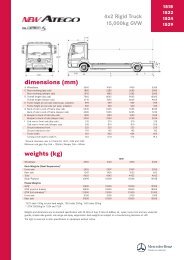

Dimensions/weights<br />

* dependent on country of registration – example here is Germany<br />

4<br />

INTEGRO INTEGRO M INTEGRO L<br />

Vehicle length 12,140 mm 12,980 mm 14,920 mm<br />

Vehicle width 2,550 mm 2,550 mm 2,550 mm<br />

Vehicle height (incl. air conditioning system) 3,355 mm 3,355 mm 3,355 mm<br />

Wheelbase, front axle-drive axle 6,080 mm 6,920 mm 6,920 mm<br />

Wheelbase, drive axle-trailing axle - - 1,600 mm<br />

Front/rear overhang 2,760 mm/3,300 mm 2,760 mm/3,300 mm 3,100 mm/3,300 mm<br />

Angle of approach/departure (at sides) 7.65°/6,9° 7.65°/6,9° 6.6°/6.9°<br />

Tyre size 295/80 R 22.5 295/80 R 22.5 295/80 R 22.5<br />

Passenger handling capacity (standard) 53 57 69<br />

Entrance height front/rear 350 mm/365 mm 350 mm/365 mm 350 mm/375 mm<br />

Internal door width front/centre 774 mm/1,224 mm 774 mm/1,224 mm 774 mm/1,224 mm<br />

Standing height in aisle 2,170 mm 2,170 mm 2,170 mm<br />

Height of floor, driver’s area (above road surface) 860 mm 860 mm 860 mm<br />

Height of floor, aisle (above road surface) 860 mm 860 mm 860 mm<br />

Platform height (above aisle floor) 170 mm 170 mm 170 mm<br />

Waistline height (above platforms) 815 mm 815 mm 815 mm<br />

Luggage compartment/capacity approx. 4.5 m 3 approx. 5.5 m 3 approx. 6.2 m 3<br />

Fuel tank capacity 340 l 340 l 340 l<br />

Capacity of AdBlue additive tank 50 l 50 l 50 l<br />

Gross vehicle weight, max. permissible* 18,000 kg 18,000 kg 24,000 kg<br />

Axle loads, max. permissible*<br />

-Front axle 7,100 kg 7,100 kg 7,100 kg<br />

-Rear axle 11,500 kg 11,500 kg 11,500 kg<br />

-Trailing axle - - 5,750 kg

Turning circle<br />

A C¹ B<br />

E<br />

F<br />

D<br />

A C1 C2 B<br />

INTEGRO INTEGRO M INTEGRO L<br />

A: Front overhang 2,760 mm 2,760 mm 3,100 mm<br />

B: Rear overhang 3,300 mm 3,300 mm 3,300 mm<br />

C1: Wheelbase 6,080 mm 6,920 mm 6,920 mm<br />

C2: Wheelbase, rear - - 1,600 mm<br />

D: Minimum turning circle approx. 20,980 mm approx. 23,120 mm approx. 23,450 mm<br />

E: Minimum track circle approx. 16,950 mm approx. 19,080 mm approx. 18,850 mm<br />

F: Swept annular width – minimum turning circle approx. 6,930 mm approx. 7,330 mm approx. 7,570 mm<br />

D: BOKraft turning circle 25,000 mm 25,000 mm 25,000 mm<br />

F: BOKraft swept annular width approx. 5,870 mm approx. 6,750 mm approx. 6,970 mm<br />

F: Maximum permissible swept annular width according to BOKraft 7,200 mm 7.200 7,200 mm<br />

Maximum front axle turning angle, inside/outside wheel 58°/46° 58°/46° 58°/46°<br />

E<br />

F<br />

D<br />

5

Drive train/Technology<br />

Specific Spez. consumption Verbrauch<br />

(g/kWh)<br />

6<br />

Output Leistung (kW) (kW)<br />

380<br />

340<br />

300<br />

260<br />

220<br />

180<br />

140<br />

100<br />

210<br />

190<br />

Euro V engine<br />

170 800 1000 1200 1400 1600 1800 2000 2200<br />

2000<br />

1600<br />

1200<br />

800<br />

Speed (rpm)<br />

Drehzahl (1/min)<br />

P 220 kW at 2,000 rpm (80/1269/EEC)<br />

max P 220 kW bei 2000/min (80/1269/EWG)<br />

max<br />

Md 1250<br />

T<br />

Nm<br />

1250<br />

bei 1100/min,<br />

Nm at 1,100<br />

Md<br />

rpm, max = 19%<br />

T = 19%<br />

trans<br />

max ü Stationäre Volllastkurven<br />

Steady-state full-load curves<br />

Torque (Nm)<br />

Drehmoment (Nm)<br />

INTEGRO INTEGRO M<br />

Engine (Euro V/EEV*) OM 457 hLA OM 457 hLA<br />

Displacement 11,967 cm 3 11,967 cm 3<br />

Output (standard) 220 kW 220 kW<br />

Cylinders/arrangement 6/in-line 6/in-line<br />

Max. torque 1,250 Nm at 1,100 rpm 1,250 Nm at 1,100 rpm<br />

Transmission Mercedes-Benz GO 190 Mercedes-Benz GO 190<br />

Axles<br />

Front axle ZF, independent wheel suspension ZF, independent wheel suspension<br />

Drive axle Mercedes-Benz HO6 Mercedes-Benz HO6<br />

Trailing axle – –<br />

Steering ZF 8098 Servocom ZF 8098 Servocom<br />

Brakes Electronic Braking System with disk brakes<br />

Hydrodynamic retarder (Voith VR 115 E)<br />

Anti-lock Braking System (ABS)<br />

* Our buses achieve the EEV emission standard (optional), depending on model and power unit, with or without a diesel particulate filter.

Drive train/Technology<br />

Leistung (kW)<br />

Output (kW)<br />

Specific Spez. Verbrauch consumption<br />

(g/kWh)<br />

380<br />

340<br />

300<br />

260<br />

220<br />

180<br />

140<br />

100<br />

210<br />

190<br />

170<br />

Euro V engine<br />

800 1000 1200 1400 1600 1800 2000 2200<br />

Drehzahl Speed (1/min) (rpm)<br />

P max 260 kW at 2,000 rpm (80/1269/EEC)<br />

P 260 kW<br />

T<br />

bei<br />

1600<br />

2000/min<br />

Nm at<br />

(80/1269/EWG)<br />

1,100 rpm, T = 29%<br />

max trans<br />

max<br />

Md 1600 Nm bei 1100/min, Md = 29% Stationäre Volllastkurven<br />

max Steady-state full-load curves ü<br />

2000<br />

1600<br />

1200<br />

800<br />

Torque Drehmoment (Nm) (Nm)<br />

INTEGRO L<br />

Engine (Euro V/EEV) OM 457 hLA<br />

Displacement 11,967 cm3 Output (standard) 260 kW<br />

Cylinders/arrangement 6/in-line<br />

Max. torque 1,600 Nm at 1,100 rpm<br />

Transmission<br />

Axles<br />

Mercedes-Benz GO 190<br />

Front axle ZF, independent wheel suspension<br />

Drive axle Mercedes-Benz HO6<br />

Trailing axle ZF, actively steered trailing axle<br />

Steering ZF 8098 Servocom<br />

Brakes Electronic Braking System with disk brakes<br />

Hydrodynamic retarder (Voith VR 115 E)<br />

Anti-lock Braking System (ABS)<br />

7

<strong>Integro</strong> seating variants<br />

Standard<br />

Extra (example)<br />

Extra (example)<br />

8<br />

Number of seats 53<br />

Rows 14+12<br />

Number of seats 49<br />

Rows 12+12<br />

Number of seats 55<br />

Rows 14+13

<strong>Integro</strong> M seating variants<br />

Standard<br />

Extra (example)<br />

Extra (example)<br />

Number of seats 57<br />

Rows 15+13<br />

Number of seats 53<br />

Rows 13+13<br />

Number of seats 59<br />

Rows 15+14<br />

9

<strong>Integro</strong> L seating variants<br />

Standard<br />

Extra (example)<br />

Extra (example)<br />

10<br />

Number of seats 69<br />

Rows 18+16<br />

Number of seats 65<br />

Rows 16+16<br />

Number of seats 57<br />

Rows 14+14

Standard and optional equipment (selected)<br />

Engine and running gear<br />

Engine Mercedes-Benz OM 457 hLA 220 kW (Euro V)<br />

Engine Mercedes-Benz OM 457 hLA 260 kW (Euro V)<br />

Engine Mercedes-Benz OM 457 hLA 300 kW (Euro V)<br />

Emission standard Euro V<br />

Emission standard EEV<br />

Transmission 6-speed Mercedes-Benz GO 190, power-assisted<br />

Transmission 6-speed Mercedes-Benz GO 210, power-assisted<br />

Transmission Mercedes-Benz GO 240-8, 8-speed, PowerShift (MPS), incl. bus stop brake<br />

Transmission Voith D 864.3E, automatic transmission<br />

Transmission ZF AS Tronic, 12-speed, automated transmission incl. bus stop brake<br />

Retarder hydrodynamic, type Voith VR 115 E<br />

Electronic braking system (EBS)<br />

Electronic Stability Programme (ESP ® )<br />

Brake Assist (BA)<br />

Anti-lock Braking System (ABS)<br />

Anti-Slip Regulation (ASR)<br />

Bus stop brake with/without starting-off lock<br />

Electronic level control<br />

Combined body lowering and lifting mechanism<br />

Electronic lifting and lowering system incl. kneeling<br />

Alloy rims with hub centring<br />

l Standard equipment/Equipment at no extra charge Extra<br />

INTEGRO INTEGRO M INTEGRO L<br />

l l -<br />

- -<br />

l l l<br />

l l l<br />

- -<br />

l l l<br />

l l l<br />

l<br />

-<br />

-<br />

11

Air conditioning<br />

Roof ventilator<br />

Roof-mounted heating and ventilation system<br />

Roof-mounted air conditioning system 32 kW with climate control and driver area climate control<br />

Roof-mounted air conditioning system 35 kW with climate control and driver area climate control<br />

Roof-mounted air conditioning system 39 kW with climate control and driver area climate control<br />

Roof hatch, electrically operated with automatic close via rain sensor<br />

Driver’s area<br />

Driver’s seat GRAMMER Tourea MSG 90.6 PG<br />

Driver’s seat ISRI 6860/875<br />

Seat heater for driver’s seat<br />

Driver’s cab with door and screening curtain behind driver<br />

Provision for a ticket machine printer<br />

Mountings for payment systems<br />

Steering column with height and tilt adjustment, steering wheel lock, exit position<br />

Cruise control<br />

Exterior mirrors heated, main mirror electrically adjustable<br />

Microphone integrated in back of driver’s seat<br />

Central locking for luggage compartment doors (right and left separate), via rocker switch on instrument panel<br />

Reversing aid with visual display in A-pillar<br />

Blind on windscreen, electrically operated<br />

Fire detection system for engine compartment monitoring<br />

Tour guide’s seat<br />

Tour guide's seat, single (on aisle side) with armrest, 3-point seat belt, foldup seat cushion<br />

Tour guide's seat, single (on wall side) with armrest, 3-point seat belt, foldup seat cushion<br />

Tour guide's seat, 2 seats with armrests, 3-point seat belt, foldup seat cushion<br />

Reading lamp for tour guide’s seat<br />

Microphone for tour guide’s seat with helix cable<br />

Refrigerator in the instrument panel, front right<br />

l Standard equipment/Equipment at no extra charge Extra<br />

12<br />

INTEGRO INTEGRO M INTEGRO L<br />

l l l<br />

- -<br />

- -<br />

l l l<br />

l l l<br />

l l l<br />

l l l<br />

-<br />

-

Interior<br />

Inter Star Eco seats, attached handle, aisle-side corner handle, 2-point seat belt<br />

Travel Star Eco seats, rigid backrest, integrated aisle-side grab handles, bag hook, 2-point seat belt<br />

Folding tables on seat backs, with support arm/screwed on<br />

Luggage racks with floor/with screens<br />

Sidewall covering in needle web<br />

Other<br />

Headlamp cleaning system<br />

Litronic headlamps with headlamp cleaning system<br />

Double-pane side windows heat-absorbing, grey tint<br />

2 hinged panes in side windows<br />

BRAUN lift at centre entry, incl. bus stop brake<br />

Brackets for ski box at rear, with socket<br />

Ski box type I, brackets at rear, with socket<br />

<strong>Information</strong> systems<br />

Audio system BOSCH Classic Line incl. CD player<br />

Audio system BOSCH Professional Line incl. CD and DVD player<br />

Multi-function antenna for radio and mobile phone<br />

Destination indicator in the front end, on the side and at the rear<br />

Destination indicator LED/LCD matrix<br />

Passenger signalling system<br />

Digital clock in front dome<br />

INTEGRO INTEGRO M INTEGRO L<br />

l l l<br />

l l l<br />

l l l<br />

- -<br />

l l l<br />

l l l<br />

l Standard equipment/Equipment at no extra charge Extra <strong>Technical</strong> modifications may have occurred after the copy deadline. This data sheet is only an extract of possible equipment. Some<br />

equipment items are country-dependent. We reserve the right to make technical modifications. <strong>The</strong>refore, please contact your<br />

Mercedes-Benz bus sales representative for the latest binding version.<br />

-<br />

13

Glossary<br />

Anti-lock Braking System (ABS)<br />

<strong>The</strong> braking forces acting on the individual wheels are<br />

distributed by the ABS so that even in an emergency<br />

braking situation no wheel is blocked for any length of time<br />

and the steerability of the bus is largely maintained.<br />

Anti-Slip Regulation (ASR)<br />

ASR prevents wheelspin when driving away on a slippery<br />

surface. It provides no more power than the drive wheels<br />

are able to transfer to the road surface. Wheelspin by one<br />

wheel – e.g. on an icy roadside – is prevented by metered<br />

braking.<br />

14<br />

Brake Assist (BA)<br />

<strong>The</strong> BA electronics are able to detect emergency braking<br />

situations and automatically build up maximum braking<br />

power within fractions of a second. This shortens the<br />

stopping distance of the bus by a measurable amount.<br />

Electronic Stability Programme (ESP ® )<br />

In situations where the driving dynamics are critical, the<br />

electronic stability programme selectively controls the<br />

braking forces on each wheel individually. At the same<br />

time the engine power is throttled back. Within the<br />

boundaries of the physics, finely regulating the braking of<br />

the vehicle in this way prevents any possible "breakaway"<br />

by the vehicle. Thus ESP ® contributes noticeably to a<br />

reduction in the risk of skidding during cornering or<br />

evasive manoeuvres. If the bus enters a critical dynamic<br />

condition in wide curves or when rapidly changing lanes,<br />

the speed of the vehicle speed continues to be automatically<br />

reduced until directional stability is restored.<br />

Cataphoretic Immersion Priming (KTL)<br />

Cataphoretic immersion priming (KTL) is an electrochemical<br />

process for coating the complete body shell in an<br />

immersion bath. It is ideal for painting complicated<br />

structures and large numbers of units. This water-based<br />

paint protects the vehicle so perfectly against corrosion<br />

because the paint coat is applied everywhere to the body<br />

with uniform thickness. Cataphoretic immersion priming<br />

is demonstrably the best protection against corrosion in<br />

vehicle construction at present available.

For further information, contact your Mercedes-Benz Buses and Coaches representative. Or visit us online at: www.mercedes-benz.de/omnibus<br />

<strong>The</strong> illustrations also depict extras and accessories that are not part of the standard scope of supply. <strong>The</strong> technical information in this brochure applies to Germany (Status: July 2010).<br />

We reserve the right to make production changes.<br />

EvoBus GmbH, Mercedes-Benz Omnibusse, BUS/MPM-M 6098.3033.02.10/0810/08 Printed in the Federal Republic of Germany / Imprimé en République Fédérale d’Allemagne<br />

EvoBus GmbH, Mercedes-Benz Omnibusse, Hanns-Martin-Schleyer-Str. 21-57, D-68301 Mannheim, Germany, Phone: +49 (0)621 / 740-0, Fax: +49 (0)621/740-42 51<br />

16