IMO - 49 EJ/EJX (MODEL G) ELECTRIC ACTUATORS

IMO - 49 EJ/EJX (MODEL G) ELECTRIC ACTUATORS

IMO - 49 EJ/EJX (MODEL G) ELECTRIC ACTUATORS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

4<br />

2.2 INSTALLATION OF ACCESSORIES 2.4 INSTALLATION OF THE<br />

To remove the cover from the <strong>EJ</strong> actuators remove the indicator<br />

pointer and the cover hold down screws. On <strong>EJ</strong>X actuators only,<br />

the indicator pointer is part of the cover sub-assembly and is<br />

therefore not removed prior to removing the cover.<br />

When reinstalling the cover care must be taken not to allow the<br />

cover to cock in relation to the base. On all <strong>EJ</strong> actuators the cover<br />

gasket must be installed between the cover and base flanges before<br />

reinstalling the cover. Tighten one screw partially then another on<br />

the opposite side of the flange, repeating this procedure until all<br />

screws are partially tightened. Repeat this procedure to fully<br />

tighten screws. On the <strong>EJ</strong>X actuators replace the cover and cover<br />

hold down screws. Care must be taken during reassembly that no<br />

particles or dirt are on the mating surface of flanges.<br />

2.3 INSTALLATION OF THE<br />

Internal Heater<br />

HEATER OPTION (LK 5060)<br />

An internal heater with a thermoswitch is available for Neles-<br />

Jamesbury <strong>EJ</strong> and <strong>EJ</strong>X actuators. These heaters are recommended<br />

for use whenever an actuator is installed in areas where the<br />

temperatures will be below +4O°F (+4°C) in order to prevent<br />

condensation. Power requirement for standard heaters for <strong>EJ</strong> and<br />

<strong>EJ</strong>X actuators is 100 watts.<br />

I. Mount the thermoswitch to the Basic Board mounting bracket<br />

using the screws, nuts and lock washer provided in the linkage kit.<br />

2. Place the heater blanket around the motor(s).<br />

3. Route one lead wire through the conduit. Cut the second lead<br />

wire approximately 4" or long enough to reach one of the terminals<br />

on the thermoswitch. Assemble one of the connectors and insulator<br />

provided in the linkage kit to it and connect it to the thermoswitch.<br />

4. Assemble a connector and insulator to one end of the cut off<br />

lead wire.<br />

5. Connect the lead wire to the thermoswitch and route it through<br />

the conduit.<br />

6. Apply the label from the linkage kit to the outside of the cover.<br />

FIGURE I<br />

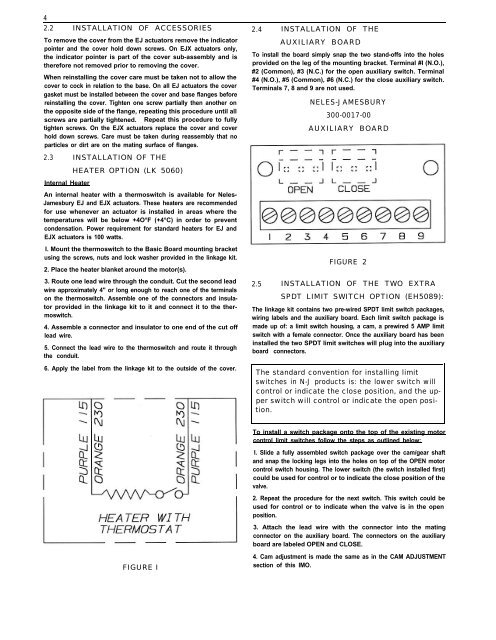

AUXILIARY BOARD<br />

To install the board simply snap the two stand-offs into the holes<br />

provided on the leg of the mounting bracket. Terminal #I (N.O.),<br />

#2 (Common), #3 (N.C.) for the open auxiliary switch. Terminal<br />

#4 (N.O.), #5 (Common), #6 (N.C.) for the close auxiliary switch.<br />

Terminals 7, 8 and 9 are not used.<br />

NELES-JAMESBURY<br />

300-0017-00<br />

AUXILIARY BOARD<br />

FIGURE 2<br />

2.5 INSTALLATION OF THE TWO EXTRA<br />

SPDT LIMIT SWITCH OPTION (EH5089):<br />

The linkage kit contains two pre-wired SPDT limit switch packages,<br />

wiring labels and the auxiliary board. Each limit switch package is<br />

made up of: a limit switch housing, a cam, a prewired 5 AMP limit<br />

switch with a female connector. Once the auxiliary board has been<br />

installed the two SPDT limit switches will plug into the auxiliary<br />

board connectors.<br />

The standard convention for installing limit<br />

switches in N-J products is: the lower switch will<br />

control or indicate the close position, and the upper<br />

switch will control or indicate the open position.<br />

To install a switch package onto the top of the existing motor<br />

control limit switches follow the steps as outlined below:<br />

I. Slide a fully assembled switch package over the cam/gear shaft<br />

and snap the locking legs into the holes on top of the OPEN motor<br />

control switch housing. The lower switch (the switch installed first)<br />

could be used for control or to indicate the close position of the<br />

valve.<br />

2. Repeat the procedure for the next switch. This switch could be<br />

used for control or to indicate when the valve is in the open<br />

position.<br />

3. Attach the lead wire with the connector into the mating<br />

connector on the auxiliary board. The connectors on the auxiliary<br />

board are labeled OPEN and CLOSE.<br />

4. Cam adjustment is made the same as in the CAM ADJUSTMENT<br />

section of this <strong>IMO</strong>.