Polymerisation Processes Polymerisation Processes Polyethylene ...

Polymerisation Processes Polymerisation Processes Polyethylene ...

Polymerisation Processes Polymerisation Processes Polyethylene ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Polymerisation</strong> <strong>Processes</strong><br />

Polymer <strong>Processes</strong><br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

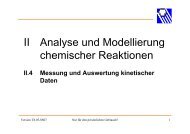

<strong>Polyethylene</strong><br />

Homo- und Copolymers of ethylene:<br />

n<br />

• PE is industrially produced bay radical- and coordinative polymerization<br />

• <strong>Polyethylene</strong> (PE) is semi-crystalline, non-polar thermoplastic material<br />

• Most important standard plastics with highest production volume<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

1<br />

3<br />

<strong>Polymerisation</strong> <strong>Processes</strong><br />

Why look processes like as they do?<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

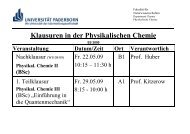

<strong>Polyethylene</strong><br />

structure<br />

crystallinity [%]<br />

Melting point [°C]<br />

density [g/cm 3 ]<br />

LDPE LLDPE HDPE PP<br />

Long- and<br />

Short chainbranching<br />

50 - 55<br />

106 - 120<br />

0,91 - 0,93<br />

Linear with<br />

short chainbranches<br />

55 - 60<br />

125 - 130<br />

0,91 - 0,93<br />

Linear with few<br />

short chainbranches<br />

70 - 80<br />

128 - 136<br />

0,93 - 0,96<br />

Linear<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

~ 70<br />

164 - 166<br />

0,91<br />

2<br />

4

<strong>Polyethylene</strong> applications<br />

• Films<br />

• packaging material<br />

• injection molding<br />

• pipes<br />

• electrical insulation material<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

<strong>Polyethylene</strong> melt flow index<br />

Melt Flow Rate / Melt Flow Index<br />

= a measure for chain length / molecular weight<br />

Amount of molten polymer [dg/min], that flows at defined conditions (pressure<br />

and temperature) through a defined capillary.<br />

Standards: ASTM 1238 / ISO R1133<br />

weight 2,16 kg / 21,6 kg<br />

temperature 190 °C<br />

geometry capillary:<br />

D=2,095 mm<br />

L=8 mm<br />

High MFR = low molecular weight<br />

Low MFR = high molecular weight<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

5<br />

7<br />

<strong>Polyethylene</strong> density<br />

Density correlates with crystallinity and structure of PE:<br />

amorphous PE: ρ = 860 kg/m³<br />

crystalline PE: ρ = 1000 kg/m³<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

Polyethylen <strong>Processes</strong><br />

PE<br />

radical coordinative<br />

homogen homogenous<br />

• bulk<br />

(LDPE high<br />

pressure process)<br />

homogenous heterogenous<br />

• solution • Suspension<br />

(3 Phase „Slurry“<br />

polymerization)<br />

• Gas phase<br />

• bimodal:<br />

slurry-slurry<br />

slurry-GP<br />

GP-GP<br />

Reactions -<br />

mechanism<br />

phases<br />

processes<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

6<br />

8

High Pressure <strong>Polyethylene</strong> <strong>Processes</strong><br />

High pressure process<br />

in one phase region<br />

low pressure process in<br />

two phase region<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

R2<br />

Side Reactions inHigh Pressure <strong>Polyethylene</strong><br />

R1<br />

Chain scission – unsaturated chains<br />

R1 CH 2 CH CH 2 R2<br />

Intermolecular transfer to polymer – long chain branching<br />

CH CH 2<br />

2<br />

CH C<br />

2<br />

H2 +<br />

CH CH CH CH 2<br />

2<br />

2<br />

2<br />

CH CH CH R3<br />

2<br />

2<br />

2<br />

R2<br />

R1<br />

CH CH 2<br />

2<br />

CH CH 2<br />

3<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

+<br />

CH CH C<br />

2<br />

2<br />

CH CH H<br />

2<br />

2<br />

CH 2<br />

n<br />

CH 2<br />

R3<br />

C<br />

H 2<br />

CH 2<br />

R2<br />

H2 C<br />

+<br />

+<br />

R1 CH CH2 R2 H2C<br />

H C CH R2 2 R1 C<br />

C<br />

H 2<br />

H2 C<br />

C<br />

H 2<br />

C<br />

H 2<br />

C<br />

H 2<br />

HC<br />

CH 2<br />

CH 2<br />

C<br />

H 2<br />

H 2<br />

H2 C<br />

R3<br />

9<br />

11<br />

High Pressure <strong>Polyethylene</strong> <strong>Processes</strong><br />

Primary<br />

compressor<br />

Granules<br />

Hyper Compr.<br />

Autoclave<br />

High pressure cycle<br />

150-300 bar<br />

Low pressure<br />

cycle<br />

Extruder<br />

M<br />

alternative<br />

High pressure<br />

separator<br />

Low pressure<br />

separator<br />

T = 200 - 300°C<br />

P = 2000 - 3000 bar<br />

Tubular reactor<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

Side Reactions inHigh Pressure <strong>Polyethylene</strong><br />

Intramolecular transfer to polymer – short chain branching<br />

R1 CH 2 CH 2 CH<br />

H<br />

CH 2<br />

C<br />

H 2<br />

R1 CH 2 CH 2 CH<br />

R1 CH 2 CH 2 CH<br />

CH 2<br />

CH 2<br />

CH 2<br />

CH H 2<br />

C<br />

H2 CH 2<br />

CH 2<br />

CH 3<br />

C<br />

H 2<br />

CH CH 2 CH 3<br />

CH CH 2 CH 3<br />

R1 CH 2 CH 2 C H<br />

CH 2<br />

n<br />

C<br />

H 2<br />

n<br />

C<br />

H 2<br />

CH 2<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

CH 2<br />

C<br />

H 3<br />

CH 2<br />

CH 2<br />

CH 2<br />

n<br />

M<br />

C<br />

H 2<br />

CH 2<br />

R1 CH 2 CH 2 CH<br />

CH 2<br />

CH 2<br />

CH 2<br />

CH 3<br />

CH 2 CH 2 CH 2 CH 2 CH 2<br />

R1 CH CH CH CH CH CH CH CH 2 2 2<br />

2 2 2<br />

CH 2<br />

CH 3<br />

CH 2<br />

CH 3<br />

Butyl side groups<br />

Ethyl side groups<br />

10<br />

12

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

I, M<br />

300<br />

200<br />

100<br />

Activation energy and volumes in LDPE<br />

Different operation modes in LDPE reactors<br />

Single monomer feed of monomer<br />

Multiple initiator possible<br />

Single initiator feed<br />

I<br />

double initiator feed<br />

300<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

200<br />

100<br />

I, M<br />

Multiple feed of monomer and initiator<br />

I, M<br />

I, M<br />

13<br />

15<br />

Process parameters and properties - Trends<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

Coordinative <strong>Polyethylene</strong> <strong>Processes</strong><br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

14<br />

16

Solution Coordinative <strong>Polyethylene</strong> <strong>Processes</strong><br />

Solution process:<br />

• broad range of comonomer types and densities possible<br />

• pure products<br />

• limitation: high molecular weight (high temperature, transfer to solvent)<br />

• temperature well above melting point of PE<br />

• commercial processes:<br />

• processes with very short residence time, e.g. 2 min:<br />

• Nova Sclairtech / Advanced Sclairtech<br />

• Sabic / Stamicarbon Compact solution process<br />

• processes with longer residence time e.g. 30 min:<br />

• Dowlex<br />

• Mitsui<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

Solution Coordinative <strong>Polyethylene</strong> <strong>Processes</strong><br />

Sclairtech Dowlex<br />

temperature 200 - 300 °C 160 °C<br />

pressure bis zu 100 bar 27 bar<br />

solvent cyclohexane C8 / C9 paraffines<br />

Residence time approx. 2 min approx. 30 min<br />

heat removal: convective convective and conductive<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

17<br />

19<br />

Solution Coordinative <strong>Polyethylene</strong> <strong>Processes</strong><br />

Flowsheet for solution polymerization (DSM)<br />

Ethylen<br />

Comonomer<br />

solvent<br />

Solvent recycle<br />

venting<br />

Additives<br />

Absorber Reactor Flash-Tank<br />

Mixer<br />

Extruder<br />

Additive<br />

solvent Hexane<br />

Temperature 130°C<br />

Residence time ~ 10 min<br />

Solid content < 10 %<br />

adiabatic<br />

High space time yield<br />

Reactor volume 5 m 3 for 5 t HDPE/h<br />

Solvent purification<br />

Flash<br />

-Tank<br />

HDPE-Granules<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

Slurry Coordinative <strong>Polyethylene</strong> <strong>Processes</strong><br />

Slurry process:<br />

• developed for HDPE<br />

• Limitation: low density, low molecular weight: partial solubility of the polymer<br />

in the suspension media, fouling<br />

• suitable for densities above 930 kg/m³ resp. 920 kg/m³ (with SSC)<br />

• CSTR‘s or slurry-loop reactors used<br />

• suspension media: paraffines, e.g. hexane, isobutane<br />

• many commercial processes:<br />

• processes with loop reactor<br />

• Phillips Loop<br />

• Solvay<br />

• processes with stirred tank reactors<br />

• Hostalen<br />

• Mitsui CX<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

18<br />

20

Slurry Coordinative– Phillips Loop<br />

Flowsheet of the Phillips Loop process<br />

a) Catalyst hopper and feed valve; b) Double loop reactor; c) Flash tank; d) Purge<br />

drier; e) Powder-fed extruder; f) Impeller; g) Sedimentation leg<br />

Suspension media:<br />

isobutane<br />

T = 85 – 100 C<br />

p = 37 bar<br />

residence time 30 – 60 min<br />

solid content: up to 50 %<br />

high specific surface<br />

reactor completely filled<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

Polypropylene applications<br />

PP is versatile in application:<br />

• packaging material (flexible films and rigid packings)<br />

• fibers<br />

• injection molding parts for automotive, electrical applications, consumer<br />

electronics<br />

• Chemical equipment, piping<br />

High growth rates for PP<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

21<br />

23<br />

Fluidized Bed <strong>Polyethylene</strong> <strong>Processes</strong><br />

Fluidized-bed process<br />

a) Catalyst hopper and feed valve; b) Fluidized-bed reactor; c) Cyclone; d) Filter;<br />

e) Polymer take-off system; f) Product recovery cyclone; g) Monomer recovery<br />

compressor; h) Purge hopper; i) Recycle compressor; j) Recycle gas cooler<br />

T=80 – 100° C<br />

P = 7 – 20 bars<br />

RTD comparable to CSTR<br />

Body widening in upper<br />

part of the reactor in order<br />

to reduce gas velocity<br />

Partly condensation<br />

cooling („condensed mode“<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

Polypropylene structure<br />

Crystallinity correlates with stereo selectivity and melting point<br />

Isotactic = crystalline<br />

Atactic = amorphous<br />

Isotactic PP<br />

misinsertion<br />

syndiotactic PP<br />

atactic PP<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

22<br />

24

Types of Polypropylene<br />

• homopolymers<br />

• random-copolymers<br />

with ethylene (1-8 wt.-%)<br />

mit 1-butene<br />

terpolymers<br />

• heterophasic copolymers<br />

at least two-stage processes,<br />

in which a second,<br />

elastomeric phase is generated<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

Spheripol Process<br />

Spheripol process<br />

a) Loop reactors; b) Primary cyclone; c) Copolymer fluidized bed; d) Secondary and copolymer cyclone;<br />

e) Deactivation; f) Purging<br />

1. Stage:<br />

Matrix homopolymer in bulk<br />

in loop-reactors<br />

2. stage:<br />

Impact-Copolymers in gas<br />

phas polymerization<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

25<br />

27<br />

Polypropylene <strong>Processes</strong> – a variety<br />

Slurry process in hydrocarbon slurry, tank or loop reactors<br />

Novolen gas phase, vertical stirred powder bed<br />

Innovene gas phase, horizontal stirred powder bed<br />

Unipol fluidized bed<br />

Spheripol slurry loop reactors ( + gas phase copolymer)<br />

Mitsui slurry bulk + gas phase<br />

Borstar liquid / scf proyplen (+gas phase copolymer)<br />

MZCR gas phasem, multi zone circulating reactor<br />

Cat, cocat.<br />

C 3 , H 2 ,<br />

1.Reactor<br />

PP homopolymer<br />

slurry<br />

gas<br />

Active<br />

powder<br />

C 3 , C 2 ,<br />

2. Reactor<br />

PP copolymer<br />

gas<br />

Extrusion<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

BASF/ Novolen Gas Phase Process<br />

BASF gas-phase Novolen process<br />

a) Primary reactor; b) Copolymerizer; c) Compressors; d) Condensers; e) Liquid pump; f)<br />

Filters; g) Primary cyclone; h) Deactivation/purge<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

26<br />

28

Amoco Gas Phase Process<br />

Amoco – Chisso gas-phase process<br />

a) Horizontal reactor; b) Fluidized-bed deactivation; c) Compressor; d) Condenser;<br />

e) Hold/separator tank<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

Borstar Process<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

29<br />

31<br />

Unipol Fludized Bed Gas Phase Process<br />

UCC/Shell – Unipol fluidized-bed process<br />

a) Primary fluidized bed; b) Copolymer fluidized bed; c) Compressors; d) Coolers; e),<br />

f) Discharge cyclones; g) Purge<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

processes with different reaction zones in one reactor:<br />

M Z C R<br />

RISER<br />

fa st<br />

fluidization<br />

(upw ard<br />

tra n s p o rt)<br />

Catalyst<br />

in le t<br />

Propylene<br />

barrier<br />

stream<br />

DOWNER<br />

packed<br />

bed<br />

(m oving<br />

downward)<br />

Product<br />

discharge<br />

Gas<br />

circulating<br />

com pressor<br />

B A R R IE R S E C TIO N<br />

Condenser<br />

Ethylene<br />

stripping<br />

colum n<br />

Propylene<br />

fe e d<br />

Heat<br />

exchanger<br />

Basell‘s spherizone® Draught tube reactor proposed by<br />

Weickert<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

30<br />

32

Tailoring of mwd and comonomer distribution<br />

:<br />

• new property combinations<br />

different approaches possible:<br />

• multistage process<br />

• reactors with different reaction zones<br />

• multisite - catalysts<br />

%<br />

Reduced<br />

impact<br />

strength.<br />

Migration,<br />

taste.<br />

Smoke<br />

and odour<br />

during<br />

extrusion<br />

Processability,<br />

stiffness<br />

Matrix<br />

Mechanical<br />

strength<br />

Conventional<br />

ESCR and creep resistance<br />

Melt<br />

strength<br />

during<br />

extrusion<br />

Molecular weight (= polymer chain length)<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

Bimodal<br />

Controlling mmd by different methods<br />

Aternative processes for<br />

bimodal PP<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

M<br />

H 2<br />

H 2<br />

t<br />

33<br />

35<br />

Melt flow dependent in mwd<br />

normierte Viskosität η/η o<br />

10 0<br />

-1<br />

10<br />

-2<br />

10<br />

-3<br />

10<br />

melt flow behaviour of different HDPE at 190°C<br />

rel. Häufigkeit<br />

HDPE 3<br />

HDPE 2<br />

HDPE 1<br />

Molmasse<br />

-4<br />

10<br />

-5<br />

10<br />

-3<br />

10<br />

-1<br />

10<br />

Scherrate γ / s<br />

1<br />

10<br />

3<br />

10<br />

-1<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

Weight %<br />

Controlling mmd by different methods<br />

V<br />

M i<br />

Ti<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

V<br />

V<br />

V<br />

Ti<br />

Ti<br />

Ti<br />

34<br />

36

Bimodal properties by multi-site catalyst<br />

unimodal process with multi-site catalysts:<br />

• bimodal polymers can be produced with multi-site catalysts in<br />

single stage processes:<br />

Kim, J. D., Soares, J. B. P., Journal of Polymer Science: Part A:<br />

Polymer Chemistry, 38, 1427-1432, (2000)<br />

• lower investment costs compared to multireactor processes /<br />

processes with multizone reactors<br />

• control of polymer structure more difficult / less flexible<br />

• narrower product window compared to multistage processes<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

Bimodal properties in a reactor cascade<br />

catalyst Cocatalyst<br />

M Propylene<br />

hydrogen<br />

1. Reactor 2. Reactor<br />

M<br />

Silo<br />

Catalyst poison<br />

Propylene<br />

hydrogen<br />

Temperatur[°C]<br />

H 2 -concentration<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

M w<br />

Catalyst poison<br />

controls fraction in 2.<br />

reactor<br />

37<br />

1. Reactor 2. Reactor<br />

low high<br />

low high<br />

800.000-<br />

1,5 Mio<br />

50.000-<br />

200.000<br />

39<br />

hydrogen response for Ziegler catalysts<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

Bimodal properties in an oscillating reactor<br />

M<br />

1. Reaktor<br />

Katalysator Cokatalysator<br />

Propylen<br />

Wasserstoff<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

38<br />

40

Styrenic Polymers<br />

α-MeS<br />

P[S/a-MS]<br />

P[a-MS/AN]<br />

-heat resistant<br />

S/Bu (block-)<br />

copolymers<br />

- tough<br />

- translucent<br />

- low weather<br />

resistance<br />

Bu<br />

PS<br />

- transparent<br />

-stiff<br />

-brittle<br />

MMA<br />

Polybutadienerubber<br />

HIPS<br />

- tough<br />

- opaque<br />

- low weather<br />

resistance<br />

MBS, MABS<br />

- tough<br />

- transparent<br />

Acrylnitril<br />

Polybutadienrubber<br />

ABS<br />

- tough<br />

- opaque<br />

- low weather<br />

resistance<br />

MMA<br />

PSAN<br />

-environmental<br />

stress resistant<br />

Polyacrylaterubber<br />

ASA<br />

- tough<br />

- opaque<br />

- weather<br />

resistance<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

Styrenic Polymers – processes over the years<br />

IG Farben, 1936 Union Carbide, 1943 Dow, 1952 BASF 1965<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

41<br />

43<br />

Styrenic Polymers – thermal initiation<br />

*<br />

.<br />

*<br />

+<br />

*<br />

*<br />

* *<br />

H<br />

+<br />

H<br />

*<br />

CH3 * CH<br />

Pn*<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

Styrenic Polymers –process and mwd<br />

* *<br />

dm<br />

10<br />

dP<br />

-2<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

+ Pn<br />

Styrene / EB<br />

50-80% conv.<br />

130-170°C<br />

2000 4000 6000 8000<br />

42<br />

44

Degassing polymer solutions / melts<br />

Heat<br />

exchanger<br />

Vacuum<br />

Falling strand devolatiizer<br />

Vacuum<br />

Extruder<br />

Falling strangs<br />

Long diffusion<br />

Adiabatic flash<br />

Renewal of melt surface<br />

Short diffusion paths<br />

Nearly isothermal flash<br />

Vacuum<br />

Vacuum<br />

´tubular / pipe degassing<br />

Separation melt/gas<br />

in tubes<br />

Heating during evaporation<br />

Non-isothermal flash<br />

Thin film evaporator<br />

Extremely thin films<br />

Short diffusion ways<br />

Heating during evaporation<br />

Nearly isothermal flash<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

Brittle and tough materials<br />

Pure thermoplastic polymer, T g >T use<br />

brittle, hard tough, hard<br />

stress, strain, σ<br />

Area= energy<br />

elongation, ε<br />

Thermoplastic polymer + rubber, T g

HIPS, solution/mass ABS - principles<br />

Rubber ( PBu) dissolved in Styrene<br />

(/ Ethyl benzene)<br />

Polymerization of styrene, homo-PS<br />

and grafted PBu<br />

Phase separation ( PBu/S and PS/S)<br />

Phase inversion<br />

Particle formation<br />

End of reaction<br />

A<br />

B<br />

D<br />

C<br />

Course of reaction<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

HIPS – phase inversion in first 2 reactors<br />

Viscosity<br />

Reactor 1 Reactor 2<br />

in out in out<br />

Homogene<br />

Lösung<br />

Polybutadiene in styrene<br />

Polystyrene in styrene<br />

conversion<br />

Phase inversion when<br />

volume ratio = 1:1 of<br />

disperse : continuous phase<br />

Stabilization of particles by<br />

graft polymers formed in 1. reactor<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

49<br />

51<br />

HIPS grafting and phase inversion<br />

PBu in S PS in S<br />

S S<br />

Phase separation Phase inversion<br />

S<br />

B<br />

B<br />

B<br />

B<br />

S S<br />

S S<br />

B<br />

B<br />

B<br />

S B B<br />

S<br />

S<br />

Graft copolymers needed for<br />

stabilization of morphology<br />

S<br />

B<br />

B<br />

B<br />

B<br />

B<br />

S<br />

S<br />

S<br />

S<br />

B<br />

BS<br />

B<br />

B B<br />

S<br />

S<br />

S<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

HIPS – phase inversion in first 2 reactors<br />

Viscosity<br />

Conversion<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

S<br />

50<br />

52

HIPS – various continuous processes<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

Specific heat removal capacity for different reactors<br />

1 – SMR, 2- static mixers, 3- empty tube, 4 – stirred tank, 5 extruder<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

53<br />

55<br />

HIPS – process with static mixers<br />

solvent<br />

monomer<br />

comonomer<br />

additives<br />

Recycle solvent<br />

water<br />

additives<br />

water<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

SAN copolymers<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

54<br />

56

SAN copolymerization behaviour<br />

X_Styrol<br />

1.0<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

0.0<br />

Copolymerisationsdiagramm für<br />

Styrol / Acrylnitril<br />

0 0.2 0.4 0.6 0.8 1<br />

x_Styrol<br />

r S=0.34<br />

r AN=0.05<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

SAN copolymers in CSTR<br />

To flare<br />

SAN,<br />

EB<br />

Multiple degassing unit:<br />

toxic AN<br />

high temperatures give<br />

yellow polymer<br />

W-% AN in polymer<br />

SAN-melt<br />

To Extruder<br />

65% AN<br />

30% AN<br />

24% AN<br />

conversion<br />

10% AN<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

M<br />

PRC<br />

continous<br />

SAN-<strong>Polymerisation</strong><br />

degassing<br />

SAN-Granulat<br />

57<br />

59<br />

SAN copolymers by….<br />

Suspension polymerization<br />

only azeotropic composition<br />

water- solubility of AN<br />

Emulsion polymerzation<br />

semi- batch, starved feed<br />

shows some haze<br />

Continuous solution polymerization in CSTR<br />

all compositions available<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

Rubber modification of SAN –> ABS<br />

rubber from emulsion or solution process<br />

Emulsion polymerization<br />

•High glance of surface<br />

•Yellowish colour<br />

•waste water<br />

•Separate polymerization of SAN<br />

(solution polymerization) and rubber<br />

(in emulsion)<br />

1µm<br />

Solution polymerisation<br />

Mat surface<br />

White<br />

No waste water<br />

Solution polymerization of SAN in the<br />

presence of rubber as for HIPS<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

1µm<br />

58<br />

60

Emulsion Rubbers for impact modification of SAN<br />

100-250nm<br />

Product<br />

Rubber type<br />

Double bonds<br />

T g<br />

Weather resistance<br />

Low temperature impact resistance<br />

SAN matrix<br />

Crosslinked<br />

rubber<br />

SAN graft<br />

ABS<br />

Polybutadiene<br />

Many<br />

-80°C<br />

-<br />

high<br />

ASA<br />

Acrylic ester+ bifunctional<br />

monomer<br />

-<br />

-40°C<br />

High<br />

low<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

PMMA – Polymethyl methacrylate<br />

Some special features<br />

Strong gel effect<br />

Low ceiling temperature<br />

Tendency to depolymerization<br />

High shrinkage<br />

Termination by combination and disproportionation<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

61<br />

63<br />

ABS, ASA via emulsion rubber and solution SAN<br />

SAN-melt<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

PRCS<br />

M<br />

vapor<br />

PMMA – gel an glass effect effect<br />

M<br />

PRC<br />

conversion<br />

M<br />

M<br />

M<br />

M M M M<br />

Due to<br />

glass effect<br />

M<br />

Vacuum<br />

Base rubber<br />

SAN grafting<br />

Storage tank<br />

precipitation<br />

De-watering<br />

extruder<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

ABS<br />

Due to<br />

Ceiling temperature<br />

50 100 150 200<br />

100%<br />

T/°C<br />

62<br />

64

PMMA – weak links<br />

From combination<br />

O<br />

O O<br />

O<br />

O<br />

O<br />

From disproportionation<br />

Comonomers stop unzipping<br />

O<br />

O<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

2<br />

C*<br />

O<br />

CH 3<br />

O<br />

+ CH2 *<br />

C*<br />

O<br />

CH 3<br />

O<br />

O<br />

Starting point for depolymerization<br />

MMMMMMMMMMMMMMMMMXMMMMMM* MMMMMMMMMMMMMMMMMX* + M<br />

PMMA – process for plates and sheets<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

O<br />

65<br />

67<br />

PMMA – continuous bulk process<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

PVC – suspension process<br />

⎛ ⎞<br />

1 ln⎜ p<br />

⎟ = ln( 1−<br />

Φ<br />

0<br />

2)<br />

+ Φ2<br />

+ χΦ<br />

⎜ ⎟<br />

⎝ p1<br />

⎠<br />

χ=0.98<br />

s = kH<br />

2<br />

2<br />

p<br />

0<br />

p<br />

p=const- =<br />

separate monomer phase<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

66<br />

68

PVC – suspension process<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

PVC – bulk process, post reactors<br />

High solid<br />

Particle size 0.08-0.2 mm<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

69<br />

71<br />

PVC – bulk process<br />

Prepolymerization up to 10%<br />

Post polymerization up to 85-90%<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

PVC – bulk process, particle size and stirring<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

70<br />

72

The Nylon revolution 1945<br />

O O<br />

N (CH2 ) N 6 C (CH2 ) C 6 n<br />

H H<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

Polyamides – base materials<br />

ε-Caprolactam: OH<br />

+6H<br />

(Ni)<br />

OH<br />

H<br />

-2H<br />

O<br />

+H2NOH -H2O N H<br />

Phenol Cyclohexanol Cyclohexanon Cyclohexanon-oxim<br />

Hexamethylene diamine:<br />

Adipic acid:<br />

+6H<br />

(Ni)<br />

Benzene Cyclohexan<br />

H 2C = CH – CH = CH 2<br />

H2C – CH = CH – CH2 CN CN<br />

+CINO<br />

- HCI<br />

(H 2 SO 4 )<br />

H2 C<br />

H2C CO<br />

H2C NH<br />

H2C CH2 ε-Caprolactam:<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

+Cl 2<br />

+2H<br />

(Ni)<br />

+2NaCN<br />

H2C = CH – CH = CH2 -2NaCl<br />

Cl Cl<br />

NC – (CH2) 4 –CN<br />

+8H<br />

(Ni, NH3 )<br />

H2N – (CH2) 6 –NH2 Adiponitrile Hexamethylendiamin<br />

H2C H2C CH2 C<br />

H2C CH2 H<br />

OH<br />

H2C H2C CH2 C = O<br />

COOH<br />

(CH2 ) 4<br />

H2C CH2 COOH<br />

Cyclohexanol Cyclohexanone Adipic acid<br />

73<br />

75<br />

Polyamides – basic structures<br />

PA 6: Perlon PA6.6: Nylon<br />

O<br />

NH ( CH ) 2 C<br />

NH ( NH<br />

5<br />

CH ) 2 C (<br />

6 CH ) 2 C<br />

4<br />

n<br />

n<br />

PA 6: Caprolactam<br />

PA 11: Undecanlactam<br />

PA 12: Laurinlactam<br />

PA 6.6: Hexamethylendiamine<br />

+ Adipic acid<br />

PA 6.10: Hexamethylendiamien<br />

+ Sebacic acid<br />

PA 4.6: Butandiamine<br />

+ Adipic acid<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

PA6 – basic reactions<br />

1. Ring opening<br />

NH (CH2 ) CO + H 5 2O H NH (CH2 ) COOH<br />

5<br />

2. Polyaddition<br />

NH (CH2 ) CO + H NH (CH CO OH<br />

5<br />

2 ) 5<br />

3. Polycondensation<br />

n<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

O<br />

H NH (CH2 ) CO OH<br />

5<br />

H NH (CH2 ) CO OH + H NH (CH CO OH H NH CO OH + H2O 5 2 ) (CH 5 2 ) 5<br />

n<br />

m<br />

n+1<br />

n+m<br />

O<br />

74<br />

76

Polyamide 6 - VK column<br />

water<br />

ε-Caprolactame<br />

melting<br />

80°C<br />

preparation<br />

Melt filter<br />

Pre condensation<br />

250°C, 40 bar<br />

Mean residence time VK column ≈ 15 - 30 h<br />

throughput:<br />

≈ 2000 moto<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

M<br />

VK-column<br />

270°C<br />

280°C<br />

Water<br />

granulation<br />

Extractor<br />

95°C<br />

silo<br />

dryer 80°C<br />

PA6-process – modelling of melt process<br />

Model input:<br />

Kinetic scheme and<br />

parameters<br />

Non-ideal phase behavior<br />

using NRTL model<br />

Model output:<br />

Molecular weight<br />

end groups<br />

Residual monomer<br />

Oligomer concentration<br />

Granules<br />

Vacuum<br />

(1 mbar)<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

180<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

simulation results taking into account exp. binary VLE date<br />

Extract, %, CL, H2O, Oligomers<br />

NH2-end groups<br />

degree of polymerization<br />

dimer, %<br />

0<br />

0<br />

235 240 245 250 255 260 265 270 275 280<br />

temperature in top of VK-Rohr<br />

1<br />

0.9<br />

0.8<br />

0.7<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

77<br />

79<br />

PA6-process – modelling of each process unit<br />

Melt polymerization<br />

Schmelzepolymerisation im VK - Rohr Extraction Extraktion of oligomers Trocknung/Temperung<br />

Drying,<br />

N 2<br />

Caprolactam<br />

(+Kettenregler) (+chain regulator + 0,5% + H2O) H 2O Bedingungen:<br />

τ : 9 - 17 h<br />

T : 250 - 280 °C<br />

p : 0 - 0,3 bar<br />

PA 6 - Granules<br />

Extracttwater<br />

Bedingungen:<br />

τ : 17 - 30 h<br />

T : 95 - 120 °C<br />

Water<br />

solid state polymerization<br />

N2 -O2 Granulation<br />

air<br />

Polyamide 6<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

PA6-process – modelling of extraction<br />

Model assumptions:<br />

Nernst law at phase<br />

boundaries<br />

Nernst coefficient dependent<br />

on monomer concentration<br />

Fick diffusion in polymer<br />

phase and liquid boundary<br />

layer<br />

Model output:<br />

Concentration profile of<br />

residual monomer and<br />

oligomer in polymer and<br />

liquid phase<br />

-H 2 O<br />

Bedingungen:<br />

τ : 20 - 40 h<br />

T : 135 - 180 °C<br />

nitorgen<br />

Top2 4 6 8 10 bottom 12<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

10<br />

8<br />

6<br />

4<br />

2<br />

1<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

% extractable<br />

% dimer in granules<br />

Top 2 4 6 8 10 12 bottom<br />

78<br />

80

PA6-process – modelling of solid state condensation<br />

Model assumptions:<br />

Polymer end groups, water,<br />

monomer und oligomere only in<br />

amorphous phase<br />

reaction kinetics as in melt<br />

diffusion coefficients dependent on<br />

degree of crystallinity<br />

surface is free of water<br />

Isothermal spherical particle<br />

Model output<br />

Pn, monomer and oligomer<br />

concentration<br />

0 10 20 30 40 50<br />

reaction tim e [h]<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

Polyamide 66 - tank process<br />

mass fraction of caprolactam [%]<br />

number-average chain length<br />

0.20<br />

0.18<br />

0.16<br />

0.14<br />

0.12<br />

0.10<br />

0.08<br />

0.06<br />

0.04<br />

0.02<br />

0.00<br />

450<br />

400<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

0 10 20 30 40 50<br />

T = 125°C<br />

T = 145°C<br />

T = 165°C<br />

T = 180°C<br />

T = 190°C<br />

model<br />

reaction tim e [h]<br />

T = 145°C<br />

T = 165°C<br />

T = 190°C<br />

model<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

81<br />

83<br />

PA66- basic reactions<br />

O O<br />

HO C (CH2 ) C<br />

4<br />

OH<br />

Adipic acid Hexamethylene diamine<br />

–H 2 O<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

+<br />

+ H 2 O<br />

AH-salt solution<br />

Polycondensation<br />

O O<br />

HO C (CH2 ) C<br />

4<br />

NH<br />

NH<br />

(CH 2 ) 6<br />

H2N (CH CH2<br />

) NH<br />

6 2<br />

Polyamide 66 – continous tubular process<br />

H 2 O-Steam<br />

tube reactor<br />

Pump<br />

Separator<br />

40-60%<br />

AH-Salt Solution<br />

Devolatilisation<br />

e.g. Extruder<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

H<br />

Pump<br />

Polymer<br />

Melt<br />

Postcondensation<br />

82<br />

High energy consumption<br />

Evt. loss of volatiles in<br />

vapor<br />

84

Polyamide 66 – countercurrent process – reactive<br />

distillation<br />

Reactive<br />

distillation<br />

Temperature<br />

conventional<br />

Molten diacid<br />

feed (bb)<br />

Steam<br />

Pressure<br />

atmospheric<br />

typically<br />

Gaseous diamine<br />

feed (aa)<br />

Polymer<br />

(aabb)<br />

Product Mn<br />

9000<br />

typically<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

Some processes – PET, PBT from DMT<br />

O O<br />

CH3 O C C O CH3 Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

85<br />

87<br />

Polyethylen(butylen)terephtalat, PET, PBT<br />

O O<br />

O O<br />

CH3 O C C O CH3HO (CH2 ) OH<br />

x<br />

HO C C OH<br />

Terephtalic acid ester Diol Terephtalic acid<br />

transesterification esterfication<br />

O O<br />

HO (CH2 ) O<br />

x<br />

C C O (CH2 ) OH<br />

x<br />

Pre-condensation<br />

Post-condensation<br />

O O<br />

HO C C O (CH2 ) O H<br />

x<br />

x=2: PET<br />

x=4: PBT<br />

Side reactions: acetaldehyde, THF from butane diol (PBT)<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

Rotating disc reactor for PET, PBT<br />

n<br />

To force conversion from 0.95 to 0.99 –<br />

0.995 ( or P n >100), water removal more<br />

important than for polyamides, because<br />

of low equilibrium constants<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

86<br />

88

Polyoxymethylene – anionic polymerization of CH 2 O<br />

CH 2 O<br />

Purification, drying<br />

CH 2 O<br />

R Hexane<br />

Suspensions polymerization<br />

Formaldehyde<br />

(water solution.)<br />

Formaldehyde<br />

(Gas)<br />

R O CH2 O CH2O n<br />

Acetic anhydride<br />

End group stabilization by chemical modification<br />

R O CH2 O CH2O O CH<br />

n<br />

3<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

Polyoxymethylene – end group stabilization<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

O<br />

89<br />

91<br />

Polyoxymethylene – anionic polymerization of CH 2 O<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

Polyoxymethylene – cationic bulk process –<br />

‘Schalenkreis’<br />

Milling<br />

Vacuum<br />

Heat Stabilizier<br />

Antioxidant<br />

Polymerized<br />

Material<br />

Additives<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

90<br />

92

Polyoxymethylene – cationic kneader process<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

93