WSCAD51 Getting Started - FTP Directory Listing

WSCAD51 Getting Started - FTP Directory Listing

WSCAD51 Getting Started - FTP Directory Listing

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>WSCAD51</strong> <strong>Getting</strong> <strong>Started</strong>

Table Of Contents<br />

Introduction ......................................................................................................1<br />

General..........................................................................................................1<br />

Documentation................................................................................................1<br />

General.......................................................................................................1<br />

Online Help – WebHelp ..................................................................................2<br />

Features ...........................................................................................................5<br />

General Information about WSCAD 5...................................................................5<br />

Basic - version .............................................................................................5<br />

Compact - version.........................................................................................5<br />

Professional - version ....................................................................................5<br />

Features of WSCAD 5.1 ....................................................................................5<br />

General.......................................................................................................5<br />

Drawing functions .........................................................................................6<br />

Automatic functions.......................................................................................6<br />

Automated listings/charts...............................................................................7<br />

Interfaces....................................................................................................7<br />

New Features of WSCAD 5.1 ...........................................................................7<br />

Hardware requirements ....................................................................................9<br />

Working with WSCAD 5 ..................................................................................... 11<br />

Restrictions of the Demo version ...................................................................... 11<br />

Starting WSCAD 5 ......................................................................................... 12<br />

Screen layout................................................................................................ 13<br />

The pull down menus................................................................................... 13<br />

The mouse pointer/cursor arrow .................................................................... 13<br />

Grid.......................................................................................................... 14<br />

Mouse button functions................................................................................ 14<br />

Free memory ............................................................................................. 14<br />

Drawing co-ordinate (Path)........................................................................... 14<br />

File names ................................................................................................. 15<br />

Common input field..................................................................................... 15<br />

Status and prompt display ............................................................................ 15<br />

Mouse operation............................................................................................ 16<br />

Function keys................................................................................................ 17<br />

Important keyboard functions .......................................................................... 18<br />

Special key combinations ................................................................................ 18<br />

Configuring the screen layout .......................................................................... 19<br />

Design capture ................................................................................................ 21<br />

General........................................................................................................ 21<br />

Norm IEC 61346............................................................................................ 21<br />

Setting up a project ....................................................................................... 22<br />

General..................................................................................................... 22<br />

Creating new pages for a drawing set................................................................ 25<br />

Adjusting the practice files .............................................................................. 28<br />

Page configuration ......................................................................................... 30<br />

Placing Components....................................................................................... 31<br />

General..................................................................................................... 31<br />

Load a symbol without parts......................................................................... 31<br />

Placing symbols with database ...................................................................... 34<br />

Editing Terminals ........................................................................................... 38<br />

General..................................................................................................... 38<br />

Placing Terminals ........................................................................................ 38<br />

Terminal browser........................................................................................ 40<br />

Input via Terminal Number........................................................................... 42<br />

Drawing macros ............................................................................................ 42<br />

Inserting drawing macro .............................................................................. 42<br />

Contactor Manager......................................................................................... 44<br />

i

Table Of Contents<br />

General..................................................................................................... 44<br />

Semi-automatic Contactor Manager ............................................................... 44<br />

Contactor Manager...................................................................................... 54<br />

Full automatic Contactor Manager.................................................................. 60<br />

Cross-reference Navigator............................................................................... 61<br />

PLC Manager................................................................................................. 62<br />

General..................................................................................................... 62<br />

First you load the PLC main module ............................................................... 62<br />

Loading the individual PLC channels first ......................................................... 64<br />

Modifying the PLC byte address ..................................................................... 66<br />

Inserting connections (destination wiring) .......................................................... 67<br />

General..................................................................................................... 67<br />

Shortcuts .................................................................................................. 69<br />

Inserting corners ........................................................................................ 70<br />

Inserting direction symbols (T-pieces) ............................................................ 70<br />

Open line ends ........................................................................................... 70<br />

Completing the drawing sheets ..................................................................... 71<br />

Naming lines................................................................................................. 71<br />

General..................................................................................................... 71<br />

Inserting potential arrows ............................................................................ 72<br />

Completing the schematic ............................................................................... 74<br />

General..................................................................................................... 74<br />

Page 3 ...................................................................................................... 74<br />

Page 2 ...................................................................................................... 75<br />

Cable Manager.............................................................................................. 77<br />

General..................................................................................................... 77<br />

Drawing cables with the Cable Manager .......................................................... 77<br />

Splitting cables........................................................................................... 79<br />

Cable shield ............................................................................................... 80<br />

Modify Object properties ................................................................................. 80<br />

Automatic functions .......................................................................................... 83<br />

General........................................................................................................ 83<br />

Auto-numbering ............................................................................................ 83<br />

Auto cross reference ...................................................................................... 84<br />

Material browser............................................................................................ 85<br />

Control Cabinet Layout ................................................................................... 86<br />

General........................................................................................................ 86<br />

Inserting components..................................................................................... 87<br />

Excluding unwanted components...................................................................... 89<br />

Construction lines .......................................................................................... 90<br />

Inserting the control cabinet ............................................................................ 91<br />

Inserting the mounting plate ........................................................................... 91<br />

Drawing Cable trays, top hat rails and collection bars ........................................... 92<br />

Inserting assembly symbols ............................................................................. 93<br />

Inserting terminals ........................................................................................ 94<br />

Putting symbols on control cabinet door............................................................. 95<br />

Calculate dimensions of the Control cabinet........................................................ 96<br />

Drawing sheet variables .................................................................................. 96<br />

Foreign Languages ......................................................................................... 98<br />

Automated listings...........................................................................................101<br />

General.......................................................................................................101<br />

Individual listings via the 'Automatic funct.' menu ..............................................101<br />

Individual listings via the Project manager ........................................................101<br />

Automated listings of an entire Project .............................................................102<br />

General.......................................................................................................102<br />

Specific information for the Project summary .....................................................102<br />

Starting the creation of automated listings ........................................................103<br />

Project data.................................................................................................104<br />

ii

Table Of Contents<br />

Revision history ............................................................................................105<br />

Drawing pages .............................................................................................105<br />

Control cabinet layout ...................................................................................105<br />

Terminal chart .............................................................................................105<br />

Cable list .....................................................................................................106<br />

Cable chart ..................................................................................................106<br />

Wiring chart.................................................................................................107<br />

Material list .................................................................................................107<br />

Reference name chart ...................................................................................108<br />

Summary ....................................................................................................108<br />

Creating the project database.........................................................................109<br />

Output to printer ..........................................................................................109<br />

Creating a symbol ...........................................................................................111<br />

WSCAD Services .............................................................................................115<br />

In conclusion ... ...........................................................................................115<br />

Service Software - Subscription.......................................................................115<br />

Service Digitizing Drawings ............................................................................116<br />

Digitizing Drawings: Transferring “Paper” Drawings into CAD.............................116<br />

Epilog............................................................................................................117<br />

iii

Introduction<br />

General<br />

With WSCAD 5 you have chosen one of the most advanced programs to create electrical<br />

schematic drawings, with an excellent price/performance ratio.<br />

WSCAD 5 is already being used successfully by more than 25.000 users worldwide.<br />

Careful consideration has been given to user-friendliness, simplicity and universality.<br />

The easy-to-use On-line Help of WSCAD 5 gives instant on-screen answers<br />

to your questions.<br />

WSCAD 5 is undoubtedly one of the most effective CAD programs you can buy. You have<br />

instant access to all the functions and you can browse through your drawings easily, but<br />

most important, the program’s simplicity of operation and rapid processing enable you to<br />

produce extensive projects in a very short time. Whatever you are doing, WSCAD 5<br />

shows you the simplest way to accomplish your task. Clear menus, and the additional<br />

online information of the two mouse buttons functions makes WSCAD 5 a very easy<br />

program to use.<br />

The challenge of combining versatility of functions with great simplicity of use has been<br />

fully met in WSCAD 5. It provides you with all common functions of a CAD software<br />

program for generating electrical schematics (and some unusual ones as well), for<br />

example: loading symbols from libraries, combining them, creating new symbols, … .<br />

In addition, WSCAD 5 offers you much more! With functions such as subsequent<br />

rotation, mirroring, copying, moving, automatic assignment of reference numbers,<br />

automatic cross-references, free-form design of drawing frames, universal list<br />

generation, fully automatic contactor management, PLC manager and versatile<br />

configuration options you have all the features of a powerful circuit diagram generation<br />

program. And this list is by no far complete.<br />

On top of this we are constantly working to develop the program. Apart from the<br />

creativity of our programmers, feedback from users is an essential part of<br />

development. Please do not hesitate to give us your comments and suggestions at any<br />

time!<br />

Some comments about software protection: Due to previous experience, we are forced<br />

to deliver our software with a dongle. This may be a new situation for you, but this<br />

protection provides security for the program and enables us to maintain a low price, by<br />

providing a high degree of performance and functionality at the same time.<br />

For security reasons, it is possible to make as many copies of the original files as you like<br />

and install them on several other PCs. However, you can only use the program if the<br />

dongle is connected to one of the PC’s parallel or USB ports.<br />

Documentation<br />

General<br />

By offering a software-service contract we ensure essential further development of<br />

WSCAD to remain compliant with new legal regulation. The software service ensures<br />

timely automatic updates are immediately at your disposal. As well as being updated<br />

1

<strong>Getting</strong> <strong>Started</strong><br />

automatically with each new major release of our software products, you will receive<br />

continuous minor documentation changes and function improvements that we make from<br />

time to time.<br />

As the documentation and the software is integral though on line<br />

help, we have decided to provide “First steps …” as the only printed<br />

documentation.<br />

Up-to-date documentation can be found as 'WebHelp' on our web-site. You can<br />

activate the help function directly within the WSCAD software with .<br />

Online Help – WebHelp<br />

With the menu command 'Help –WebHelp' or , you can start directly start online<br />

help. Online help is installed automatically on your system and you can use it<br />

continuously. If your PC has web access and the connection (menu entry 'Help-<br />

WebHelp') is activated, you can get direct assistance from the internet with function key<br />

.<br />

If you need a special information on a subject, press the key and the related help<br />

files will be loaded from the internet.<br />

2

WebHelp supports you with just the information needed.<br />

Introduction<br />

The 'WebHelp' is always up to date. These files are complemented with tips and advice.<br />

You can have a look at these files on your system anytime.<br />

3

Features<br />

General Information about WSCAD 5<br />

WSCAD is modular, meaning that you are able to start with the Basic - version and, at a<br />

later time, expand it to a higher-version (Compact or Professional) with more<br />

features. Drawings that have been made with a lower version are fully compatible with<br />

higher versions.<br />

The three software versions are build up on each other and contain comprehensive and<br />

practical features.<br />

Basic - version<br />

The Basic - version is suitable for factory schematics of existing installations, You can<br />

also use it as a tool for small and less extensive schematics.<br />

Compact - version<br />

The Compact - version is good for maintaining existing schematics. The strength of the<br />

Compact - version is the adaptable schematic construction, for example, if a plant or<br />

machine already exists and has be expanded. In addition the Compact - version is used<br />

to create small and middle projects. The user can use some different automatic functions<br />

like: auto numbering; cross reference; terminal charts; contact reflection and much<br />

more.<br />

Professional - version<br />

The Professional - version is the version to use for planning, developing and documentation of new<br />

schematics. The user can use powerful on-line and control functions, which he needs to create new<br />

project. Operation errors decrease and so productivity will increase.<br />

Features of WSCAD 5.1<br />

- Schematic<br />

General Basic Compact Professional<br />

Drawing pages 10000 10000 >10000<br />

Sub pages <br />

New design <br />

Project management with file preview and sorting functions <br />

Project manager with individual listings. Project-specific<br />

information is automatically copied into the drawing frame <br />

Project import/export <br />

Unit/Field management; Unit/Field region - - <br />

Text box<br />

Path text <br />

5

<strong>Getting</strong> <strong>Started</strong><br />

Black Box - <br />

Destination wiring <br />

Material browser - - <br />

Text find/replace - <br />

Free configuration of drawing frames and lists (layout) <br />

Foreign language display/translate / - / - / <br />

Dimensions <br />

Printout labels of equipment, cables and terminals - <br />

6<br />

Drawing functions Basic Compact Professional<br />

- Schematic<br />

Choice of standards: Facility to work with old standard JEC 40719<br />

or new JEC 61346 standard <br />

Symbol explorer with preview when loading a symbol, including<br />

symbol search and favourites <br />

Symbol editor for drawing own schematic symbols <br />

Drawing macro Explorer with preview <br />

Terminal browser functions - <br />

Drawing plug + socket separately / plug + socket together / - / / <br />

- Floor plan<br />

Symbol libraries of all areas for electrical installation <br />

Symbol editor for drawing own electrical installation <br />

Drawing functions for floor plans <br />

Drawing format DIN and free format until 30mx30m <br />

Scale 1:1 until 1:1000 <br />

Fly Eye for display actually position in the drawing <br />

Clearly arranged floor management with installation zones <br />

Print preview of the drawings <br />

Snap functions <br />

- Schematic<br />

Automatic functions Basic Compact Professional<br />

Numbering of symbols - <br />

Generating cross references with designation wiring/online - / - - / / <br />

Automatic generation of line names in various forms - - <br />

Control cabinet manually / semi automatic / - / - / <br />

Terminal browser for locating and modifying terminals, single terminal,<br />

multi level terminal, jumper - <br />

Cable manager and connector manager online - - <br />

Contactor management - <br />

Contactor manager - <br />

Coil cross reference/ generate reflector - <br />

Coil cross reference and contact manager online - - <br />

Generate PLC cross references - <br />

PLC cross references and PLC manager online - - <br />

Replacing drawing frames -

- Schematic<br />

Features<br />

Automated listings/charts Basic Compact Professional<br />

Separate listings (terminal chart, material list, …) - <br />

Automated listing for all lists - - <br />

Project data - <br />

Summary - <br />

Revision history - - <br />

Terminal Chart - <br />

Connector chart - - <br />

Cable list - - <br />

Cable chart - - <br />

Wiring chart - - <br />

Reference list - - <br />

Material list - <br />

- Schematic<br />

Interfaces Basic Compact Professional<br />

DWG/DXF/HPGL Export <br />

DWG/DXF/HPGL Import <br />

VNS Export - - <br />

ASCII, ACCESS, Excel, dBase, Import/Export (Data) - - <br />

Import of parts data via ECAD standard component interface - - <br />

UGL/UGS Export - - <br />

Import of ASCII-, Excel- and Datanorm 4.0 - files - - <br />

Material list output as ACCESS, dBase, ASCII or Excel - - <br />

Label-Export to Grafoplast, Phoenix, Murrplastik, Excel or ACCESS - <br />

Import/Export of SEQ list for PLC module as Excel, SEQ-txt-format - - <br />

- Floor plan<br />

DWG/DXF Import with taking over all layers <br />

New Features of WSCAD 5.1 Basic Compact Professional<br />

- Project management:<br />

Hide and show of several projects <br />

Export of several projects <br />

Sorting in 2 levels <br />

Advanced copy function for projects <br />

Exclude components for additional material listings <br />

DWG/DXF- import and -export <br />

Export to BMP-, PCX- and PNG- format <br />

-CPP and UFD-management:<br />

Fast navigation through CPP-projects - - <br />

7

<strong>Getting</strong> <strong>Started</strong><br />

UFD-management with view of concerned pages - - <br />

Changing of UFD for one or several pages - - <br />

Using of UFD-region without CPP-mode - - <br />

- Contactor management:<br />

Contactor management - <br />

New contactor manager with advanced functionality: - - <br />

- intuitive handling - <br />

- smart listing of contactors during work - <br />

- assigning contacts to preselect pin numbers - - <br />

- split a 3pole power contact to a 3 single power contacts - - <br />

- simple expand functionality for aux. contactor block - - <br />

- creating an individual contact block - - <br />

- free changings or moves of pin designations - <br />

- Lexicon:<br />

Selective text import and translation with new dialogue - - <br />

- Drawing functions:<br />

Simple text: expanded to 100 characters <br />

Simple text: Rotation 0°/90°/180°/270° adjustable <br />

Text box: used for more than 100 characters with import functionality <br />

Direct access to File description and Comments (1+2) with Sheet text<br />

functionality<br />

8<br />

<br />

Direct access to function text and additional texts <br />

Zooming with mouse wheel and keyboard +/- <br />

Page up/down: goto; button next / prev; shortcuts <br />

Sequential and unique number for project pages - - <br />

Variable sheet number , sheet quantity l, filename short/long would be updated <br />

Terminal browser: changing the terminal destination - <br />

Material browser: insert external texts by using drag'n drop - - <br />

Protect frame elements <br />

Cabel visible or invisible by using a menu item <br />

Graphic - company logo & graphic as link resizeable <br />

Graphic used in symbols <br />

Drawing macro Explorer for fast selection of drawing macros <br />

Accessibility Quick Text: preselect already known text - - <br />

- Interface/Printing:<br />

Output to ASCII: Material list - <br />

Print: Margins are adjustable for printout <br />

- Help:<br />

Informations refering the Update-Download <br />

Display the available shortkeys

Hardware requirements<br />

Minimum requirements Recommend<br />

Operation System: Windows 98/2000/XP Windows 2000/XP<br />

CPU: 800 MHz 2 GHz<br />

RAM: 128 MB 512 MB<br />

Harddisk 200 MB 500 MB<br />

Graphics Card: 32 MB 128 MB<br />

Make sure that the newest Microsoft service packages are installed!<br />

Features<br />

9

Working with WSCAD 5<br />

Restrictions of the Demo version<br />

The Demo version of WSCAD 5 has all features of the Professional version (if you<br />

select this option), including all automatic functions such as contactor manager, database<br />

links, cross references, numbering and so on. Only the output functions (Printer,<br />

DXF/VNS-export) are restricted. Only a small part of the drawing can be printed (max. 8<br />

components and some elements).<br />

Please select after inserting Demo CD the option "start WSCAD 5.1 demo setup" .<br />

after a view steps you're able to choose the feature you will work with.<br />

11

<strong>Getting</strong> <strong>Started</strong><br />

With the Demo version only a few libraries are installed, containing the components<br />

required for the practice example plus some general components. The full licence version<br />

contains very comprehensive libraries with over 1000 symbols, and the Professional<br />

version includes more than 250 varied contact combs, as well as several hundred<br />

mechanical components for the control cabinet layout.<br />

Similarly the database contains only those entries which are needed for the practice<br />

example. The Professional version contains a very comprehensive database with<br />

thousands of parts from various manufacturers.<br />

Warning<br />

12<br />

Drawings which are created or modified with the Demo version<br />

cannot be edited with a full licence version. So take care!<br />

This demonstration manual is only a brief description of the program and contains a short<br />

example, some information about the installation and some general hints for using the<br />

program. You have full access to the on-line help files of WSCAD 5.<br />

Starting WSCAD 5<br />

After installation has been successful completed you will find the program group 'WSCAD<br />

5. on your screen. You will see icons for the program, on-line help, the Readme file and<br />

the Uninstall program. You will also find icons for the WSCAD file viewer WSVIEW and<br />

the associated help file.

WSCAD 5.1<br />

Demo<br />

Working with WSCAD 5<br />

To start WSCAD double click on the icon created on the desktop during<br />

installation.<br />

Screen layout<br />

After starting WSCAD 5, the screen typically looks as shown below:<br />

The pull down menus<br />

With the pull down menus you can select appropriate commands, or you have access to<br />

some of the most frequently used commands by clicking on an icon button. To see what<br />

the icons mean, just position the mouse pointer on each one in turn to reveal the ‘tool<br />

tip’ fly-out.<br />

The mouse pointer/cursor arrow<br />

The arrow or cursor location determines the actual position within the drawing. You can<br />

position the arrow or cursor with the mouse. In addition you can position with the cursor<br />

keys or by type in the specific co-ordinates. It is also possible to change the format of<br />

the cursor (e.g. to a crosshair) by using 'Settings - Options'.<br />

13

<strong>Getting</strong> <strong>Started</strong><br />

Grid<br />

As a drawing aid, a grid can be displayed if required by turning it on or off with the<br />

function key . The grid spacing can be set ('Settings - Options'), the default<br />

spacing is 2.5 mm. Components are created to match the grid and automatic<br />

connection requires components to be in line with each other, it is helpful to keep the<br />

grid displayed and switch the Snap Mode 'on' with the function key .<br />

Mouse button functions<br />

The functions of the left and right mouse buttons are always displayed by the little yellow<br />

mouse at the bottom of the screen. This makes WSCAD much more easier to use. It is<br />

helpful to have a look at them frequently! The left button (corresponding to the<br />

key) is used typically to execute a command. The right button<br />

(corresponding to the key) is typically used to exit a command or to activate the<br />

property menu.<br />

Free memory<br />

The capacity of free memory is shown as a percentage, on the right bottom edge of the<br />

WSCAD window. If available memory is getting low, the 'Compress' command in File<br />

menu should help to increase the memory capacity.<br />

Drawing co-ordinate (Path)<br />

To locate components in a drawing easily, the drawing is divided into numbered vertical<br />

strips, numbered horizontally, and this number is known as the vertical path. The width<br />

of each strip and the numbering sequence are set in 'Settings - Common Settings -<br />

Cross reference'. It is this path number that is used, along with the sheet number, to<br />

indicate the location of a cross referenced element.<br />

14

Enter for example an 'A' as first vertical sign.<br />

Working with WSCAD 5<br />

In the centre at the bottom of the screen, next to the current sheet size, is a number and<br />

letter that indicates the grid reference of the drawing that the cursor is currently located<br />

in.<br />

File names<br />

The top bar of the Windows screen displays the name of the current project and of the<br />

active drawing. If you are working in the symbol editor or selecting a component from<br />

the library, you will see the name of the active library in this field, instead of the drawing<br />

file name.<br />

Common input field<br />

When inserting text or co-ordinates with the keyboard, you will see these values appear<br />

in a box at the bottom of the screen.<br />

Status and prompt display<br />

At the lower left hand side of the screen, there is a box that displays the status of<br />

settings and commands. The letters (S, O, A) are displayed when the corresponding<br />

function is activated.<br />

15

<strong>Getting</strong> <strong>Started</strong><br />

Mouse operation<br />

16<br />

The status display contains:<br />

Snap function on/off 'S' as 1st character<br />

Ortho Mode on/off 'O' as 2nd character<br />

Auto.-connecting on/off 'A' as 3rd character<br />

When working with a graphical user interface such as Windows it is normal to work with<br />

the mouse to move the cursor. However the cursor can also be used for other tasks as<br />

e.g. inserting components.<br />

One click with the left mouse button indicates a positive confirmation. The internal<br />

functions of WSCAD 5 allow the right button to be used for cancelling, as in the earlier<br />

version, but not in case of the main menu, because this is not compatible with standard<br />

Windows functions.<br />

Moving and sizing of individual windows are normal parts of the Windows operation and<br />

the form of the cursor gives visual hints on how to do.<br />

The right mouse button gives you also access to a very important function of the<br />

program. When you position the cursor on any object, and clic k the right mouse button,<br />

you will see a specific menu displaying the characteristics of the selected object. This<br />

applies not only to elements within the drawings but also to the buttons on the toolbars.<br />

You can use the mouse to mark an area (rectangle) of the drawing to (for example)<br />

move or copy the selected components.<br />

If you want to select a particular area of a drawing window to edit or to copy it, you can<br />

do by using the mouse. Click with the left mouse button on a corner of the desired area,<br />

hold the mouse button down and move the cursor with the mouse. This will cause a<br />

rectangle to be drawn and when the mouse button is released all components within the<br />

rectangle will be shown highlighted. Then you can apply the copy command to this<br />

area. To cancel the selection you simply click anywhere in the drawing window.<br />

Another useful feature is 'Panning', which moves the whole picture in the drawing<br />

window when the cursor bumps against the side of the window. However this function is<br />

only activated by holding the key down, or when you are loading a symbol or<br />

drawing a line. This prevents the screen from ‘panning’ every time you move the mouse<br />

towards the menus or toolbars.<br />

The Object properties concept provides a new and very fundamental feature. A click<br />

with the right mouse button opens a menu, which relates exactly to the object on which<br />

the cursor is located. For example, if the object is a component, you will get the<br />

component parameters menu and its applicable commands, if you click near a command<br />

toolbar you can switch them on and off. By using this feature frequently you will soon<br />

come to appreciate it’s usefulness!<br />

Mouse wheel zoom<br />

On the basis of the current cursor position the representation is constantly increased<br />

and/or reduced depending upon direction of rotation, which picture shifted after<br />

possibility in such a way that the cursor position becomes the picture center. The<br />

function is activated and/or deactivated through to press on the mouse wheel. An<br />

identical effect as over mouse wheel tricks you obtain with + and - keys

Function keys<br />

Working with WSCAD 5<br />

Even with a graphical interface the function keys should not be forgotten, as they can<br />

also be used to give fast access to frequently used commands. For instance you will<br />

often find the key very useful for fitting your drawing to the current window,<br />

and for rapid Zooming, for Snap mode switching or for<br />

Grid display switching.<br />

Every experienced Windows user, will of course, already be familiar with function key:<br />

for On-line help or WebHelp which will give access to the whole of the reference<br />

manual and there are also “topical” hints and tips.<br />

The full list of the available function keys is shown belows:<br />

Hint<br />

Key Function<br />

On-line help<br />

Zoom in at the cursor (enlarge picture)<br />

Zoom out (reduce picture)<br />

Zoom Extents (fill the window completely)<br />

- Scale the display 1:1<br />

- Quit WSCAD<br />

Toggle Snap mode on/off<br />

Toggle Orthogonal mode on/off<br />

Toggle Grid display on/off<br />

Display co-ordinates in mm/inches<br />

Cursor zero point absolute/relative<br />

Auto -connection on/off<br />

Redraw current window<br />

Full screen mode on/off<br />

Don’t forget when you install the demo version you also get the<br />

complete Online Help of the licence version. This means that you<br />

can access virtually the whole of the reference manual.<br />

General<br />

In addition to normal text input and the function keys, you can also access all the menu<br />

commands from the keyboard: simply press the key and the underlined letters<br />

from the menu. You also use the key to quit operations even in Windows.<br />

17

<strong>Getting</strong> <strong>Started</strong><br />

Important keyboard functions<br />

There are also some further keyboard functions that are very important:<br />

Hint<br />

18<br />

• The four cursor keys are equivalent to the mouse functions during drawing<br />

operations. Sometimes it is more easy to use these keys instead of the mouse for<br />

positioning. Holding down the key speeds up the cursor movement.<br />

• In most cases, the key has the same function as the left mouse button.<br />

• With or you can move through the individual sheets<br />

in a set of drawings.<br />

• With you can copy the components of a selected area (see “Mouse<br />

operation”), i.e. these components are transferred to a temporary file and onto<br />

the Windows clipboard.<br />

• With or you can re-insert this temporary file. This is the same<br />

as the command ‘insert block’.<br />

• With or you can delete the elements in the selected area.<br />

• With you can activate the UNDO function.<br />

If you want to enter new text, and text is already entered in the<br />

text entry window, it is automatically selected and shown as an<br />

inverse highlight. If you wish to keep the pre-entered text and just<br />

modify it, you either position the cursor at the appropriate point<br />

and press the left mouse button, or press the key<br />

or the key. If you enter new text directly, the selected text<br />

is immediately erased. Previous entered text you can select by<br />

clicking the arrow down button located right of the text edit line.<br />

Special key combinations<br />

When drawing with destination wiring symbols (DW) the following Shortcuts are<br />

available:<br />

Shortcut DW Elements<br />

-left arrow T left<br />

right arrow T right<br />

- up arrow T-top<br />

- down arrow T-bottom<br />

- left arrow Arrows<br />

- right arrow "<br />

- up arrow Angles<br />

- down arrow "

Configuring the screen layout<br />

Working with WSCAD 5<br />

The command toolbars and the library toolbars can be docked against the other side of<br />

the screen or placed as a free-standing window. You can try this easily: move the cursor<br />

onto a toolbar (but not onto a button), press the left mouse button and then move the<br />

cursor, keeping the mouse button pressed. The new position of the toolbar appears in<br />

outline and as soon as you release the mouse button the toolbar appears in this position.<br />

If you click once with the right mouse button on the area beside a docked toolbar or in<br />

the window header, you will get a small menu that gives you (e.g.) a list of all available<br />

library toolbars. With one mouse click you can activate or hide a library toolbar.<br />

Of course you can configure the toolbars: If you click with the right mouse button on a<br />

button, you can immediately insert a new button (or a separator) in this position. Click<br />

on the new button, select ‚Record’ and then use the relevant command from the menu<br />

bar. The command is accepted and its icon appears on the button.<br />

The buttons of the command toolbar have preset icons, but for icons on the symbol<br />

toolbars you have a completely free hand. The button is assigned via the Component<br />

Editor, because each button must be assigned to both a component name and a library.<br />

You can ‚snapshot’ the relevant icon out of the component editor and apply different<br />

background colours if you wish.<br />

Hint<br />

You can design the buttons on the library toolbars by yourself,<br />

using the symbol editor.<br />

The above description has been kept deliberately simple. If you would like to know more,<br />

please use the Online Help. Look in the section 'Working with WSCAD 5' to find further<br />

information on the individual elements of the screen layout. In the section 'Settings –<br />

Configure Screen' you will find a detailed description of creating and managing the<br />

toolbars.<br />

19

Design capture<br />

General<br />

In this chapter, you will learn about the most important features of the Professional<br />

version of WSCAD 5 by completing a small sample project. You will use the<br />

'Favourites' 'EXAMPLE' and the database 'EXAMPLE.MDB' and you may find it helpful<br />

to study the sample drawings on the preceding pages. The complete practice example<br />

can be found as 'WSCAD example project 1' in the Project Manager.<br />

Hint<br />

Please note that this sample schematic aims to answer questions of<br />

the type: "How can I ....?" It does not reflect the usual procedure for creating<br />

a project.<br />

While reading this section, please refer to the foregoing sample<br />

drawings<br />

Norm IEC 61346<br />

All examples are created referring the norm IEC 61346 which is valid since<br />

01.March.2001.<br />

The latest date for using this norm on international level is the 01. June 2003.<br />

This international norm changes the reference names of symbols to represent the<br />

symbols function oriented and administered.<br />

In WSCAD 5 it is possible to draw with the “old norm” or with the “new norm”. The<br />

following exa mple is using the “new norm”.<br />

Hint<br />

The new norm IEC 61346 contains function informed reference<br />

names. For this reason the existing reference names differ to the<br />

new reference names.<br />

e.g.: a manual motor starter have had a reference name “–Q”. Since<br />

01.June.2003 it is defined as a protection installation and now has<br />

the reference name “-F”.<br />

21

<strong>Getting</strong> <strong>Started</strong><br />

Setting up a project<br />

General<br />

The Project Manager is the central organizer for all your projects. It enables you for<br />

example to copy, to import and to export projects, and allows you to make auto-saves<br />

for creating regular backups. You can also set up a customer database referring back to<br />

this data later.<br />

The first step is to set up a new project. A folder is created which contains the entire files<br />

specific to the project. On the pull-down menu, select 'File – Project Manager'. This<br />

will open the Project Manager.<br />

Some example projects have already been created. To get the details of an existing<br />

project, select the project name with the mouse. In the right-hand window, all the<br />

information about that project is displayed. Now select from the menu 'Project- New', to<br />

create a new project. The following dialog appears:<br />

22

Design capture<br />

Enter the project name as 'WSCAD example'. The project name is automatically added<br />

to the preset project path. For the template, select 'A4-Horizontal..'. This template will<br />

be used for the entire project. It automatically inserts a specific frame into the drawing<br />

sheet when you are creating schematics or terminal charts.<br />

Hint<br />

Please make sure the option 'CPP – Mode' is switched off.<br />

Otherwise, you will be working in Combined Part Project mode,<br />

which is only necessary for very large projects.<br />

Exit with 'OK'.<br />

23

<strong>Getting</strong> <strong>Started</strong><br />

The project 'WSCAD example' is opened automatically. You see the open project on<br />

the open book symbol! Now, in the right-hand window of the Project Manager, enter the<br />

information which has to appear on the drawing frame. Enter the following values (or<br />

something else):<br />

24

Hint<br />

Double clicking the line 'Customer' takes you to the customer<br />

database.<br />

The project data is now complete. The next step is to create the drawing sheets.<br />

Creating new pages for a drawing set<br />

Design capture<br />

In order to draw a schematic diagram, start the Project Manager ('File – Project<br />

Manager') and open the directory tree for the project. Activate the project you will work<br />

with by clicking the right mouse button on 'Project name' and select 'Open' (not<br />

necessary, if the project is already open).<br />

Hint<br />

The main window of the Project Manager shows you which project<br />

is currently open.<br />

Now click with the right mouse button on 'Schematics' and select 'Create'.<br />

25

<strong>Getting</strong> <strong>Started</strong><br />

Hint<br />

26<br />

You will also find the command 'Create' in the Project Manager<br />

menu under 'Modify’. Nevertheless you must select 'Schematics'<br />

first.<br />

In this example you will be using '4' drawing sheets. Enter this number in the following<br />

dialog.<br />

The next dialog already has 'File name' displayed. To open it, click the 'OK' button.<br />

If you need more sheets later on, you can add them to the existing sheets in the same<br />

way.

Design capture<br />

Four Drawing sheets have been created and the data you entered in the Project Manager<br />

have been transferred automatically into the drawing sheets.<br />

Check the amount of pages by pressing the 'Next sheet' or 'previous page' keys to<br />

browse through the sheets.<br />

You see also the name of the drawing file and the sheet number at the top of the main<br />

window:<br />

The total number of sheets and the current page number are displayed automatically.<br />

Finally, go back to Sheet 1 of your example.<br />

27

<strong>Getting</strong> <strong>Started</strong><br />

Adjusting the practice files<br />

If you are working with a licence version, you must now activate the example<br />

database. First, select 'Settings' on the menu, then the command 'Common Settings'<br />

and then the 'Database' tab.<br />

The display now lists the directories including information on the database.<br />

Click with the left mouse button in the database field and then on the button.<br />

28

Design capture<br />

You will see this standard Windows dialog for selecting a file. Click on the file<br />

'example.mdb' and then 'OK'. You will automatically be returned to the 'Database' tab in<br />

the 'Common Settings' dialog. You will see the name and the path of the selected file<br />

now correctly displayed. Store the setting by clicking the 'OK' button. If you click 'Cancel'<br />

in the 'Common Settings' dialog, you will exit without storing any changes.<br />

29

<strong>Getting</strong> <strong>Started</strong><br />

Page configuration<br />

Before you begin to draw the example project, you should check some of the settings for<br />

your new project:<br />

Exit the Project Manager with 'OK' and click on 'Settings’ in the pull-down menu. Then<br />

select the command 'Options'. Check the following settings:<br />

To change the form of the cursor (e.g. to Cross-hair form), click on the relevant cursor<br />

symbol.<br />

Exit the 'Options' dialog with a mouse click on the 'OK' button.<br />

Hint<br />

30<br />

Note the display in the information bar on the lower edge of the<br />

screen. It shows hints about the current command and the<br />

function of both mouse buttons.

Placing Components<br />

General<br />

In WSCAD you have several options to load a symbol:<br />

• Load a symbol without parts<br />

• Load a symbol with parts<br />

Load a symbol without parts<br />

Design capture<br />

The first task is to place the main isolator switch, which is identified in the example<br />

drawing as '-Q1'. This is the so-called reference name which is incremented by<br />

automatic numbering. The component is placed without having access to the database,<br />

which is one of the functions of the Professional - version.<br />

Check whether the database access is deactivated or not. Select the menu command<br />

'Settings– Common Settings', the tab 'Connect+Load' and disable the Option 'Take<br />

values from database'. Accept the message ('The cable manager must be ...') with<br />

'OK' and leave the Common settings with 'OK'.<br />

31

<strong>Getting</strong> <strong>Started</strong><br />

To load a component, select the 'Schematic' menu and then select 'Load symbol ...'.<br />

The 'Symbol Explorer' will appear:<br />

The 'Symbol Explorer' offers several options to access the libraries or to load a symbol<br />

directly:<br />

Hint<br />

32<br />

• Loading a symbol directly from a library (Library)<br />

• Loading a symbol via the reference name (Designation)<br />

• Loading a symbol after a search (Search)<br />

• Loading a symbol as a favourite (Favourites)<br />

In the Demo version the Symbol Explorer shows a reduced number<br />

of available libraries. The licence version contains many more<br />

libraries.

Design capture<br />

Go to the tab 'Favourites' and click on the '+' next to 'Example' if it is not yet open. All<br />

Component names are listed, choose 'Mainswitch_3pol' and you have a preview at the<br />

top of the symbol explorer.<br />

Select the component 'Mainswitch-3pol' using the left mouse button and 'OK' (or a<br />

double click).<br />

Make sure that the Snap mode, (indicated by 'S', the first letter in the box on the<br />

information bar; switches it on/off) and Automatic connection ('A' is the third<br />

letter; function key switches it on/off) are turned on and displayed.<br />

The component jumps from grid point to grid point with the snap mode on. This<br />

is necessary to ensure perfect alignment and valid connection of the<br />

components.<br />

Position the switch at co-ordinates 47.5 / 162.5 mm (these are displayed on the status<br />

bar at the bottom right of your screen).<br />

Fix the component with the left mouse button or key. Now the symbol,<br />

explorer will be shown again and you can choose a further component. If you have<br />

finished placing components, you can press . If you have loaded the wrong<br />

component, you can delete it with 'Undo' in the menu 'Delete/Move' and load the<br />

correct one as described before.<br />

If you press the right mouse button before positioning the<br />

component, the 'Rotation' menu will appear. In addition to<br />

rotate, you can mirror the component, modify the component<br />

name and parameters, etc. or abort the command. The<br />

placed component has the reference name 'Q' and not 'Q1' as<br />

shown in the completed example drawing. The number will be<br />

added later using the automatic numbering capability.<br />

Hint<br />

After placing the component the component a selection window will<br />

reappear. Simply exit by pressing .<br />

33

<strong>Getting</strong> <strong>Started</strong><br />

Placing symbols with database<br />

The next task is to place additional components, but this time using the database, which<br />

is only possible with the Professional version.<br />

Hint<br />

34<br />

In this example the database access does not apply to contactors<br />

and contacts.<br />

From the main menu choose 'Settings - Common Settings - Connect+Load Tab’ and<br />

tick 'Take values from database'. Also check that in the tab 'Contactor and PLC<br />

Modules' the options 'Activate Contactor Manager' and 'Semi-automatic' are both<br />

activated. Choose 'OK' to save the setting and exit.<br />

Also check the tab 'Cable' the option 'Activates On-line cable management' and on<br />

tab 'Connectors' the option 'Enable On-line connector management', please make<br />

sure that they are activated.<br />

Hint<br />

Only the Professional - version can access the database.

Design capture<br />

Now place the motor -M1. The 'Favourites' library 'EXAMPLE' contains the motor -M1.<br />

You can access the graphical component selection window again via menu 'Schematic-<br />

Load Symbol ...'. You will find M1 under 'Motor~3phas' .<br />

Position the motor at 90.0 / 50.0 mm. Co-ordinates can also be entered using the<br />

numeric keys. There has to be either a blank or a slash '/' between the co-ordinates, but<br />

not a comma. Quit using the key.<br />

Now a selection dialog is displayed, showing the available motors in the database:<br />

35

<strong>Getting</strong> <strong>Started</strong><br />

Select '1LA7083-6AA10'. The component parameters for the selected component are<br />

displayed and can be edited if desired.<br />

36

Design capture<br />

The original component name is overwritten with the component name from the<br />

database and the part number is copied across.<br />

Text can be typed in via the common input field at the bottom of the screen in the<br />

information toolbar. The text input field is automatically activated when the program<br />

expects an input.<br />

Click on 'Function text' and enter 'Feed'. After you have pressed , the text is<br />

positioned at the cursor. Now place (click with the left mouse button) the text wherever<br />

you like below the motor. This brings you back to the component parameters. Select<br />

the 'Function text' again. A menu appears where you can choose various text<br />

properties. Select 'Alignment' and set the text alignment to 'centered', place the text<br />

at 95.0 / 37.5 mm and leave the settings menu with a right mouse click in the drawing<br />

area or with .<br />

Hint<br />

If you have placed the motor from the library using 'Schematic-<br />

Load symbol ...', the open library reappears. Quit with 'Cancel' or<br />

.<br />

Please note that the power rating of the motor was extracted from the database and<br />

placed in Text 2 of symbol parameters The text is also marked as invisible (using '!' as<br />

the first character). By deleting the '!' character, you can position the text to display<br />

wherever you want. (Although you can enter information into the text fields, the<br />

component editor in Text 2 already provides appropriate text, it is often better to use this<br />

value directly from the database and to make it visible in the drawing.)<br />

This applies similarly to Texts 3-16, i.e. they can be assigned to any database field.<br />

TIP<br />

Component setting 'Text2' will always be transferred from data<br />

base field 'Text2'. It will be automatically visible in the drawing<br />

only if 'Text2' of the component has been set in the library (i.e.<br />

without an '!' in front of the text). You can modify this at any time<br />

by clicking the right button on components and altering 'Text2'.<br />

37

<strong>Getting</strong> <strong>Started</strong><br />

Now place another motor, positioning it at 160.0 / 50.0 mm. This M2 should actually be the<br />

same component as M1, nevertheless this time choose type '1LA7106-6AA10' from the<br />

database selection, and modify the function text to 'Worm' (it means Worm drive),<br />

positioning it at 165.0 / 37.5 mm. Then go back to the beginning with or a click the<br />

right mouse button.<br />

Incorrect assignments can be corrected simply and easily!<br />

Now we want to correct our "mistake" (the incorrectly assigned part number for M2):<br />

position the cursor on motor M2 and click with the right mouse button. The<br />

'Component Parameters' menu will appear, giving the most important commands for<br />

this component. With the left mouse button select the field 'Part number': the<br />

database list will reappear immediately and you can choose the correct type '1LA7083-<br />

6AA10' with a double click.<br />

Now, to protect the unit we need a 'Fuse -3pol', placed at 47.5 / 130.0 mm, preferably via<br />

the button. Use the type 'S27/C/FORMP+P-E27', and the value for 'Text2' is nominal<br />

current '16A'.<br />

TIP<br />

38<br />

Component reference names (like M, Q..) are not numbered at this<br />

point. This will be done later using the automatic numbering<br />

function.<br />

Editing Terminals<br />

General<br />

The terminal designations from the terminal strip -X0 cannot all be set automatically<br />

because the automatic process can only generate consecutive numbers. This also applies<br />

to the 'PE' terminals of -X1.<br />

WSCAD 5 offers a clear and simple tool to deal with this problem: the Terminal Browser.<br />

Placing Terminals<br />

Terminals are components with special features. They can be found in the Favourites<br />

library 'EXAMPLE'.<br />

First, the terminal -X0 is to be added to the drawing (this is the numbered reference<br />

name). To view the entire drawing sheet in the drawing frame, change the viewing scale<br />

by pressing either the function key (Fit View) or the and function<br />

keys to zoom in or out.<br />

Select the favourites library 'EXAMPLE' and select the component 'Terminal' and<br />

position it at 47.5 / 82.5 mm. Make sure that the terminal pin exactly matches the end<br />

of the line, overlapping should be avoided (turn Snap on!!). Press the left mouse button<br />

to position the terminal pin. Now the database selection appears, select 'terminal Insta<br />

2,5mm'.<br />

Enter a complete reference name (e.g. –X0), so that the automatic functions can locate<br />

the appropriate terminal pins (which could be located on ma ny pages throughout your<br />

diagram) and assign them to one complete terminal strip.<br />

To do this, select the 'Reference name' in the 'Component Parameters' menu, and<br />

you will be prompted, at the bottom of the screen, to input a reference name. Enter '-

Design capture<br />

X0' and confirm with . Exit from the 'Component Parameters' menu by<br />

clicking with the mouse in the drawing area (or use ).<br />

Hint<br />

The pin numbers entered here are only used in the example<br />

drawing. Normally the terminal pins are placed without numbering<br />

because the automatic function does the numbering for you.<br />

You can also modify easily the reference name of a terminal connection later. One<br />

possibility is via the command 'Modify – Reference name', but the quickest way is of<br />

course via menu 'Component Parameters': move the cursor across the component and<br />

a click with the right mouse button will show you the Component Parameters including<br />

the reference name.<br />

The designation 'L1' of the terminal connection (=pin number of the component) will be<br />

done later. At the upper end of the terminal, there is a little dot on the left. This is a<br />

visible designation for the internal destination assignment in the terminal list. You<br />

can change the destination to external by using the 'Modify - Terminal dest.'<br />

command. If you click on a terminal after selecting this command then the internal<br />

destination assignment will turn over. Note that the position of the dot changes from<br />

top to bottom.<br />

Alternative: a right button click on any terminal brings up a sub- menu including the<br />

'Terminal dest.' command, or, when placing the terminal, by pressing the right mouse<br />

button to activate the rotate/mirror sub- menu. (Modifying the assignment is not<br />

necessary on page 1 of this example, but you will see it on page 2 with the valves).<br />

Place a second terminal at 52.5 / 82.5 mm (preferably with the cursor keys, with Snap<br />

ON!). On this one, you do not have to enter a reference name, because the automatic<br />

function will assign terminals at the same level to the same terminal strip (like the one<br />

on the left). After placing the terminal, the menu 'Component Parameters' appears<br />

and now you select the 'Reference name' line. Clear the input line for e.g. pressing<br />

and press to confirm.<br />

In menu 'Component Parameters', the reference name is already correctly<br />

displayed. You can alter the reference at any time, e.g. when the terminal belongs to<br />

another terminal strip. Exit from menu with and you will notice that the terminal<br />

is displayed in the diagram without a reference name.<br />

You can place the other three terminals in the<br />

same manner as the second one, but it is much<br />

faster to use the 'Repeat' function within the<br />

menu 'Delete/Move'. Select 'Repeat'. At the<br />

prompt 'Set start position', position the cursor at<br />

57.5 / 82.5mm and press the left mouse button<br />

(or key) three times to place three more<br />

terminals (without a reference name). Every mouse<br />

click represents a repetition at the same<br />

displacement distance. Exit the command by<br />

pressing the right mouse button (or key).<br />

Placing the terminal for terminal strip '-X1' (belonging to the motor 'M1') at 90.0 /<br />

82.5mm by using the component: 'Terminal'. This terminal is to be assigned to a<br />

different terminal strip, alter the 'Reference name' in the 'Component Parameters' to<br />

'-X1' (remember the component parameter appears after placing the terminal).<br />

39

<strong>Getting</strong> <strong>Started</strong><br />

The automatic function will do the pin assignments later. Place the second the third and<br />

the 'PE' terminal of the terminal strip '-X1' the same way, but clear the 'Reference<br />

name'.<br />

Position the first terminal for M2 at 160.0 / 82.5 mm. Place the other terminals as for<br />

M1 in the same way. Make sure that they are at the same level as the one to the left, so<br />

you will not have to enter the reference name '-X1'.<br />

Hint<br />

40<br />

The terminal components used have an additional connection in the<br />

middle, called a 'jumper pin’. This pin makes it easier for the<br />

automatic process to manage the jumper connections between the<br />

terminals. A more detailed description of this connection method is<br />

given in the electronic reference manual located on your CD in the<br />

chapter ’Terminals’ and in the Online Help.<br />

Terminal browser<br />

To open the Terminal browser, click with the right mouse button on a terminal of the<br />

terminal strip '-X0' and choose 'Browser'. The dialog 'Terminal browser' opens:

Design capture<br />

Select '-X0' and you will see a list with all terminals from terminal strip '-X0'. Select on<br />

the right side of the dialog the sort modus 'Co-ordinate', now you see the terminals in<br />

this sequence you have been drawing in the sheet, sorted by page/path. In the column<br />

'Number' you didn't see a terminal number for the pin. To adjust a terminal number,<br />

double click in row '1' column 'Number' and type in 'L1'.<br />

Confirm the input with . The terminal number was adjusted and the cursor<br />

moved to the next field. Fill in for the next number 'L2' and complete the next fields with<br />

'L3', 'N' and 'PE'.<br />

41

<strong>Getting</strong> <strong>Started</strong><br />

Close the Terminal browser with 'OK' and confirm 'Save modifications?' with yes. Now<br />

all numbers are written to the terminals.<br />

Input via Terminal Number<br />

With this method, you can assign the terminal number separately for each individual<br />

terminal. In the menu, select 'Modify – Terminal / Cable numbers' and from the '-<br />

X1' terminal strip select the first terminal.<br />

At the prompt (Input Pin Number) type in '1' and confirm with . The terminal is<br />

now labeled and you are immediately prompted for the next terminal in the terminal<br />

strip. Continue until you have reached the 'PE' connection of motor M1 (M2 as well).<br />

Here enter 'PE' as the designation. (But you should increase your logical terminal<br />

numbering by one for the next terminal number).<br />

Confirm the existing inputs with (if you don't want to change it), when you<br />

reach the final connection in the terminal strip of the current drawing sheet, the input<br />

routine will be terminated.<br />

Drawing macros<br />

Inserting drawing macro<br />

Now you will add an additional symbol to your drawing using a previously created device<br />

that has been stored as a so-called 'Drawing Macro'. Drawing Macros contain<br />

components, lines and text, etc. that have been created from existing sections of<br />

42

Design capture<br />

drawings, and saved as Drawing Macros (they also contain all the parameters of a sub<br />

assembly of parts).<br />

From the menu bar, select 'File – Insert drawing macro'. The available drawing<br />

macros are displayed in the Drawing macro Explorer with preview (including an<br />

example of drawing frames).<br />

Select 'Transform_24V.0000' from the menu window and place it at 230.0 / 195.0<br />

mm.<br />

43

<strong>Getting</strong> <strong>Started</strong><br />

Hint<br />

44<br />

Circuit diagrams should mainly be based on macros. Set up macros<br />

whenever you can and create them that way that you can easily<br />

delete unwanted components from the macros.<br />

Contactor Manager<br />

General<br />

The Contactor Manager coordinates the relationship between coils and contacts. The<br />

difference between the semi-automatic and fully automatic processes is as follows:<br />

• The Semi-automatic Contactor Manager allows you to assign contacts to coils<br />

(or vice versa) immediately, without any database reference (part number). The<br />

part number will be allocated later via the Contactor Browser.<br />

• The Fully-automatic Contactor Manager takes you back to the database<br />

selection as soon as the component has been placed, and a part number has to be<br />

assigned. The cross-reference to the contact is generated online and the<br />

connection names are added automatically.<br />

Semi-automatic Contactor Manager<br />

The following coils are managed with the Contactor Manager in semi-automatic<br />

mode. Please check whether the semi-automatic Contactor Manager is active or<br />

not. Select the menu command 'Settings – Common Settings', (tab) 'Contactors and<br />

PLCmodules' and activate the Options 'Activate contactor manager' and 'Semiautomatic'.<br />

Exit with 'OK'.<br />

Hint

Do not alter the reference name; this will be automatically assigned<br />

and managed. The numbering is done automatically after the<br />

diagram is completed, using your data input.<br />

There are two possible ways using the Contactor Manager:<br />

Method 1: The coil is first positioned in the drawing and then the<br />

contacts are assigned to the coil<br />

Design capture<br />

From the menu select 'Schematic – Load symbol ...'. If no library is opened yet, select<br />

the Favourites library 'EXAMPLE'. You will find the motor circuit breaker under<br />

'MPCB_3pol+Aux-contact'. Position it at 90.0 / 162.5 mm.<br />

The Contactor list dialogue is becomes active. Here you see all used contactors and their<br />

contacts together.<br />

45

<strong>Getting</strong> <strong>Started</strong><br />

Select New and you'll get a reference name suggested. Pleas accept this suggestion<br />

and insert the function text ("!MPCB feed") in the text field on the top. Remember: the<br />

first character '!' in the function text makes it invisible in the drawing but this<br />

information will be very useful later.<br />

Leave the dialogue by pressing the OK button . Now the Symbol Parameters starts<br />

automatically. Please insert at Text2: 1 A. This text must positioned beneath the<br />

reference name.<br />

46

Design capture<br />

You're closing the Symbol Parameters and the Symbol Explorer by pressing the ESC<br />

key two times. Due to 'Auto-Connect ()' is activated, the connections to the<br />

motor are generated automatically.<br />

Hint<br />

The component parameters are displayed and you can accept the<br />

references as they are. The page and continuous numbers that<br />

make up the complete component reference number will be added<br />

automatically later.<br />

Important!<br />

For the assignment of coil contacts, it is necessary that the<br />

reference name is unique, e.g. with continuous numbers. Contacts<br />

that belong to a coil must have the same reference name as the<br />

coil. However, this is an easy task with the automatic contactor<br />

manager.<br />

You can now place the second MPCB 'MPCB_3pol+Aux-contact', this time using the<br />

'Copy' command. To do this, go back in the menu to 'Delete/Move' and select 'Copy<br />

immediately'. At the prompt 'Select one element…' select (click with left mouse<br />

button) the same circuit breaker as before and position it at 160.0 / 162.5 mm.<br />

47

<strong>Getting</strong> <strong>Started</strong><br />

Replace the 'Function text' input line with '!MPCB Worm' (it means a worm drive) and<br />

position it again below the circuit breaker.<br />

Method 2: The contacts are placed first and the coil is assigned to<br />

the contacts later (virtual contactor)<br />

Now draw the main circuit for motors M1 and M2. For this you need three 3-pole main<br />

contacts, which you will find via 'Schematic - Load symbol ...' under<br />

'NO_3pol_power'. Position the first contact at 90.0 / 130.0 mm.<br />

48

Design capture<br />

Create an new reference name in the Contactor list an insert a function text for the<br />

contacts.<br />

49

<strong>Getting</strong> <strong>Started</strong><br />

Make no changes in the following menu 'Component Parameters' and position the<br />

function text '!Feed forward’ anywhere.<br />

Repeat the whole procedure for the second and third 3-pole contacts, using the same<br />

procedure as above. The positions are 125.0 / 130.0 mm (the function text is '!Feed<br />

backward') and 160.0 / 130.0 mm (the function text is '!Worm on').<br />

Hint<br />

50<br />

Do not worry about the contact reference names. The Contactor<br />

Manager will first generate them, and will change them into the<br />

required form later.<br />

Contactor Manager<br />

You have now learned how to handle contacts whose coils have not yet been placed. The<br />

automatic process is handling them as a 'virtual contactor'. The assignment of contacts<br />

to contactors (also 'virtual') and the placing of contactor coils will be done later.<br />

Now look at the Contactor Manager. Click with the right mouse button on a contact or<br />

a contact and in 'Symbol Parameters' choose 'Assign anew'. In the Contactor<br />

Manager, you can see all the coils and contacts used in the drawing.

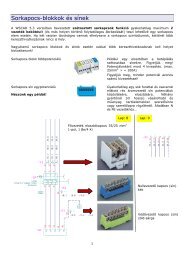

Contactor Manager symbols<br />

Symbol Description Explanation<br />

Design capture<br />

Green box Coil has item number with defined number of<br />

contacts and is already positioned on the page<br />

Green box with red<br />

cross<br />

Grey box with few<br />

points<br />

Coil is available on the page. Item number and<br />

contact are not yet determined or not positioned<br />

Contact is already positioned on the page but coils<br />