Polymerisation Processes Polymerisation Processes Polyethylene ...

Polymerisation Processes Polymerisation Processes Polyethylene ...

Polymerisation Processes Polymerisation Processes Polyethylene ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

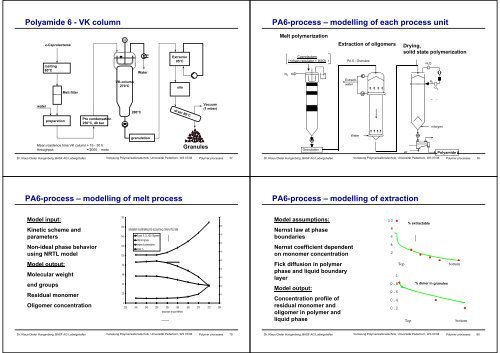

Polyamide 6 - VK column<br />

water<br />

ε-Caprolactame<br />

melting<br />

80°C<br />

preparation<br />

Melt filter<br />

Pre condensation<br />

250°C, 40 bar<br />

Mean residence time VK column ≈ 15 - 30 h<br />

throughput:<br />

≈ 2000 moto<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

M<br />

VK-column<br />

270°C<br />

280°C<br />

Water<br />

granulation<br />

Extractor<br />

95°C<br />

silo<br />

dryer 80°C<br />

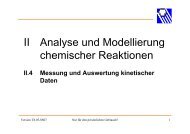

PA6-process – modelling of melt process<br />

Model input:<br />

Kinetic scheme and<br />

parameters<br />

Non-ideal phase behavior<br />

using NRTL model<br />

Model output:<br />

Molecular weight<br />

end groups<br />

Residual monomer<br />

Oligomer concentration<br />

Granules<br />

Vacuum<br />

(1 mbar)<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

180<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

simulation results taking into account exp. binary VLE date<br />

Extract, %, CL, H2O, Oligomers<br />

NH2-end groups<br />

degree of polymerization<br />

dimer, %<br />

0<br />

0<br />

235 240 245 250 255 260 265 270 275 280<br />

temperature in top of VK-Rohr<br />

1<br />

0.9<br />

0.8<br />

0.7<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

77<br />

79<br />

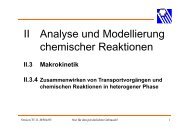

PA6-process – modelling of each process unit<br />

Melt polymerization<br />

Schmelzepolymerisation im VK - Rohr Extraction Extraktion of oligomers Trocknung/Temperung<br />

Drying,<br />

N 2<br />

Caprolactam<br />

(+Kettenregler) (+chain regulator + 0,5% + H2O) H 2O Bedingungen:<br />

τ : 9 - 17 h<br />

T : 250 - 280 °C<br />

p : 0 - 0,3 bar<br />

PA 6 - Granules<br />

Extracttwater<br />

Bedingungen:<br />

τ : 17 - 30 h<br />

T : 95 - 120 °C<br />

Water<br />

solid state polymerization<br />

N2 -O2 Granulation<br />

air<br />

Polyamide 6<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

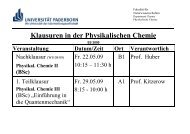

PA6-process – modelling of extraction<br />

Model assumptions:<br />

Nernst law at phase<br />

boundaries<br />

Nernst coefficient dependent<br />

on monomer concentration<br />

Fick diffusion in polymer<br />

phase and liquid boundary<br />

layer<br />

Model output:<br />

Concentration profile of<br />

residual monomer and<br />

oligomer in polymer and<br />

liquid phase<br />

-H 2 O<br />

Bedingungen:<br />

τ : 20 - 40 h<br />

T : 135 - 180 °C<br />

nitorgen<br />

Top2 4 6 8 10 bottom 12<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

10<br />

8<br />

6<br />

4<br />

2<br />

1<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

% extractable<br />

% dimer in granules<br />

Top 2 4 6 8 10 12 bottom<br />

78<br />

80