TECHNICAL SPECIFICATIONS - LISEGA

TECHNICAL SPECIFICATIONS - LISEGA

TECHNICAL SPECIFICATIONS - LISEGA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

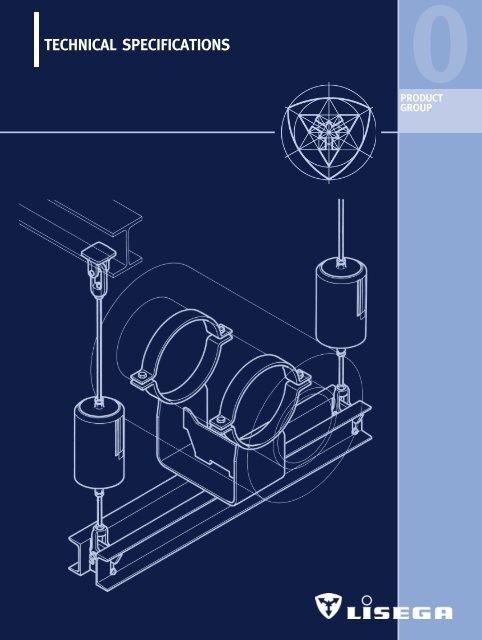

<strong>TECHNICAL</strong> <strong>SPECIFICATIONS</strong><br />

0<br />

PRODUCT<br />

GROUP

<strong>TECHNICAL</strong><br />

<strong>SPECIFICATIONS</strong><br />

CONTENTS PAGE<br />

1. Standard supports ________________________________________________ 0.1<br />

1.1 Requirements ____________________________________________________ 0.1<br />

1.2 Definition________________________________________________________ 0.1<br />

2. <strong>LISEGA</strong> standard supports _________________________________________ 0.1<br />

2.1 Scope___________________________________________________________ 0.1<br />

2.2 Design features __________________________________________________ 0.1<br />

2.3 Principle of the optimum design type________________________________ 0.2<br />

3. <strong>LISEGA</strong> modular system ___________________________________________ 0.2<br />

3.1 Fundamentals ____________________________________________________ 0.2<br />

3.2 Scope___________________________________________________________ 0.2<br />

3.3 Product groups___________________________________________________ 0.2<br />

3.4 Load groups _____________________________________________________ 0.2<br />

3.5 Permissible loads_________________________________________________ 0.3<br />

3.6 Travel ranges ____________________________________________________ 0.6<br />

3.7 Type designations ________________________________________________ 0.6<br />

3.8 Type designation system __________________________________________ 0.7<br />

4. Standards and calculations_________________________________________ 0.9<br />

5. Materials ________________________________________________________ 0.9<br />

6. Qualification levels for standard and nuclear application________________ 0.9<br />

7. Welding ________________________________________________________ 0.10<br />

8. Surface treatment _______________________________________________ 0.10<br />

8.1 Standard coating systems_________________________________________ 0.10<br />

8.2 Standard surface protection acc. to products ________________________ 0.11<br />

8.3 Extended surface protection_______________________________________ 0.11<br />

8.4 Extended surface protection acc. to products ________________________ 0.12<br />

8.5 Surface protection in extremely aggressive atmospheres _________________ 0.12<br />

9. Connection dimensions___________________________________________ 0.12<br />

9.1 Installation dimension E __________________________________________ 0.12<br />

9.2 Regulation of the total installation length ___________________________ 0.13<br />

10. Operational behavior_____________________________________________ 0.13<br />

10.1 Function _______________________________________________________ 0.13<br />

10.2 Spring relaxation ________________________________________________ 0.14<br />

11. Quality assurance________________________________________________ 0.14<br />

11.1 Fundamentals ___________________________________________________ 0.14<br />

11.2 Quality management _____________________________________________ 0.14<br />

11.3 International qualifications ________________________________________ 0.14<br />

11.4 Tests and qualifications __________________________________________ 0.15<br />

11.5 Suitability tests acc. to KTA 3205.3 and VGB R 510 L _________________ 0.15<br />

12. Shipment_______________________________________________________ 0.16<br />

13. Warranty _______________________________________________________ 0.16<br />

14. Technical modifications___________________________________________ 0.16<br />

0 <strong>TECHNICAL</strong><br />

0<br />

<strong>SPECIFICATIONS</strong><br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

0.0

0.1<br />

<strong>TECHNICAL</strong><br />

<strong>SPECIFICATIONS</strong><br />

The products outlined in<br />

this catalog - STANDARD<br />

SUPPORTS 2010 - are fully<br />

in line with the latest developments<br />

in support technology<br />

and satisfy general<br />

requirements for plant<br />

installation at the highest<br />

level. For the general<br />

design of <strong>LISEGA</strong> standard<br />

supports, uniform criteria<br />

are applied. They are<br />

described in the following<br />

<strong>TECHNICAL</strong> <strong>SPECIFICATIONS</strong><br />

and are binding for the<br />

contents of this catalog.<br />

Componentrelated features<br />

are outlined in the corresponding<br />

sections of the<br />

product groups and in the<br />

type data sheets<br />

Unless expressly agreed<br />

otherwise, the stipulations<br />

in the catalog STANDARD<br />

SUPPORTS 2010 apply to<br />

all our shipments.<br />

1. STANDARD SUPPORTS<br />

1.1 Requirements<br />

For the support of industrial piping systems,<br />

the use of standard supports is regarded as<br />

well proven, up-to-date technology.<br />

Only a correspondingly high level of standardization<br />

in support components can adequately<br />

satisfy the justifiable demand for products<br />

that are technically top-class and economically<br />

attractive at the same time. The complex<br />

requirements for modern pipe supports are:<br />

➜ reliable functioning<br />

➜ maintenance-free operation<br />

➜ low unit prices<br />

➜ simple planning with DP systems<br />

➜ instant availability<br />

➜ economical installation strategy<br />

➜ easy to install designs<br />

➜ supplementary service benefits<br />

1.2 Definition<br />

Standard supports must fulfill the following<br />

criteria:<br />

➜ component shapes are uniform and<br />

designed for optimum exploitation<br />

of material<br />

➜ units are compatible regarding connecting<br />

dimensions and loading capacity<br />

➜ units are cataloged and clearly identifiable<br />

by a designation system<br />

➜ components are manufactured in<br />

series production<br />

➜ components comply with the relevant<br />

standards and international regulations<br />

➜ functional capacity, suitability and<br />

durability of the units is well proven<br />

➜ components are certified and<br />

approved for use<br />

The relevant codes for pipe supports in<br />

German plant construction (power plants),<br />

VGB guideline R 510 L, require the preferential<br />

use of standard supports and define the<br />

criteria as follows:<br />

“Standard supports are pipe support components,<br />

the construction of which, in form<br />

and dimensions as well as in the design<br />

data relating to loading capacity, is certificated<br />

and cataloged, and which are manufactured<br />

according to firmly established, reproducible<br />

procedures, e.g. series production”.<br />

2. <strong>LISEGA</strong> STANDARD SUPPORTS<br />

2.1 Scope<br />

At <strong>LISEGA</strong>, standard supports form the basis<br />

of a comprehensive performance package.<br />

A complete program from more than 8000<br />

standardized components thereby covers all<br />

operational loads, temperatures and travel<br />

ranges normally met in piping systems in<br />

industrial plant construction:<br />

➜ 1200°F operating temperature for<br />

pipe clamps and clamp bases<br />

➜ 90 kips nominal load for all mainly<br />

statically determined components<br />

➜ 224 kips nominal load for rigid struts<br />

and standard shock absorbers<br />

➜ 1124 kips design load for large bore<br />

shock absorbers<br />

➜ 36 inch travel range for constant hangers<br />

➜ 16 inch travel range for spring hangers<br />

2.2 Design features<br />

Specially developed components are available<br />

for the various support functions. In the<br />

design and construction of the units, fundamental<br />

design principles have been taken<br />

into consideration:<br />

➜ symmetrical design shapes<br />

➜ compact installation dimensions<br />

➜ especially reliable function principles<br />

➜ extra wide adjustment ranges<br />

➜ fully compatible load ranges and<br />

connection dimensions<br />

➜ favorable performance/weight ratios<br />

➜ integrated installation aids

In addition, <strong>LISEGA</strong> hangers feature only one<br />

upper attachment point. As a result, and due<br />

also to the compact and symmetrical design<br />

shape, the load transfer free of moments to<br />

the connecting elements is ensured and<br />

simple installation enabled. The operational<br />

position of the moving parts (hangers,<br />

supports and shock absorbers) can be read<br />

directly off a travel scale. Load adjustment<br />

of the constant hangers and supports can be<br />

modified at all times, also in the installed<br />

condition under load. Hangers and supports<br />

can be blocked in any travel position.<br />

2.3 Principle of the optimum design type<br />

For the design of support components, optimum<br />

coverage of the specific support function<br />

is the decisive factor. For each function<br />

only one component is therefore required,<br />

namely, the optimum one for the purpose.<br />

The project engineer is spared costly selection<br />

from a series of alternative solutions. This<br />

not only facilitates application but also<br />

increases safety. Above and beyond this, it<br />

is a prerequisite for the rational application<br />

of standardized construction on the principle<br />

of the modular system.<br />

➜ There’s only ONE best solution!<br />

3. <strong>LISEGA</strong> MODULAR SYSTEM<br />

3.1 Fundamentals<br />

The cost of pipe supports is a major element<br />

in the total cost of a piping system.<br />

The cost of the supports is the accumulated<br />

total cost arising from:<br />

➜ project management (processing)<br />

➜ design and engineering work<br />

➜ use of materials (components) as well as<br />

➜ installation work<br />

The pipe supports are almost always critical<br />

for the commissioning deadline and can,<br />

through delayed delivery, cause incalculable<br />

extra costs. The aim of <strong>LISEGA</strong> product strategy<br />

is to forge, out of all the cost factors involved,<br />

the common cost minimum for the<br />

user in the sense of the economic principle.<br />

The <strong>LISEGA</strong> modular system is specially targeted<br />

towards this efficiency. The standardization<br />

of components forms the foundation and<br />

is the precondition for rational series production,<br />

dependable quality, systematic warehousing<br />

and computer assisted application. With<br />

the LICAD design system and corresponding<br />

logistics, significant rationalization effects<br />

can be achieved in engineering, design and<br />

installation.<br />

3.2 Scope<br />

The standardization at <strong>LISEGA</strong> extends beyond<br />

the components to their systematic interaction.<br />

To this end, load and travel distribution<br />

as well as function and connections<br />

are meaningfully coordinated.<br />

In this way the <strong>LISEGA</strong> standard support<br />

program has been developed as a functional<br />

modular system with logical linking. The individual<br />

units form modules therein and are<br />

compatible regarding loads and connections.<br />

This enables the formation of meaningful combinations<br />

to produce support configurations<br />

fulfilling all requirements. The large selection<br />

of components makes adaptation possible to<br />

widely differing support and application<br />

situations.<br />

3.3 Product groups<br />

The standardized units are divided into 7<br />

product groups according to their basic modes<br />

of function (see diagram, page 0.3, and table,<br />

Standardized Components, page 0.4).<br />

3.4 Load groups<br />

To guarantee compatible loads in unit combinations,<br />

the load spectrum is split into<br />

fixed load groups.<br />

Within a load group (nominal load), all components<br />

feature uniform load limits and stress<br />

safety characteristics. The connection shapes<br />

of the units (threads - either metric or UNC<br />

according to market area - or pin diameters)<br />

are uniform within a group and thus compatible.<br />

Components of different product groups<br />

can therefore be connected only within a uniform<br />

load group to safe load chains and the<br />

faulty combination of different load groups<br />

is precluded. As all units in a load group are<br />

designed uniformly regarding strength, the<br />

stresses on a complete chain of components<br />

0<br />

The economic principle:<br />

= from the least possible<br />

effort the maximum<br />

possible profit<br />

–––––––––––––––––––––––<br />

= Total Cost Minimum/TCM<br />

=====================<br />

Product groups<br />

+ load groups<br />

+ travel ranges<br />

+ connection compatibility<br />

––––––––––––––––––––––<br />

= Modular System<br />

===================<br />

Modular System<br />

+ CAD design<br />

+ DP logitic systems<br />

––––––––––––––––––––––<br />

= High tech application<br />

===================<br />

0.2

0.3<br />

are uniformly determined.<br />

For permissible stresses, a difference is made<br />

between statically and dynamically determined<br />

components. The units in product groups 1,<br />

2, 4, 5, 6 and 7 are stressed in only one<br />

load direction (statically or quasistatically)<br />

and are considered to be statically determined<br />

components. The components in Product<br />

Group 3, as well as their accessories, are<br />

loaded in alternating directions and are therefore<br />

regarded as dynamically determined<br />

components.<br />

3.5 Permissible loads<br />

The permissible loads for components,<br />

arranged in matrix form according to load<br />

pipe surrounding<br />

components<br />

spring<br />

hangers<br />

structural<br />

attachment elements<br />

CONNECTING THREADS<br />

Ø CONNECTING BOLTS<br />

constant<br />

hangers<br />

pipe bearing and<br />

saddle components<br />

load & connection<br />

compatibility<br />

dynamically<br />

loaded components<br />

design development<br />

tools<br />

LOAD GROUPS<br />

NOMINAL LOADS (lbs)<br />

threaded connecting<br />

components<br />

groups and load cases, are set out in the<br />

<strong>LISEGA</strong> load tables (see page 0.5). The definition<br />

of load cases is regulated according to<br />

ASME III, Div. 1 Subsection NF, ASME B<br />

31.1/MSS SP58 and DIN 18800, VGB-R 510<br />

L, KTA 3205.<br />

The load table applies uniformly to all components<br />

in the <strong>LISEGA</strong> modular system and<br />

to other <strong>LISEGA</strong> units systematically connected<br />

to it, e.g. integral special designs (see load<br />

table, page 0.5).

Product<br />

group<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

Standardized components<br />

Group Unit Unit<br />

designation type designation<br />

Constant 11 constant hanger<br />

hangers 12-14 multi-cell constant hanger<br />

16 constant support<br />

16 angulating const. support<br />

17 servo hanger<br />

71 support<br />

79 const. hanger, trapeze<br />

Spring 20 articulated spring support<br />

hangers 21 spring hanger<br />

22 heavy duty spring hanger<br />

25 spring hanger, seated<br />

26 heavy d. spr. hang., seated<br />

27 sway brace<br />

28 heavy duty spring support<br />

29 variable spring support<br />

72 base plate<br />

79 spring hanger trapeze<br />

Dynamically 30 shock absorber<br />

loaded 31 large bore shock absorber<br />

components 32 energy absorber<br />

33 installation extension<br />

35 weld-on bracket<br />

36-37 dynamic pipe clamp<br />

39 rigid strut<br />

Pipe<br />

40 U-bolt<br />

surrounding 41 weld-on lug<br />

components 42-44 horizontal clamp<br />

45-48 riser clamp<br />

49 clamp base, lift-off restraints<br />

Pipe<br />

51 cylinder roller bearing<br />

bearings 52 double taper roller bearing<br />

and saddle 53 double cylinder roller bear.<br />

components 54 weld-on pipe saddle<br />

54 pipe saddle w. pipe clamp<br />

54 support tray<br />

55 lift-off restraint<br />

56 insulated pipe bearing<br />

57 weld-on pipe shoe<br />

58 stanchion<br />

58 elbow pad<br />

Threaded 60 eye nut<br />

connecting 61 clevis<br />

elements 62 turnbuckle<br />

63 hexagon nut<br />

64 rod coupling<br />

65 tie rod L/R<br />

66 tie rod<br />

67 threaded rod / stud bolt<br />

Structural 73 weld-on clevis<br />

attachment 74 weld-on pl. w. spher. wash.<br />

elements 75 weld-on eye nut<br />

76 beam adapter<br />

77 connecting plate<br />

78 beam clamp<br />

79 trapeze<br />

Load<br />

group<br />

C<br />

D<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

20<br />

30<br />

40<br />

50<br />

Statically defined components<br />

Product group 1, 2, 4, 6, 7<br />

Nominal<br />

load [lbs]<br />

70<br />

141<br />

281<br />

562<br />

1125<br />

2250<br />

4495<br />

8990<br />

13490<br />

17985<br />

22480<br />

35970<br />

44960<br />

53955<br />

67400<br />

90000<br />

Ø Connection<br />

thread<br />

3/ 8<br />

3/ 8<br />

1/ 2<br />

1/ 2<br />

5/ 8<br />

3/ 4<br />

1<br />

11/ 4<br />

11/ 2<br />

13/ 4<br />

2<br />

21/ 4<br />

21/ 2<br />

23/ 4<br />

3<br />

31/ 4<br />

Wrench<br />

size<br />

11/ 16<br />

11/ 16<br />

7/ 8<br />

7/ 8<br />

11/ 16<br />

11/ 4<br />

15/ 8<br />

2<br />

23/ 8<br />

23/ 4<br />

31/ 8<br />

31/ 2<br />

37/ 8<br />

41/ 4<br />

45/ 8<br />

5<br />

3.5.1 Static components<br />

The nominal load is used for the determination<br />

of load groups. For the statically determined<br />

components in Product Groups 1, 2,<br />

4, 6, 7, the nominal load corresponds to<br />

the max. adjustment load of the spring elements,<br />

such as spring hangers and constant<br />

hangers. The maximum permissible hot load<br />

(load case H) lies considerably higher than<br />

the nominal load when components are<br />

used as rigid supports, and is tied to the<br />

load capacity of the connection threads.<br />

<strong>LISEGA</strong> threaded rods should therefore only<br />

be replaced in kind (see page 6.5, 6.6).<br />

Spring and constant hangers in the blocked<br />

position also count as rigid supports, whereby<br />

for cold loads in hydrostatic tests (short<br />

duration) the emergency loads (level C) can<br />

be exploited.<br />

For Product Group 4 (pipe connections) a limited<br />

area of overlapping in the load groups<br />

is foreseen, due to the temperature-related,<br />

variable spectrum of loading capacities. Data<br />

on the permissible loads relating to the respective<br />

operating temperature are set out for<br />

pipe connection components in the individual<br />

type data sheets.<br />

For Product Group 5 see 3.5.5, page 0.5.<br />

Ø<br />

Pin<br />

3/ 8<br />

3/ 8<br />

1/ 2<br />

1/ 2<br />

5/ 8<br />

13/ 16<br />

1<br />

15/ 16<br />

19/ 16<br />

13/ 4<br />

2<br />

23/ 8<br />

23/ 4<br />

23/ 4<br />

31/ 8<br />

31/ 2<br />

0<br />

Dyn. defined components<br />

Product group 3<br />

Load<br />

group<br />

–<br />

–<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

20<br />

30<br />

40<br />

50<br />

Nominal<br />

load [lbs]<br />

–<br />

–<br />

675<br />

900<br />

1800<br />

4000<br />

10350<br />

22450<br />

44900<br />

78600<br />

123500<br />

224000<br />

448000<br />

670000<br />

900000<br />

1124000<br />

Ø<br />

Pin<br />

–<br />

–<br />

0.39<br />

0.39<br />

0.47<br />

0.59<br />

0.78<br />

1.18<br />

1.96<br />

2.36<br />

2.75<br />

3.93<br />

4.72<br />

5.51<br />

6.29<br />

7.08<br />

3.5.2 Dynamic components<br />

For dynamically determined<br />

units, the stipulation of the<br />

nominal loads follows from<br />

the meaningful division of<br />

the standardizable load<br />

spectrum. Here, the nominal<br />

load corresponds at the<br />

same time to the operating<br />

load for load event level<br />

A/B (ASME).<br />

As these components are<br />

generally used to guard<br />

against emergencies, the<br />

load event level C (ASME),<br />

possibly even level D, is<br />

usually adopted as the max.<br />

expected operating load.<br />

In each case the project<br />

engineer’s instructions<br />

apply.<br />

0.4

Max. operating load for spring<br />

and constant hangers corresponding<br />

to max. load on load springs.<br />

Permissible loads according to<br />

the design criteria for US code<br />

MSS SP 58 (ASME B 31.1).<br />

All loads are to be included<br />

hereunder that can possibly result<br />

from the normal operation of the<br />

plant, including start-up and shutdown,<br />

load tolerances and hydrostatic<br />

tests.<br />

Loads outside normal operation<br />

are grouped hereunder, possibly<br />

also hydrostatic tests. In each case<br />

a final inspection of the whole<br />

support arrangement is recommended.<br />

For the given loads, the yield<br />

stress of components can be<br />

reached. In each case replacement<br />

is recommended.<br />

Hereunder all dynamic loads<br />

are to be included that can possibly<br />

result from plant operation,<br />

including pressure shock forces<br />

from valve operation, and perhaps<br />

operating basis earthquakes (OBE).<br />

Hereunder all the dynamic<br />

loads are grouped which lie outside<br />

normal operation, as for<br />

example safe shutdown earthquakes<br />

(SSE). In each case a final inspection<br />

of the whole support arrangement<br />

is recommended.<br />

Dynamic loads from faulted<br />

conditions. For the given loads,<br />

the yield stress of components<br />

can be reached. Replacement is<br />

recommended in each case.<br />

Load groups 1 and 2 are load<br />

and connection compatible, whereby<br />

load group 1 applies to the<br />

smallest shock absorber and load<br />

group 2 to the corresponding<br />

rigid struts and weld-on brackets.<br />

0.5<br />

3.5.3 Max. permissible loads (lbs) for statically determined components<br />

Load<br />

group<br />

C<br />

D<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

20<br />

30<br />

40<br />

50<br />

Load<br />

group<br />

1<br />

<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

20<br />

30<br />

40<br />

50<br />

Normal operation Emergency Faulted condition <br />

Nominal<br />

load <br />

Level A/B<br />

176°F<br />

Upset<br />

302°F<br />

Level C<br />

176°F 302°F<br />

Level D<br />

176°F 302°F<br />

70 157 179 157<br />

247 224<br />

314 292<br />

141 382 562 494<br />

741 651<br />

966 854<br />

281 629 944 831 1258 1124<br />

1618 1438<br />

562 990 1505 1350 2025 1800<br />

2990 2700<br />

1125 1910 2540 2270 3370 3010<br />

4990 4495<br />

2250 3150 5240 4700 6970 6250<br />

9215 8320<br />

4495 6070 7645 6745 10340 9215<br />

13710 12365<br />

8990 9665 12590 11240 16635 14835<br />

21575 19330<br />

13490 14160 18660 16635 24275 21800<br />

31465 28320<br />

17985 19110 25620 22925 33715 30340<br />

43825 39330<br />

22480 25180 33935 30340 44050 39555<br />

57310 51690<br />

35970 40015 49895 44725 66300 59555<br />

85625 77085<br />

44960 48330 66750 59780 88700 79780 115065 103605<br />

53955 60700 76410 68545 101580 91245 131470 118210<br />

67400 71940 85400 76400 113500 101200 146100 131500<br />

90000 90000 110100 98900 146100 131500 188800 169700<br />

3.5.4 Max. permissible loads (lbs) for dynamically determined components, Product Group 3<br />

675<br />

900<br />

1800<br />

4000<br />

10350<br />

22450<br />

44900<br />

78600<br />

123500<br />

224000<br />

448000<br />

670000<br />

900000<br />

1124000<br />

Normal (Fn)/Upset <br />

Level A/B<br />

176°F 302°F<br />

650<br />

875<br />

1680<br />

3710<br />

9900<br />

21200<br />

39300<br />

76100<br />

120000<br />

210000<br />

426000<br />

640000<br />

854000<br />

1067000<br />

900<br />

1190<br />

2380<br />

5380<br />

13700<br />

31000<br />

60000<br />

106000<br />

165000<br />

300000<br />

597000<br />

898000<br />

1195000<br />

1495000<br />

3.5.5 Product Group 5<br />

The units in Product Group 5, pipe clamp<br />

bases for cold piping systems, cryogenic<br />

systems, as well as roller bearings and pipe<br />

saddles, are regarded as statically determined,<br />

but are not directly connected with the hanger<br />

supports. As they are comparable with secondary<br />

steel components, they constitute a special<br />

group. The nominal load corresponds<br />

here to the max. operational load according<br />

to level A.<br />

Emergency <br />

Level C<br />

176°F 302°F<br />

850<br />

1150<br />

2180<br />

4950<br />

13150<br />

28000<br />

53500<br />

95000<br />

160000<br />

277000<br />

566000<br />

853000<br />

1135000<br />

1420000<br />

1160<br />

1550<br />

3070<br />

6960<br />

17300<br />

40400<br />

75500<br />

147000<br />

210000<br />

391000<br />

773000<br />

1159000<br />

1545000<br />

1930000<br />

Faulted condition <br />

Level D<br />

176°F 302°F<br />

permissible loads (lbs)<br />

1120<br />

1500<br />

2800<br />

6400<br />

16700<br />

36400<br />

67500<br />

132000<br />

205000<br />

362000<br />

734000<br />

1101000<br />

1465000<br />

1830000<br />

3.5.6 Max. permissible loads (lbs) for<br />

Product Group 5<br />

Normal load H 900 1800 3600 7870 13500 27000<br />

Emerg. load HZ 1235 2470 4945 10560 18000 36000

3.6. Travel ranges<br />

3.6.1 Travel ranges of static components<br />

Moving parts such as spring and constant<br />

hangers are divided into travel ranges corresponding<br />

to the usable spring travel of the<br />

standard springs employed.<br />

The appropriate travel range in each case is<br />

marked by the 4th digit of the type designation<br />

according to the following table.<br />

Constant hanger<br />

0 - 6<br />

Travel range<br />

inch [150mm]<br />

0- 12 inch [300mm]<br />

0- 18 inch [450mm]<br />

0 - 24 inch [600mm]<br />

0- 291/ 2 inch [750mm]<br />

0 - 351/ 2 inch [900mm]<br />

Designation No.<br />

1. .2 . .<br />

1. .3 . .<br />

1. .4 . .<br />

1. .5 . .<br />

1. .6 . .<br />

1. .7 . .<br />

Spring hanger<br />

Travel range Designation No.<br />

0 - 2 inch [50mm]<br />

2. .1 . .<br />

0- 4 inch [100mm]<br />

2. .2 . .<br />

0- 8 inch [200mm]<br />

2. .3 . .<br />

0 - 12 inch [300mm]<br />

2. .4 . .<br />

0- 16 inch [400mm]<br />

2. .5 . .<br />

For spring hangers and supports (Product<br />

Group 2) the springs are already installed<br />

preset to approx. 1/3 of their nominal load.<br />

The initial load follows from this and the<br />

spring travel is correspondingly reduced.<br />

3.6.2 Shock absorber travel ranges<br />

The maximum strokes of <strong>LISEGA</strong> shock absorbers<br />

are divided into economical stroke<br />

ranges as standard, and are so designated<br />

in the 4th digit of the type designation according<br />

to the following table.<br />

Stroke<br />

5 7/ 8 inch [150mm]<br />

11 3/ 4 inch [300mm]<br />

15 3/ 4 inch [400mm]<br />

19 3/ 4 inch [500mm]<br />

23 5/ 8 inch [600mm]<br />

29 1/<br />

Shock absorber<br />

Type<br />

30<br />

30<br />

30<br />

30<br />

30<br />

2 inch [750mm] 30<br />

4 inch [100mm] 30/31<br />

8 inch [200mm] 30/31<br />

Design. No.<br />

. . .2 . .<br />

. . .3 . .<br />

. . .4 . .<br />

. . .5 . .<br />

. . .6 . .<br />

. . .7 . .<br />

. . .8 . .<br />

. . .9 . .<br />

3.7 Type designation<br />

All components can be clearly identified via<br />

coded type designations. Six digits contain<br />

all the necessary information required.<br />

The type designation system facilitates the<br />

use of modern information technology and<br />

enables the unrestricted application of the<br />

modular system in current CAD programs.<br />

3.7.1 Example of constant hanger, type 11<br />

115325<br />

3.7.2 Example of clamp base, type 49<br />

495185<br />

3.7.3 Example of rigid strut, type 39<br />

396254<br />

1985<br />

standard<br />

travel range 3/0-12 inch<br />

load group 5/FN 4495 lbs<br />

single cell<br />

constant hanger<br />

high design, welded<br />

13CrMo4-5, Nuclear spec.<br />

pipe diameter 20 inch<br />

clamp base<br />

pipe conn. part<br />

standard spec.<br />

length 98 1/ 4 inch<br />

load group 6 / FN 22480 lbs<br />

rigid strut<br />

Complete integrated<br />

application of 8000<br />

components possible<br />

through clearcut type<br />

designation key!<br />

0<br />

0.6

3.8 Type designation system<br />

The <strong>LISEGA</strong> type designations can be decoded using the<br />

following tables.<br />

3.8.1 Constant hangers and constant supports<br />

Digit<br />

1<br />

Product<br />

group<br />

1<br />

Digit<br />

1<br />

Product<br />

group<br />

2<br />

0.7<br />

Digit<br />

2<br />

Model<br />

1= constant<br />

hanger<br />

6= constant<br />

support/<br />

angulating<br />

constant<br />

support<br />

2= CH<br />

2-cell coupl.<br />

3= CH<br />

3-cell coupl.<br />

4= CH<br />

4-cell coupl.<br />

7= servo<br />

hanger<br />

Digit<br />

3<br />

Load group<br />

C= 3 / 8UNC-70lbs<br />

D= 3 / 8UNC-141lbs<br />

1= 1 / 2UNC-281lbs<br />

2= 1 / 2UNC-562lbs<br />

3= 5 / 8UNC-1125lbs<br />

4= 3 / 4UNC-2250lbs<br />

5=1UNC-4495lbs<br />

6=1 1 / 4UNC-8990lbs<br />

7=1 1 / 2UNC-13490lbs<br />

8=1 3 / 4UNC-17985lbs<br />

9=2UNC-22480lbs<br />

8=2 1 / 4UNC-35970lbs<br />

9=2 1 / 2UNC-44960lbs<br />

8=2 3 / 4UNC-53955lbs<br />

9=3UNC-67400lbs<br />

8=3UNC-71940lbs<br />

9=3 1 / 4UNC-90000lbs<br />

5=1UNC-4495lbs<br />

6=1 1 / 4UNC-8990lbs<br />

7=1 1 / 2UNC-13490lbs<br />

8=1 3 / 4UNC-17985lbs<br />

9=2UNC-22480lbs<br />

Digit<br />

4<br />

Travel<br />

range<br />

2=6inch<br />

3=12inch<br />

4=18inch<br />

5=24inch<br />

6=30inch<br />

7=36inch<br />

2=6inch<br />

3=12inch<br />

3.8.2 Spring hangers and spring supports<br />

Digit<br />

2<br />

Model<br />

0= angul.<br />

spring supp.<br />

0= extens. f.<br />

type 20<br />

1= spring h.<br />

suspended<br />

5= spring h.<br />

seated<br />

7= sway brace<br />

7= extens. f.<br />

type 27<br />

9= spring sup.<br />

2= SH,<br />

suspended<br />

6= SH,<br />

seated<br />

8= spring sup.<br />

1=2 1 / 4UNC-35970lbs<br />

2=2 1 / 2UNC-44960lbs<br />

3=2 3 / 4UNC-53955lbs<br />

4=3UNC-67400lbs<br />

5=3 1 / 4UNC-90000lbs<br />

3.8.3 Dynamic components<br />

Digit<br />

1<br />

Product<br />

group<br />

3<br />

Digit<br />

2<br />

Model<br />

0= hydraulic<br />

shock absor.<br />

stand. design<br />

2= energy<br />

absorber<br />

3= extension<br />

1= hydraulic<br />

shock absor.<br />

large bore<br />

Digit<br />

5<br />

Field of<br />

application<br />

2=standard<br />

6=nuclear<br />

application<br />

STANDARD<br />

1=std. design<br />

2=angulated<br />

design<br />

NUCLEAR<br />

APPLICATION<br />

5=std. design<br />

6=ang. design<br />

3=standard<br />

7=nuclear<br />

application<br />

2=standard<br />

6=nuclear<br />

application<br />

Digit<br />

3<br />

Load group<br />

C= 3 / 8UNC-56lbs<br />

D= 3 / 8UNC-120lbs<br />

1= 1 / 2UNC-281lbs<br />

2= 1 / 2UNC-562lbs<br />

3= 5 / 8UNC-1125lbs<br />

4= 3 / 4UNC-2250lbs<br />

5=1UNC-4495lbs<br />

6=1 1 / 4UNC-8990lbs<br />

7=1 1 / 2UNC-13490lbs<br />

8=1 3 Digit<br />

4<br />

Digit<br />

5<br />

Travel Field of<br />

range application<br />

/ 4UNC-17985lbs<br />

9=2UNC-22480lbs<br />

1=2inch<br />

2=4inch<br />

3=8inch<br />

4=12inch<br />

5=16inch<br />

9=extens.<br />

f. type 20<br />

&. type 27<br />

1,2=standard<br />

5,6=nuclear<br />

application<br />

Digit<br />

3<br />

Load group<br />

1= 675lbs 4= 4000lbs<br />

2= 900lbs 5=10350lbs<br />

3= 1800lbs 6=22450lbs<br />

7= 44900lbs<br />

8= 78600lbs<br />

9= 123500lbs<br />

0= 224000lbs<br />

9= 123500lbs<br />

0= 224000lbs<br />

2= 448000lbs<br />

3= 670000lbs<br />

4= 900000lbs<br />

5= 1124000lbs<br />

Digit<br />

4<br />

Travel<br />

range<br />

2=5 7 /8inch<br />

3=11 3 /4inch<br />

4=15 3 /4inch<br />

5=19 3 /4inch<br />

8=4inch<br />

9=8inch<br />

8=4inch<br />

9=8inch<br />

Digit<br />

5<br />

Field of<br />

application<br />

1= standard<br />

5= nuclear<br />

application<br />

Digit<br />

6<br />

Prod.<br />

series<br />

5=1985<br />

9=1999<br />

Digit<br />

6<br />

Prod.<br />

series<br />

4=1994<br />

8=1978<br />

9=1999<br />

Digit<br />

6<br />

Prod.<br />

series<br />

2=2002<br />

3=1993<br />

6=1986<br />

8=1988<br />

at Type 32<br />

6=1996<br />

3.8.3 Dynamic components (cont.)<br />

Digit<br />

1<br />

Product<br />

group<br />

3<br />

3.8.4 Pipe clamps and clamp bases<br />

Digit<br />

1<br />

Product<br />

group<br />

4<br />

Digit<br />

2<br />

Model<br />

5= weld-on<br />

bracket<br />

6= dynamic<br />

pipe clamp<br />

with U-bolt<br />

7=dynamic<br />

pipe clamp<br />

with strap<br />

9= rigid<br />

struts<br />

Digit<br />

2<br />

Model<br />

1= weld-on<br />

lug<br />

horiz. clamp<br />

2=clevis clamp<br />

2=2 bolt clamp<br />

3=3 bolt clamp<br />

4= with Ubolt<br />

or strap<br />

riser clamps<br />

5=formed<br />

riser clamp<br />

6=riser cl., lugs<br />

8=riser clamp,<br />

trunnions<br />

9= clamp<br />

bases<br />

0= U-bolts<br />

9=Lift-off<br />

restraints for<br />

clamp bases<br />

Digit<br />

3<br />

Load group<br />

Digit<br />

3+4<br />

Pipe diameter in inch<br />

D9 = 141lbs<br />

29 = 562lbs<br />

39 = 1125lbs<br />

49 = 2250lbs<br />

01 = 0.84<br />

02 = 1.06<br />

03 = 1.33<br />

04 = 1.67<br />

05 = 1.90<br />

06 = 2.37<br />

07 = 2.87<br />

08 = 3.00<br />

09 = 3.50<br />

10 = 4.25<br />

11 = 4.50<br />

13 = 5.25<br />

14 = 5.50<br />

16 = 6.25<br />

17 = 6.63<br />

19 = 7.63<br />

22 = 8.63<br />

00=Lift-off<br />

restraints<br />

Digit<br />

4<br />

Travel<br />

range<br />

19= 675lbs 79= 44900lbs<br />

29= 900lbs 89= 78600lbs<br />

39= 1800lbs 99= 123500lbs<br />

49= 4000lbs 09= 224000lbs<br />

59= 10350lbs 20= 448000lbs<br />

69= 22450lbs<br />

pipe diameter<br />

in inch·2.54 [mm/10]<br />

2 = 900lbs<br />

3 = 1800lbs<br />

4 = 4000lbs<br />

5 = 10350lbs<br />

6 = 22450lbs<br />

7 = 44900lbs<br />

8 = 78600lbs<br />

9 = 123500lbs<br />

0 = 224000lbs<br />

middle<br />

installation<br />

dimension<br />

in inch/4<br />

59 = 4495lbs<br />

69 = 8990lbs<br />

79 = 13490lbs<br />

24 = 9.63<br />

26 = 10.50<br />

27 = 10.75<br />

32 = 12.75<br />

36 = 14.00<br />

37 = 14.50<br />

41 = 16.00<br />

42 = 16.50<br />

46 = 18.00<br />

51 = 20.00<br />

56 = 22.00<br />

61 = 24.00<br />

66 = 26.00<br />

71 = 28.00<br />

76 = 30.00<br />

81 = 32.00<br />

91 = 36.00<br />

Digit<br />

5<br />

Field of<br />

application<br />

1= standard<br />

5= nuclear<br />

application<br />

STANDARD<br />

1= up to 660°F<br />

2= up to 930°F<br />

3= up to 1040°F<br />

NUCLEAR<br />

APPLICATION<br />

6= up to 660°F<br />

7= up to 930°F<br />

8= up to 1040°F<br />

Digit<br />

5<br />

Field of<br />

application<br />

1= standard<br />

1= standard<br />

STANDARD<br />

1= up to 660°F<br />

2= up to 930°F<br />

3= up to 1040°F<br />

4= up to 1110°F<br />

5= up to 1200°F<br />

NUCLEAR<br />

APPLICATION<br />

6= up to 660°F<br />

7= up to 930°F<br />

8= up to 1040°F<br />

2= carbon<br />

steel<br />

4= stainless<br />

steel<br />

0=Lift-off<br />

restraints<br />

Digit<br />

6<br />

Prod.<br />

series<br />

1=1991<br />

3=1993<br />

6=1986<br />

9=1989<br />

1-6=<br />

U-bolts<br />

1-9=<br />

flat steel<br />

strap<br />

3-4=<br />

standard<br />

8-9=<br />

nuclear<br />

application<br />

Digit<br />

6<br />

Prod.<br />

series<br />

f. straight pipes,<br />

max. insul. thickn.<br />

1= 3 / 8inch<br />

2=4inch<br />

for pipe elbows<br />

R1.5OD<br />

max. insul. thickn.<br />

3,4= 3 / 8inch<br />

5,6=4inch<br />

depends<br />

on load<br />

range and<br />

design<br />

1=low<br />

2=medium<br />

3=low,<br />

welded<br />

4=medium,<br />

welded<br />

5=high,<br />

welded<br />

8=standard<br />

1-4=size

3.8.5 Roller bearings, cryogenic clamp bases<br />

Digit<br />

1<br />

Product<br />

group<br />

5<br />

Digit<br />

2<br />

Model<br />

1=cylinder<br />

roller bearings<br />

2=double taper<br />

roller bearings<br />

3=double cylinder<br />

roller bearings<br />

5=lift-off restr.<br />

f. roller bear.<br />

4=pipe saddle/<br />

support tray<br />

6= preinsulated<br />

pipes<br />

7= weld-on<br />

pipe bases<br />

8=<br />

stanchions<br />

8=elbow<br />

pads<br />

Digit<br />

3+4<br />

Load group<br />

Pipe diameter<br />

04= 900lbs<br />

08= 1800lbs<br />

12= 27000lbs<br />

16= 3600lbs<br />

35= 7870lbs<br />

60= 13500lbs<br />

01 = 0.84<br />

02 = 1.06<br />

03 = 1.33<br />

05 = 1.90<br />

06 = 2.37<br />

07 = 2.87<br />

08 = 3.00<br />

09 = 3.50<br />

10 = 4.25<br />

11 = 4.50<br />

13 = 5.25<br />

14 = 5.50<br />

16 = 6.25<br />

17 = 6.63<br />

19 = 7.63<br />

22 = 8.63<br />

24 = 9.63<br />

26 = 10.50<br />

27 = 10.75<br />

32 = 12.75<br />

36 = 14.00<br />

37 = 14.50<br />

41 = 16.00<br />

42 = 16.50<br />

46 = 18.00<br />

51 = 20.00<br />

56 = 22.00<br />

61 = 24.00<br />

66 = 26.00<br />

71 = 28.00<br />

76 = 30.00<br />

81 = 32.00<br />

91 = 36.00<br />

3.8.6 Connecting elements, connecting rods<br />

Digit<br />

1<br />

Product<br />

group<br />

6<br />

Digit<br />

2<br />

Model<br />

0=eye nut<br />

1=clevis<br />

2=turnbuckle<br />

4=rod<br />

coupling<br />

Digit<br />

3+4<br />

Load group<br />

D9 = 3 / 8UNC-141lbs<br />

29 = 1 / 2UNC-562lbs<br />

39 = 5 / 8UNC-1125lbs<br />

49 = 3 / 4UNC-2250lbs<br />

59 = 1UNC-4495lbs<br />

69 = 1 1 / 4UNC-8990lbs<br />

79 = 1 1 / 2UNC-13490lbs<br />

89 = 1 3 / 4UNC-17985lbs<br />

99 = 2UNC-22480lbs<br />

10 = 2 1 / 4UNC-35970lbs<br />

20 = 2 1 / 2UNC-44960lbs<br />

30 = 2 3 / 4UNC-53955lbs<br />

40 = 3UNC-67400lbs<br />

50 = 3 1 / 4UNC-90000lbs<br />

Digit<br />

5<br />

Field of<br />

application<br />

1=standard<br />

2=movable<br />

laterally<br />

1=weldable<br />

2=with pipe<br />

clamp<br />

3=support<br />

plate<br />

1=<br />

12inch long<br />

2,4,6=<br />

20inch long<br />

9=cold block<br />

1=standard<br />

1=<br />

stanchions<br />

2=telescopic<br />

stanchions<br />

3=standard<br />

Digit<br />

5<br />

Field of<br />

application<br />

2=standard<br />

6=nuclear<br />

4=hot dip<br />

galvanized<br />

Digit<br />

6<br />

Prod.series<br />

9=1989<br />

Insul. thickn.<br />

0=1inch<br />

1=1 1 / 2inch<br />

2=2inch<br />

3=3inch<br />

4=4inch<br />

5=5inch<br />

6=6inch<br />

7=7inch<br />

8=8inch<br />

9=10inch<br />

1= Cold<br />

Block<br />

1=from<br />

T-sections<br />

2=from<br />

C-sections<br />

1,2= for<br />

streight<br />

pipes<br />

3,4= for<br />

elbow<br />

R OD<br />

5,6= for<br />

elbow<br />

R1,5OD<br />

1=carbon steel<br />

2=stainless steel<br />

Digit<br />

6<br />

Prod.series<br />

2=1982<br />

5=1995<br />

8=1978<br />

9=1999<br />

3.8.6 Connecting elements, connecting rods (cont.)<br />

Digit<br />

1<br />

Digit<br />

2<br />

Digit<br />

3<br />

Product Model Load group<br />

group<br />

6<br />

3=hexag.<br />

nut<br />

5=tie rod<br />

left/right<br />

D=<br />

6=tie rod<br />

right/right<br />

7=stud bolt/<br />

threaded rod<br />

3 / 8UNC-141lbs<br />

2= 1 / 2UNC-562lbs<br />

3= 5 / 8UNC-1125lbs<br />

4= 3 / 4UNC-2250lbs<br />

5=1UNC-4495lbs<br />

6=11 / 4UNC-8990lbs<br />

7=11 / 2UNC-13490lbs<br />

8=13 Digit<br />

4<br />

Digit<br />

5<br />

Digit<br />

6<br />

Length Field of Prod.-<br />

application series<br />

9 (Model 3)<br />

1=not standardized<br />

1=standard<br />

6=nuclear<br />

application<br />

2=standard<br />

6=nuclear<br />

3=1993<br />

8=1978<br />

9=1999<br />

2=24inch<br />

3=48inch<br />

/ 4UNC-17985lbs 4=72inch<br />

9=2UNC-22480lbs 5=96inch<br />

6=120inch<br />

7=144inch<br />

10 = 2<br />

application<br />

4=hot dip<br />

galvanized<br />

1 / 4UNC-35970lbs<br />

20 = 21 / 2UNC-44960lbs<br />

30 = 23 / 4UNC-53955lbs<br />

40 = 3UNC-67400lbs<br />

50 = 31 0<br />

length<br />

not<br />

standardized{<br />

/ 4UNC-90000lbs<br />

3.8.7 Structural attachments and trapezes<br />

Digit<br />

1<br />

Product<br />

group<br />

7<br />

Digit<br />

2<br />

Model<br />

9=trapeze<br />

0=PTFE slide<br />

plate<br />

7=connecting<br />

plate<br />

Digit<br />

3<br />

Load group<br />

Digit<br />

4<br />

Function<br />

1= support<br />

for constant<br />

hanger<br />

C =<br />

2=base plate f.<br />

spring hanger<br />

3=weld-on clevis<br />

4=weld-on plate<br />

5=weld-on eye<br />

nut<br />

6=beam adapter<br />

and bolts<br />

8=beam clamp<br />

3 / 8UNC-70lbs<br />

D = 3 / 8UNC-141lbs<br />

1 = 1 / 2UNC-281lbs<br />

2 = 1 / 2UNC-562lbs<br />

3 = 5 / 8UNC-1125lbs<br />

4 = 3 / 4UNC-2250lbs<br />

5 = 1UNC-4495lbs<br />

6 = 11 / 4UNC-8990lbs<br />

7 = 11 / 2UNC-13490lbs<br />

8 = 13 / 4UNC-17985lbs<br />

9 = 2UNC-22480lbs<br />

10 = 21 / 4UNC-35970lbs<br />

20 = 21 / 2UNC-44960lbs<br />

30 = 23 / 4UNC-53955lbs<br />

40 = 3UNC-67400lbs<br />

50 = 31 2...7=<br />

travel<br />

range of<br />

constant<br />

hanger<br />

6-36inch<br />

1, 2, 3, 9=<br />

depends<br />

on design<br />

/ 4UNC-90000lbs<br />

Digit<br />

5<br />

Field of<br />

application<br />

STANDARD<br />

6= bolted<br />

7= loose<br />

NUCLEAR<br />

8= bolted<br />

9= loose<br />

1=standard<br />

5=nuclear<br />

application<br />

2=2 con- 2=const.hang.<br />

nections trapeze<br />

3=3 con- 1 and 2=<br />

nections<br />

1...3= travel<br />

spring hanger<br />

range of trapeze<br />

spring han- 3=rigid trapeze<br />

ger 2-8 inch<br />

3 rd to 6 th digits correspond to clamps to be coupled<br />

Digit<br />

6<br />

Prod.series<br />

5,9 =<br />

bracket 1x<br />

6 =<br />

bracket 2x<br />

7 =<br />

bracket 3x<br />

8 =<br />

bracket 4x<br />

1=1991/<br />

2001<br />

2=1982<br />

3=1993<br />

4=1994<br />

5=1985<br />

6=1996<br />

8=1978<br />

9=1989<br />

4, 6 and 9=<br />

U-sections<br />

7=<br />

L-sections<br />

0.8

Worldwide coverage<br />

of recognized codes<br />

and standards!<br />

Standardized selection<br />

of high temperature<br />

materials!<br />

0.9<br />

4. STANDARDS AND CALCULATIONS<br />

In design, stress and load calculations, as<br />

well as in manufacturing, the relevant German<br />

and international standards, technical regulations<br />

and codes are taken into account.<br />

The following codes apply:<br />

MSS SP 58 Pipe supports - material and design USA<br />

MSS SP 69 Pipe supports - applications USA<br />

ANSI ASME B31.1 Pressure piping systems USA<br />

ASME III Div.I - NF Supports for nuclear components USA<br />

VGB-R 510 L Standard supports Germany<br />

DIN 18800 Steelwork Germany<br />

KTA 3205.1/2/3 Nuclear regulations Germany<br />

AD-Merkblätter Working group for pressure vessels Germany<br />

TRD-Regel Techn. regulations, steam boilers Germany<br />

BS 3974 Pipe supports UK<br />

RCC-M Specifications for pipe supports France<br />

MITI 501 Technical regulations Japan<br />

JEAG 4601 Nuclear design regulations Japan<br />

5. MATERIALS<br />

Materials are exclusively used which correspond<br />

to ASTM material requirements and<br />

DIN or DIN-EN norms.<br />

5.1 Preferred materials for pipe connection parts<br />

S235JRG2<br />

S235JRG2<br />

S235JRG2<br />

S355J2G3<br />

S355J2G3<br />

S355J2G3<br />

P235T1<br />

P235G11TH<br />

16Mo 3<br />

13CrMo 4-5<br />

10CrMo 9-10<br />

X10CrMoVNb9-1<br />

X5CrNi 18-10<br />

42CrMoV 4<br />

X10CrMoVNb9-1<br />

21 CrMoV 5-7<br />

X22CrMoV12-1<br />

24CrMo 5<br />

6. QUALIFICATION LEVELS FOR STANDARD AND<br />

NUCLEAR APPLICATION<br />

Standard supports have the same function<br />

both in the conventional and in the nuclear<br />

field of application, and therefore do not<br />

The characteristic values of materials that all<br />

design calculations are based on are taken<br />

from the relevant standards and recognized<br />

technical codes.<br />

As a matter of principle, only materials of<br />

guaranteed strength properties are used for<br />

supporting components.<br />

EN<br />

Material<br />

Material-No. EN 10027-2 ASTM 660<br />

Temperature of medium in °F<br />

840 930 985 1040 1110 1200<br />

COMPONENTS<br />

1.0038 A 36<br />

x<br />

1.0038 A 515 Gr. 60 x<br />

1.0038 A 675 Gr. 55 x<br />

1.0570 A 675 Gr. 70 x<br />

1.0570 A 299<br />

x<br />

1.0570 A 516 Gr. 70 x<br />

1.0254 A 53 S Gr. A x<br />

1.0305 A 53 S Gr. A x<br />

1.5415 A 204<br />

x x x<br />

1.7335 A 387 Gr. 12 x x x x x<br />

1.7380 A 387 Gr. 22 x x x x x x<br />

1.4903 A 387 Gr. 91 Cl.II x x x x x x x<br />

1.4301 A 312 TP 304 x x x x<br />

MEANS OF CONNECTION<br />

1.7225 A 193 B7<br />

x<br />

A 193 B8<br />

x x x x x x x<br />

1.4903 A 182 F91 x x x x x x x<br />

1.7709<br />

x x x x x<br />

1.4923<br />

x x x x x x x<br />

1.7258 A 194 Gr. 2H x x x x x<br />

differ in design. Due to additional qualityassuring<br />

measures and materials with special<br />

certification, separate manufacture is however<br />

necessary.

In the field of nuclear application, all materials<br />

are traceable right through to the finished<br />

product via heat number restamping, and the<br />

components themselves are marked according<br />

to ASME and KTA regulations. In the<br />

type designation, the nuclear design is noted<br />

in the 5th digit (for struts, the 6th digit). The<br />

relevant component documentation relates<br />

to this and to the fabrication order number.<br />

In this catalog, the standard design, i.e. nonnuclear<br />

applications, provides the basis for<br />

the type designations. As the given functional<br />

data and unit dimensions are the same for<br />

nuclear applications, selection can also be<br />

made here with the help of the catalog.<br />

On planning or ordering, attention must however<br />

be paid to corresponding conformity of<br />

the type designations. The table showing the<br />

type designation system (3.8, page 0.7) can be<br />

consulted in this respect.<br />

7. WELDING<br />

All welding is carried out as gas metal arc<br />

welding - in special cases by stick welding.<br />

<strong>LISEGA</strong> holds certifications according to:<br />

➜ ASME III Div I NCA NPT stamp<br />

➜ DIN EN 729-2 by the German TÜV<br />

➜ AD-HPO, production and testing of<br />

pressure vessels, by the TÜV<br />

➜ DIN 18800 T7 Extended suitability<br />

certification for steelwork and bridge<br />

construction by the SLV, the training<br />

and testing institute for welding<br />

technology<br />

<strong>LISEGA</strong> welding inspection personnel are qualified<br />

according to ASME III NCA 4000 NF,<br />

DIN EN 719, AD HP3 and HP4. Nondestructive<br />

tests are carried out by testing<br />

staff qualified acc. to ASME IX and DIN EN<br />

473, level 2, and SNT-TC-1A, level II.<br />

Supporting connections are produced corresponding<br />

to the material group by qualified<br />

welders according to ASME IX or DIN EN<br />

287, part 1. The welding procedure is qualified<br />

according to ASME IX and DIN EN 288.<br />

8. SURFACE TREATMENT<br />

8.1 Standard coating systems<br />

The surfaces of <strong>LISEGA</strong> products are protected<br />

as standard from corrosive influences by high<br />

quality protection systems that are also suitable<br />

for external use in aggressive conditions<br />

(coastal, industrial and chemical areas).<br />

The following coating systems are applied<br />

to the different products:<br />

8.1.1 Primer coating<br />

Components that are either to be welded<br />

to existing structure in the plant or simply<br />

require higher quality transport protection are<br />

coated on a bright metal surface with weldable<br />

primer (thickness app. 1.18 mil [30µm],<br />

color reddish brown).<br />

8.1.2 Electrogalvanizing<br />

Spring hangers and supports up to load size<br />

9, as well as all threaded parts and special<br />

function parts, are electrogalvanized (zinc<br />

thickness app. 0.59 mil [15µm], yellow chromatized).<br />

UNC threaded parts are white chromatized.<br />

8.1.3 Paint coatings<br />

Constant hangers and supports and other<br />

products according to table 8.2 receive the<br />

following surface treatment:<br />

1. Steel grit blasting according to SP-6 or<br />

SP-10 for the U.S. and EN ISO 12944-4<br />

grade SA 2 1/2 for Europe.<br />

2. Undercoat of 1-component polyurethane<br />

zinc dust primer, dry film thickness 2.36 mil<br />

[60µm], approx. 62% zinc in solid state<br />

volume, color grey.<br />

3. Final coating of 2-component acrylic polyurethane<br />

paint, dry film thickness 2.36 mil<br />

[60µm], color RAL 5012, light blue.<br />

The total dry film thickness of the system<br />

amounts to approx. 4.72 mil [120µm].<br />

8.1.4 Hot dip galvanization<br />

Roller bearings, pipe saddles and cryogenic<br />

pipe clamp bases are hot dip galvanized as<br />

standard, zinc thickness approx. 2.36 mil<br />

[60µm].<br />

0<br />

Separate manufacture<br />

of products for nuclear<br />

applications for the<br />

traceability of<br />

qualified materials!<br />

0.10

Standardized procedures<br />

for surface protection for<br />

constant quality!<br />

0.11<br />

8.1.5 Stainless steel designs<br />

Shock absorbers and energy absorbers<br />

(E-Bars) are made entirely of non-corroding<br />

materials. Connecting parts are electrogalvanized<br />

according to 8.1.2.<br />

8.1.6 Cathodic immersion process (CIP)<br />

All <strong>LISEGA</strong> springs are given special treatment<br />

because of their distinctive functional<br />

8.2 Standard surface protection in order of products (corresp. to 8.1)<br />

Product Type<br />

Constant hangers, constant supports<br />

Support for constant hangers<br />

Spring hangers, sway braces<br />

Spring supports (incl. load group 9)<br />

Spring hangers<br />

Spring supports (from load group 10)<br />

Weld-on brackets<br />

Dynamic pipe clamps<br />

Rigid struts<br />

Shock absorber extensions<br />

U-bolts<br />

Weld-on lugs, pipe clamps<br />

Riser clamps, pipe clamp bases<br />

Cylinder roller bearings<br />

Taper roller bearings<br />

Pipe saddles/support tray<br />

Lift-off restraints<br />

Pipe clamp bases f. cryogenic appl.<br />

Weld-on pipe shoe<br />

Elbow pads<br />

Stanchions<br />

Eye nuts, clevises<br />

Turnbuckles, rod couplings<br />

Hexagonal nuts, tie rods<br />

Threaded rods, stud bolts<br />

Base plates, weld-on clevises<br />

Spherical washers, weld-on eye nuts<br />

Beam adapters<br />

Connection plates<br />

Beam clamps<br />

Trapezes<br />

11 - 17<br />

71<br />

21, 25, 27<br />

20, 29<br />

22, 26<br />

28<br />

35<br />

36, 37<br />

39<br />

33<br />

40<br />

41, 42, 43, 44,<br />

45, 46, 48, 49<br />

51, 53<br />

52<br />

54<br />

55<br />

56<br />

57<br />

58<br />

58<br />

60, 61<br />

62, 64<br />

63, 65<br />

66, 67<br />

72, 73<br />

74, 75<br />

76<br />

77<br />

78<br />

79<br />

8.3 Extended surface protection<br />

For applications in the open involving highly<br />

corrosive conditions, such as coastal sites or<br />

chemical plants, extra protection can be supplied,<br />

insofar as this has not already been<br />

provided as standard by hot dip galvanizing<br />

or special steel versions. The following coating<br />

systems are thereby applied:<br />

significance. The peeled surface of the springs<br />

is steel ball blasted and zinc-phosphated; subsequently<br />

a 2-component epoxy resin coating<br />

is applied via electroimmersion and then<br />

burnt in at approx. 392°F [200°C] (CIP).<br />

This highly sophisticated process has been<br />

adopted from the automobile industry.<br />

Primer<br />

acc. to 8.1.1<br />

x<br />

x<br />

x<br />

x<br />

x<br />

x<br />

x<br />

x<br />

x<br />

x<br />

Electrogalvanized<br />

acc. to 8.1.2<br />

x<br />

x<br />

x<br />

x<br />

x<br />

x<br />

x<br />

x<br />

Standard<br />

paint<br />

coating<br />

acc. to 8.1.3<br />

x<br />

x<br />

x<br />

x<br />

x<br />

x<br />

x<br />

Hot dip<br />

galvanized<br />

acc. to 8.1.4<br />

8.3.1 Electrogalvanization with additional<br />

coats of paint<br />

1. A barrier layer (dry film thickness 18 mil<br />

[30µm]) is applied to the galvanized surface<br />

acc. to 8.1.2.<br />

2. As a final layer, a 2-component acrylic<br />

polyurethane finish (dry film thickness 2.36<br />

mil [60µm], color RAL 5012 - light blue) is<br />

applied.<br />

x<br />

x<br />

x<br />

x<br />

x<br />

x

8.3.2 Extra paint layer<br />

Over the standard paint coating according to<br />

8.1.3, a third protective layer consisting of a<br />

2-component acrylic polyurethane coating is<br />

applied. Dry film thickness 2.36 mil [60µm],<br />

color RAL 5012 - light blue, total dry film<br />

thickness app. 7.085 mil [180µm].<br />

8.4 Extended surface protection in order of products acc. to 8.3<br />

Product Type Electrogalvanization with Extra paint coating<br />

add. coating acc. to 8.3.1 acc. to 8.3.2<br />

Constant hangers, constant supports<br />

Supports for constant hangers<br />

Spring hangers, sway braces<br />

Spring supp. (incl. load group 9)<br />

Spring hangers<br />

Spring supp. (from load group 10)<br />

Rigid struts<br />

Shock absorber extensions<br />

Eye nuts, clevises<br />

Turnbuckles, rod couplings<br />

Hexagon nuts, tie rods<br />

Threaded rods, stud bolts<br />

Trapezes<br />

11 - 17<br />

71<br />

21, 25, 27<br />

20, 29<br />

22, 26<br />

28<br />

39<br />

33<br />

60, 61,<br />

62, 64<br />

63, 65,<br />

66, 67<br />

79<br />

8.5 Surface protection in extremely<br />

aggressive atmospheres<br />

For applications in specially aggressive atmospheres,<br />

e.g. coastal areas, certain industrial<br />

gases or offshore, special measures are to be<br />

agreed on.<br />

9. CONNECTION DIMENSIONS<br />

9.1 Installation dimension E<br />

For the simple determination of minimum<br />

installation lengths, the installation dimension<br />

E is given for all components except the<br />

connecting rods (Product Group 6). This<br />

dimension comprises the installation length<br />

minus the engaging length of the connecting<br />

part. For load chains, the E therefore designates<br />

the complete rod section.<br />

Special product-related features are to be<br />

taken into account as follows:<br />

x<br />

x<br />

8.3.3 Hot dip galvanizing<br />

Hot dip galvanized surface, layer thickness<br />

approx. 2.36 mil [60µm], bolts approx.<br />

1.57 mil [40µm].<br />

8.3.4 Stainless steel<br />

For the connecting parts of shock absorbers,<br />

energy absorbers (E-Bars) and rigid struts,<br />

stainless steel designs can be supplied.<br />

x<br />

x<br />

x<br />

x<br />

x<br />

x<br />

x<br />

Hot dip galvanizing<br />

acc. to 8.3.3<br />

To determine the total length of the rods in<br />

a load chain, all the E dimensions are to be<br />

added together. The sum of these is then to<br />

be compared with the total installation length.<br />

If the resulting difference is greater than the<br />

sum of the engagement depths (X dimensions),<br />

the chain selected is appropriate for the total<br />

installation height.<br />

For load chains consisting solely of pin connections,<br />

the minimum installation dimension<br />

follows from the sum of all E dimensions.<br />

x<br />

x<br />

x<br />

x<br />

0<br />

Simple checks for<br />

installation possibilities<br />

through dimension “E” !<br />

0.12

Sensible devices on hand<br />

for readjusting installation<br />

lengths!<br />

0.13<br />

9.2 Regulation of the total installation<br />

length<br />

9.2.1 Turnbuckle function of the connecting<br />

threads<br />

For length adjustment in installation condition<br />

(adjustment of pipe installation position, actuation<br />

of loading), the lower connections in<br />

constant and spring hangers provide a turnbuckle<br />

function. This way, subsequent adjustment<br />

of the installation lengths (attachment<br />

rods) within a sufficient range is possible:<br />

➜ for constant hangers type 11,<br />

by 11 3 /4 inch [300mm]<br />

➜ for spring hangers type 21, by the<br />

adjustment possibility of a turnbuckle,<br />

type 62<br />

➜ for spring hangers type 22,<br />

by min. 5 1 /2 inch [140mm]<br />

➜ for spring hangers types 25 and 26,<br />

the load bearing rod is fed through the<br />

weld-on support tube and fixed with<br />

an adjustment nut. The adjustment can<br />

be made within the scope of the available<br />

threaded length of the rod.<br />

All connection threads are supplied as right<br />

hand threads.<br />

9.2.2 Spring supports<br />

For spring supports types 28 and 29, the<br />

installation height can be regulated by the<br />

support tube, functioning as a spindle independently<br />

of the presetting.<br />

The necessary load is actuated on installation<br />

by screwing the support tube upwards.<br />

9.2.3 Turnbuckle, type 62, tie rod, left<br />

hand/right hand thread, type 65<br />

For rigid hanging support arrangements with<br />

short installation lengths, a defined reserve<br />

length in the connection parts type 60 and<br />

61 usually enables sufficient length adjustment.<br />

For longer installation lengths, the use<br />

of a turnbuckle L/R, type 62, in conjunction<br />

with a tie rod L/R, type 65, is appropriate.<br />

For easy access, this combination should be<br />

arranged at the lower end of the load chain.<br />

9.2.4 Rigid struts, type 39<br />

The connections in rigid struts type 39 are<br />

supplied as left/right, with fine threading for<br />

length adjustment in the installation condition<br />

as standard.<br />

Flat faces on the body of the rigid struts enable<br />

simple adjustment with a wrench.<br />

10. OPERATIONAL BEHAVIOR<br />

10.1 Function<br />

Constant hangers type 1 are designed so that<br />

in theory no load deviation occurs over the<br />

whole range of action. The total deviation<br />

resulting from springs, bearing friction, and<br />

fabrication tolerances is held to within 5%<br />

in series production.<br />

The load adjustment follows with a level of<br />

accuracy of 2%.<br />

load F<br />

FN = nominal load<br />

F min = min. load (upwards)<br />

F max = max. load (downwards)<br />

SN = nominal travel (incl. reserve)<br />

For spring hangers and supports, the load<br />

alters linearly corresponding to the spring<br />

travel. The deviation of the spring force from<br />

theoretical values, resulting from spring hysteresis<br />

and fabrication tolerances, amounts to<br />

less than 5% within the ordered travel.<br />

load F<br />

operating load<br />

FN = nominal load<br />

SN = nominal travel (incl. reserve)<br />

S = operating travel<br />

travel s<br />

travel s

10.2 Spring relaxation<br />

Conventional helical coil springs under load,<br />

depending on time and temperature factors,<br />

lose part of their tension by relaxation (settling<br />

loss), a loss that is not inconsiderable.<br />

If no appropriate measures are taken, for<br />

constant and spring hangers this can in the<br />

long run lead to a reduction in adjusted ultimate<br />

load of more than 10%.<br />

In contrast to common practice, <strong>LISEGA</strong> only<br />

uses springs that, through special treatment,<br />

permit no settling loss of any significance.<br />

In these springs the settling loss normally to<br />

be expected is anticipated via the process of<br />

hot setting from a longer coil length, producing<br />

corresponding prerelaxation.<br />

Relaxation<br />

Shear stress<br />

Relaxation behavior of helical coil springs<br />

Cold set helical coil springs<br />

(values loosely based on DIN 2089)<br />

<strong>LISEGA</strong> hot set helical coil springs<br />

qualified by TÜV and VGB suitability tests<br />

(independent German authorities)<br />

11. QUALITY ASSURANCE<br />

11.1 Fundamentals<br />

Superior product quality has an important place<br />

among the fundamental company goals at<br />

<strong>LISEGA</strong> and also involves the activities of<br />

and relationships with our business partners.<br />

The organization and attitudes of those working<br />

in the company are correspondingly attuned<br />

to this aim. In a quality management<br />

program (QMP), special quality-assuring<br />

measures are prescribed. They are an integral<br />

part of order processing and embrace the<br />

whole <strong>LISEGA</strong> group.<br />

11.2 Quality management program, QMP<br />

The QMP is clearly laid out in a quality management<br />

manual, QMM, and regulates all the<br />

quality-assuring activities in the company.<br />

The QMM covers the organization as a whole,<br />

whereby the observance of rules is monitored<br />

by the independent quality management department<br />

QM. The QMM has been compiled<br />

according to international quality norms and<br />

standards and specifically takes into account<br />

the regulations according to ASME III - NCA<br />

3800 and NCA 4000 incl. NF as well as DIN<br />

EN ISO 9001 and KTA 1401.<br />

The QMM applies in principle to both the conventional<br />

and nuclear fields. The extent of<br />

monitoring of materials and tests, as well as<br />

the documentation, can in each case be<br />

exactly adapted to special requirements by the<br />

use of extended QA levels. All international<br />

requirements concerning nuclear applications<br />

can be covered. Corresponding qualifications<br />

are available and are regularly renewed.<br />

11.3 International qualifications<br />

Certification code<br />

DIN/EN/ISO 9001<br />

DIN/EN/ISO 9001<br />

ASME-III NCA 4000/NF<br />

(NPT-Stamp)<br />

ASME-III NCA 3800/NF<br />

Stamping agreement<br />

AD-Merkblatt HP 0; HP 3; HP 4<br />

Welding certification according to EN 729-2<br />

DIN 18800T7<br />

Major qualification certificate<br />

ASME III - NCA/NF; ASME IX<br />

SKIFS 1994:1<br />

ASME-III NF/NCA 3800;<br />

10CFR50 App. B; 10CFR21;<br />

N45.2; NQA1<br />

Certification No.<br />

Reg.Nr. 200550<br />

1996/5030<br />

N-2951<br />

QSC 552<br />

0121WO29784<br />

07-702-0194<br />

07-703-0080<br />

60317/62/9804<br />

No. 1606<br />

No. DNV 5477<br />

CEXO-99/00210<br />

0<br />

QMP and Processing<br />

constitute a single entity!<br />

Certifying body<br />

Lloyd’s Register QA<br />

L’AFAQ<br />

ASME Accreditation and<br />

Certification<br />

ASME Accreditation and<br />

Certification<br />

TÜV Nord e.V.<br />

(independent German<br />

authority)<br />

SLV-Hannover<br />

TRACTEBEL (Vincotte)<br />

DET NORSKE VERITAS<br />

NUPIC<br />

0.14

Proven operational safety<br />

and long life through type<br />

and suitability tests!<br />

0.15<br />

11.4 Tests and qualifications<br />

11.4.1 Raw material and material reception<br />

All materials used undergo receiving control<br />

by the quality management department. The<br />

materials used are qualified, corresponding<br />

to requirements by material tests according<br />

to ASME and DIN EN 10204.<br />

11.4.2 Monitoring of manufacture<br />

Manufacture is monitored via accompanying<br />

quality control according to the QM manual.<br />

In particular, for nuclear applications the<br />

quality-assuring requirements according to<br />

ASME III NF and KTA are fulfilled.<br />

11.4.3 Final inspection<br />

Before shipment, constant and spring hangers<br />

as well as shock absorbers undergo a function<br />

test on test benches by quality management<br />

personnel. The tests are carried out<br />

using computer-assisted equipment. The<br />

values measured can be recorded by means<br />

of a diagram. In addition, for constant and<br />

spring hangers the digital values can be<br />

printed out over the whole travel range.<br />

The specific test benches employed undergo<br />

regular inspections by an independent supervisory<br />

body.<br />

11.4.4 Documentation on shipment<br />

If so ordered, the materials used are documented<br />

by certification from material tests according<br />

to ASME and DIN EN 10204. In addition,<br />

the results of the function tests can be<br />

confirmed by issuing an acceptance test<br />

certificate, also from a supervisory body if<br />

desired.<br />

Stress reports according to particular specifications<br />

and quality-assuring documents can<br />

be agreed between customer, manufacturer<br />

and supervisory body.<br />

11.5 Suitability test according to KTA 3205.3<br />

and type test according to VGB R 510 L<br />

For the use of series-made standard supports<br />

in conventional power plants, a type test by a<br />

supervisory body (according to § 14 of the<br />

appliance safety law GSG) is foreseen in the<br />

VGB code R 510 L.<br />

For use in nuclear installations a corresponding<br />

suitability test, according to directive 35<br />