Datasheet #35992: DP1 Pump - Bijur Delimon

Datasheet #35992: DP1 Pump - Bijur Delimon

Datasheet #35992: DP1 Pump - Bijur Delimon

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

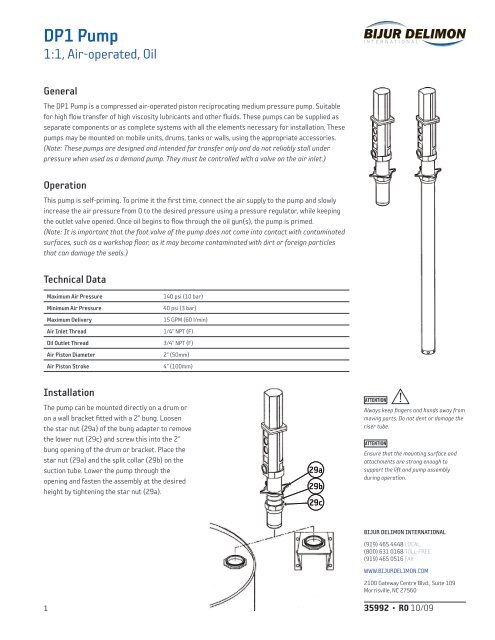

<strong>DP1</strong> <strong>Pump</strong><br />

1:1, Air-operated, Oil<br />

General<br />

The dP1 <strong>Pump</strong> is a compressed air-operated piston reciprocating medium pressure pump. Suitable<br />

for high flow transfer of high viscosity lubricants and other fluids. These pumps can be supplied as<br />

separate components or as complete systems with all the elements necessary for installation. These<br />

pumps may be mounted on mobile units, drums, tanks or walls, using the appropriate accessories.<br />

(Note: These pumps are designed and intended for transfer only and do not reliably stall under<br />

pressure when used as a demand pump. They must be controlled with a valve on the air inlet.)<br />

Operation<br />

This pump is self-priming. To prime it the first time, connect the air supply to the pump and slowly<br />

increase the air pressure from 0 to the desired pressure using a pressure regulator, while keeping<br />

the outlet valve opened. Once oil begins to flow through the oil gun(s), the pump is primed.<br />

(Note: It is important that the foot valve of the pump does not come into contact with contaminated<br />

surfaces, such as a workshop floor, as it may become contaminated with dirt or foreign particles<br />

that can damage the seals.)<br />

Technical Data<br />

1<br />

Maximum Air Pressure 140 psi (10 bar)<br />

Minimum Air Pressure 40 psi (3 bar)<br />

Maximum Delivery 15 GPm (60 l/min)<br />

Air Inlet Thread 1/4” nPT (F)<br />

Oil Outlet Thread 3/4” nPT (F)<br />

Air Piston Diameter 2” (50mm)<br />

Air Piston Stroke 4” (100mm)<br />

Installation<br />

The pump can be mounted directly on a drum or<br />

on a wall bracket fitted with a 2” bung. Loosen<br />

the star nut (29a) of the bung adapter to remove<br />

the lower nut (29c) and screw this into the 2”<br />

bung opening of the drum or bracket. Place the<br />

star nut (29a) and the split collar (29b) on the<br />

suction tube. Lower the pump through the<br />

opening and fasten the assembly at the desired<br />

height by tightening the star nut (29a).<br />

29a<br />

29b<br />

29c<br />

Always keep fingers and hands away from<br />

moving parts. Do not dent or damage the<br />

riser tube.<br />

Ensure that the mounting surface and<br />

attachments are strong enough to<br />

support the lift and pump assembly<br />

during operation.<br />

BIJUR DELIMON INTERNATIONAL<br />

(919) 465 4448 LOCAL<br />

(800) 631 0168 TOLL-FREE<br />

(919) 465 0516 FAX<br />

www.bijuRdELimOn.COm<br />

2100 Gateway Centre blvd., Suite 109<br />

morrisville, nC 27560<br />

35992 • R0 10/09

Typical Layout<br />

See drawing below for typical layout with all the recommended accessories for the pump to operate<br />

correctly. The compressed air supply must be fixed between 40 and 140 psi (3 and 10 bar), 90 psi<br />

(6 bar) is the recommended pressure. An air shut-off valve must be installed to be able to close the<br />

compressed air line at the end of the day (if the air inlet is not closed and there is leakage in some<br />

point of the grease outlet circuit, the pump will start automatically, emptying the container).<br />

2<br />

A<br />

B F G<br />

H<br />

1000mm<br />

C D<br />

Item Description<br />

A Air shut-off valve<br />

b Filter/Regulator<br />

C Air hose<br />

d Quick coupler<br />

E Air nipple<br />

F 1:1 <strong>Pump</strong> (200 liter drum)<br />

G Oil hose<br />

H High delivery control valve<br />

i bung bushing adapter<br />

I<br />

E<br />

3000mm<br />

BIJUR DELIMON INTERNATIONAL<br />

(919) 465 4448 LOCAL<br />

(800) 631 0168 TOLL-FREE<br />

(919) 465 0516 FAX<br />

www.bijuRdELimOn.COm<br />

2100 Gateway Centre blvd., Suite 109<br />

morrisville, nC 27560<br />

35992 • R0 10/09

Maintenance<br />

Separate the Air Motor from the <strong>Pump</strong><br />

1.<br />

2.<br />

3.<br />

Secure the pump in a vice in the horizontal position, clamping it on the provided pads along the<br />

pump body (13).<br />

To unscrew the suction tube (30) from the pump body (13), use a 46mm wrench on the milling of<br />

the foot valve body (34) for stub pump (see drawing on right), or a rod in the holes of the foot<br />

valve body (36) for long pump.<br />

Remove the upper roll pin (21) located in the upper part of the connecting rod (20) and unscrew<br />

the rod from the air piston (8) (see drawing on right).<br />

Foot Valve<br />

1.<br />

2.<br />

Gently attach the suction tube assembly to the vice and unscrew the foot valve body (34: stub<br />

pump, 36: long pump) from the suction tube (30).<br />

unscrew the nut (35), remove and clean the screw (31), the washer (32) and the valve body, and<br />

replace if damaged. Assemble the pump following the previous instructions, reversing each step.<br />

Upper Valve<br />

1.<br />

2.<br />

3.<br />

unscrew the nut (28) from the connecting rod (20) and remove the washer (27), the valve body<br />

(26) and O-ring (25), the washer (24) and the spring (23).<br />

Clean these parts carefully. if any of them are damaged, replace them before reassembly.<br />

Assemble the pump following the previous instructions, reversing each step.<br />

Reversing Set and Air Motor<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

6.<br />

Secure the air motor body (13) in the vise and loosen the four screws (14) to remove the air<br />

motor cylinder (1).<br />

Check the upper spring (2) and the spring stop (3) inside the air motor cylinder (1). Replace<br />

if damaged.<br />

Remove the lower circlip (15) and muffler (16) and pull up the air motor assembly (4) until the<br />

hole in air piston (8) is visible in the opening where the muffler was removed. insert a steel rod<br />

(8 mm) in the hole to lock the piston.<br />

use a prepared 17mm wrench to disassemble the air motor assembly (4) (see drawing on right).<br />

Remove the air piston (8) and disassemble the circlip (9), the washers (10) and the air piston<br />

seal (11). Check the piston for scratches and replace damaged parts.<br />

Assemble the pump following the previous instructions, reversing each step.<br />

Packing Set<br />

1. Follow the above procedure for the air motor until the air piston (8) has been removed from the<br />

air motor body (13).<br />

2. Remove the circlip (18) and the packing set (17) from the air motor body (13) (see drawing on<br />

right). Replace if damaged.<br />

3. Assemble the pump following the previous instructions, reversing each step. (Note: The packing<br />

set is directional. It is not marked and must be installed correctly or it will leak. Look carefully at<br />

the inside diameter of the seal, you will see three components. The middle black ring that is split<br />

is a bearing. Above and below it are the brownish Turcite® seals, these are made with a step, and<br />

the step faces the oil. Confirm this by looking into the seal from both directions, from one side<br />

you will not see the steps, and from the other you will; this is the side that faces the oil. See<br />

drawing on right.)<br />

3<br />

Refer to page 5 for parts reference.<br />

Before starting any kind of maintenance<br />

or repair, disconnect the compressed air<br />

supply and open a downstream valve to<br />

relieve the oil pressure.<br />

Unscrew suction tube, remove rod<br />

Remove inverting set with 17mm wrench<br />

Packing set installation<br />

BIJUR DELIMON INTERNATIONAL<br />

(919) 465 4448 LOCAL<br />

(800) 631 0168 TOLL-FREE<br />

(919) 465 0516 FAX<br />

www.bijuRdELimOn.COm<br />

2100 Gateway Centre blvd., Suite 109<br />

morrisville, nC 27560<br />

35992 • R0 10/09<br />

17<br />

18

Troubleshooting<br />

4<br />

Symptom Possible Cause Remedy<br />

The pump is not working or there is no<br />

oil delivery.<br />

The pump begins to operate very fast<br />

and no oil is being delivered at the gun.<br />

The pump runs on continuously after<br />

the oil outlet is closed.<br />

Oil is leaking through the<br />

exhaust muffler.<br />

Air is leaking through the<br />

exhaust muffler.<br />

The oil delivery has diminished or the<br />

flow is uneven.<br />

The pump operates only one cycle and<br />

then stops<br />

How to Order<br />

not enough air supply pressure. Slowly increase the air supply pressure.<br />

Some outlet line component is clogged<br />

or closed.<br />

The drum is empty or the oil level is<br />

beneath the suction tube inlet.<br />

There is an oil leak in some point of the<br />

outlet circuit.<br />

Contamination in the upper valve<br />

(23-28) or in the foot valve (31-35).<br />

The lubricator is sending too much oil<br />

into the airline.<br />

Oil has by-passed to the air motor<br />

caused by worn or damaged packing<br />

set (17).<br />

The air piston seal (11) is worn<br />

or damaged.<br />

Clean or open the outlet circuit.<br />

Replace the drum or lower the suction<br />

tube until the inlet reaches below the<br />

oil level.<br />

Verify and tighten or repair.<br />

disassemble and clean.<br />

Replace damaged components.<br />

Adjust the lubricator.<br />

Replace the packing set.<br />

disassemble and clean.<br />

Replace damaged components.<br />

The air motor cylinder (1) is scored. Replace air motor cylinder.<br />

The air piston rod (8) is scored. Replace the air piston rod.<br />

The air motor assembly (4) is worn<br />

or damaged.<br />

Contamination in the upper valve<br />

(23-28) or in the foot valve (31-35).<br />

Replace the reversing set.<br />

disassemble and clean.<br />

Replace damaged components.<br />

The upper spring (2) is damaged. Replace the upper spring.<br />

Name Drum Size Part #<br />

dP1 <strong>Pump</strong> Stub <strong>Pump</strong> F214<br />

16 gallon F216<br />

55 gallon F218<br />

when ordering, specify by name, description and part number, e.g. dP1 <strong>Pump</strong>, 16 Gallon drum,<br />

Part #F216.<br />

Refer to page 5 for parts reference.<br />

BIJUR DELIMON INTERNATIONAL<br />

(919) 465 4448 LOCAL<br />

(800) 631 0168 TOLL-FREE<br />

(919) 465 0516 FAX<br />

www.bijuRdELimOn.COm<br />

2100 Gateway Centre blvd., Suite 109<br />

morrisville, nC 27560<br />

35992 • R0 10/09

Service Parts<br />

5<br />

Item Description Part #<br />

1 Air motor cylinder F735100<br />

8 Air piston F735414<br />

10 Seal support washer F735211<br />

13 <strong>Pump</strong> body nPT F735103<br />

14 Air cylinder bolt F940321<br />

15 Circlip F942730<br />

16 muffler F835400<br />

20 Connecting rod (1:1) F735208<br />

21 upper roll pin F943041<br />

22 Lower roll pin F943042<br />

23 Check spring F835300<br />

24 Check washer (1:1) F735206<br />

26 Valve body (1:1) F735207<br />

27 washer (1:1) F735408<br />

28 Plunger body nut F941008<br />

29 bung adapter (1:1) F2029<br />

30 Suction tube (1:1) F735204<br />

31 Foot valve screw F735214<br />

32 Foot valve washer F835303<br />

33 Foot valve O-ring F946025<br />

34 Foot valve body (stub) F735229<br />

35 Foot valve nut F941108<br />

--- Air motor kit FAK-4<br />

Upper spring (2) ---<br />

Spring stop (3) ---<br />

Air motor assembly (4) ---<br />

Lower spring (5) ---<br />

Spacer (6) ---<br />

Washer (7) ---<br />

Air cylinder O-ring (12) ---<br />

Square cut seal (19) ---<br />

--- Packing set & seal kit FAK-5<br />

Upper snap ring (9) ---<br />

Air piston seal (11) ---<br />

Air cylinder O-ring (12) ---<br />

Packing set (17) ---<br />

Circlip (18) ---<br />

Square cut seal (19) ---<br />

O-ring (25) ---<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

10<br />

12<br />

13<br />

14<br />

15 16<br />

14<br />

19<br />

20<br />

23<br />

24<br />

25<br />

26<br />

27<br />

28<br />

29<br />

30<br />

31<br />

32<br />

33<br />

34<br />

35<br />

BIJUR DELIMON INTERNATIONAL<br />

(919) 465 4448 LOCAL<br />

(800) 631 0168 TOLL-FREE<br />

(919) 465 0516 FAX<br />

www.bijuRdELimOn.COm<br />

2100 Gateway Centre blvd., Suite 109<br />

morrisville, nC 27560<br />

35992 • R0 10/09

D<br />

Dimensional Schematics<br />

AIR<br />

IN<br />

1/4”<br />

6<br />

Part # A B C D<br />

F214 590mm<br />

(23.25”)<br />

F216 1060mm<br />

(41.7”)<br />

F218 1285mm<br />

(50.6”)<br />

OIL<br />

OUT<br />

3/4”<br />

A<br />

365mm<br />

(14.5”)<br />

365mm<br />

(14.5”)<br />

365mm<br />

(14.5”)<br />

B<br />

52mm<br />

(2”)<br />

52mm<br />

(2”)<br />

52mm<br />

(2”)<br />

C<br />

215mm<br />

(8.5”)<br />

695mm<br />

(27.3”)<br />

910mm<br />

(35.8”)<br />

D<br />

AIR<br />

IN<br />

1/4”<br />

OIL<br />

OUT<br />

3/4”<br />

A<br />

Measurements shown in millimeters.<br />

BIJUR DELIMON INTERNATIONAL<br />

(919) 465 4448 LOCAL<br />

(800) 631 0168 TOLL-FREE<br />

(919) 465 0516 FAX<br />

www.bijuRdELimOn.COm<br />

2100 Gateway Centre blvd., Suite 109<br />

morrisville, nC 27560<br />

35992 • R0 10/09