EIMCO Surface Aerators - CMS

EIMCO Surface Aerators - CMS

EIMCO Surface Aerators - CMS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>EIMCO</strong> <strong>Surface</strong> <strong>Aerators</strong><br />

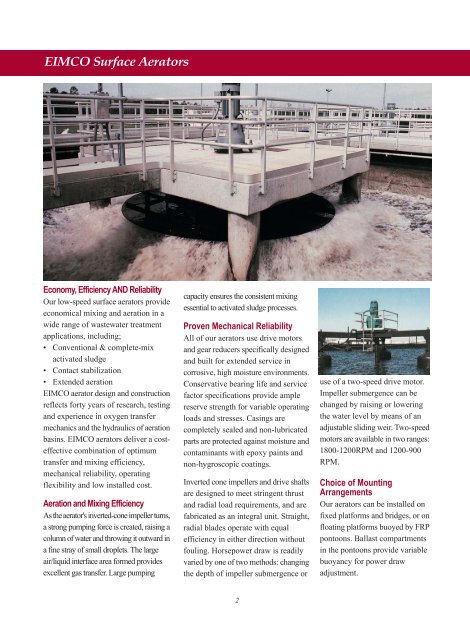

Economy, Efficiency AND Reliability<br />

Our low-speed surface aerators provide<br />

economical mixing and aeration in a<br />

wide range of wastewater treatment<br />

applications, including;<br />

• Conventional & complete-mix<br />

activated sludge<br />

• Contact stabilization<br />

• Extended aeration<br />

<strong>EIMCO</strong> aerator design and construction<br />

reflects forty years of research, testing<br />

and experience in oxygen transfer<br />

mechanics and the hydraulics of aeration<br />

basins. <strong>EIMCO</strong> aerators deliver a costeffective<br />

combination of optimum<br />

transfer and mixing efficiency,<br />

mechanical reliability, operating<br />

flexibility and low installed cost.<br />

Aeration and Mixing Efficiency<br />

As the aerator's inverted-cone impeller turns,<br />

a strong pumping force is created, raising a<br />

column of water and throwing it outward in<br />

a fine stray of small droplets. The large<br />

air/liquid interface area formed provides<br />

excellent gas transfer. Large pumping<br />

capacity ensures the consistent mixing<br />

essential to activated sludge processes.<br />

Proven Mechanical Reliability<br />

All of our aerators use drive motors<br />

and gear reducers specifically designed<br />

and built for extended service in<br />

corrosive, high moisture environments.<br />

Conservative bearing life and service<br />

factor specifications provide ample<br />

reserve strength for variable operating<br />

loads and stresses. Casings are<br />

completely sealed and non-lubricated<br />

parts are protected against moisture and<br />

contaminants with epoxy paints and<br />

non-hygroscopic coatings.<br />

Inverted cone impellers and drive shafts<br />

are designed to meet stringent thrust<br />

and radial load requirements, and are<br />

fabricated as an integral unit. Straight,<br />

radial blades operate with equal<br />

efficiency in either direction without<br />

fouling. Horsepower draw is readily<br />

varied by one of two methods: changing<br />

the depth of impeller submergence or<br />

2<br />

use of a two-speed drive motor.<br />

Impeller submergence can be<br />

changed by raising or lowering<br />

the water level by means of an<br />

adjustable sliding weir. Two-speed<br />

motors are available in two ranges:<br />

1800-1200RPM and 1200-900<br />

RPM.<br />

Choice of Mounting<br />

Arrangements<br />

Our aerators can be installed on<br />

fixed platforms and bridges, or on<br />

floating platforms buoyed by FRP<br />

pontoons. Ballast compartments<br />

in the pontoons provide variable<br />

buoyancy for power draw<br />

adjustment.