ABS HIGH SPEED TURBOCOMPRESSOR S9000 - CMS

ABS HIGH SPEED TURBOCOMPRESSOR S9000 - CMS

ABS HIGH SPEED TURBOCOMPRESSOR S9000 - CMS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>ABS</strong> <strong>HIGH</strong> <strong>SPEED</strong> <strong>TURBOCOMPRESSOR</strong><br />

<strong>S9000</strong><br />

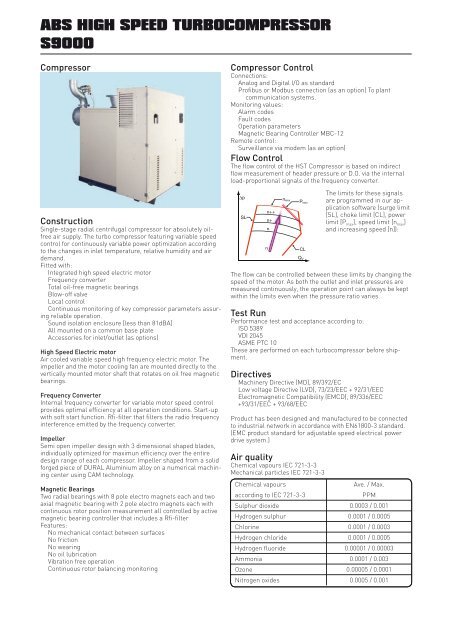

Compressor<br />

Construction<br />

Single-stage radial centrifugal compressor for absolutely oilfree<br />

air supply. The turbo compressor featuring variable speed<br />

control for continuously variable power optimization according<br />

to the changes in inlet temperature, relative humidity and air<br />

demand.<br />

Fitted with:<br />

Integrated high speed electric motor<br />

Frequency converter<br />

Total oil-free magnetic bearings<br />

Blow-off valve<br />

Local control<br />

Continuous monitoring of key compressor parameters assuring<br />

reliable operation.<br />

Sound isolation enclosure [less than 81dBA]<br />

All mounted on a common base plate<br />

Accessories for inlet/outlet (as options)<br />

High Speed Electric motor<br />

Air cooled variable speed high frequency electric motor. The<br />

impeller and the motor cooling fan are mounted directly to the<br />

vertically mounted motor shaft that rotates on oil free magnetic<br />

bearings.<br />

Frequency Converter<br />

Internal frequency converter for variable motor speed control<br />

provides optimal efficiency at all operation conditions. Start-up<br />

with soft start function. Rfi-filter that filters the radio frequency<br />

interference emitted by the frequency converter.<br />

Impeller<br />

Semi open impeller design with 3 dimensional shaped blades,<br />

individually optimized for maximun efficiency over the entire<br />

design range of each compressor. Impeller shaped from a solid<br />

forged piece of DURAL Aluminium alloy on a numerical machining<br />

center using CAM technology.<br />

Magnetic Bearings<br />

Two radial bearings with 8 pole electro magnets each and two<br />

axial magnetic bearing with 2 pole electro magnets each with<br />

continuous rotor position measurement all controlled by active<br />

magnetic bearing controller that includes a Rfi-filter<br />

Features:<br />

No mechanical contact between surfaces<br />

No friction<br />

No wearing<br />

No oil lubrication<br />

Vibration free operation<br />

Continuous rotor balancing monitoring<br />

Compressor Control<br />

Connections:<br />

Analog and Digital I/O as standard<br />

Profibus or Modbus connection (as an option) To plant<br />

communication systems.<br />

Monitoring values:<br />

Alarm codes<br />

Fault codes<br />

Operation parameters<br />

Magnetic Bearing Controller MBC-12<br />

Remote control:<br />

Surveillance via modem (as an option)<br />

Flow Control<br />

The flow control of the HST Compressor is based on indirect<br />

flow measurement of header pressure or D.O. via the internal<br />

load-proportional signals of the frequency converter.<br />

∆p<br />

SL<br />

n<br />

n++<br />

n+<br />

n<br />

nMAX PMAX<br />

CL<br />

QV<br />

The limits for these signals<br />

are programmed in our application<br />

software (surge limit<br />

[SL], choke limit [CL], power<br />

limit [P max], speed limit [n max]<br />

and increasing speed [n]):<br />

The flow can be controlled between these limits by changing the<br />

speed of the motor. As both the outlet and inlet pressures are<br />

measured continuously, the operation point can always be kept<br />

within the limits even when the pressure ratio varies.<br />

Test Run<br />

Performance test and acceptance according to:<br />

ISO 5389<br />

VDI 2045<br />

ASME PTC 10<br />

These are performed on each turbocompressor before shipment.<br />

Directives<br />

Machinery Directive (MD), 89/392/EC<br />

Low voltage Directive (LVD), 73/23/EEC + 92/31/EEC<br />

Electromagnetic Compatibility (EMCD), 89/336/EEC<br />

+93/31/EEC + 93/68/EEC<br />

Product has been designed and manufactured to be connected<br />

to industrial network in accordance with EN61800-3 standard.<br />

(EMC product standard for adjustable speed electrical power<br />

drive system.)<br />

Air quality<br />

Chemical vapours IEC 721-3-3<br />

Mechanical particles IEC 721-3-3<br />

Chemical vapours Ave. / Max.<br />

according to IEC 721-3-3 PPM<br />

Sulphur dioxide 0.0003 / 0.001<br />

Hydrogen sulphur 0.0001 / 0.0005<br />

Chlorine 0.0001 / 0.0003<br />

Hydrogen chloride 0.0001 / 0.0005<br />

Hydrogen fluoride 0.00001 / 0.00003<br />

Ammonia 0.0001 / 0.003<br />

Ozone 0.00005 / 0.0001<br />

Nitrogen oxides 0.0005 / 0.001

Performance curve<br />

Compressor data<br />

<strong>S9000</strong>-1-L <strong>S9000</strong>-1-H<br />

Air flow range [SCFM] ~1362-6019 ~2091-5702<br />

Pressure rise [PSI] 5.8-9.4 8.7-12.3<br />

Max. noise level [dB(A)] 79 78<br />

Input power [Hp] 255 322<br />

Max. current [460V, 575V](A) 268, 214 339, 271<br />

Power supply [V] 460-575 460-575<br />

Auxiliary power [Hp] 1.34 1.34<br />

Auxiliary current [A] 10 10<br />

Auxiliary supply [V] 460-575 460-575<br />

Input frequency [Hz] 60 60<br />

Enclosures NEMA3R NEMA3R<br />

NEMA4 NEMA4 with FAC NEMA4 with FAC<br />

Thermal protection 2 x PT100 2 x PT100<br />

| <strong>ABS</strong> Group, Roskildevägen 1, Box 394, SE-201 23 Malmö, Sweden | Tel +46 40 35 04 00 | Fax +46 40 30 50 45 |<br />

| www.absgroup.com |<br />

2008-08-13 | We reserve the rights to alter specifications due to technical developments.