PRODUCT INFORMATION ROSOMA Check Weigher

PRODUCT INFORMATION ROSOMA Check Weigher

PRODUCT INFORMATION ROSOMA Check Weigher

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>PRODUCT</strong> <strong>INFORMATION</strong><br />

<strong>ROSOMA</strong> <strong>Check</strong> <strong>Weigher</strong><br />

<strong>ROSOMA</strong> machines and systems represent the current and future state-of-the-art technology in fish processing.<br />

They comply with the rules and regulations in force and the high hygiene standards of the food<br />

industry.<br />

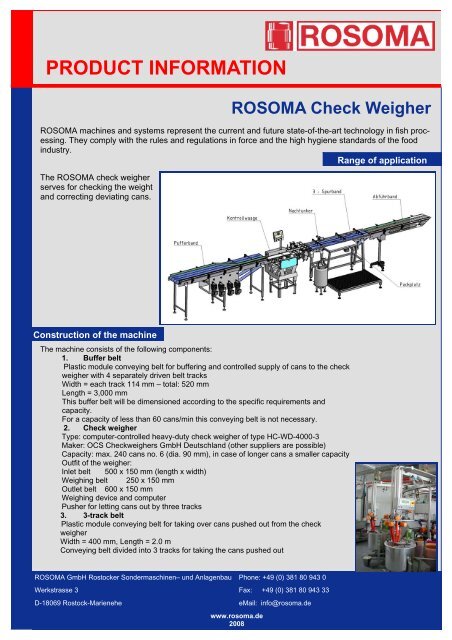

Range of application<br />

The <strong>ROSOMA</strong> check weigher<br />

serves for checking the weight<br />

and correcting deviating cans.<br />

Construction of the machine<br />

The machine consists of the following components:<br />

1. Buffer belt<br />

Plastic module conveying belt for buffering and controlled supply of cans to the check<br />

weigher with 4 separately driven belt tracks<br />

Width = each track 114 mm – total: 520 mm<br />

Length = 3,000 mm<br />

This buffer belt will be dimensioned according to the specific requirements and<br />

capacity.<br />

For a capacity of less than 60 cans/min this conveying belt is not necessary.<br />

2. <strong>Check</strong> weigher<br />

Type: computer-controlled heavy-duty check weigher of type HC-WD-4000-3<br />

Maker: OCS <strong>Check</strong>weighers GmbH Deutschland (other suppliers are possible)<br />

Capacity: max. 240 cans no. 6 (dia. 90 mm), in case of longer cans a smaller capacity<br />

Outfit of the weigher:<br />

Inlet belt 500 x 150 mm (length x width)<br />

Weighing belt 250 x 150 mm<br />

Outlet belt 600 x 150 mm<br />

Weighing device and computer<br />

Pusher for letting cans out by three tracks<br />

3. 3-track belt<br />

Plastic module conveying belt for taking over cans pushed out from the check<br />

weigher<br />

Width = 400 mm, Length = 2.0 m<br />

Conveying belt divided into 3 tracks for taking the cans pushed out<br />

<strong>ROSOMA</strong> GmbH Rostocker Sondermaschinen– und Anlagenbau Phone: +49 (0) 381 80 943 0<br />

Werkstrasse 3 Fax: +49 (0) 381 80 943 33<br />

D-18069 Rostock-Marienehe eMail: info@rosoma.de<br />

www.rosoma.de<br />

2008

4. Sauce refiller<br />

The sauce refiller is mounted at the left track of the three-track belt and consists of:<br />

Dosing head<br />

Pulse valve<br />

Pressure tank (0.5 - 0.9 bar)<br />

5. Working table<br />

Mounted on the right-hand side of the three-track belt, the table serves as a working<br />

place for 1-2 persons for manual re-packing of cans.<br />

6. Electrical switch cabinet<br />

A high-grade steel switch cabinet holds the program control and all electrical fittings<br />

for controlling of the overall system. The system is pre-installed with regard to cabling.<br />

Functional Description<br />

The cans are conveyed to the four-track belt and can here<br />

be buffered for a short time. The four-track belt has four individual<br />

drives which are controllable in each case.<br />

Thus it is avoided that a deformation of piled up cans happens.<br />

The check weigher ensures the following evaluation<br />

variants:<br />

�Can weight OK � Can passes through straight ahead.<br />

�Little deviation � Can is pushed out to the left-hand side and sauce is re-filled automatically.<br />

�Great deviation � Can is pushed out to the right-hand side, the weight is corrected manually.<br />

(Mirror-inverted design is possible.)<br />

The pushed out cans are subsequently lead to the center track again and carried on by the following conveying belt.<br />

All weight values and tolerances can be set. Furthermore, the weigher has a statistics version for evaluation of production<br />

and for statistical determination of weight deviations.<br />

Technical Parameters<br />

Dimensions<br />

Length: 6,500 mm<br />

Width: 1,700 mm<br />

Output max. 220 cans/minute<br />

Container for sauce re-filler Capacity of abt. 5 litres<br />

Pressure 0.5 – 0.9 bar<br />

Electric supply Totally abt. 3.5 kW, 400 V/50 Hz<br />

Degree of protection IP 56<br />

<strong>ROSOMA</strong> GmbH Rostocker Sondermaschinen– und Anlagenbau Phone: +49 (0) 381 80 943 0<br />

Werkstrasse 3 Fax: +49 (0) 381 80 943 33<br />

D-18069 Rostock-Marienehe eMail: info@rosoma.de<br />

www.rosoma.de