Geha Foods Evaluation of Irrigation for Processed Tomatoes

Geha Foods Evaluation of Irrigation for Processed Tomatoes

Geha Foods Evaluation of Irrigation for Processed Tomatoes

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

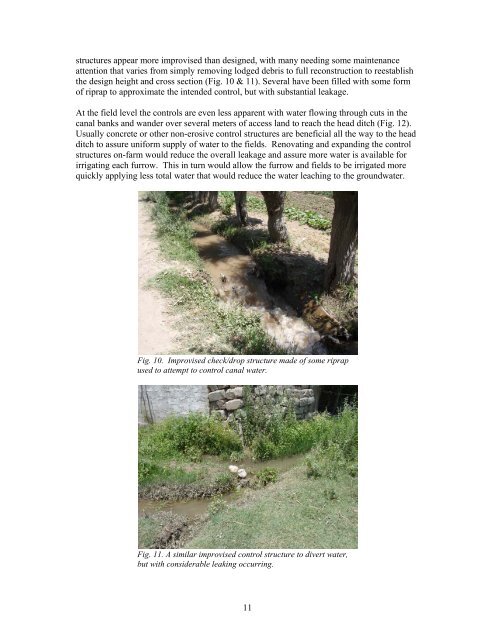

structures appear more improvised than designed, with many needing some maintenance<br />

attention that varies from simply removing lodged debris to full reconstruction to reestablish<br />

the design height and cross section (Fig. 10 & 11). Several have been filled with some <strong>for</strong>m<br />

<strong>of</strong> riprap to approximate the intended control, but with substantial leakage.<br />

At the field level the controls are even less apparent with water flowing through cuts in the<br />

canal banks and wander over several meters <strong>of</strong> access land to reach the head ditch (Fig. 12).<br />

Usually concrete or other non-erosive control structures are beneficial all the way to the head<br />

ditch to assure uni<strong>for</strong>m supply <strong>of</strong> water to the fields. Renovating and expanding the control<br />

structures on-farm would reduce the overall leakage and assure more water is available <strong>for</strong><br />

irrigating each furrow. This in turn would allow the furrow and fields to be irrigated more<br />

quickly applying less total water that would reduce the water leaching to the groundwater.<br />

Fig. 10. Improvised check/drop structure made <strong>of</strong> some riprap<br />

used to attempt to control canal water.<br />

Fig. 11. A similar improvised control structure to divert water,<br />

but with considerable leaking occurring.<br />

11