Polymerisation Processes Polymerisation Processes Polyethylene ...

Polymerisation Processes Polymerisation Processes Polyethylene ...

Polymerisation Processes Polymerisation Processes Polyethylene ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

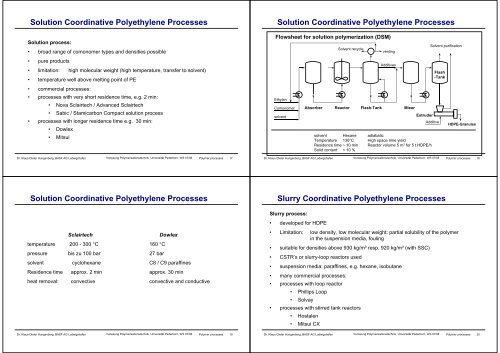

Solution Coordinative <strong>Polyethylene</strong> <strong>Processes</strong><br />

Solution process:<br />

• broad range of comonomer types and densities possible<br />

• pure products<br />

• limitation: high molecular weight (high temperature, transfer to solvent)<br />

• temperature well above melting point of PE<br />

• commercial processes:<br />

• processes with very short residence time, e.g. 2 min:<br />

• Nova Sclairtech / Advanced Sclairtech<br />

• Sabic / Stamicarbon Compact solution process<br />

• processes with longer residence time e.g. 30 min:<br />

• Dowlex<br />

• Mitsui<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

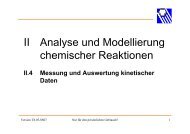

Solution Coordinative <strong>Polyethylene</strong> <strong>Processes</strong><br />

Sclairtech Dowlex<br />

temperature 200 - 300 °C 160 °C<br />

pressure bis zu 100 bar 27 bar<br />

solvent cyclohexane C8 / C9 paraffines<br />

Residence time approx. 2 min approx. 30 min<br />

heat removal: convective convective and conductive<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

17<br />

19<br />

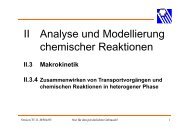

Solution Coordinative <strong>Polyethylene</strong> <strong>Processes</strong><br />

Flowsheet for solution polymerization (DSM)<br />

Ethylen<br />

Comonomer<br />

solvent<br />

Solvent recycle<br />

venting<br />

Additives<br />

Absorber Reactor Flash-Tank<br />

Mixer<br />

Extruder<br />

Additive<br />

solvent Hexane<br />

Temperature 130°C<br />

Residence time ~ 10 min<br />

Solid content < 10 %<br />

adiabatic<br />

High space time yield<br />

Reactor volume 5 m 3 for 5 t HDPE/h<br />

Solvent purification<br />

Flash<br />

-Tank<br />

HDPE-Granules<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

Slurry Coordinative <strong>Polyethylene</strong> <strong>Processes</strong><br />

Slurry process:<br />

• developed for HDPE<br />

• Limitation: low density, low molecular weight: partial solubility of the polymer<br />

in the suspension media, fouling<br />

• suitable for densities above 930 kg/m³ resp. 920 kg/m³ (with SSC)<br />

• CSTR‘s or slurry-loop reactors used<br />

• suspension media: paraffines, e.g. hexane, isobutane<br />

• many commercial processes:<br />

• processes with loop reactor<br />

• Phillips Loop<br />

• Solvay<br />

• processes with stirred tank reactors<br />

• Hostalen<br />

• Mitsui CX<br />

Dr. Klaus-Dieter Hungenberg, BASF AG Ludwigshafen Vorlesung <strong>Polymerisation</strong>stechnik, Universität Paderborn, WS 07/08 Polymer processes<br />

18<br />

20