Turning Gear for Gas Turbines - Voith Turbo

Turning Gear for Gas Turbines - Voith Turbo

Turning Gear for Gas Turbines - Voith Turbo

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

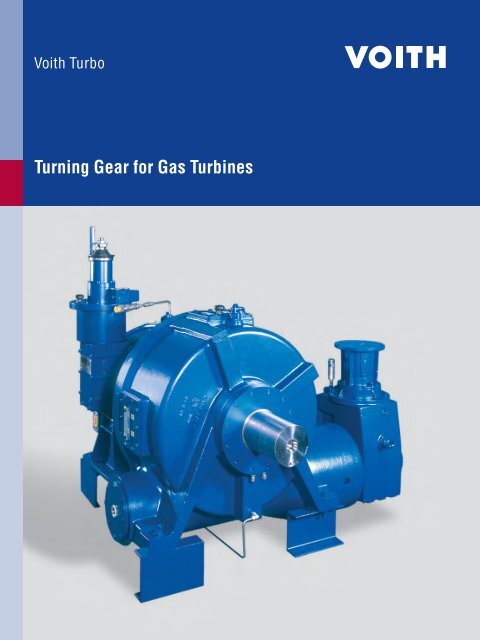

<strong>Turning</strong> <strong>Gear</strong> <strong>for</strong> <strong>Gas</strong> <strong>Turbines</strong>

Design<br />

<br />

<br />

Within the last 25 years, <strong>Voith</strong> has<br />

supplied more than 5 000 hydrodynamic<br />

torque converters and more<br />

than 1 000 of those with integrated<br />

turning gears <strong>for</strong> starting and turning<br />

gas turbines. These combined<br />

units have starting powers from<br />

400 kW up to 10 000 kW. The torque<br />

range of the turning gears varies<br />

from 6 000 to 110 000 Nm. However,<br />

greater torque values can easily be<br />

offered. With this experience we are<br />

now taking the next logical step in<br />

our product line with ”free standing”<br />

turning gears.<br />

<br />

The use of our well proven design<br />

from the integrated version provides<br />

the same outstanding reliability, availability<br />

and service life our customers<br />

are used to. Also our customers can<br />

take advantage of our well established<br />

and worldwide service network.<br />

<br />

<br />

<br />

<br />

1. Inner ring of overrunning clutch<br />

2. Outer ring of overrunning clutch<br />

3. Cage with clamping pieces<br />

4. <strong>Turning</strong> gear output shaft<br />

5. Housing<br />

6. Worm gear wheel<br />

7. Worm gear shaft<br />

8. Bevel gear (with overload<br />

limitation if required)<br />

9. Electric motor with manual turning<br />

capability<br />

10. Antifriction bearings <strong>for</strong> worm<br />

gear wheel<br />

11. Antifriction bearings <strong>for</strong> worm<br />

gear shaft<br />

12. Radial sleeve bearing<br />

13. Thrust bearing<br />

14. Lube oil supply<br />

15. Lube oil drain<br />

16. Connection coupling

Function<br />

The inner ring (1) is connected to<br />

the output shaft (4), and the outer<br />

ring (2) to the worm gear (6). The<br />

cage with the clamping pieces (3)<br />

is connected to the inner ring (1).<br />

The worm gear wheel (6) is driven<br />

through the worm gear shaft (7)<br />

and the bevel gear (8) is driven by<br />

the electric motor (9).<br />

The antifriction bearings (10, 11)<br />

support the worm gear set in the<br />

housing. The worm gear uses a<br />

constant oil fi lling, independent of<br />

the gas turbines oil supply.<br />

The sleeve and thrust bearings<br />

(12, 13) support the output shaft in<br />

the housing. These bearings are<br />

supplied with lube oil from the gas<br />

turbine oil system.<br />

The cage with the clamping pieces<br />

(3) always rotates with the output<br />

shaft (4). Even a low speed of the<br />

output shaft (4) lifts the clamping<br />

pieces (3) due to centrifugal <strong>for</strong>ce<br />

of the outer ring (2). Consequently<br />

the outer ring (2) is no longer connected<br />

to the inner ring (1). During<br />

gas turbine operation the overrunning<br />

clutch operates without contact<br />

and thus wear free.<br />

If the gas turbine speed decreases<br />

to a value below 200 rpm, the centrifugal<br />

<strong>for</strong>ce decreases to such an<br />

extent that the clamping pieces (3)<br />

touch the outer ring (2) again due to<br />

spring tension. If the inner ring (1)<br />

now rotates slower than the outer<br />

ring (2), the overrunning clutch is<br />

engaged and a torque can be transmitted<br />

from the outer ring (2) to the<br />

inner ring (1).<br />

The torque can only be transmitted<br />

in one predetermined direction of<br />

rotation.<br />

An overload limitation can be used<br />

to protect the internal parts of the<br />

gear and the gas turbine or generator<br />

related parts against excessive<br />

torque.<br />

The following output shaft speeds<br />

(gas turbine) can exist, when the<br />

motor of the turning device is<br />

switched on:<br />

■ Output speed = 0:<br />

The overrunning clutch is engaged;<br />

the gas turbine breaks away<br />

■ Output speed < outer ring speed:<br />

The overrunning clutch is engaged;<br />

the gas turbine is accelerated<br />

to turning speed<br />

■ Output speed > outer ring speed:<br />

The overrunning clutch is disengaged;<br />

no infl uence on the gas<br />

turbine speed<br />

Scope of supply<br />

■ <strong>Turning</strong> gear<br />

■ Attached base structure to „adapt“<br />

to customers foundation<br />

(upon request)<br />

■ Connection coupling between<br />

turning gear and generator<br />

■ Electric motor<br />

■ Manual turning device<br />

■ Piping to locate lube oil feed &<br />

drain connections in customer<br />

specifi ed location (upon request)<br />

■ Coupling guard<br />

■ Factory assembling and testing<br />

Data worksheet<br />

Specifi c technical data<br />

worksheet<br />

■ The unit is used <strong>for</strong><br />

___________________________<br />

gas turbine.<br />

■ The design is according to<br />

<strong>Turning</strong> <strong>Gear</strong> Specifi cation<br />

___________________________<br />

Customer to defi ne:<br />

■ <strong>Turning</strong> speed<br />

__________________ rpm<br />

■ Break away torque<br />

__________________ ftlb or Nm<br />

■ Continuous torque<br />

__________________ ftlb or Nm<br />

■ Direction of rotation<br />

(looking in direction of power fl ow)<br />

CW CCW<br />

■ Voltage _____ DC or<br />

_____ AC _____ Hz _____ Phase<br />

■ Required design margin <strong>for</strong> break<br />

away torque<br />

__________________<br />

<strong>Voith</strong> to defi ne:<br />

■ Speed of electric motor<br />

__________________ rpm<br />

■ Power of electric motor<br />

(continuous operation)<br />

__________________ kW<br />

■ Lube oil supply<br />

__________________<br />

■ Ratio of bevel gear<br />

__________________<br />

■ Ratio of worm gear<br />

__________________

<strong>Voith</strong> <strong>Turbo</strong> GmbH & Co. KG<br />

Variable-speed drives<br />

<strong>Voith</strong>straße 1<br />

74564 Crailsheim<br />

Tel. +49 7951 32-0<br />

Fax +49 7951 32-650<br />

vs.drives@voith.com<br />

www.variable-speed.com<br />

www.voithturbo.com<br />

Cr 289 e KO/WA 07/2007 Print run 2000. Printed in Germany. Subject to modifications due to technical development.