Mosher Ester Analysis - Department of Chemistry and Physics

Mosher Ester Analysis - Department of Chemistry and Physics

Mosher Ester Analysis - Department of Chemistry and Physics

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Mosher</strong> <strong>Analysis</strong> <strong>of</strong> Enantiomeric Purity <strong>and</strong> Assignment <strong>of</strong> Absolute Configuratoin<br />

by NMR spectroscopy.<br />

References:<br />

Patterson, J.; Sigurdsson, S.T. J. Chem. Educ. 2005, 82, 1049-1050.<br />

Sullivan, G. R.; Dale, J.A.; <strong>Mosher</strong>, H.S. J. Am. Chem. Soc. 1973, 95, 512-519.<br />

Dale, J.A.; <strong>Mosher</strong>, H.S. J. Org. Chem. 1973, 38, 2143-2147.<br />

Prelab: Prepare your reagent table <strong>and</strong> procedure sheet, including the reaction. The<br />

reaction is described below. Have them ready to do the experiment when you come into<br />

the lab. You can find all <strong>of</strong> the reagents at www.sigmaaldrich.com. Also get NMR<br />

spectra for the starting materials that you can use to compare with your crude product.<br />

Background<br />

While we <strong>of</strong>ten discuss chiral compounds as single enantiomers, it is common to<br />

encounter these compounds as mixtures <strong>of</strong> enantiomers. This occurs both in the<br />

laboratory <strong>and</strong> in nature. In the laboratory, this most commonly arises from the use <strong>of</strong><br />

less than enantiopure starting materials or reagents during synthesis or by racemization<br />

during reactions. In nature, this can be due to competing enantomeric biosynthetic<br />

pathways <strong>and</strong> by enzymatic or chemical racemization. Mixtures <strong>of</strong> enantiomers can be<br />

racemic (50:50 mixture <strong>of</strong> enantiomers) or scalemic (any other proportion).<br />

The analysis <strong>of</strong> enantiomeric mixtures can be divided into two objectives. The<br />

first is the analysis <strong>of</strong> enantiomeric excess <strong>and</strong> the second is the establishment <strong>of</strong> absolute<br />

configuration. Enantiomeric excess is the amount <strong>of</strong> one enantiomer over the other <strong>and</strong> is<br />

usually expressed as a percentage value. Percent e.e. is calculated as:<br />

% e.e. = (100%)|R – S|<br />

R + S<br />

Establishment <strong>of</strong> configuration is simply determining which enantiomer is R <strong>and</strong><br />

which is S, <strong>and</strong> determination <strong>of</strong> which is in excess. The latter is a difficult task as,<br />

enantiomers are identical in all physical <strong>and</strong> spectral properties. Enantiomers do differ in<br />

the sign <strong>of</strong> their optical rotation <strong>and</strong> certain compounds can be distinguished by<br />

spectropolarimetry (the study <strong>of</strong> variation <strong>of</strong> rotation with wavelength, <strong>of</strong>ten referred to<br />

as circular dichroism (CD) or optical rotatory dispersion (ORD)). However, this<br />

approach is <strong>of</strong>ten limited to certain classes <strong>of</strong> compounds with large changes in their<br />

rotation <strong>and</strong> it is not generally applicable.<br />

In many cases both assignment <strong>of</strong> configuration <strong>and</strong> determination <strong>of</strong> e.e. can be<br />

achieved by reacting the molecule in question with a chiral compound <strong>of</strong> known absolute<br />

configuration <strong>and</strong> enantiomeric purity (preferably a single enantiomer). This produces a<br />

mixture <strong>of</strong> diastereomers. The requirements for such a method are that the chemistry<br />

involved does not cause the chiral centers <strong>of</strong> either <strong>of</strong> the reactants to racemize <strong>and</strong> that<br />

the reaction is quantitative in reaction with both enantiomers <strong>of</strong> the compound you are<br />

analyzing. That is, in some cases, one enantiomer reacts faster than the other. This is

called kinetic resolution. Usually this is avoided by using an excess <strong>of</strong> the enantiopure<br />

reactant <strong>and</strong> using reactions that are fast <strong>and</strong> irreversible.<br />

In this lab, you will prepare a chiral ester <strong>of</strong> a chiral secondary alcohol, 1phenylethanol.<br />

The ester is derived from the chiral carboxlic acid -methoxy-trifluoromethylphenylacetic<br />

acid (MTPA, <strong>Mosher</strong>’s acid), shown below.<br />

F3C<br />

MTPA<br />

Diastereomers, unlike enantiomers, have distinguishable physical <strong>and</strong> spectral<br />

properties because they are not mirror images. Diastereomers have two (or more) chiral<br />

centers. The added chiral center(s) can be the same or opposite configuration as that <strong>of</strong><br />

the original molecule. The matched <strong>and</strong> mismatched diastereomers will have different<br />

spectra <strong>and</strong> can thus be distinguished as shown below for one <strong>of</strong> the enantiomers <strong>of</strong><br />

MTPA <strong>and</strong> scalemic 1-phenylethanol.<br />

F3C<br />

O<br />

OCH 3<br />

OH<br />

+<br />

OH<br />

CH 3<br />

single enantiomer mixture <strong>of</strong> enantiomers<br />

mixture <strong>of</strong> diastereomers<br />

MTPA is a useful chiral acid for analyzing enantiomeric excess for several<br />

reasons. First, both enantiomers are available in high enantiomeric purity. Second, the<br />

chiral center is adjacent to the carboxyl bringing it in close proximity to the chiral center<br />

<strong>of</strong> the alcohol when the ester is prepared. Also, the chiral center is not able to be<br />

racemized as it is quaternary <strong>and</strong> thus contains no acidic protons. Finally, the presence <strong>of</strong><br />

the trifluoromethyl group allows for clean analysis <strong>of</strong> enantiomeric excess by 19 F NMR,<br />

which is uncomplicated by signals from the chiral alcohol, unlike the 1 H NMR spectrum.<br />

However, 1 H NMR can also be used if the signals are sufficiently resolved. This also<br />

allows for assignment <strong>of</strong> configuration based on a preferred conformation <strong>of</strong> the ester. In<br />

this experiment, you will team up with a partner. You will be given a sample <strong>of</strong> 1phenylethanol<br />

<strong>of</strong> unknown enantiomeric composition. One <strong>of</strong> you will prepare the (R)-<br />

(+)-MTPA ester <strong>of</strong> your 1-phenylethanol sample <strong>and</strong> the other will prepare the (S)-(-)-<br />

MTPA ester <strong>of</strong> the sample. You will then compare your 19 F NMR <strong>and</strong> 1 H NMR data <strong>and</strong><br />

determine both the enantiomeric excess <strong>and</strong> the major enantiomer present according to<br />

the published methods by <strong>Mosher</strong>.<br />

We will prepare our esters using N,N’-dicyclohexylcarbodiimide (DCC) to<br />

activate the acid toward substitution <strong>and</strong> 4-dimethylaminopyridine (DMAP) as a catalyst.<br />

*<br />

O<br />

OCH 3<br />

OH<br />

F3C<br />

F3C<br />

O<br />

OCH 3<br />

O<br />

+<br />

OCH 3<br />

H<br />

O<br />

H<br />

O<br />

CH 3<br />

CH 3

This is an exceptionally mild method <strong>of</strong> carboxyl activation <strong>and</strong> is used extensively for<br />

the synthesis <strong>of</strong> both esters an amides, particularly for peptide synthesis.<br />

O<br />

R OH<br />

R'OH, DCC, DMAP<br />

CH 2Cl 2<br />

O<br />

R OR'<br />

The reaction proceeds in two steps. First, the the acid reacts with DCC, forming<br />

an O-acylisourea. This species is similar to an anhydride <strong>and</strong> the carbonyl is highly<br />

susceptible to substitution. In the second step, the alcohol attacks the carbonyl to produce<br />

the ester <strong>and</strong> eliminates dicyclohexylurea as shown below.<br />

Step 1.<br />

O<br />

R O<br />

Step 2.<br />

O<br />

N<br />

c-Hx<br />

c-Hx<br />

R O N<br />

H<br />

O-acylisourea<br />

(similar to an anhydride)<br />

O<br />

H<br />

+<br />

N C N<br />

Dicyclohexylcarbodiimide<br />

(DCC)<br />

O<br />

HN<br />

c-Hx<br />

+<br />

c-Hx<br />

R OR'<br />

O N<br />

H<br />

Dicyclohexylurea (DCU)<br />

N<br />

c-Hx<br />

O<br />

R O<br />

O<br />

R O<br />

R' O H +<br />

c-Hx<br />

R' O +<br />

R O N<br />

H<br />

+<br />

+<br />

O<br />

H<br />

R O<br />

OR'<br />

H<br />

N C N<br />

H<br />

N C N<br />

H-bond<br />

O<br />

R O<br />

While this process can proceed by itself or with added bases such as<br />

triethylamine, it is somewhat sluggish. In order to speed the process, a nucleophilic<br />

N<br />

c-Hx<br />

N<br />

H<br />

H<br />

N<br />

c-Hx<br />

c-Hx<br />

N<br />

H<br />

c-Hx

catalyst, 4-dimethylaminopyridine (DMAP) is used. DMAP facilitates the process both<br />

by acting as a base <strong>and</strong> by forming activated acylpyridinium derivatives (below) from<br />

DCC <strong>and</strong> from the O-acylisourea. These are much more reactive as the pyridine is an<br />

excellent leaving group. This accelerates the reaction severalfold over the uncatalyzed<br />

reaction.<br />

H 3C<br />

N<br />

CH 3<br />

N<br />

N<br />

c-Hx<br />

N<br />

H<br />

c-Hx<br />

Procedure<br />

Wear gloves. DCC <strong>and</strong> DMAP are very toxic.<br />

You will be provided with a culture tube containing a scalemic solution <strong>of</strong> 6.0 L<br />

<strong>of</strong> 1-phenylethanol in 1 mL <strong>of</strong> dry CH2Cl2. To this add a stir bar <strong>and</strong> 13 mg <strong>of</strong> (R)-(+)- or<br />

(S)-(-)-MTPA as directed by your instructor. Be sure to record which enantiomer <strong>of</strong><br />

MTPA you use. Also be sure to cap the tube quickly to minimize any moisture entry<br />

after each addition <strong>of</strong> reagent. A nitrogen balloon <strong>and</strong> septum can be used if you wish.<br />

Cool the flask in an ice bath <strong>and</strong> add 12 mg <strong>of</strong> DCC <strong>and</strong> a spatula point (~1-2 mg) <strong>of</strong><br />

DMAP in sequence. Add the DCC to the reaction as soon as it is weighed as it tends to<br />

pick up moisture in the air. Stir the solution for 5 minutes in the ice bath, <strong>and</strong> then 25<br />

minutes at room temperature, during which time dicyclohexylurea will precipitate.<br />

While you are waiting on the reaction to complete, experiment with different TLC<br />

systems to determine if your reaction has finished. Spot 1-phenylethanol, DCC, DMAP,<br />

MTPA, <strong>and</strong> your reaction separately on the TLC plate <strong>and</strong> develop. Visualize the plate<br />

with UV light <strong>and</strong> circle the spots with a pencil. Begin with 1:1 hexane-ethyl acetate <strong>and</strong><br />

evaluate several mixtures until you find one that separates all <strong>of</strong> the components well,<br />

especially the product. This mixture will be used for preparative TLC to purify the<br />

product.<br />

Also while you are waiting on the reaction to complete, prepare two large test<br />

tubes for exraction <strong>of</strong> the reaction mixture. To one tube add 2 mL <strong>of</strong> 5% NaHCO3 <strong>and</strong> to<br />

the second add 2 mL <strong>of</strong> saturated NaHCO3.<br />

When the reaction is judged to be complete or 30 minutes passed, add 2 drops <strong>of</strong><br />

water <strong>and</strong> stir an additional 10 minutes. Then, add one mL <strong>of</strong> CH2Cl2 <strong>and</strong> 2 mL <strong>of</strong> 5%<br />

acetic acid to the culture tube <strong>and</strong> swirl vigorously. Using a pipet, transfer the organic<br />

layer to the test tube containing 5% NaHCO3 <strong>and</strong> swirl as before. Repeat this for the tube<br />

containing saturated NaHCO3. Prepare a pipet drying column plugged with glass wool<br />

<strong>and</strong> filled with ~3 cm <strong>of</strong> anhydrous Na2SO4. Clamp the tube in place <strong>and</strong> place a tared 10<br />

mL round bottom flask below to collect the eluent. Add the organic phase from the last<br />

tube <strong>and</strong> allow it to pass through the column <strong>and</strong> collect in the flask. Once all <strong>of</strong> the<br />

organic phase has been added <strong>and</strong> the top <strong>of</strong> the liquid reaches the Na2SO4, wash the<br />

column twice with 2 mL CH2Cl2. Remove the solvent by rotary evaporation <strong>and</strong> remove<br />

any traces under high vacuum for no more than a minute or two (The instructor will show<br />

R<br />

O<br />

N<br />

N<br />

CH 3<br />

CH 3

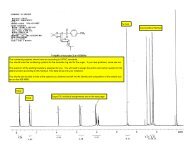

you how to do this). Obtain a crude yield, dissolve the product in CDCl3 <strong>and</strong> obtain a 1 H<br />

NMR spectrum <strong>of</strong> the crude ester.<br />

Preparative Thin-Layer Chromatography<br />

The <strong>Mosher</strong> ester will be purified by preparative thin-layer chromatography. This<br />

is essentially the same as what you use for monitoring your reactions, only on larger<br />

scale. We will use a large developing tank, <strong>and</strong> large, thickly coated plates. The plates<br />

we are using are capable <strong>of</strong> separating around 10-20 mg, depending on separation<br />

efficiency. Unlike flash chromatography, no specific Rf value is required. Simply<br />

identify a solvent system which will adequately separate your compounds <strong>and</strong> develop<br />

the plate. The technique does have limitations, however. The large surface area <strong>of</strong> the<br />

silica, combined with its mildly acidic nature tend to promote air oxidation <strong>of</strong> sensitive<br />

functionalities such as aldehydes, amines, <strong>and</strong> reactive double bonds. Also, the method is<br />

rather expensive to perform on other than small scale separations. Nonetheless, it is <strong>of</strong><br />

great utility in difficult separations <strong>of</strong> small amounts <strong>of</strong> material, such as extracts <strong>of</strong><br />

natural products <strong>and</strong> separation <strong>of</strong> diastereomers. In the second part <strong>of</strong> this experiment,<br />

you will separate the products <strong>of</strong> your <strong>Mosher</strong> ester reaction by preparative TLC <strong>and</strong><br />

characterize your product by 1 H <strong>and</strong> 19 FNMR.<br />

Preparative TLC Procedures<br />

1. Set up TLC Developing tank.<br />

a. Examine TLC’s in various solvent systems (TLC hood) if you have not yet<br />

determined an optimal composition.<br />

b. Dissolve your sample in 1.0 mL CH2Cl2 or use the NMR sample directly.<br />

c. Perform a TLC on your material using that system. (Don’t forget to cospot<br />

with your starting material).<br />

d. Make up 100 mL <strong>of</strong> your chosen solvent system <strong>and</strong> put it in the tank.<br />

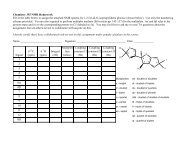

2. Prepare your TLC plate.<br />

a. Set up the solvent streaker (Have the instructor help you.)<br />

b. Draw a pencil line about 1” from the bottom <strong>of</strong> the plate.<br />

c. Set the streaker up so that the tip <strong>of</strong> the capillary traverses this line as you<br />

draw it along the benchtop.<br />

d. Fill the streaker with your solution. The reservoir will only hold around<br />

0.25-0.5 mL.<br />

e. Streak the plate on the line you drew. Try to keep the thickness <strong>of</strong> your<br />

b<strong>and</strong> between 1-3mm. Wave your h<strong>and</strong> over the plate to assist drying.<br />

f. Refill the reservoir again <strong>and</strong> repeat.<br />

g. Clean the reservoir with acetone. Dry it under a nitrogen flow. Give it to<br />

the next person to use. Be gentle with the streaker. We only have one <strong>and</strong><br />

if broken, it will end our experiment.<br />

3. Develop your plate.<br />

a. Place your plate in the developing tank.<br />

b. Develop the plate until the solvent front reaches within one inch <strong>of</strong> the top.<br />

This will take about an hour. Be sure to check the plate every 15 minutes<br />

to see its progress.

c. Remove the plate from the tank <strong>and</strong> mark the solvent front with a pencil.<br />

d. Wait for the plate to dry. You can assist this by fanning the plate with a<br />

folder or using a flow <strong>of</strong> dry nitrogen. While you are waiting, you should<br />

be cleaning glassware or something else productive. Do not wait an<br />

excessive amount <strong>of</strong> time. Many compounds are sensitive to oxidation on<br />

a TLC plate as the surface area is very large.<br />

4. Isolate the product.<br />

a. When your plate is dry enough, visualize the b<strong>and</strong>s using UV light. Mark<br />

them lightly with a pencil.<br />

b. Using an exacto knife or the flat edge <strong>of</strong> a spatula, scrape the b<strong>and</strong>s <strong>of</strong>f<br />

onto a lengthwise folded piece <strong>of</strong> clean, white paper.<br />

c. Prepare a vacuum filtration using a fritted glass funnel as shown below.<br />

d. Place the scrapings into a fritted glass funnel <strong>and</strong> press them into a pad.<br />

e. Wash the compound <strong>of</strong>f the silica into a round bottomed flask using 3 x 5<br />

mL <strong>of</strong> TLC solvent.<br />

f. Remove the solvent by rotary evaporation <strong>and</strong> determine the mass <strong>of</strong> your<br />

product. While this is occurring have your sample analyzed by chiral GC<br />

or be cleaning your glassware.<br />

5. Characterize your product by 1 H <strong>and</strong> 19 FNMR.<br />

Since one member <strong>of</strong> your team will prepare the R-MTPA ester <strong>and</strong> the other will<br />

prepare the S-MTPA ester, compare your results <strong>and</strong> assign the stereochemistry <strong>of</strong> the<br />

alcohol <strong>and</strong> the % e.e. according to the two <strong>Mosher</strong> references.<br />

Questions:<br />

1. Compare the % e.e. based on the integration <strong>of</strong> the 1 H <strong>and</strong> the 19 F spectra <strong>of</strong> the<br />

<strong>Mosher</strong> ester you made. For 1 H, calculate for all resonances that are sufficiently<br />

resolved to integrate reliably. Do they agree? If not, suggest a reason for the<br />

discrepancy.<br />

2. Calculate the % e.e. from your crude product <strong>and</strong> compare with that from the<br />

purified sample. Do they agree? If not, suggest a reason for the discrepancy.<br />

3. Compare the % e.e. you obtained to that obtained by your partner. Do they agree?<br />

If not, suggest a reason for the discrepancy.<br />

4. Suggest two alternate methods for determining the % e.e. <strong>of</strong> your alcohol.

Plate<br />

20 cm x 20 cm<br />

2.5 mm layer<br />

thickness<br />

Bench Guide/<br />

Reservoir Holder<br />

Streak line<br />

~1" from bottom<br />

1-3mm thickness<br />

Glass Plate Cover<br />

Developing chamber<br />

Solvent<br />

~3/4" from bottom<br />

About 100 mL<br />

TLC Plate Streaker<br />

Bench<br />

Preparative TLC Plate<br />

Development<br />

Reservoir<br />

Capillary<br />

TLC Plate<br />

to aspirator<br />

25 mL<br />

Claisen<br />

head