Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ENGLISH<br />

1<br />

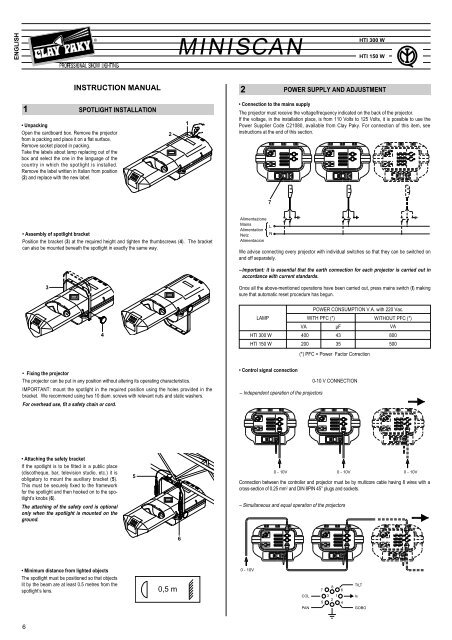

• Unpacking<br />

Open the cardboard box. Remove the projector<br />

from is packing and place it on a flat surface.<br />

Remove socket placed in packing.<br />

Take the labels about lamp replacing out of the<br />

box and select the one in the language of the<br />

country in which the spotlight is installed.<br />

Remove the label written in Italian from position<br />

(2) and replace with the new label.<br />

6<br />

3<br />

®<br />

INSTRUCTION MANUAL<br />

SPOTLIGHT INSTALLATION<br />

• Assembly of spotlight bracket<br />

Position the bracket (3) at the required height and tighten the thumbscrews (4). The bracket<br />

can also be mounted beneath the spotlight in exactly the same way.<br />

4<br />

• Fixing the projector<br />

The projector can be put in any position without altering its operating characteristics.<br />

IMPORTANT: mount the spotlight in the required position using the holes provided in the<br />

bracket. We re<strong>com</strong>mend using two 10 diam. screws with relevant nuts and static washers.<br />

For overhead use, fit a safety chain or cord.<br />

• Attaching the safety bracket<br />

If the spotlight is to be fitted in a public place<br />

(discotheque, bar, television studio, etc.) it is<br />

obligatory to mount the auxiliary bracket (5).<br />

This must be securely fixed to the framework<br />

for the spotlight and then hooked on to the spotlight’s<br />

knobs (6).<br />

The attaching of the safety cord is optional<br />

only when the spotlight is mounted on the<br />

ground.<br />

• Minimum distance from lighted objects<br />

The spotlight must be positioned so that objects<br />

lit by the beam are at least 0.5 metres from the<br />

spotlight’s lens.<br />

5<br />

2<br />

0,5 m<br />

<strong>MINISCAN</strong><br />

6<br />

1<br />

<strong>MINISCAN</strong><br />

2<br />

• Connection to the mains supply<br />

We advise connecting every projector with individual switches so that they can be switched on<br />

and off separately.<br />

– Important: it is essential that the earth connection for each projector is carried out in<br />

accordance with current standards.<br />

Once all the above-mentioned operations have been carried out, press mains switch (I) making<br />

sure that automatic reset procedure has begun.<br />

LAMP<br />

POWER SUPPLY AND ADJUSTMENT<br />

The projector must receive the voltage/frequency indicated on the back of the projector.<br />

If the voltage, in the installation place, is from 110 Volts to 125 Volts, it is possible to use the<br />

Power Supplier Code C21080, available from Clay Paky. For connection of this item, see<br />

instructions at the end of this section.<br />

Alimentazione<br />

Mains<br />

Alimentation<br />

Netz<br />

Alimentacion<br />

0 - 10V<br />

7<br />

L<br />

N<br />

VA<br />

POWER CONSUMPTION V.A. with 220 Vac.<br />

WITH PFC (*)<br />

HTI 300 W 400 43<br />

800<br />

µF<br />

WITHOUT PFC (*)<br />

HTI 150 W 200 35<br />

500<br />

• Control signal connection<br />

– Independent operation of the projectors<br />

(*) PFC = Power Factor Correction<br />

0 - 10V 0 - 10V 0 - 10V<br />

5 PAN<br />

0-10 V CONNECTION<br />

Connection between the controller and projector must be by multicore cable having 8 wires with a<br />

cross-section of 0.25 mm 2 and DIN 8PIN 45° plugs and sockets.<br />

– Simultaneous and equal operation of the projectors<br />

7<br />

8<br />

6<br />

TILT<br />

COL<br />

5<br />

3 1<br />

2<br />

4<br />

Is<br />

PAN GOBO<br />

HTI 300 W<br />

HTI 150 W<br />

VA<br />

i

DMX 512<br />

RS 232/423<br />

• Projector adddressing (for digital signals)<br />

Each <strong>MINISCAN</strong> occupies 4 channels. To ensure that the control signals are properly directed<br />

to each projector the projector needs to have a address given to it. This is to be done for each<br />

and every <strong>MINISCAN</strong> projector by changing the DIL switches as set out in the table below.<br />

THE DIGITAL START<br />

ADDRESS IS THE SUM<br />

OF THE NUMBERS<br />

PRODUCED BY THE<br />

SELECTED SWITCHES<br />

DIGITAL INPUT<br />

DIGITAL<br />

START<br />

ADDRESS<br />

AND<br />

OPTIONS<br />

SELECT<br />

EG.<br />

RESPOND<br />

C.1 - 4<br />

EG.<br />

RESPOND<br />

C.17 - 20<br />

RUN TEST<br />

SEQUENCE<br />

1<br />

2<br />

4<br />

8<br />

16<br />

32<br />

64<br />

128<br />

256<br />

TEST<br />

ON<br />

DMX 512 : 1 = ,2 = SIG - ,3 = SIG +<br />

RS232/423 : 1 = ,2 = SIG ,3 = SIG<br />

Projector 1 - Channels 1-4<br />

Projector 2 - Channels 5-8<br />

Projector 3 - Channels 9-12<br />

Projector 4 - Channels 13-16<br />

Projector 5 - Channels 17-20<br />

Projector 6 - Channels 21-24<br />

Projector 7 - Channels 25-28<br />

Projector 8 - Channels 29-32<br />

Projector 9 - Channels 33-36<br />

Projector 10 - Channels 37-40<br />

Projector 11 - Channels 41-44<br />

Projector 12 - Channels 45-48<br />

Projector 13 - Channels 49-52<br />

Projector 14 - Channels 53-56<br />

Projector 15 - Channels 57-60<br />

RS 232/423 - DMX 512 CONNECTION<br />

Connection between the controller and the projector or between one projector and another must<br />

be by screened 2 core cable. Canon 5PIN XLR plugs and sockets.<br />

When using DMX, a terminating plug containing a 100 R resistor between pins 2 and 3 must be<br />

inserted in the last spotlight. This is not required for PMX.<br />

The wires must not <strong>com</strong>e into contact with each other or with the metal covering of the<br />

plug.<br />

The screen of the cable should be connected to pin 1 and the body of the XLR plug or<br />

socket.<br />

RS232/423<br />

(PMX)<br />

SCREEN<br />

1 2<br />

3<br />

5 4<br />

CODIFICA<br />

SIGNAL<br />

SIGNAL<br />

1 2 3 4 5 6 7 8 9 10 11 12<br />

ON<br />

OFF<br />

ON<br />

OFF<br />

With the projector on, put the test switch in position ON for a few seconds to automatically reset<br />

the projector. Leave the test switch ON to <strong>com</strong>plete the self-test; at the end of the self-test<br />

return the test switch to OFF.<br />

ON<br />

OFF<br />

ON<br />

OFF<br />

ON<br />

OFF<br />

ON<br />

OFF<br />

ON<br />

OFF<br />

ON<br />

OFF<br />

ON<br />

OFF<br />

ON<br />

OFF<br />

ON<br />

OFF<br />

ON<br />

OFF<br />

ON<br />

OFF<br />

ON<br />

OFF<br />

ON<br />

OFF<br />

ON<br />

OFF<br />

1<br />

PAN<br />

TILT<br />

2<br />

4<br />

DMX<br />

512<br />

Projector selection<br />

COL Is<br />

PAN<br />

ANALOGUE<br />

INPUTS 0 - 10V<br />

8<br />

16<br />

32<br />

SCREEN<br />

64<br />

1 2<br />

3<br />

5 4<br />

TILT<br />

GOBO<br />

128<br />

256<br />

TEST<br />

SIGNAL<br />

SIGNAL<br />

3<br />

CHANNEL<br />

CHANNEL<br />

POSITION<br />

1 COLOUR Keep at 0% (White)<br />

2 GOBOS 100% (Open)<br />

3 PAN 50% (Mild-way position)<br />

4 TILT 50% (Mild-way position)<br />

POSITION<br />

1 COLOUR Keep at 0% (White)<br />

2 GOBOS Adjust the Gobo as required<br />

3 PAN 50% (Mild-way position)<br />

4 TILT 50% (Mild-way position)<br />

FOCUSSING<br />

• Aiming the projector<br />

Before adjusting the spotlight, prepare the channels as shown in the following table.<br />

Once the above-mentioned operations have been carried out, proceed to loosen knob (4) and<br />

move the projector along bracket (3) until light beam is focussed on centre spot.<br />

Tighten knobs (4).<br />

• Adjusting the lens<br />

Set out the channels as shown in the table below and carry out the operations described.<br />

Loosen the thumbscrew and rotate the lens (9) on its axis until the projected image is in focus.<br />

Lock in position with the knob (8).<br />

4<br />

CHANNEL FUNCTIONS AND OPTIONS<br />

Channel<br />

1<br />

2<br />

3<br />

4<br />

Function<br />

COLOUR<br />

GOBOS / DIMMER / STOPPER-STROBE<br />

PAN<br />

TILT<br />

To chose an option, set the DIL switches as explained below.<br />

1<br />

2<br />

4<br />

8<br />

16<br />

32<br />

64<br />

128<br />

256<br />

TEST<br />

ON<br />

OPTION SELECT<br />

1 2 3 4 5 6 7 8 9 10 11 12<br />

4<br />

3<br />

PAN<br />

TILT<br />

8 9<br />

7<br />

ENGLISH

• COLOUR - channel 1<br />

• PAN - channel 3<br />

8<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

• GOBOS / DIMMER / STOPPER-STROBE - channel 2<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

ROSA<br />

BLU<br />

ARANCIO<br />

VERDE<br />

VIOLA<br />

GIALLO<br />

ROSSO<br />

BIANCO<br />

Linear colour change following the<br />

movement of the slider.<br />

In this way you can stop the colour<br />

wheel in a mid-way position between<br />

two colours thus giving bi-colour<br />

beams.<br />

From 50% to 100% the wheel begins<br />

to rotate with increasing speed: 0 to<br />

300 r.p.m.<br />

Shutter opens gradually in cursor<br />

range from 0 to 50% until full aperture.<br />

From 30% to 50% strobe effect is<br />

obtained with increase in speed from<br />

1 to 7 flash/second.<br />

On 50% aperture is fixed.<br />

From 60% GOBOS sequence begins<br />

until 85% as indicated in diagram.<br />

From 85 to 100% of cursor range,<br />

aperture ix fixed.<br />

1<br />

2<br />

4<br />

8<br />

16<br />

32<br />

64<br />

128<br />

256<br />

TEST<br />

PAN<br />

TILT<br />

ON<br />

1 2 3 4 5 6 7 8 9 10 11 12<br />

Standard operation<br />

Horizontal movement of the mirror (PAN)<br />

as you advance the slider.<br />

Gradual advance from one end of the slider<br />

to the other.<br />

The mirror can be held in any position at will.<br />

1<br />

2<br />

4<br />

8<br />

16<br />

32<br />

64<br />

128<br />

256<br />

10 TEST<br />

ON<br />

PAN<br />

TILT<br />

1 2 3 4 5 6 7 8 9 10 11 12<br />

Optional operation<br />

The start position and the direction of<br />

movement are inverted.<br />

• TILT - channel 4<br />

5<br />

BEAM OPENING m<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

Lamp HMI HTI 1200 150<br />

4<br />

3<br />

2<br />

1<br />

0<br />

1<br />

2<br />

3<br />

1<br />

2<br />

4<br />

8<br />

16<br />

32<br />

64<br />

128<br />

256<br />

TEST<br />

ON<br />

PAN<br />

TILT<br />

1 2 3 4 5 6 7 8 9 10 11 12<br />

Standard operation<br />

Vertical motion of the mirror (TILT) happens<br />

simultaneously with the advance of<br />

the adjustment dial. Gradual advance from<br />

one end of the dial to the other.<br />

The mirror can be held in any position at will.<br />

1<br />

2<br />

4<br />

8<br />

16<br />

32<br />

64<br />

128<br />

256<br />

TEST<br />

PAN<br />

TILT<br />

ON<br />

1 2 3 4 5 6 7 8 9 10 11 12<br />

Optional operation<br />

The start position and the direction of<br />

movement are inverted.<br />

OBJECTIVE LENS<br />

Objective lens 1:2,5/165 - Standard dotation<br />

Lamp. HTI 300 10450 2610 1160 650 450 290 230 165<br />

BEAM OPENING m<br />

5700 1400 600 370 232 161 118 90<br />

LUX<br />

4<br />

0 2,5 5 7,5 10 12,5 15<br />

17,5 20 DISTANCE m<br />

0 0,4 0,79 1,2 1,60 2,00 2,40 2,40 2,80 3,20 DIAMETER m<br />

Objective lens 1:2,2/100 - Available on request<br />

Lamp. HTI 300 4000 1000 445 250 160 111 81 62<br />

Lamp HMI HTI 1200 150<br />

4<br />

2000 500 220 125 80 55 41 32<br />

3<br />

2<br />

1<br />

0<br />

1<br />

2<br />

3<br />

4<br />

0 2,5 5 7,5 10 12,5 15 17,5 20 DISTANCE m<br />

0 0,67 1,34 2,00 2,70 3,37 4,05 4,72 5,40 DIAMETER m<br />

15° 20'<br />

9°<br />

LUX

K Lux<br />

5<br />

10<br />

8<br />

6<br />

4<br />

3<br />

6<br />

2<br />

10<br />

8<br />

6<br />

4<br />

3<br />

2<br />

10<br />

8<br />

6<br />

4<br />

3<br />

2<br />

10<br />

8<br />

6<br />

4<br />

3<br />

2<br />

1<br />

4<br />

3<br />

2<br />

HTI 300W 1:2,2<br />

HTI 150W 1:2,2<br />

MAINTENANCE<br />

Important: disconnect from the mains supply<br />

before carrying out any work on the<br />

projector.<br />

• Opening the projector<br />

Slide cover (10) from the projector.<br />

Carry out the maintenance and then replace<br />

covers.<br />

• HTI 150 W Lamp replacement<br />

Slide the cover off the spotlight and then<br />

remove the lamp (11) by pulling it up from the<br />

socket (12).<br />

Insert the new lamp in the socket, ensuring that<br />

the pins are correctly positioned.<br />

• HTI 300 W Lamp replacement<br />

After having opened the spotlight, loosen the<br />

two ring nuts (13) at the ends of the lamp to be<br />

replaced and take it out from the brackets.<br />

Take the new lamp from the packaging and<br />

carefully read the enclosed instruction leaflet.<br />

Release the two ring nuts (13) at the ends,<br />

insert the lamp into the brackets (14) and then<br />

re-tighten the ring nuts.<br />

Important: to achieve an even beam of light,<br />

the knob (15) at the centre of the bulb must be<br />

facing down.<br />

HTI 300W 1:2,5<br />

0 5 10 15 20 25 m<br />

DISTANCE m<br />

HTI 150W 1:2,5<br />

15<br />

10<br />

12<br />

14<br />

13<br />

13<br />

11<br />

• Lens replacement<br />

Slide the cover off the spotlight, locate the<br />

optic unit and undo the 2 screws (16) which<br />

hold the lens holder plates (17). Pull the lenses<br />

(18) and (19) up and out.<br />

Insert the new lenses into the housings, reposition<br />

the two lens holder plates (17) and retighten<br />

the 2 screws (16).<br />

• Mirror replacement<br />

To replace the mirror (20), lever out the spring<br />

(21) with a screwdriver and draw out the mirror<br />

by pulling up.<br />

Insert the new mirror into the housing and attach<br />

to the spring (21) with silicon.<br />

• Replacing dichroic filter<br />

With the spotlight open, locate the filter to be<br />

replaced, grip between your fingers and push<br />

towards the mobile anchoring point (28) until<br />

the filter <strong>com</strong>es out from the fixed anchoring<br />

points. Bend the filter outwards and take out.<br />

Insert the new filter into the mobile point (28)<br />

and anchor into the two fixed points (29).<br />

• Red : code 080303/005<br />

• Yellow: code 080303/002<br />

• Violet: code 080303/004<br />

• Green: code 080303/003<br />

• Orange: code 080303/007<br />

• Blue: code 080303/001<br />

• Pink: code 080303/006<br />

• Replacing Gobo disc<br />

With the spotlight open, locate the Gobo disc<br />

(22) and its locking pin (23). Unscrew the pin<br />

and draw out the disc on its axis until it <strong>com</strong>es<br />

off the motor shaft. (24).<br />

Slide on the new Gobo disc until reaching the<br />

end, ensuring that the locking pin is exactly in<br />

the reference slot on the motor shaft. Tighten<br />

the pin (23) and check that the disc is centred.<br />

• Replacement of fuse<br />

To replace the fuse, press the tab (25) and<br />

take out the fuse holder (26).<br />

Having changed the fuse with a new one of<br />

the type indicated on the fuseholder’s identification<br />

plate (27), insert this unit until the tab<br />

(25) clicks shut.<br />

• Periodical cleaning<br />

To ensure that the light output of the projector<br />

does not fall it is essential to carry out periodical<br />

cleaning of those parts subject to the build<br />

up of dust and grease.<br />

Perfect working can be assured by following the<br />

instructions given below (unless installed in<br />

exceptionally dirty environments).<br />

Use a soft cloth and any glass detergent liquid<br />

to remove dirt from lenses and filters.<br />

Attention: Never use solvents or alcohol.<br />

Parts requiring frequent cleaning<br />

Parts requiring monthly cleaning<br />

Use a brush to clean the Gobos.<br />

We advise cleaning the internal parts thoroughly<br />

once a year.<br />

Remove the dust using a brush and an ordinary<br />

vacuum cleaner.<br />

19 17 16 18<br />

23 22<br />

27<br />

5 x 20<br />

5A T<br />

250 V<br />

24<br />

HTI 300 W<br />

HTI 150 W<br />

29<br />

20 21<br />

FUSE FUSE<br />

26 25<br />

28<br />

5 x 20<br />

1A T<br />

250 V<br />

9<br />

ENGLISH

7<br />

8<br />

110-125 VOLTS EXTERNAL FEEDER<br />

The feeder must be connected on the outside<br />

of the <strong>MINISCAN</strong> projector as shown below.<br />

– Fix the feeder box where you intend to fix the<br />

<strong>MINISCAN</strong>, using the two lateral holes on<br />

the bottom of the box.<br />

– Remove the nut on the central base plate<br />

screw.<br />

– Fix the <strong>MINISCAN</strong> to the feeder by inserting<br />

this screw in the correct hole on the projector<br />

bracket. Tighten the self-locking nut.<br />

– Connect the power cable to the socket on<br />

the rear panel of the <strong>MINISCAN</strong>.<br />

– Use the mobile socket supplied with the<br />

<strong>MINISCAN</strong> to connect the feeder to the<br />

mains supply.<br />

Power supplying box technical specifications:<br />

Incorporated autotransformer.<br />

Incorporated power correction factor.<br />

Voltage: Standard 110 V.<br />

At request 100 or 125 V<br />

10<br />

PROJECTOR FAILS TO LIGHT UP<br />

•<br />

•<br />

•••<br />

• •<br />

•<br />

9<br />

FAULTY ELECTRONICS<br />

FAULTY PROJECTION<br />

TROUBLE SHOOTING<br />

REDUCTION IN BRIGHTNESS<br />

PROJECTION WITH HALO EFFECT<br />

210<br />

170<br />

PFC: Reduce Power Consumption<br />

from 560 V.A. a 250 V.A.<br />

Dimensioni: 210 x 170 x 85 mm<br />

Peso: 3,6 kg<br />

FAULT<br />

POSSIBLE CAUSES CHECKS AND REMEDY<br />

No mains power Check for mains power at the supply<br />

socket and check the fuse.<br />

• Lamp worn out or defective<br />

Signal transmission cable short-circuited<br />

or disconnected<br />

Replace lamp (see instructions)<br />

Change cable.<br />

CARATTERISTICHE ELETTRO-MECCANICHE<br />

Power supply<br />

– HTI 150 W version:<br />

• 200-240 V 50/60 Hz<br />

– HTI 300 W version:<br />

• 220-240 V 50/60 Hz<br />

Lamp<br />

Two alternative versions are available<br />

1. Metal halide discharge lamp, with built-in<br />

transformer.<br />

– HTI 150 W.<br />

– Socket: GY9.5.<br />

– Lamp life: 750 hours on average.<br />

– Flux: 10,000 lumen.<br />

– Colour temperature: 6,500 K<br />

2. Metal halide discharge lamp, with built-in<br />

transformer.<br />

– HTI 300 W.<br />

– Socket: SFC 10-4.<br />

– Lamp life: 750 hours on average.<br />

– Flux: 20,000 lumen.<br />

– Colour temperature: 6,500 K<br />

Power consumption<br />

– See table<br />

Wrong coding See instructions for addressing spotlight.<br />

Electronic circuit fault Call in authorized technician.<br />

Broken lens Call in authorized technician.<br />

Dust and grese deposits Carry out cleaning operation<br />

(see instructions)<br />

Dirty objective lens and mirror Carry out cleaning operation<br />

(see instructions)<br />

Motors<br />

– 4 stepper motors, controlled by microprocessor.<br />

OPTICAL SYSTEM<br />

Optical group<br />

– Made from die-cast aluminium, consisting of<br />

TECHNICAL CHARACTERISTICS<br />

85<br />

double condenser lens and high efficiency<br />

parabolic mirror.<br />

Objective lens<br />

– Interchangeable with two different possibilities<br />

Standard 1:2.5/165 mm<br />

Wide-angle lens on request 1:2.2/100mm<br />

MIRROR ADAPTOR<br />

– Fixed on spotlight body<br />

Mirror<br />

– Very high luminous yield<br />

Rotation<br />

– Using two microstepping microprocessor controlled<br />

motors.<br />

– Variable rotation speed; Maximum values:<br />

• horizontal movement (pan)<br />

0.4 sec/150°<br />

• vertical movement (tilt)<br />

0.3 sec/110°<br />

– Smooth and continuous movement thanks to<br />

high resolution microstepping (5376 steps for<br />

pan, 1972 for tilt)<br />

CONTROL SYSTEM<br />

Channels<br />

– 4 control channels<br />

– Channel functions<br />

Channel 1 - Colour Disk<br />

Channel 2 - Gobos / Dimmer / Stopper-Strobe<br />

Channel 3 - Horizontal Mirror movement<br />

Channel 4 - Vertical Mirror movement<br />

Input<br />

– <strong>MINISCAN</strong> can accept either analogue or digital<br />

control signals from controllers or <strong>com</strong>puters.<br />

• analogue input: from 0 to 10 V<br />

• digital serial input: RS 232/423 or DMX 512<br />

SAFETY FEATURES<br />

Safety Devices<br />

– Equipment manufactured according to safety<br />

regulations in force: degree of protection IP 20.<br />

Devices<br />

– Automatic power supply cut out in case of<br />

overheating or cooling system failure.<br />

Cooling system<br />

– Forced ventilation cooling with axial fan.<br />

10<br />

M<br />

M<br />

M<br />

M<br />

L<br />

N<br />

E<br />

BROWN<br />

GREY<br />

ORANGE<br />

GREEN<br />

BROWN<br />

GREY<br />

ORANGE<br />

GREEN<br />

L<br />

N<br />

E<br />

BROWN<br />

GREY<br />

ORANGE<br />

GREEN<br />

BROWN<br />

GREY<br />

ORANGE<br />

GREEN<br />

fuse<br />

fuse<br />

B1<br />

B2<br />

B3<br />

B4<br />

A1<br />

A2<br />

A3 TILT<br />

A4<br />

fuse<br />

fuse<br />

B1<br />

B2<br />

B3<br />

B4<br />

MOT.<br />

PAN<br />

MOT.<br />

MOT.<br />

PAN<br />

A1<br />

A2<br />

A3 TILT<br />

A4<br />

MOT.<br />

SW<br />

20V<br />

20V<br />

SW<br />

20V<br />

20V<br />

WIRING DIAGRAM<br />

FAN<br />

FAN<br />

HTI 300 W<br />

MSW 0<br />

BACK PANNEL<br />

DIGITAL ANALOGUE<br />

HTI 150 W<br />

0<br />

BACK PANNEL<br />

BALLAST<br />

230V-50Hz<br />

DIGITAL ANALOGUE<br />

GENERAL CHARACTERISTIC<br />

Housing<br />

– Die-cast aluminium.<br />

– Epoxy paint finish.<br />

Bracket<br />

– Steel, epoxy paint finish mounting bracket.<br />

– Two positions.<br />

– Secondary safety support.<br />

Working Position<br />

– Any position.<br />

Inside<br />

– Easily accessible thanks to large opening<br />

cover.<br />

Dimensions<br />

HTI 150 W: mm 238x150x582; peso 9,2 kg<br />

HTI 300 W: mm 238x150x582; peso 11,2 kg<br />

Clay Paky reserves the right to modify any of the characteristics mentioned in its catalogue without prior<br />

notice to improve production quality.<br />

BALLAST<br />

230V-50Hz<br />

230V-60Hz<br />

200V-50Hz<br />

200V-60Hz<br />

L<br />

N<br />

230V-60Hz<br />

200V-50Hz<br />

200V-60Hz<br />

L<br />

N<br />

STOP<br />

STROBO<br />

COLOR<br />

DISK<br />

E<br />

L<br />

N<br />

STOP<br />

STROBO<br />

COLOR<br />

DISK<br />

E<br />

L<br />

N<br />

t<br />

t<br />

D<br />

L<br />

IGNITOR<br />

N<br />

GREEN<br />

C4<br />

ORANGE<br />

C3<br />

GREY<br />

C2<br />

BROWN<br />

C1<br />

GREEN<br />

D4<br />

ORANGE<br />

D3<br />

GREY<br />

D2<br />

BROWN<br />

D1<br />

D<br />

L<br />

IGNITOR<br />

N<br />

GREEN<br />

C4<br />

ORANGE<br />

C3<br />

GREY<br />

C2<br />

BROWN<br />

C1<br />

GREEN<br />

D4<br />

ORANGE<br />

D3<br />

GREY<br />

D2<br />

BROWN<br />

D1<br />

M<br />

M<br />

M<br />

M