- Page 2 and 3:

Filtration and Purification in the

- Page 4 and 5:

1. Pharmacokinetics, Milo Gibaldi a

- Page 6 and 7:

55. Radiopharmaceuticals: Chemistry

- Page 8 and 9:

107. Drug Stability: Principles and

- Page 10:

156. Pharmacogenomics: Second Editi

- Page 13:

Informa Healthcare USA, Inc. 52 Van

- Page 18:

Foreword Filtration has been used s

- Page 21 and 22:

viii Preface describing essential p

- Page 23 and 24:

x Contents 14. Extractables and Lea

- Page 25 and 26:

xii Contributors Theodore H. Meltze

- Page 27 and 28:

2 Quigley liquids. The problem can

- Page 29 and 30:

4 Quigley FIGURE 3 Diatoms in diato

- Page 31 and 32:

6 Quigley This inertial force depen

- Page 33 and 34:

8 Quigley Adsorption Activated Carb

- Page 35 and 36:

10 Quigley easier to change than a

- Page 37 and 38:

12 Quigley The graded pore size for

- Page 39 and 40:

14 Quigley FIGURE 15 Depth and memb

- Page 41 and 42:

16 Quigley The proper cake formatio

- Page 43 and 44:

18 Quigley The sterile bulk albumin

- Page 45 and 46:

20 Quigley When running a forward f

- Page 48 and 49:

2 Charge Modified Filter Media Euge

- Page 50 and 51:

Charge Modified Filter Media 25 pro

- Page 52 and 53:

Charge Modified Filter Media 27 saf

- Page 54 and 55:

Charge Modified Filter Media 29 FIG

- Page 56 and 57:

Charge Modified Filter Media 31 FIG

- Page 58 and 59:

Charge Modified Filter Media 33 FIG

- Page 60 and 61:

Charge Modified Filter Media 35 At

- Page 62 and 63:

Charge Modified Filter Media 37 FIG

- Page 64 and 65:

Charge Modified Filter Media 39 FIG

- Page 66 and 67:

Charge Modified Filter Media 41 FIG

- Page 68 and 69:

Charge Modified Filter Media 43 DNA

- Page 70 and 71:

Charge Modified Filter Media 45 Hag

- Page 72 and 73:

3 Filter Designs Suraj B. Baloda Mi

- Page 74 and 75:

Filter Designs 49 The most common 4

- Page 76 and 77:

Filter Designs 51 Multiple steps an

- Page 78 and 79:

Filter Designs 53 air filtration or

- Page 80 and 81:

Filter Designs 55 pleat pack that c

- Page 82 and 83:

Filter Designs 57 FIGURE 7 Differen

- Page 84 and 85:

Filter Designs 59 the tailoring of

- Page 86 and 87:

Filter Designs 61 measured. This gi

- Page 88 and 89:

Filter Designs 63 FIGURE 12 (A) Pil

- Page 90 and 91:

4 Pore Sizes and Distributions C. T

- Page 92 and 93:

Pore Sizes and Distributions 67 Fil

- Page 94 and 95:

Pore Sizes and Distributions 69 FIG

- Page 96 and 97:

Pore Sizes and Distributions 71 pre

- Page 98 and 99:

Pore Sizes and Distributions 73 whe

- Page 100 and 101:

Pore Sizes and Distributions 75 FIG

- Page 102 and 103:

Pore Sizes and Distributions 77 FIG

- Page 104:

Pore Sizes and Distributions 79 fil

- Page 107 and 108:

82 Meltzer and Jornitz The pore str

- Page 109 and 110:

84 Meltzer and Jornitz Pore Size Di

- Page 111 and 112:

86 Meltzer and Jornitz The dilution

- Page 113 and 114:

88 Meltzer and Jornitz per cm 2 EFA

- Page 115 and 116:

90 Meltzer and Jornitz TABLE 2 Rete

- Page 117 and 118:

92 Meltzer and Jornitz FIGURE 9 B.

- Page 119 and 120:

94 Meltzer and Jornitz Viscosity Vi

- Page 121 and 122:

96 Meltzer and Jornitz TABLE 5 Rete

- Page 123 and 124:

98 Meltzer and Jornitz fluid in its

- Page 125 and 126:

100 Meltzer and Jornitz TABLE 7 Flu

- Page 127 and 128:

102 Meltzer and Jornitz THE MODELIN

- Page 129 and 130:

104 Meltzer and Jornitz FIGURE 12 P

- Page 131 and 132:

106 Meltzer and Jornitz the mechani

- Page 133 and 134:

108 Meltzer and Jornitz filters in

- Page 135 and 136:

110 Meltzer and Jornitz particles f

- Page 137 and 138:

112 Meltzer and Jornitz from the el

- Page 139 and 140:

114 Meltzer and Jornitz modified to

- Page 141 and 142:

116 Meltzer and Jornitz This finds

- Page 143 and 144:

118 Meltzer and Jornitz The hydroge

- Page 145 and 146:

120 Meltzer and Jornitz Solvating E

- Page 147 and 148:

122 Meltzer and Jornitz filter’s

- Page 149 and 150:

124 Meltzer and Jornitz bonding of

- Page 151 and 152:

126 Meltzer and Jornitz and strongl

- Page 153 and 154:

128 Meltzer and Jornitz bacteria ne

- Page 155 and 156:

130 Meltzer and Jornitz The Electri

- Page 157 and 158:

132 Meltzer and Jornitz namely VDW

- Page 159 and 160:

134 Meltzer and Jornitz (non-flowin

- Page 161 and 162:

136 Meltzer and Jornitz hydrocarbon

- Page 163 and 164:

138 Meltzer and Jornitz neutralized

- Page 165 and 166:

140 Meltzer and Jornitz Interesting

- Page 167 and 168:

142 Meltzer and Jornitz the endotox

- Page 169 and 170:

144 Meltzer and Jornitz (1) The equ

- Page 171 and 172:

146 Meltzer and Jornitz Bowman FW,

- Page 173 and 174:

148 Meltzer and Jornitz Ridgway HF.

- Page 176 and 177:

6 Microbiological Considerations in

- Page 178 and 179:

Microbiological Considerations 153

- Page 180 and 181:

Microbiological Considerations 155

- Page 182 and 183:

Microbiological Considerations 157

- Page 184 and 185:

Microbiological Considerations 159

- Page 186:

Microbiological Considerations 161

- Page 189 and 190:

164 Meltzer and Jornitz some lower

- Page 191 and 192:

166 Meltzer and Jornitz taken that

- Page 193 and 194:

168 Meltzer and Jornitz 8. Initial

- Page 195 and 196:

170 Meltzer and Jornitz flow decrea

- Page 197 and 198:

172 Meltzer and Jornitz FIGURE 3 Pa

- Page 199 and 200:

174 Meltzer and Jornitz FIGURE 5 Se

- Page 201 and 202:

176 Meltzer and Jornitz Homogeneous

- Page 203 and 204:

178 Meltzer and Jornitz Prefilter A

- Page 205 and 206:

180 Meltzer and Jornitz upon the us

- Page 207 and 208:

182 Meltzer and Jornitz obtained by

- Page 209 and 210:

184 Meltzer and Jornitz published.

- Page 211 and 212:

186 Meltzer and Jornitz If flow dec

- Page 213 and 214:

188 Meltzer and Jornitz effect, the

- Page 215 and 216:

190 Meltzer and Jornitz differentia

- Page 217 and 218:

192 Meltzer and Jornitz Trotter AM,

- Page 219 and 220:

194 Bardo We will survey key aspect

- Page 221 and 222:

196 Bardo corrosion cracking, inclu

- Page 223 and 224:

198 Bardo were to skip any of the m

- Page 225 and 226:

200 Bardo stainless steel and other

- Page 227 and 228:

202 Bardo all the obligations requi

- Page 229 and 230:

204 Bardo built into the top plate,

- Page 231 and 232:

206 Bardo often called domes or she

- Page 233 and 234:

208 Bardo FIGURE 3 T-style sanitary

- Page 235 and 236:

210 Bardo In multi-round sanitary h

- Page 237 and 238:

212 Bardo FIGURE 6 (A) 222- and (B)

- Page 239 and 240:

214 Bardo Cartridge replacement. St

- Page 241 and 242:

216 Bardo ever larger. As the bioph

- Page 243 and 244:

218 Bardo n Difficult to scale-up n

- Page 245 and 246:

220 Bardo that is free of many of t

- Page 247 and 248:

222 Bardo TABLE 3 Comparison of Sta

- Page 249 and 250:

224 Bardo From this productive amal

- Page 251 and 252:

226 Bardo n integrity testing, n va

- Page 253 and 254:

228 Bardo CONCLUSION The evolution

- Page 256 and 257:

9 Stainless Steel Application and F

- Page 258 and 259:

Stainless Steel Application and Fab

- Page 260 and 261:

Stainless Steel Application and Fab

- Page 262 and 263:

Stainless Steel Application and Fab

- Page 264 and 265:

Stainless Steel Application and Fab

- Page 266 and 267:

Stainless Steel Application and Fab

- Page 268 and 269:

Stainless Steel Application and Fab

- Page 270 and 271:

Stainless Steel Application and Fab

- Page 272 and 273:

Stainless Steel Application and Fab

- Page 274 and 275:

Stainless Steel Application and Fab

- Page 276 and 277:

Stainless Steel Application and Fab

- Page 278 and 279:

Stainless Steel Application and Fab

- Page 280:

Stainless Steel Application and Fab

- Page 283 and 284:

258 Meltzer operational mechanism (

- Page 285 and 286:

260 Meltzer adsorptive interactions

- Page 287 and 288:

262 Meltzer surfaces to which they

- Page 289 and 290:

264 Meltzer matter, the bovine seru

- Page 291 and 292:

266 Meltzer FIGURE 2 Outer coats of

- Page 293 and 294:

268 Meltzer molecular arrangements

- Page 295 and 296:

270 Meltzer Extents of adsorption d

- Page 297 and 298:

272 Meltzer Qualitative Measurement

- Page 299 and 300:

274 Meltzer albumin solution, etc.

- Page 301 and 302:

276 Meltzer hydrophobic bonding. An

- Page 303 and 304:

278 Meltzer network. Thus, the mole

- Page 305 and 306:

280 Meltzer FIGURE 8 The hydrogen b

- Page 307 and 308:

282 Meltzer TABLE 4 Flu-Vaccine Fil

- Page 309 and 310:

284 Meltzer feedstream. At this poi

- Page 311 and 312:

286 Meltzer FIGURE 10 Different pro

- Page 313 and 314:

288 Meltzer factors, the short rang

- Page 315 and 316:

290 Meltzer plotted trace signals b

- Page 317 and 318:

292 Meltzer instead of flat membran

- Page 319 and 320:

294 Meltzer Characklis WG. Microbia

- Page 322 and 323:

11 The Filter Integrity Tests Theod

- Page 324 and 325:

The Filter Integrity Tests 299 befo

- Page 326 and 327:

The Filter Integrity Tests 301 side

- Page 328 and 329:

The Filter Integrity Tests 303 the

- Page 330 and 331:

The Filter Integrity Tests 305 supe

- Page 332 and 333:

The Filter Integrity Tests 307 thes

- Page 334 and 335:

The Filter Integrity Tests 309 Data

- Page 336 and 337:

The Filter Integrity Tests 311 The

- Page 338 and 339:

The Filter Integrity Tests 313 FIGU

- Page 340 and 341:

The Filter Integrity Tests 315 may

- Page 342 and 343:

The Filter Integrity Tests 317 pres

- Page 344 and 345:

The Filter Integrity Tests 319 FIGU

- Page 346 and 347:

The Filter Integrity Tests 321 Due

- Page 348 and 349:

The Filter Integrity Tests 323 Log

- Page 350 and 351:

The Filter Integrity Tests 325 Pres

- Page 352 and 353:

The Filter Integrity Tests 327 filt

- Page 354 and 355:

The Filter Integrity Tests 329 are

- Page 356 and 357:

The Filter Integrity Tests 331 the

- Page 358 and 359:

The Filter Integrity Tests 333 the

- Page 360 and 361:

The Filter Integrity Tests 335 test

- Page 362 and 363:

The Filter Integrity Tests 337 Is t

- Page 364 and 365:

The Filter Integrity Tests 339 (Tro

- Page 366 and 367:

The Filter Integrity Tests 341 an i

- Page 368 and 369:

The Filter Integrity Tests 343 FIGU

- Page 370 and 371:

The Filter Integrity Tests 345 The

- Page 372 and 373:

The Filter Integrity Tests 347 EMEA

- Page 374: The Filter Integrity Tests 349 Waib

- Page 377 and 378: 352 Jornitz For this reason vendors

- Page 379 and 380: 354 Jornitz Nevertheless, the vendo

- Page 381 and 382: 356 Jornitz meaning every step requ

- Page 383 and 384: 358 Jornitz successes will also ens

- Page 385 and 386: 360 Jornitz components are required

- Page 387 and 388: 362 Jornitz API WFI Higher Risk or

- Page 389 and 390: 364 Jornitz FIGURE 9 Typical flow d

- Page 391 and 392: 366 Jornitz is supplied to assure a

- Page 393 and 394: 368 Jornitz FIGURE 12 Validation sc

- Page 396 and 397: 13 Validation of the Filter and of

- Page 398 and 399: Validation of the Filter and of the

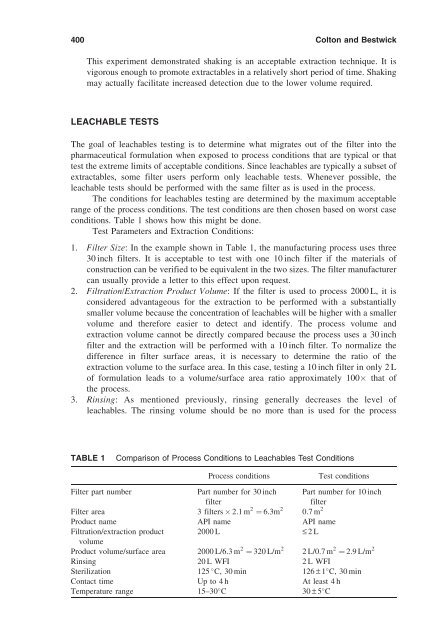

- Page 400 and 401: Validation of the Filter and of the

- Page 402 and 403: Validation of the Filter and of the

- Page 404 and 405: Validation of the Filter and of the

- Page 406 and 407: Validation of the Filter and of the

- Page 408 and 409: Validation of the Filter and of the

- Page 410 and 411: Validation of the Filter and of the

- Page 412: Validation of the Filter and of the

- Page 415 and 416: 390 Colton and Bestwick FIGURE 1 Cr

- Page 417 and 418: 392 Colton and Bestwick such as pol

- Page 419 and 420: 394 Colton and Bestwick Filters use

- Page 421 and 422: 396 Colton and Bestwick 3. Composit

- Page 423: 398 Colton and Bestwick Another con

- Page 427 and 428: 402 Colton and Bestwick and leachab

- Page 429 and 430: 404 Colton and Bestwick The mass fr

- Page 431 and 432: 406 Colton and Bestwick through the

- Page 433 and 434: 408 Colton and Bestwick Alternative

- Page 435 and 436: 410 Colton and Bestwick Modeling Le

- Page 438 and 439: 15 Endotoxin, Limulus Amebocyte Lys

- Page 440 and 441: Endotoxin, Limulus Amebocyte Lysate

- Page 442 and 443: Endotoxin, Limulus Amebocyte Lysate

- Page 444 and 445: Endotoxin, Limulus Amebocyte Lysate

- Page 446 and 447: Endotoxin, Limulus Amebocyte Lysate

- Page 448: Endotoxin, Limulus Amebocyte Lysate

- Page 451 and 452: 426 Gould thousand to roughly 25,00

- Page 453 and 454: 428 Gould different endotoxin prepa

- Page 455 and 456: 430 Gould Because turbidity can be

- Page 457 and 458: 432 Gould ERROR OF THE LAL TEST The

- Page 459 and 460: 434 Gould qualification of the LAL

- Page 461 and 462: 436 Gould promotes adsorption and d

- Page 463 and 464: 438 Gould Twohy CW, Nierman ML, Dur

- Page 465 and 466: 440 Jornitz and Meltzer form a high

- Page 467 and 468: 442 Jornitz and Meltzer Another imp

- Page 469 and 470: 444 Jornitz and Meltzer commonly sh

- Page 471 and 472: 446 Jornitz and Meltzer required to

- Page 473 and 474: 448 Jornitz and Meltzer FIGURE 10 F

- Page 475 and 476:

450 Jornitz and Meltzer filter devi

- Page 477 and 478:

452 Jornitz and Meltzer filter (600

- Page 479 and 480:

454 Jornitz and Meltzer FIGURE 15 F

- Page 481 and 482:

456 Jornitz and Meltzer the end use

- Page 484 and 485:

18 Downstream Processing Uwe Gottsc

- Page 486 and 487:

Downstream Processing 461 medium wi

- Page 488 and 489:

Downstream Processing 463 explore s

- Page 490 and 491:

Downstream Processing 465 (A) (B) S

- Page 492 and 493:

Downstream Processing 467 impuritie

- Page 494 and 495:

Downstream Processing 469 TABLE 1 D

- Page 496 and 497:

Downstream Processing 471 (A) (B) S

- Page 498 and 499:

Downstream Processing 473 n flux us

- Page 500 and 501:

Downstream Processing 475 Feed Resi

- Page 502 and 503:

Downstream Processing 477 TABLE 2 S

- Page 504 and 505:

Downstream Processing 479 Chromatog

- Page 506 and 507:

Downstream Processing 481 TABLE 3 S

- Page 508 and 509:

Downstream Processing 483 crystalli

- Page 510 and 511:

Downstream Processing 485 presents

- Page 512 and 513:

Downstream Processing 487 and react

- Page 514 and 515:

Downstream Processing 489 The chall

- Page 516 and 517:

Downstream Processing 491 Jagschies

- Page 518:

Downstream Processing 493 Zhou JX,

- Page 521 and 522:

496 Dosmar and Pinto Pore size (mic

- Page 523 and 524:

498 Dosmar and Pinto Flux (ml/min/c

- Page 525 and 526:

500 Dosmar and Pinto APPLICATIONS I

- Page 527 and 528:

502 Dosmar and Pinto In instances w

- Page 529 and 530:

504 Dosmar and Pinto TABLE 1 The Th

- Page 531 and 532:

506 Dosmar and Pinto 40% respective

- Page 533 and 534:

508 Dosmar and Pinto The polysulfon

- Page 535 and 536:

510 Dosmar and Pinto 0.4 0.3 0.2 0.

- Page 537 and 538:

512 Dosmar and Pinto Flux (mL/min/c

- Page 539 and 540:

514 Dosmar and Pinto interface. The

- Page 541 and 542:

516 Dosmar and Pinto Permeate port

- Page 543 and 544:

518 Dosmar and Pinto layer is on th

- Page 545 and 546:

520 Dosmar and Pinto TABLE 4 Factor

- Page 547 and 548:

522 Dosmar and Pinto If the tempera

- Page 549 and 550:

524 Dosmar and Pinto Excessive TMP

- Page 551 and 552:

526 Dosmar and Pinto Permeate Flow

- Page 553 and 554:

528 Dosmar and Pinto rate, identify

- Page 555 and 556:

530 Dosmar and Pinto shown) at any

- Page 557 and 558:

532 Dosmar and Pinto TABLE 6 Casset

- Page 559 and 560:

534 Dosmar and Pinto to the feed ta

- Page 561 and 562:

536 Dosmar and Pinto TABLE 8 Biolog

- Page 563 and 564:

538 Dosmar and Pinto TABLE Adsorpti

- Page 565 and 566:

540 Dosmar and Pinto MWCO Abbreviat

- Page 567 and 568:

542 Dosmar and Pinto Marshall AD, M

- Page 569 and 570:

544 Aranha were directed at selecti

- Page 571 and 572:

546 Aranha CONTROL OF PRODUCTION PR

- Page 573 and 574:

548 Aranha There are several availa

- Page 575 and 576:

550 Aranha TABLE 4 Risk Minimizatio

- Page 577 and 578:

552 Aranha proteins from chromatogr

- Page 579 and 580:

554 Aranha side of the filter is ta

- Page 581 and 582:

556 Aranha If the size of the prote

- Page 583 and 584:

558 Aranha Regulatory guidelines (C

- Page 585 and 586:

560 Aranha vary depending on the un

- Page 587 and 588:

562 Aranha the virus, it cannot be

- Page 589 and 590:

564 Aranha Steps that require dilut

- Page 591 and 592:

566 Aranha TABLE 10 Categorization

- Page 593 and 594:

568 Aranha TABLE 12 Main Characteri

- Page 595 and 596:

570 Aranha rederivatization. CBER h

- Page 597 and 598:

572 Aranha also virus removal filte

- Page 599 and 600:

574 Aranha every single reported ca

- Page 601 and 602:

576 Aranha Golker CF, Whiteman MD,

- Page 604 and 605:

21 A Rapid Method for Purifying Esc

- Page 606 and 607:

A Rapid Method for Purifying Escher

- Page 608 and 609:

A Rapid Method for Purifying Escher

- Page 610 and 611:

A Rapid Method for Purifying Escher

- Page 612 and 613:

A Rapid Method for Purifying Escher

- Page 614 and 615:

A Rapid Method for Purifying Escher

- Page 616 and 617:

A Rapid Method for Purifying Escher

- Page 618 and 619:

A Rapid Method for Purifying Escher

- Page 620 and 621:

A Rapid Method for Purifying Escher

- Page 622 and 623:

22 Membrane Chromatography Jeffrey

- Page 624 and 625:

Membrane Chromatography 599 contami

- Page 626 and 627:

Membrane Chromatography 601 the cyl

- Page 628 and 629:

Membrane Chromatography 603 Even so

- Page 630 and 631:

Membrane Chromatography 605 TABLE 2

- Page 632 and 633:

Membrane Chromatography 607 TABLE 4

- Page 634 and 635:

Membrane Chromatography 609 Isoelec

- Page 636 and 637:

Membrane Chromatography 611 validat

- Page 638 and 639:

Membrane Chromatography 613 C/CO 1

- Page 640 and 641:

Membrane Chromatography 615 TABLE 6

- Page 642 and 643:

Membrane Chromatography 617 spiked

- Page 644 and 645:

23 Expanded Polytetrafluoroethylene

- Page 646 and 647:

Expanded Polytetrafluoroethylene Me

- Page 648 and 649:

Expanded Polytetrafluoroethylene Me

- Page 650 and 651:

Expanded Polytetrafluoroethylene Me

- Page 652 and 653:

Expanded Polytetrafluoroethylene Me

- Page 654 and 655:

Expanded Polytetrafluoroethylene Me

- Page 656 and 657:

Expanded Polytetrafluoroethylene Me

- Page 658 and 659:

Expanded Polytetrafluoroethylene Me

- Page 660 and 661:

Expanded Polytetrafluoroethylene Me

- Page 662 and 663:

Expanded Polytetrafluoroethylene Me

- Page 664 and 665:

Expanded Polytetrafluoroethylene Me

- Page 666 and 667:

24 Air Filtration Applications in t

- Page 668 and 669:

Air Filtration Applications in the

- Page 670 and 671:

Air Filtration Applications in the

- Page 672 and 673:

Air Filtration Applications in the

- Page 674 and 675:

Air Filtration Applications in the

- Page 676 and 677:

Air Filtration Applications in the

- Page 678 and 679:

Air Filtration Applications in the

- Page 680 and 681:

Air Filtration Applications in the

- Page 682 and 683:

Air Filtration Applications in the

- Page 684 and 685:

Air Filtration Applications in the

- Page 686 and 687:

Air Filtration Applications in the

- Page 688 and 689:

Air Filtration Applications in the

- Page 690 and 691:

Air Filtration Applications in the

- Page 692 and 693:

Air Filtration Applications in the

- Page 694 and 695:

Air Filtration Applications in the

- Page 696 and 697:

Air Filtration Applications in the

- Page 698 and 699:

Air Filtration Applications in the

- Page 700 and 701:

Air Filtration Applications in the

- Page 702 and 703:

Air Filtration Applications in the

- Page 704 and 705:

Air Filtration Applications in the

- Page 706 and 707:

25 Sterility Testing by Filtration

- Page 708 and 709:

Sterility Testing by Filtration in

- Page 710 and 711:

Sterility Testing by Filtration in

- Page 712 and 713:

Sterility Testing by Filtration in

- Page 714 and 715:

Sterility Testing by Filtration in

- Page 716 and 717:

Sterility Testing by Filtration in

- Page 718 and 719:

Sterility Testing by Filtration in

- Page 720 and 721:

Sterility Testing by Filtration in

- Page 722:

Sterility Testing by Filtration in

- Page 725 and 726:

700 Mittelman phospholipids surroun

- Page 727 and 728:

702 Mittelman 1. Trace organics, wh

- Page 729 and 730:

704 Mittelman from chemical treatme

- Page 731 and 732:

706 Mittelman Flow Effects In the s

- Page 733 and 734:

708 Mittelman TREATMENT Inactivatio

- Page 735 and 736:

710 Mittelman TABLE 3 Chemical Trea

- Page 737 and 738:

712 Mittelman Khoury AE, Lam K, Ell

- Page 739 and 740:

714 Mittelman Richards GK, Gagnon R

- Page 742 and 743:

27 Steam Sterilization of Filters S

- Page 744 and 745:

Steam Sterilization of Filters 719

- Page 746 and 747:

Steam Sterilization of Filters 721

- Page 748 and 749:

Steam Sterilization of Filters 723

- Page 750 and 751:

Steam Sterilization of Filters 725

- Page 752 and 753:

Steam Sterilization of Filters 727

- Page 754 and 755:

Steam Sterilization of Filters 729

- Page 756 and 757:

Steam Sterilization of Filters 731

- Page 758 and 759:

Steam Sterilization of Filters 733

- Page 760 and 761:

Steam Sterilization of Filters 735

- Page 762 and 763:

Steam Sterilization of Filters 737

- Page 764 and 765:

Steam Sterilization of Filters 739

- Page 766 and 767:

Steam Sterilization of Filters 741

- Page 768 and 769:

Steam Sterilization of Filters 743

- Page 770 and 771:

Steam Sterilization of Filters 745

- Page 772 and 773:

Steam Sterilization of Filters 747

- Page 774 and 775:

Steam Sterilization of Filters 749

- Page 776:

Steam Sterilization of Filters 751

- Page 779 and 780:

754 Manfredi TABLE 1 List of Organo

- Page 781 and 782:

756 Manfredi Based upon its unstabl

- Page 783 and 784:

758 Manfredi Ozone, unlike chlorine

- Page 785 and 786:

760 Manfredi FIGURE 3 Tubular coron

- Page 787 and 788:

762 Manfredi Ozone monitors, for bo

- Page 789 and 790:

764 Manfredi ultraviolet decomposit

- Page 791 and 792:

766 Manfredi entering the vessel ma

- Page 793 and 794:

768 Manfredi d[O 3] = dt k o3 [M] [

- Page 795 and 796:

770 Manfredi pressure, although the

- Page 797 and 798:

772 Manfredi Ozone. 9 September 200

- Page 799 and 800:

774 Index [Air filtration applicati

- Page 801 and 802:

776 Index [Charge-modified filters]

- Page 803 and 804:

778 Index [ePTFE] lyophilization, 6

- Page 805 and 806:

780 Index [Filter validation/filter

- Page 807 and 808:

782 Index [Integrity tests] redunda

- Page 809 and 810:

784 Index Optimum TMP, definition,

- Page 811 and 812:

786 Index [Product capture/purifica

- Page 813 and 814:

788 Index [Steam sterilization of f

- Page 815:

790 Index Wetted membrane, rate of