TERMS FOR AUTOMATIC TRANSMISSION REPAIR MANUAL

TERMS FOR AUTOMATIC TRANSMISSION REPAIR MANUAL

TERMS FOR AUTOMATIC TRANSMISSION REPAIR MANUAL

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

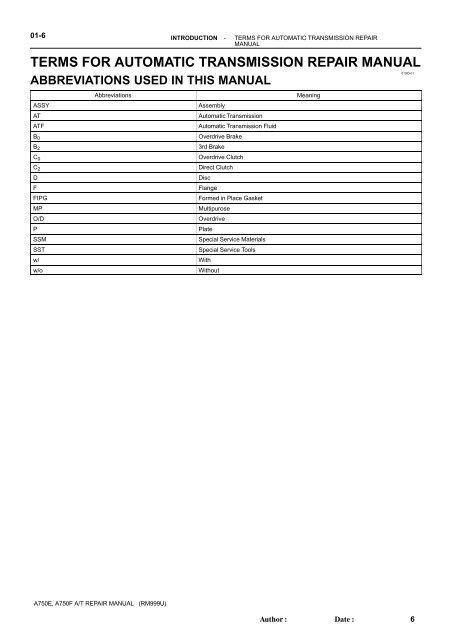

01-6 INTRODUCTION - <strong>TERMS</strong> <strong>FOR</strong> <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> <strong>REPAIR</strong><br />

<strong>MANUAL</strong><br />

<strong>TERMS</strong> <strong>FOR</strong> <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> <strong>REPAIR</strong> <strong>MANUAL</strong><br />

010ID-01<br />

ABBREVIATIONS USED IN THIS <strong>MANUAL</strong><br />

Abbreviations Meaning<br />

ASSY Assembly<br />

AT Automatic Transmission<br />

ATF Automatic Transmission Fluid<br />

B 0<br />

B 2<br />

C 0<br />

C 2<br />

D Disc<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

Overdrive Brake<br />

3rd Brake<br />

Overdrive Clutch<br />

Direct Clutch<br />

F Flange<br />

FIPG Formed in Place Gasket<br />

MP Multipurose<br />

O/D Overdrive<br />

P Plate<br />

SSM Special Service Materials<br />

SST Special Service Tools<br />

w/ With<br />

w/o Without<br />

Author: Date:<br />

6

6.4 (65, 57 in.⋅lbf)<br />

Lock Plate<br />

Straight Pin<br />

N⋅m (kgf⋅cm, ft⋅lbf) : Specified torque<br />

Non-reusable part<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANS - <strong>TRANSMISSION</strong> VALVE BODY ASSY (A750E/A750F)<br />

<strong>TRANSMISSION</strong> VALVE BODY ASSY (A750E/A750F)<br />

COMPONENTS<br />

Shift Solenoid<br />

Valve SLT<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

Shift Solenoid<br />

Valve SL2<br />

Straight<br />

Pin<br />

Shift Solenoid<br />

Valve SLU<br />

6.4 (65, 57 in.⋅lbf)<br />

Shift Solenoid<br />

Valve SL1<br />

6.4 (65, 57 in.⋅lbf)<br />

Lock Plate<br />

Straight<br />

Pin<br />

Shift Solenoid<br />

ValveSR<br />

Shift Solenoid<br />

Valve S1<br />

Author: Date:<br />

4007L-02<br />

6.4 (65, 57 in.⋅lbf)<br />

O-ring<br />

Shift Solenoid<br />

Valve S2<br />

40-77<br />

10 (100, 7)<br />

D27981<br />

96

40-56<br />

Snap Ring<br />

Reverse Clutch<br />

Return Spring<br />

Clutch Balancer No.3<br />

Clutch Plate<br />

Forward Clutch Flange<br />

Clutch Balancer No.1<br />

O-Ring<br />

Forward Clutch<br />

Return Spring<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANS - CLUTCH DRUM & INPUT SHAFT ASSY (A750E/A750F)<br />

CLUTCH DRUM & INPUT SHAFT ASSY (A750E/A750F)<br />

COMPONENTS<br />

Reverse Clutch Piston<br />

Shaft Snap Ring<br />

Direct Clutch Return Spring<br />

Direct Clutch Piston<br />

O-Ring<br />

Clutch Drum<br />

Hole Snap Ring<br />

Input Shaft Oil<br />

Seal Ring<br />

Reverse Clutch Flange<br />

Thrust Bearing Race<br />

Direct Clutch Disc<br />

Hole Snap Ring<br />

Clutch Disc<br />

Shaft Snap<br />

Ring<br />

Reverse Clutch Disc<br />

Clutch Plate<br />

Reverse Clutch Hub<br />

Thrust Needle Roller Bearing<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

O-Ring<br />

Clutch Plate<br />

Clutch Balance No.2<br />

40075-02<br />

Forward Clutch Piston<br />

Input Shaft<br />

Forward Clutch Hub<br />

Thrust Bearing<br />

Race No.2<br />

Thrust Needle Roller<br />

Bearing<br />

Clutch Hub (For Multiple Disc Clutch)<br />

Thrust Needle Roller Bearing<br />

Forward Clutch Flange<br />

Reverse Clutch Flange<br />

O-ring<br />

Clutch Drum Thrust<br />

Washer No.2<br />

Snap Ring<br />

Reverse Clutch Reaction Sleeve<br />

Clutch Cushion Plate<br />

Author: Date:<br />

D28526<br />

75

40-50<br />

Front<br />

Oil Pump<br />

Oil Seal<br />

Front Oil Pump Body<br />

N⋅m (kgf⋅cm, ft⋅lbf) : Specified torque<br />

Non-reusable part<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANS - OIL PUMP ASSY (A750E/A750F)<br />

OIL PUMP ASSY (A750E/A750F)<br />

COMPONENTS<br />

Front Oil Pump<br />

Drive Gear<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

Front Oil Pump<br />

Driven Gear<br />

Front Oil<br />

Pump Body<br />

O-ring<br />

Stator Shaft Assy<br />

Front Oil<br />

Pump Body<br />

O-ring<br />

× 14<br />

12 (122, 9)<br />

Author: Date:<br />

Clutch Drum<br />

Oil Seal Ring<br />

40073-02<br />

D27949<br />

69

40-2<br />

COMPONENTS<br />

A750# 4RUNNER<br />

O-Ring<br />

Automatic Transaxle Breather Tube<br />

O-Ring<br />

Park/Neutral Position Switch Assy<br />

Transmission Wire<br />

13 (130, 9)<br />

6.9 (70, 61 in.⋅lbf)<br />

Oil Cooler Union<br />

29 (296, 21)<br />

5.4 (55, 48 in.⋅lbf)<br />

Transmission<br />

Revolution<br />

Sensor<br />

Lock Washer<br />

34 (345, 25)<br />

x2<br />

x6<br />

5.4 (55, 48 in.⋅lbf)<br />

O-Ring<br />

O-Ring<br />

x2<br />

Transmission Revolution Sensor<br />

34 (345, 25)<br />

Automatic Transmission<br />

Housing<br />

57 (581, 42)<br />

Automatic Transaxle<br />

Breather Tube<br />

Transmission Case<br />

Adapter Adapter<br />

A750# 4RUNNER<br />

Transmission<br />

Control Shaft Lever<br />

LH<br />

x4<br />

34 (345, 25)<br />

Transmission Control<br />

Shaft Lever LH<br />

A750E 4RUNNER<br />

A750F 4RUNNER,GX470<br />

34 (345, 25)<br />

Automatic<br />

Transmission<br />

Extension Housing<br />

Oil Seal<br />

x4<br />

34 (345, 25)<br />

Transmission Case<br />

Adapter Oil Seal<br />

x4<br />

x2<br />

34 (345, 25)<br />

Extension Housing Assy<br />

Extension Housing<br />

Dust Deflector<br />

5.4 (55, 48 in.⋅lbf)<br />

N⋅m (kgf⋅cm, ft⋅lbf) : Specified torque Non-reusable part<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANS - <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> ASSY (A750E/A750F)<br />

O-Ring<br />

5.4 (55, 48 in.⋅lbf)<br />

5.4 (55, 48 in.⋅lbf)<br />

Transmission Case<br />

Adapter Adapter<br />

34 (345, 25)<br />

x4<br />

Washer<br />

16 (163, 12)<br />

x4<br />

Author: Date:<br />

34 (345, 25)<br />

400XJ-01<br />

Transmission Case<br />

Adapter Oil Seal<br />

D28807<br />

21

Manual Valve Lever<br />

Shaft Oil Seal<br />

Manual Valve<br />

Lever Shaft<br />

Transaxle Case Gasket<br />

Manual Valve<br />

Spacer<br />

Spring Pin<br />

C-1<br />

Spring<br />

Brake<br />

Drum Gasket<br />

Spring<br />

Lever Sub-assy<br />

Parking Lock<br />

Accumulator<br />

Valve<br />

C-2 Accumulator Piston<br />

Pawl Bracket B-3 Accumulator Piston<br />

Parking Lock Rod<br />

Spring<br />

O-Ring<br />

7.4 (75, 65 in.⋅lbf)<br />

Parking Lock Pawl<br />

Shaft E-Ring<br />

Parking Lock<br />

Pawl Shaft<br />

Parking Lock Pawl<br />

Torsion spring<br />

Parking Lock Pawl<br />

Automatic Transmission<br />

Oil Pan Gasket<br />

Automatic Transmission<br />

Oil Pan<br />

N⋅m (kgf⋅cm, ft⋅lbf) : Specified torque<br />

Non-reusable part<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANS - <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> ASSY (A750E/A750F)<br />

O-Ring<br />

Check Ball Body<br />

Oil<br />

Strainer<br />

O-Ring<br />

x19<br />

11 (110, 8)<br />

x20<br />

C-3 Accumulator Piston<br />

Transmission Valve<br />

Body Assy<br />

Valve Body Oil<br />

Strainer Assy<br />

10 (100, 7)<br />

Transmission Oil<br />

Cleaner Magnet<br />

Gasket<br />

Drain Plug<br />

4.4 (45, 39 in.⋅lbf)<br />

Author: Date:<br />

28 (285, 21)<br />

40-3<br />

D28808<br />

22

40-4<br />

Brake Flange No.3<br />

Oil Pump Assy<br />

21 (214, 15)<br />

Front Planetary Gear Assy<br />

1 Way Clutch<br />

Inner Race<br />

Brake Plate No.3<br />

Brake Disc No.3<br />

Thrust Bearing<br />

Race No.1<br />

O-Ring<br />

Thrust Needle<br />

Roller Bearing<br />

Thrust Bearing<br />

Race No.3<br />

1 Way Clutch Assy<br />

Flange<br />

2nd Brake piston<br />

Hole Snap Ring<br />

Clutch Drum & Input Shaft Assy<br />

Thrust Needle<br />

Roller Bearing<br />

N⋅m (kgf⋅cm, ft⋅lbf) : Specified torque<br />

Non-reusable part<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANS - <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> ASSY (A750E/A750F)<br />

Front Planetary<br />

Ring Gear<br />

Planetary Carrier<br />

Thrust Washer No.2<br />

CTR Planetary<br />

Ring Gear<br />

Brake Plate No.1<br />

Brake Flange No.1<br />

Front Planetary<br />

Ring Gear Flange<br />

2nd Brake<br />

Cylinder<br />

2nd Brake Piston<br />

Snap Ring<br />

2nd Brake Piston<br />

Planetary Carrier<br />

Thrust Washer No.1<br />

Front Planetary Ring<br />

Gear Shaft Snap Ring<br />

2nd Brake piston<br />

Snap Ring<br />

1 Way Clutch Assy No.2<br />

Clutch Drum<br />

Thrust Washer No.2<br />

Brake Disc No.1<br />

2nd Brake<br />

Piston O-Ring<br />

Author: Date:<br />

Brake No.3 Snap Ring<br />

Clutch Drum<br />

Thrust Washer<br />

D28810<br />

23

Snap Ring<br />

Brake Disc No.2<br />

1 Way Clutch<br />

Inner Race<br />

1 Way Clutch<br />

Assy No.3<br />

Brake Piston<br />

Return Spring No.2<br />

Thrust Bearing<br />

Race No.7<br />

Planetary Ring<br />

Gear Flange<br />

Brake Piston No.2<br />

Brake Piston<br />

No.2 O-Ring<br />

Brake Plate No.2<br />

Brake Flange No.2<br />

Brake Piston No.1<br />

O-Ring<br />

Brake Piston<br />

Return Spring<br />

Snap Ring<br />

Non-reusable part<br />

Brake Piston<br />

Return Spring<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANS - <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> ASSY (A750E/A750F)<br />

<br />

Brake Piston No.1<br />

Thrust Needle<br />

Roller Bearing<br />

Thrust Needle<br />

Roller Bearing<br />

Brake Cylinder No.2<br />

Intermediate Shaft<br />

Brake No.2 Snap Ring<br />

Brake Cylinder No.1<br />

Thrust Bearing<br />

Race No.8<br />

CTR Planetary<br />

Gear Assy<br />

Thrust Bearing<br />

Race No.4<br />

Author: Date:<br />

Planetary<br />

Sun Gear<br />

40-5<br />

D28811<br />

24

40-6<br />

1st & Reverse Brake Return<br />

Spring Shaft Snap Ring<br />

1st & Reverse Brake Piston<br />

Thrust Needle<br />

Roller Bearing<br />

1st & Reverse Brake<br />

Return Spring<br />

Sub-assy<br />

Brake Disc No.4<br />

Brake Reaction<br />

Sleeve<br />

Brake<br />

Reaction Sleeve<br />

Inner Ring<br />

Brake<br />

Reaction<br />

Sleeve Outer Ring<br />

1st & Reverse Brake<br />

Piston O-Ring<br />

Brake Plate No.4<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANS - <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> ASSY (A750E/A750F)<br />

Thrust Needle<br />

Roller Bearing<br />

Brake Piston No.4<br />

Brake Flange No.4<br />

Brake<br />

Piston No.4<br />

O-Ring<br />

Brake Plate<br />

Stopper Spring<br />

Rear Planetary<br />

Gear Assy<br />

A750E 4RUNNER<br />

Thrust Needle<br />

Roller Bearing<br />

Bearing Race<br />

Author: Date:<br />

Thrust Bearing<br />

Race No.9<br />

Snap Ring<br />

D28812<br />

25

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

INTRODUCTION - <strong>TERMS</strong> <strong>FOR</strong> <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> <strong>REPAIR</strong><br />

<strong>MANUAL</strong><br />

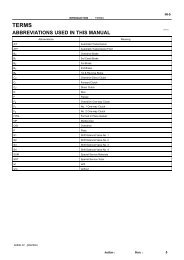

GLOSSARY OF SAE AND TOYOTA <strong>TERMS</strong><br />

This glossary lists all SAE-J1930 terms and abbreviations used in this manual in compliance with SAE recommendations,<br />

as well as their Toyota equivalents.<br />

SAE<br />

ABBREVIATIONS<br />

SAE <strong>TERMS</strong><br />

TOYOTA <strong>TERMS</strong><br />

( )--ABBREVIATIONS<br />

A/C Air Conditioning Air Conditioner<br />

ACL Air Cleaner Air Cleaner<br />

AIR Secondary Air Injection Air Injection (AI)<br />

AP Accelerator Pedal -<br />

B+ Battery Positive Voltage +B, Battery Voltage<br />

BARO Barometric Pressure -<br />

CAC Charge Air Cooler Inter cooler<br />

CARB Carburetor Carburetor<br />

CFI Continuous Fuel Injection -<br />

CKP Crankshaft Position Crank Angle<br />

CL Closed Loop Closed Loop<br />

CMP Camshaft position Cam Angle<br />

CPP Clutch Pedal Position -<br />

CTOX Continuous Trap Oxidizer -<br />

CTP Closed Throttle Potion -<br />

DFI Direct Fuel Injection (Diesel) Direct Injection (DI)<br />

DI Distributor Ignition -<br />

DLC1<br />

Data Link Connector 1<br />

1: Check Connector<br />

DLC2<br />

Data Link Connector 2<br />

2: Total Diagnosis Communication Link (TDCL)<br />

DLC3<br />

Data Link Connector 3<br />

3: OBD II Diagnostic Connector<br />

DTC Diagnostic Trouble Code Diagnostic Code<br />

DTM Diagnostic Test Mode -<br />

ECL Engine Control Level -<br />

ECM Engine Control Module Engine ECU (Electronic Control Unit)<br />

ECT Engine Control Temperature Coolant Temperature, Water Temperature (THW)<br />

EEPROM<br />

Electrically Erasable Programmable Read Only<br />

memory<br />

Electrically Erasable Programmable Read Only memory<br />

(EEPROM),<br />

Erasable Programmable Read Only memory (EPROM)<br />

EFE Early Fuel Evaporation Cold Mixture Heater (CMH), Heat Control Valve (HCV)<br />

EGR Exhaust Gas Recirculation Exhaust Gas Recirculation (EGR)<br />

EI Electronic Ignition Distributorless Ignition (DI)<br />

EM Engine Modification Engine Modification (EM)<br />

EPROM Erasable Programmable Read Only Memory Programmable Read Only Memory (PROM)<br />

EVAP Evaporative Emission Evaporative Emission Control (EVAP)<br />

FC Fan Control -<br />

FEEPROM<br />

Flash Electrically Erasable Programmable<br />

Read Only Memory<br />

-<br />

FEPROM Flash Erasable Programmable Read Only Memory -<br />

FF Flexible Fuel -<br />

FP Fuel Pump Fuel Pump<br />

GEN Generator Alternator<br />

GND Ground Ground (GND)<br />

HO2S Heated Oxygen Sensor Heated Oxygen Sensor (HO2S)<br />

IAC Idol Air Control Idol Speed Control (ISC)<br />

IAT Intake Air Temperature Intake or Inlet Air Temperature<br />

ICM Ignition Control Module -<br />

IFI Indirect Fuel Injection Indirect Injection<br />

IFS Inertia Fuel-Shutoff -<br />

Author: Date:<br />

01-7<br />

010IE-01<br />

7

01-8 INTRODUCTION - <strong>TERMS</strong> <strong>FOR</strong> <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> <strong>REPAIR</strong><br />

<strong>MANUAL</strong><br />

ISC Idle Speed Control -<br />

KS Knock Sensor Knock Sensor<br />

MAF Mass Air Flow Air Flow Meter<br />

MAP Manifold Absolute Pressure<br />

Manifold Pressure<br />

Intake Vacuum<br />

Electric Bleed Air Control Valve (EBCV)<br />

MC Mixture Control<br />

Mixture Control Valve (MCV)<br />

Electric Air Control Valve (EACV)<br />

MDP Manifold Differential Pressure -<br />

MFI Multiport Fuel Injection Electronic Fuel Injection (EFI)<br />

MIL Malfunction Indicator Lamp Check Engine Light<br />

MST Manifold Surface temperature -<br />

MVZ Manifold Vacuum Zone -<br />

NVRAM Non-Volatile Random Access Memory -<br />

O2S Oxygen Sensor Oxygen Sensor, O2 Sensor (O2S) OBD On-Board Diagnostic On-Board Diagnostic (OBD)<br />

OC Oxidation Catalytic Converter Oxidation Catalyst Converter (OC), CC0 OP Open Loop Open Loop<br />

PAIR Pulsed Secondary Air Injection Air Suction (AS)<br />

PCM Powertrain Control Module -<br />

PNP Park/Neutral Position -<br />

PROM Programmable Read Only Memory -<br />

PSP Power Steering Pressure -<br />

PTOX Periodic Trap Oxidizer<br />

Diesel Particulate Filter (DPF)<br />

Diesel Particulate Trap (DPT)<br />

RAM Random Access Memory Random Access Memory (RAM)<br />

RM Relay Module -<br />

ROM Read Only Memory Read Only Memory (ROM)<br />

RPM Engine Speed Engine Speed<br />

SC Supercharger Supercharger<br />

SCB Supercharger Bypass -<br />

SFI Sequential Multiport Fuel Injection Electronic Fuel Injection (EFI), Sequential Injection<br />

SPL Smoke Puff Limiter -<br />

SRI Service Reminder Indicator -<br />

SRT System Readiness Test -<br />

ST Scan Tool -<br />

TB Throttle Body Throttle Body<br />

TBI Throttle Body Fuel Injection<br />

Single Point Injection<br />

Central Fuel Injection (Ci)<br />

TC Turbocharger Turbocharger<br />

TCC Torque Converter Clutch Torque Converter<br />

TCM Transmission Control Module Transmission ECU (Electronic Control Unit)<br />

TP Throttle Position Throttle Position<br />

TR Transmission Range -<br />

TVV Thermal Vacuum Valve<br />

Bimetallic Vacuum Switching Valve (BVSV)<br />

Thermostatic Vacuum Switching Valve (TVSV)<br />

TWC Three-Way Catalytic Converter<br />

Three-Way Catalytic (TWC)<br />

CCRO TWC+OC Three-Way + Oxidation Catalytic Converter CCR + CCO VAF Volume Air Flow Air Flow Meter<br />

VR Voltage Regulator Voltage Regulator<br />

VSS Vehicle Speed Sensor Vehicle Speed Sensor (Read Switch Type)<br />

WOT Wide Open Throttle Full Throttle<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

Author: Date:<br />

8

WU-OC Warm Up Oxidation Catalytic Converter -<br />

INTRODUCTION - <strong>TERMS</strong> <strong>FOR</strong> <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> <strong>REPAIR</strong><br />

<strong>MANUAL</strong><br />

WU-TWC Warm Up Three-Way Catalytic Converter Manifold Converter<br />

3GR Third Gear -<br />

4GR Fourth Gear -<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

Author: Date:<br />

01-9<br />

9

6N<br />

8N<br />

10N<br />

11N<br />

12N<br />

Nut Type<br />

Present Standard<br />

Old Standard Hexagon Nut<br />

Hexagon Nut Cold Forging Nut Cutting Processed Nut<br />

No Mark<br />

No Mark (w/ Washer)<br />

SERVICE SPECIFICATIONS - STANDARD BOLT<br />

HOW TO DETERMINE NUT STRENGTH<br />

*: Nut with 1 or more marks on one side surface of the nut.<br />

No Mark (w/ Washer) No Mark<br />

*<br />

No Mark<br />

Class<br />

4N<br />

5N (4T)<br />

6N<br />

7N (5T)<br />

8N<br />

10N (7T)<br />

HINT:<br />

Use the nut with the same number of the nut strength classification or the greater than the bolt strength classification<br />

number when tightening parts with a bolt and nut.<br />

Example: Bolt = 4T<br />

Nut = 4N or more<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

Author: Date:<br />

11N<br />

12N<br />

03-3<br />

0313Q-01<br />

B06432<br />

15

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

Hexagon Head Bolt<br />

Normal Recess Bolt Deep Recess Bolt<br />

No Mark<br />

w/ Washer<br />

SERVICE SPECIFICATIONS - STANDARD BOLT<br />

STANDARD BOLT<br />

HOW TO DETERMINE BOLT STRENGTH<br />

No Mark<br />

w/ Washer<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

Bolt Type<br />

Stud Bolt Weld Bolt<br />

No Mark<br />

Author: Date:<br />

Class<br />

4T<br />

5T<br />

6T<br />

7T<br />

8T<br />

9T<br />

10T<br />

11T<br />

03-1<br />

0313O-01<br />

B06431<br />

13

INTRODUCTION - HOW TO USE THIS <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong><br />

<strong>REPAIR</strong> <strong>MANUAL</strong><br />

HOW TO USE THIS <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> <strong>REPAIR</strong><br />

<strong>MANUAL</strong><br />

GENERAL IN<strong>FOR</strong>MATION<br />

1. GENERAL DESCRIPTION<br />

(a) This manual was created in accordance with SAE J2008.<br />

(b) Generally repair operations can be separated in the following 3 main processes:<br />

1. Diagnosis<br />

2. Removing and Installing, Replacing, Disassembling, Installing and Checking, Adjusting<br />

3. Final Inspection<br />

(c) This manual explains” Removing and Installing, Replacing, Disassembling, Instaling and Checking,<br />

Adjusting”, but” Final inspection” is omitted.<br />

(d) The following essential operations are not written in this manual, however these operations must be<br />

done in the practical situation.<br />

(1) Operation with a jack or lift<br />

(2) Cleaning of a removed part if necessary<br />

(3) Visual check<br />

2. INDEX<br />

(a) An alphabetical INDEX is provided as a section on the end of the book to guide you to the item to be<br />

repaired.<br />

3. PREPARATION<br />

(a) Use of special service tools (SST) and special service materials (SSM) may be required, depending<br />

on the repairing condition. Be sure to use SST and SSM when they are required and follow the working<br />

procedure properly. A list of SST and SSM is in the Preparation section in this manual.<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

Author: Date:<br />

01-1<br />

010IB-01<br />

1

01-2 INTRODUCTION - HOW TO USE THIS <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong><br />

<strong>REPAIR</strong> <strong>MANUAL</strong><br />

4. <strong>REPAIR</strong> PROCEDURES<br />

(a) Component drawing is placed as the section or title if necessary.<br />

(b) Illustrations of the parts catalog are placed as the” disassembled parts drawing” so that it enables you<br />

to understand the fitting condition of the components.<br />

(c) Non-reusable parts, grease applied parts, precoated parts and torque are specified in the components<br />

drawing.<br />

Example:<br />

Oil Seal<br />

N·m (kgf·cm, ft·lbf)<br />

Non-reusable part<br />

: Specified torque<br />

Oil Pump Drive Gear<br />

O-Ring<br />

Oil Pump Driven Gear<br />

Stator Shaft Assy<br />

x13<br />

10 (100, 7)<br />

Oil Seal Ring<br />

(d) Torque, oil applying position, and non-reusable parts are described as important points in the procedure.<br />

NOTICE:<br />

There are cases where such information can only be indicated by an illustration. In those cases, all<br />

the information such as torque, oil, etc. is described in the illustration.<br />

(e) Installing procedure of operation item is performed in the reverse order of the removal, and only the<br />

important points are described.<br />

(f) Only items with points are described in the procedure, and the operational portion and content are<br />

placed using an illustration. In the explanations, details of the operational method, standard value and<br />

notice are placed.<br />

(g) There may be cases where the illustrations of similar models are used. In those cases, the details may<br />

be different from the actual vehicle.<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

Author: Date:<br />

D25697<br />

2

Illustration:<br />

what to do and where<br />

SST<br />

INTRODUCTION - HOW TO USE THIS <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong><br />

<strong>REPAIR</strong> <strong>MANUAL</strong><br />

(h) The procedures are presented in a step-by-step format:<br />

(1) The illustration shows what to do and where to do.<br />

(2) The task heading tells what to do.<br />

(3) The detailed text tells how to perform the task and gives other information such as specifications<br />

and warnings.<br />

Example:<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

Set part No.<br />

Task heading: what to do<br />

87. INSTALL FR DIFFERENTIAL CASE FRONT TAPERED<br />

ROLLER BEARING<br />

(a) Using SST and a press, install the front differential case<br />

tapered roller bearing front inner race to the differential<br />

case.<br />

SST 09316-60011 (09316-00011)<br />

Component part No.<br />

Author: Date:<br />

01-3<br />

Detailed text:<br />

how to do task<br />

HINT:<br />

This format provides an experienced technician with a FAST TRACK to the necessary information. The task<br />

heading can be read at a glance when necessary, and the text below provides detailed information. Important<br />

specifications and warnings always stand out in bold type.<br />

5. SERVICE SPECIFICATIONS<br />

(a) Specifications are presented in bold type throughout the manual. You never have to leave the procedure<br />

to look up your specifications. The specifications are also found in the Service Specifications section<br />

for a quick reference.<br />

6. <strong>TERMS</strong> DEFINITION<br />

CAUTION Indicate the possibility of injury to you or other people.<br />

NOTICE Indicate the possibility of damage to the components being repaired.<br />

HINT Provide additional information to help you perform the repair efficiently.<br />

7. SI UNIT<br />

(a) The UNITS used in this manual are primarily expressed according to the SI UNIT (International System<br />

of Unit), and alternately expressed in the metric system and in the English System.<br />

Example:<br />

Torque: 30 N⋅m (310 kgf⋅cm, 22 ft⋅lbf)<br />

D27528<br />

3

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANS - <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> ASSY (A750E/A750F)<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> ASSY (A750E/A750F)<br />

PRECAUTION<br />

NOTICE:<br />

The automatic transmission is composed of highly precision-finished parts, necessitating<br />

careful inspection before reassembly because even a small nick could cause fluid leakage or<br />

affect the performance. The instructions here are organized so that you work on only one component<br />

group at a time. This will help avoid confusion from similar-looking parts of different<br />

sub-assemblies being on your workbench at the same time. The component groups are inspected<br />

and repaired from the converter housing side. As much as possible, complete the inspection,<br />

repair and reassembly before proceeding to the next component group. If a defect is<br />

found in a certain component group during reassembly, inspect and repair this group immediately.<br />

If a component group cannot be assembled because parts are being ordered, be sure to<br />

keep all parts of the group in a separate container while proceeding with disassembly, inspection,<br />

repair and reassembly of other component groups.<br />

Recommended ATF: T-IV<br />

All disassembled parts should be washed clean, and any fluid passages and holes should be<br />

blown through with compressed air.<br />

Dry all parts with compressed air-never use shop rags.<br />

When using compressed air, always aim away from yourself to prevent accidentally spraying<br />

ATF or kerosene on your face.<br />

The recommended automatic transmission fluid or kerosene should be used for cleaning.<br />

After cleaning, the parts should be arranged in the correct order for efficient inspection, repairs,<br />

and reassembly.<br />

When disassembling a valve body, be sure to match each valve together with the corresponding<br />

spring.<br />

New discs for the brakes and clutches that are to be used for replacement must be soaked in<br />

ATF for at least 15 minutes before reassembly.<br />

All oil seal rings, clutch discs, clutch plates, rotating parts, and sliding surfaces should be<br />

coated with ATF prior to reassembly.<br />

All gaskets and rubber O-rings should be replaced.<br />

Do not apply adhesive cements to gaskets and similar parts.<br />

Make sure that the ends of a snap ring are not aligned with one of the cutouts and are installed<br />

in the groove correctly.<br />

If a worn bushing is to be replaced, the sub-assembly containing the bushing must also be replaced.<br />

Check thrust bearings and races for wear or damage. Replace if necessary.<br />

Use petroleum jelly to keep parts in place.<br />

When working with FIPG material, you must follow the below.<br />

Using a razor blade and a gasket scraper, remove all the old packing (FIPG) material from the<br />

gasket surface.<br />

Thoroughly clean all components to remove all the loose material.<br />

Clean both sealing surfaces with a non-residue solvent.<br />

Parts must be reassembled within 10 minutes of application. Otherwise, the packing (FIPG) material<br />

must be removed and reapplied.<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

Author: Date:<br />

40-1<br />

4007T-04<br />

20

01-4 INTRODUCTION - <strong>REPAIR</strong> INSTRUCTION <strong>FOR</strong> <strong>AUTOMATIC</strong><br />

<strong>TRANSMISSION</strong> <strong>REPAIR</strong> <strong>MANUAL</strong><br />

<strong>REPAIR</strong> INSTRUCTION <strong>FOR</strong> <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong><br />

<strong>REPAIR</strong> <strong>MANUAL</strong><br />

PRECAUTION<br />

1. BASIC <strong>REPAIR</strong> HINT<br />

(a) PRECOATED PARTS<br />

(1) Precoated parts are bolts, nuts, etc. that are coated<br />

with a seal lock adhesive at the factory.<br />

(2) If a precoated part is retightened, loosened or<br />

caused to move in any way, it must be recoated with<br />

the specified adhesive.<br />

Seal Lock Adhesive<br />

(3) When reusing precoated parts, clean off the old<br />

adhesive and dry with compressed air. Then apply<br />

Z11554<br />

the specified seal lock adhesive to the bolt, nut or<br />

threads.<br />

NOTICE:<br />

Do the torque checking with the lower limit value of the torque tolerance.<br />

(4) Depending on the seal lock agent to apply, there may be a case where it is necessary to leave<br />

it for a specified time until it hardens.<br />

(b) GASKETS<br />

When necessary, use a sealer on gaskets to prevent leaks.<br />

(c) BOLTS, NUTS AND SCREWS<br />

Carefully observe all specifications for bolt tightening torques. Always use a torque wrench.<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

Author: Date:<br />

010IC-01<br />

4

L1 L2<br />

L1<br />

L2<br />

L1<br />

L2<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

INTRODUCTION - <strong>REPAIR</strong> INSTRUCTION <strong>FOR</strong> <strong>AUTOMATIC</strong><br />

<strong>TRANSMISSION</strong> <strong>REPAIR</strong> <strong>MANUAL</strong><br />

D02612<br />

D01201<br />

D01202<br />

Author: Date:<br />

01-5<br />

(d) TORQUE WHEN USING EXTENSION TOOL WITH<br />

TORQUE WRENCH<br />

(1) In case of tightening by extending the entire length<br />

of the torque wrench combined with SST or tool, if<br />

you tighten until the reading of the torque wrench<br />

reached the specified torque value, the actual<br />

torque becomes excessive.<br />

(2) In this text, only the specified torque is described.<br />

In case of using SST or extension tool, find the reading<br />

of the torque wrench by the formula.<br />

(3) Formula T’=T x L2/(L1 + L2)<br />

T’ Reading of torque wrench {N⋅m (kgf⋅cm, ft⋅lbf)}<br />

T Torque {N⋅m (kgf⋅cm, ft⋅lbf)}<br />

L1 Length of SST or tool (cm)<br />

L2 Length of torque wrench (cm)<br />

5

03-4<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

SERVICE SPECIFICATIONS - <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANSAXLE<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANSAXLE<br />

SERVICE DATA<br />

OIL PUMP<br />

Body clearance STD<br />

Maximum<br />

Tip clearance STD<br />

Maximum<br />

Side clearance STD<br />

Maximum<br />

Driver and driven gear thickness 0<br />

1<br />

2<br />

3<br />

4<br />

0.10 - 0.17 mm (0.0039 - 0.0067 in.)<br />

0.17 mm (0.0067 in.)<br />

0.070 - 0.150 mm (0.0028 - 0.0059 in.)<br />

0.150 mm (0.0059 in.)<br />

0.02 - 0.05 mm (0.0008 - 0.0020 in.)<br />

0.05 mm (0.0020 in.)<br />

10.740 - 10.749 mm (0.4228 - 0.4232 in.)<br />

10.750 - 10.759 mm (0.4232 - 0.4236 in.)<br />

10.760 - 10.770 mm (0.4236 - 0.4240 in.)<br />

10.771 - 10.780 mm (0.4241 - 0.4244 in.)<br />

10.781 - 10.790 mm (0.4244 - 0.4248 in.)<br />

Pump body bushing inside diameter Maximum 38.188 mm (1.504 in.)<br />

Stator shaft bushing inside diameter (Front side) Maximum<br />

(Rear side) Maximum<br />

2nd BRAKE<br />

21.577 mm (0.850 in.)<br />

32.08 mm (1.263 in.)<br />

Piston return spring free length STD 15.72 mm (0.619 in.)<br />

B3 BRAKE<br />

Piston stroke 0.42 - 0.72 mm (0.017 - 0.028 in.)<br />

Flange thickness No. 0<br />

No. 1<br />

No. 2<br />

No. 3<br />

FRONT PLANETARY GEAR<br />

2.0 mm (0.079 in.)<br />

2.2 mm (0.087 in.)<br />

2.4 mm (0.094 in.)<br />

2.6 mm (0.102 in.)<br />

Planetary gear bushing inside diameter Maximum 57.48 mm (2.263 in.)<br />

Planetary pinion gear thrust clearance STD<br />

Maximum<br />

BRAKE PISTON No.1<br />

0.2 - 0.6 mm (0.008 - 0.024 in.)<br />

0.65 mm (0.026 in.)<br />

Piston return spring free length STD 17.05 mm (0.671 in.)<br />

CENTER PLANETARY GEAR<br />

Planetary pinion gear thrust clearance STD<br />

Maximum<br />

B2 BRAKE<br />

0.12 - 0.68 mm (0.005 - 0.027 in.)<br />

0.73 mm (0.029 in.)<br />

Piston return spring free length STD 17.45 mm (0.687 in.)<br />

RR PLANETARY RING GEAR FLANGE<br />

Planetary ring gear flange bushing inside diameter Maximum 32.175 mm (1.267 in.)<br />

INTERMEDIATE SHAFT<br />

Intermediate shaft run out Maximum 0.08 mm (0.003 in.)<br />

Intermediate shaft diameter STD A:<br />

B:<br />

C:<br />

D:<br />

Min A:<br />

B:<br />

C:<br />

D:<br />

25.962 - 25.975 mm (1.022 - 1.023 in.)<br />

25.962 - 25.975 mm (1.022 - 1.023 in.)<br />

32.062 - 32.075 mm (1.262 - 1.263 in.)<br />

32.062 - 32.075 mm (1.262 - 1.263 in.)<br />

25.912 mm (1.020 in.)<br />

25.912 mm (1.020 in.)<br />

32.012 mm (1.260 in.)<br />

32.012 mm (1.260 in.)<br />

Author: Date:<br />

0305W-03<br />

16

REAR PLANETARY GEAR<br />

Planetary pinion gear thrust clearance STD<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

SERVICE SPECIFICATIONS - <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANSAXLE<br />

Maximum<br />

0.2 - 0.6 mm (0.008 - 0.024 in.)<br />

0.65 mm (0.026 in.)<br />

Planetary gear bushing inside diameter Maximum 20.075 mm (0.790 in.)<br />

1ST & REVERSE BRAKE<br />

Pack clearance 0.8 - 1.1 mm (0.032 - 0.043 in.)<br />

Piston return spring free length STD 23.74 mm (0.935 in.)<br />

H thickness No. 0<br />

No. 2<br />

No. 4<br />

No. 6<br />

No. 8<br />

No. 10<br />

No. 12<br />

No. 14<br />

DIRECT CLUTCH<br />

0 mm (0 in.)<br />

0.2 mm (0.00787 in.)<br />

0.4 mm (0.01575 in.)<br />

0.6 mm (0.02362 in.)<br />

0.8 mm (0.03150 in.)<br />

1.0 mm (0.03937 in.)<br />

1.2 mm (0.04724 in.)<br />

1.4 mm (0.05512 in.)<br />

Pack clearance 0.50 - 0.80 mm (0.020 - 0.032 in.)<br />

Clutch piston return spring free length STD 19.51 mm (0.768 in.)<br />

Flange thickness No. 0<br />

No. 1<br />

No. 2<br />

No. 3<br />

No. 4<br />

No. 5<br />

No. 6<br />

No. 7<br />

No. 8<br />

REVERSE CLUTCH<br />

Reverse clutch drum bushing inside diameter STD<br />

Maximum<br />

3.0 mm (0.118 in.)<br />

3.1 mm (0.122 in.)<br />

3.2 mm (0.126 in.)<br />

3.3 mm (0.130 in.)<br />

3.4 mm (0.134 in.)<br />

3.5 mm (0.138 in.)<br />

3.6 mm (0.142 in.)<br />

3.7 mm (0.146 in.)<br />

3.8 mm (0.150 in.)<br />

35.812 - 35.837 mm (1.4099 - 1.4109 in.)<br />

35.887 mm (1.4129 in.)<br />

Pack clearance 0.50 - 0.80 mm (0.020 - 0.032 in.)<br />

Clutch piston return spring free length STD 21.04 mm (0.828 in.)<br />

Flange thickness No. 0<br />

No. 1<br />

No. 2<br />

No. 3<br />

No. 4<br />

No. 5<br />

No. 6<br />

No. 7<br />

No. 8<br />

No. 9<br />

No. A<br />

<strong>FOR</strong>WARD CLUTCH<br />

Forward clutch drum bushing inside diameter STD<br />

Maximum<br />

2.8 mm (0.110 in.)<br />

2.9 mm (0.114 in.)<br />

3.0 mm (0.118 in.)<br />

3.1 mm (0.122 in.)<br />

3.2 mm (0.126 in.)<br />

3.3 mm (0.130 in.)<br />

3.4 mm (0.134 in.)<br />

3.5 mm (0.138 in.)<br />

3.6 mm (0.142 in.)<br />

3.7 mm (0.146 in.)<br />

3.8 mm (0.150 in.)<br />

26.037 - 26.062 mm (1.0251 - 1.0261 in.)<br />

26.112 mm (1.028 in.)<br />

Pack clearance 0.60 - 0.90 mm (0.0236 - 0.0354 in.)<br />

Author: Date:<br />

03-5<br />

17

03-6<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

SERVICE SPECIFICATIONS - <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANSAXLE<br />

Clutch piston return spring free length STD 26.74 mm (1.053 in.)<br />

Flange thickness No. 0<br />

OUTPUT SHAFT BEARING (A750E)<br />

No. 1<br />

No. 2<br />

No. 3<br />

No. 4<br />

No. 5<br />

No. 6<br />

No. 7<br />

No. 8<br />

No. 9<br />

No. A<br />

3.0 mm (0.118 in.)<br />

3.1 mm (0.122 in.)<br />

3.2 mm (0.126 in.)<br />

3.3 mm (0.130 in.)<br />

3.4 mm (0.134 in.)<br />

3.5 mm (0.138 in.)<br />

3.6 mm (0.142 in.)<br />

3.7 mm (0.146 in.)<br />

3.8 mm (0.150 in.)<br />

3.9 mm (0.154 in.)<br />

4.0 mm (0.158 in.)<br />

Clearance 0.05 - 0.33 mm (0.002 - 0.013 in.)<br />

Flange thickness No. 1<br />

No. 2<br />

No. 3<br />

No. 4<br />

No. 5<br />

No. 6<br />

ACCUMULATOR<br />

Spring<br />

Free length/Outer diameter<br />

3.7 mm (0.146 in.)<br />

3.8 mm (0.150 in.)<br />

3.9 mm (0.154 in.)<br />

4.0 mm (0.158 in.)<br />

4.1 mm (0.161 in.)<br />

4.2 mm (0.165 in.)<br />

mm (in.)<br />

B 3 70.5 (2.776) / 19.7 (0.776) Purple<br />

C 2 62.0 (2.441) / 15.9 (0.626) White<br />

C 1 inner 30.4 (1.197) / 11.4 (0.449) Pink<br />

Color<br />

outer 48.76 (1.920) / 16.6 (0.654) Light green<br />

C 3 inner 44.0 (1.732) / 14.0 (0.551) Yellow<br />

outer 73.35 (2.888) / 19.9 (0.784) Red<br />

Author: Date:<br />

18

0313P-01<br />

03-2<br />

-<br />

SERVICE SPECIFICATIONS STANDARD BOLT<br />

14<br />

Author: Date:<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

SPECIFIED TORQUE <strong>FOR</strong> STANDARD BOLTS<br />

Specified torque<br />

Class<br />

Diameter<br />

mm<br />

Pitch<br />

mm<br />

Hexagon head bolt Hexagon flange bolt<br />

Class<br />

mm mm<br />

N·m kgf·cm ft·lbf N·m kgf·cm ft·lbf<br />

4T<br />

6<br />

8<br />

10<br />

12<br />

14<br />

16<br />

1<br />

1.25<br />

1.25<br />

1.25<br />

1.5<br />

1.5<br />

5<br />

12.5<br />

26<br />

47<br />

74<br />

115<br />

55<br />

130<br />

260<br />

480<br />

760<br />

1,150<br />

48 in.·lbf<br />

9<br />

19<br />

35<br />

55<br />

83<br />

6<br />

14<br />

29<br />

53<br />

84<br />

-<br />

60<br />

145<br />

290<br />

540<br />

850<br />

-<br />

52 in.·lbf<br />

10<br />

21<br />

39<br />

61<br />

-<br />

5T<br />

6<br />

8<br />

10<br />

12<br />

14<br />

16<br />

1<br />

1.25<br />

1.25<br />

1.25<br />

1.5<br />

1.5<br />

6.5<br />

15.5<br />

32<br />

59<br />

91<br />

140<br />

65<br />

160<br />

330<br />

600<br />

930<br />

1,400<br />

56 in.·lbf<br />

12<br />

24<br />

43<br />

67<br />

101<br />

7.5<br />

17.5<br />

36<br />

65<br />

100<br />

-<br />

75<br />

175<br />

360<br />

670<br />

1,050<br />

-<br />

65 in.·lbf<br />

13<br />

26<br />

48<br />

76<br />

-<br />

6T<br />

6<br />

8<br />

10<br />

12<br />

14<br />

16<br />

1<br />

1.25<br />

1.25<br />

1.25<br />

1.5<br />

1.5<br />

8<br />

19<br />

39<br />

71<br />

110<br />

170<br />

80<br />

195<br />

400<br />

730<br />

1,100<br />

1,750<br />

69 in.·lbf<br />

14<br />

29<br />

53<br />

80<br />

127<br />

9<br />

21<br />

44<br />

80<br />

125<br />

-<br />

90<br />

210<br />

440<br />

810<br />

1,250<br />

-<br />

78 in.·lbf<br />

15<br />

32<br />

59<br />

90<br />

-<br />

7T<br />

6<br />

8<br />

10<br />

12<br />

14<br />

16<br />

1<br />

1.25<br />

1.25<br />

1.25<br />

1.5<br />

1.5<br />

10.5<br />

25<br />

52<br />

95<br />

145<br />

230<br />

110<br />

260<br />

530<br />

970<br />

1,500<br />

2,300<br />

8<br />

19<br />

38<br />

70<br />

108<br />

166<br />

12<br />

28<br />

58<br />

105<br />

165<br />

-<br />

120<br />

290<br />

590<br />

1,050<br />

1,700<br />

-<br />

9<br />

21<br />

43<br />

76<br />

123<br />

-<br />

8T<br />

8<br />

10<br />

12<br />

1.25<br />

1.25<br />

1.25<br />

29<br />

61<br />

110<br />

300<br />

620<br />

1,100<br />

22<br />

45<br />

80<br />

33<br />

68<br />

120<br />

330<br />

690<br />

1,250<br />

24<br />

50<br />

90<br />

9T<br />

8<br />

10<br />

12<br />

1.25<br />

1.25<br />

1.25<br />

34<br />

70<br />

125<br />

340<br />

710<br />

1,300<br />

25<br />

51<br />

94<br />

37<br />

78<br />

140<br />

380<br />

790<br />

1,450<br />

27<br />

57<br />

105<br />

10T<br />

8<br />

10<br />

12<br />

1.25<br />

1.25<br />

1.25<br />

38<br />

78<br />

140<br />

390<br />

800<br />

1,450<br />

28<br />

58<br />

105<br />

42<br />

88<br />

155<br />

430<br />

890<br />

1,600<br />

31<br />

64<br />

116<br />

11T<br />

8<br />

10<br />

12<br />

1.25<br />

1.25<br />

1.25<br />

42<br />

87<br />

155<br />

430<br />

890<br />

1,600<br />

31<br />

64<br />

116<br />

47<br />

97<br />

175<br />

480<br />

990<br />

1,800<br />

35<br />

72<br />

130

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

PREPARATION - <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANSAXLE<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANSAXLE<br />

PREPARATION<br />

SST<br />

Author: Date:<br />

02-1<br />

021YU-01<br />

09223-15020 Oil Seal & Bearing Replacer <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong><br />

ASSY(A750E/A750F)<br />

09226-10010<br />

Crankshaft Front & Rear Bearing<br />

Replacer<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong><br />

ASSY(A750E/A750F)<br />

09308-00010 Oil Seal Puller <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong><br />

ASSY(A750E/A750F)<br />

09320-89010<br />

Transfer Clutch Spring<br />

Compressor<br />

CLUTCH DRUM & INPUT SHAFT<br />

ASSY(A750E/A750F)<br />

09350-30020 TOYOTA Automatic Transmission<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong><br />

Tool Set<br />

ASSY(A750E/A750F)<br />

OIL PUMP ASSY(A750E/A750F)<br />

CLUTCH DRUM & INPUT SHAFT<br />

ASSY(A750E/A750F)<br />

(09350-07020) Oil Pump Puller <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong><br />

ASSY(A750E/A750F)<br />

(09350-07040) No.2 Piston Spring Compressor CLUTCH DRUM & INPUT SHAFT<br />

ASSY(A750E/A750F)<br />

(09350-07050) No.3 Piston Spring Compressor <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong><br />

ASSY(A750E/A750F)<br />

(09350-07060) No.1 Snap Ring Expander <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong><br />

ASSY(A750E/A750F)<br />

(09350-07070) No.2 Snap Ring Expander <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong><br />

ASSY(A750E/A750F)<br />

CLUTCH DRUM & INPUT SHAFT<br />

ASSY(A750E/A750F)<br />

(09350-07080) Brake Reaction Sleeve Puller <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong><br />

ASSY(A750E/A750F)<br />

(09350-07090) Brake No.1 Piston Puller <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong><br />

ASSY(A750E/A750F)<br />

10

02-2<br />

Recomended Tools<br />

Equipment<br />

Feeler gauge<br />

Cylinder Gauge<br />

Vernier calipers<br />

Dial indicator<br />

Micrometer<br />

Feeler gauge<br />

Straight edge<br />

Torque wrench<br />

Angle gauge<br />

V block<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

PREPARATION - <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANSAXLE<br />

(09350-071 10) Oil Seal Replacer <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong><br />

ASSY(A750E/A750F)<br />

(09351-32140) Oil Seal Replacer OIL PUMP ASSY(A750E/A750F)<br />

09387-00070 First & Reverse Brake Wrench CLUTCH DRUM & INPUT SHAFT<br />

ASSY(A750E/A750F)<br />

09710-30050 Suspension Arm Bushing Replacer <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong><br />

ASSY(A750E/A750F)<br />

09950-70010 Handle Set <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong><br />

ASSY(A750E/A750F)<br />

(09951-07100) Handle 100 <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong><br />

ASSY(A750E/A750F)<br />

09031-00030 Pin Punch <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong><br />

ASSY(A750E/A750F)<br />

Author: Date:<br />

11

Lubricant<br />

Automatic transmission fluid<br />

(LAND CRUISER/ LX470)<br />

Dry fill (2UZ-FE w oil cooler)<br />

Drain and refill (2UZ-FE w oil cooler)<br />

Automatic transmission fluid<br />

(LAND CRUISER)<br />

Dry fill (1HD-FTE w oil cooler)<br />

Drain and refill (1HD-FTE w oil cooler)<br />

Automatic transmission fluid<br />

(LAND CRUISER/ LX470)<br />

Dry fill (2UZ-FE w/o oil cooler)<br />

Drain and refill (2UZ-FE w/o oil cooler)<br />

Automatic transmission fluid<br />

(LAND CRUISER)<br />

Dry fill (1HD-FTE w/o oil cooler)<br />

Drain and refill<br />

(1HD-FTE w/o oil cooler)<br />

Automatic transmission fluid<br />

(4RUNNER,GX470)<br />

Dry fill<br />

Drain and refill<br />

SSM (Special Service Materials)<br />

08826-00090<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

PREPARATION - <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANSAXLE<br />

11.6 liters (12.3 US qts, 10.2 Imp. qts)<br />

3.0 liters (3.2 US qts, 2.6 Imp. qts)<br />

12.1 liters (12.8 US qts, 10.6 Imp. qts)<br />

3.0 liters (3.2 US qts, 2.6 Imp. qts)<br />

10.8 liters (11.4 US qts, 9.5 Imp. qts)<br />

3.0 liters (3.2 US qts, 2.6 Imp. qts)<br />

11.4 liters (12.0 US qts, 10.0 Imp. qts)<br />

3.0 liters (3.2 US qts, 2.6 Imp. qts)<br />

11.1 liters (11.7 US qts, 9.8 Imp. qts)<br />

3.0 liters (3.2 US qts, 2.6 Imp. qts)<br />

”Seal Packing 1281,”<br />

THREE BOND 1281 or equivalent<br />

(FIPG)<br />

Author: Date:<br />

ATF TYPE T-IV or equivalent<br />

ATF TYPE T-IV or equivalent<br />

ATF TYPE T-IV or equivalent<br />

ATF TYPE T-IV or equivalent<br />

ATF TYPE T-IV or equivalent<br />

02-3<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong><br />

ASSY(A750E/A750F)<br />

12

TORQUE SPECIFICATION<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

SERVICE SPECIFICATIONS - <strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANSAXLE<br />

Part tightened N·m kgf·cm ft·lbf<br />

Transmission housing x Transmission case 14 mm 34 345 25<br />

17 mm 57 581 42<br />

Automatic transaxle breather tube x Transmission case 5.4 55 48 in.·lbf<br />

Park/Neutral position osition switch assy Bolt<br />

13 130 9<br />

Nut 6.9 70 61 in.·lbf<br />

Transmission wire x Transmission case 5.4 55 48 in.·lbf<br />

Oil cooler tube union x Transmission case 29 296 21<br />

Transmission control shaft lever LH 16 163 12<br />

Transmission revolution sensor x Transmission case 5.4 55 48 in.·lbf<br />

Extension housing assy x Transmission case (A750E) 34 345 25<br />

Transmission case adapter adapter x Transmission case (A750F) 34 345 25<br />

Oil pan x Transmission case 4.4 45 39 in.·lbf<br />

Valve body oil strainer assy x Transmission valve body assy 10 100 7<br />

Transmission valve body assy x Transmission case 11 110 8<br />

Parking lock pawl bracket x Transmission case 7.4 75 65 in.·lbf<br />

Drain plug 28 285 21<br />

Oil pump x Transmission case 21 214 15<br />

Oil pump body x Stator shaft assy 12 122 9<br />

Lock plate x Transmission valve body assy 6.4 65 57 in.·lbf<br />

Shift solenoid valve SR x Transmission valve body assy 6.4 65 57 in.·lbf<br />

Shift solenoid valve S1 x Transmission valve body assy 6.4 65 57 in.·lbf<br />

Shift solenoid valve S2 x Transmission valve body assy 10 100 7<br />

ATF Tem Temperature erature sensor x Transmission valve body assy 36 mm 11 112 8<br />

12 mm 10 100 7<br />

Author: Date:<br />

03-7<br />

0305X-03<br />

19

40-78<br />

OVERHAUL<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANS - <strong>TRANSMISSION</strong> VALVE BODY ASSY (A750E/A750F)<br />

D12705<br />

D27982<br />

D27983<br />

D27984<br />

1. REMOVE <strong>TRANSMISSION</strong> VALVE BODY ASSY<br />

(a) Remove the 19 bolts.<br />

(b) Remove the valve body assy.<br />

2. REMOVE SHIFT SOLENOID VALVE SR<br />

(a) Remove the 2 bolts and the shift solenoid valve SR.<br />

Author: Date:<br />

4007M-02<br />

3. REMOVE SHIFT SOLENOID VALVE SLU<br />

(a) Remove the bolt, the 2 straight pins and the solenoid lock<br />

plate.<br />

(b) Remove the shift solenoid valve SLU.<br />

4. REMOVE SHIFT SOLENOID VALVE SL2<br />

(a) Remove the shift solenoid valve SL2.<br />

97

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANS - <strong>TRANSMISSION</strong> VALVE BODY ASSY (A750E/A750F)<br />

D27985<br />

D27986<br />

D27987<br />

D27988<br />

D27988<br />

Author: Date:<br />

40-79<br />

5. REMOVE SHIFT SOLENOID VALVE SLT<br />

(a) Remove the bolt, the 2 straight pins and the solenoid lock<br />

plate.<br />

(b) Remove the shift solenoid valve SLT.<br />

6. REMOVE SHIFT SOLENOID VALVE SL1<br />

(a) Remove the shift solenoid valve SL1.<br />

7. REMOVE SHIFT SOLENOID VALVE S1<br />

(a) Remove the bolt and the shift solenoid valve S1.<br />

8. REMOVE SHIFT SOLENOID VALVE S2<br />

(a) Remove the bolt and the shift solenoid valve S2.<br />

(b) Remove the O-ring from the shift solenoid valve S2.<br />

9. INSTALL SHIFT SOLENOID VALVE S2<br />

(a) Install the O-ring to the shift solenoid valve S2.<br />

(b) Install the bolt and the shift solenoid valve S2.<br />

Torque: 10 N·m (102 kgf·cm, 7 ft·lbf)<br />

98

40-80<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANS - <strong>TRANSMISSION</strong> VALVE BODY ASSY (A750E/A750F)<br />

D27987<br />

D27986<br />

D27985<br />

D27984<br />

D27983<br />

10. INSTALL SHIFT SOLENOID VALVE S1<br />

(a) Install the O-ring to the shift solenoid valve S1.<br />

(b) Install the bolt and the shift solenoid valve S1.<br />

Torque: 6.4 N·m (65 kgf·cm, 57 in.⋅lbf)<br />

11. INSTALL SHIFT SOLENOID VALVE SL1<br />

(a) Install the shift solenoid valve SL1.<br />

12. INSTALL SHIFT SOLENOID VALVE SLT<br />

(a) Install the shift solenoid valve SLT.<br />

(b) Install the bolt, the 2 straight pins and the solenoid lock<br />

plate.<br />

Torque: 6.4 N·m (65 kgf·cm, 57 in.⋅lbf)<br />

13. INSTALL SHIFT SOLENOID VALVE SL2<br />

(a) Install the shift solenoid valve SL2.<br />

14. INSTALL SHIFT SOLENOID VALVE SLU<br />

(a) Install the shift solenoid valve SLU.<br />

(b) Install the bolt, the 2 straight pins and the solenoid lock<br />

plate.<br />

Torque: 6.4 N·m (65 kgf·cm, 57 in.⋅lbf)<br />

Author: Date:<br />

99

A<br />

B<br />

A<br />

Pin<br />

A A A<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANS - <strong>TRANSMISSION</strong> VALVE BODY ASSY (A750E/A750F)<br />

D27982<br />

D12707<br />

A<br />

A<br />

D12705<br />

15. INSTALL SHIFT SOLENOID VALVE SR<br />

(a) Instal the 2 bolts and the shift solenoid valve SR.<br />

Torque: 6.4 N·m (65 kgf·cm, 57 in.⋅lbf)<br />

Author: Date:<br />

40-81<br />

16. INSTALL <strong>TRANSMISSION</strong> VALVE BODY ASSY<br />

(a) Align the groove of the manual valve with the pin of the<br />

lever.<br />

(b) Install the 19 bolts.<br />

Torque: 11 N·m (110 kgf·cm, 8 ft·lbf)<br />

HINT:<br />

Each bolt length is indicated below.<br />

Blot length:<br />

Bolt A: 25 mm (0.98 in.)<br />

Bolt B: 36 mm (1.42 in.)<br />

100

OVERHAUL<br />

Oil Pump<br />

Torque<br />

Converter<br />

Clutch<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANS - CLUTCH DRUM & INPUT SHAFT ASSY (A750E/A750F)<br />

D27995<br />

D27996<br />

D27997<br />

D27998<br />

Author: Date:<br />

40-57<br />

400XL-01<br />

1. FIX CLUTCH DRUM & INPUT SHAFT ASSY<br />

(a) Place the oil pump onto the torque converter clutch, and<br />

then place the clutch drum & input shaft assy onto the oil<br />

pump.<br />

2. REMOVE REVERSE CLUTCH HUB SUB-ASSY<br />

(a) Using a screwdriver, remove the snap ring from the clutch<br />

drum and the input shaft assy.<br />

(b) Remove the reverse clutch hub sub assy, the reverse<br />

clutch reaction sleeve, the clutch cushion, the plate reverse<br />

clutch flange, the 5 reverse clutch discs, and the 4<br />

clutch plates from the clutch drum assy.<br />

3. REMOVE REVERSE CLUTCH REACTION SLEEVE<br />

(a) Remove the reverse clutch reaction sleeve from the reverse<br />

clutch hub sub assy.<br />

76

40-58<br />

D<br />

D<br />

D<br />

D<br />

D<br />

Cushion Plate<br />

F<br />

P<br />

P<br />

P<br />

P<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANS - CLUTCH DRUM & INPUT SHAFT ASSY (A750E/A750F)<br />

D27999<br />

D01216<br />

D28000<br />

D28001<br />

D28500<br />

4. REMOVE REAR CLUTCH DISC<br />

(a) Remove the clutch cushion plate, the reverse clutch<br />

flange, the 4 plates and the 5 discs from the reverse clutch<br />

hub.<br />

5. INSPECT REAR CLUTCH DISC<br />

(a) Check whether the sliding surface of the disc, the plate<br />

and the flange are worn or burnt. If necessary, replace<br />

them.<br />

HINT:<br />

If the lining of the disc is peeled off or discolored, or even<br />

if only a part of the printed numbers is damaged, replace<br />

all discs.<br />

Before assembling new discs, soak them in ATF for at<br />

least 15 minutes.<br />

6. INSPECT REVERSE CLUTCH HUB SUB-ASSY<br />

(a) Using a dial indicator, measure the inside diameter of the<br />

reverse clutch hub bushing.<br />

Standard drum bushing:<br />

35.812 - 35.837 mm (1.4099 - 1.4109 in.)<br />

Maximum drum bushing: 35.887 mm (1.4129 in.)<br />

If the inside diameter is greater than the maximum, replace the<br />

reverse clutch hub.<br />

7. REMOVE <strong>FOR</strong>WARD CLUTCH HUB SUB-ASSY<br />

(a) Remove the forward clutch hub sub assy from the clutch<br />

drum assy.<br />

(b) Remove the 2 thrust needle roller bearings from the forward<br />

clutch hub sub assy.<br />

Author: Date:<br />

77

Thrust Bearing Race No.2<br />

D28501<br />

D28502<br />

Input Shaft<br />

Thrust<br />

Bearing<br />

Race RR<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANS - CLUTCH DRUM & INPUT SHAFT ASSY (A750E/A750F)<br />

D28503<br />

D28504<br />

D28505<br />

Author: Date:<br />

40-59<br />

8. INSPECT <strong>FOR</strong>WARD CLUTCH HUB SUB-ASSY<br />

(a) Using a dial indicator, measure the inside diameter of the<br />

forward clutch hub bushing.<br />

Standard drum bushing:<br />

26.037 - 26.062 mm (1.0251 - 1.0261 in.)<br />

Maximum drum bushing: 26.112 mm (1.028 in.)<br />

If the inside diameter is greater than the maximum, replace the<br />

forward clutch hub.<br />

9. REMOVE MULTIPLE DISC CLUTCH CLUTCH HUB<br />

(a) Remove the multiple disc clutch clutch hub from the clutch<br />

drum assy.<br />

(b) Remove the thrust bearing race No.2 and the input shaft<br />

thrust bearing race RR from the multiple disc clutch clutch<br />

hub.<br />

10. REMOVE INPUT SHAFT ASSY<br />

(a) Remove the thrust needle roller bearing from the clutch<br />

drum assy.<br />

(b) Remove the input shaft assy from the clutch drum assy.<br />

78

40-60<br />

D28518<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANS - CLUTCH DRUM & INPUT SHAFT ASSY (A750E/A750F)<br />

D29677<br />

D28519<br />

D28520<br />

D01216<br />

11. REMOVE INPUT SHAFT OIL SEAL RING<br />

(a) Remove the 3 oil seal rings from the input shaft assy.<br />

12. REMOVE <strong>FOR</strong>WARD MULTIPLE DISC CLUTCH<br />

CLUTCH DISC<br />

(a) Using a screwdriver, remove the hole snap ring.<br />

(b) Remove the 2 flanges, the 6 discs and the 5 plates from<br />

the input shaft assy.<br />

13. INSPECT <strong>FOR</strong>WARD MULTIPLE DISC CLUTCH<br />

CLUTCH DISC<br />

(a) Check whether the sliding surface of the disc, the plate<br />

and the flange are worn or burnt. If necessary, replace<br />

them.<br />

HINT:<br />

If the lining of the disc is peeled off or discolored, or even<br />

if only a part of the printed numbers is damaged, replace<br />

all discs.<br />

Author: Date:<br />

79

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANS - CLUTCH DRUM & INPUT SHAFT ASSY (A750E/A750F)<br />

D28521<br />

D28522<br />

D28523<br />

C59838<br />

Author: Date:<br />

40-61<br />

Before assembling new discs, soak them in ATF for at<br />

least 15 minutes.<br />

14. REMOVE CLUTCH BALANCER NO.1<br />

(a) Place SST on the clutch balancer No.1, and compress the<br />

return spring with a press.<br />

SST 09350-30020 (09350-07040, 09350-07070)<br />

(b) Remove the clutch balancer No.1 and the forwerd clutch<br />

return spring from the inputshaft assy.<br />

(c) Remove the O-ring from the clutch balancer No.1.<br />

15. INSPECT <strong>FOR</strong>WARD CLUTCH RETURN SPRING<br />

SUB-ASSY<br />

(a) Using a vernier calipers, measure the free length of the<br />

spring together with the spring seat.<br />

Standard free length: 26.74 mm (1.053 in.)<br />

80

40-62<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANS - CLUTCH DRUM & INPUT SHAFT ASSY (A750E/A750F)<br />

D28524<br />

D28525<br />

D28506<br />

D28507<br />

16. REMOVE <strong>FOR</strong>WARD CLUTCH PISTON<br />

(a) Holding the forward clutch piston by hand, apply compressed<br />

air (392 kPa, 4.0 kgf/cm 2 , 57 psi) to the inputshaft<br />

to remove the forward clutch piston.<br />

(b) Remove the 2 O-rings from the forward clutch piston.<br />

17. REMOVE REVERSE CLUTCH FLANGE<br />

(a) Remove the reverse clutch flange from the clutch drum<br />

assy.<br />

18. REMOVE DIRECT CLUTCH DISK<br />

(a) Using a screwdriver, remove the 2 hole snap rings from<br />

the clutch drum assy.<br />

Author: Date:<br />

81

SST<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANS - CLUTCH DRUM & INPUT SHAFT ASSY (A750E/A750F)<br />

D28508<br />

D01216<br />

D28509<br />

D28510<br />

Author: Date:<br />

40-63<br />

(b) Remove the reverse clutch flange, the 6 plates and the 5<br />

discs from the clutch drum assy.<br />

19. INSPECT DIRECT CLUTCH DISK<br />

(a) Check whether the sliding surface of the disc, the plate<br />

and the flange are worn or burnt. If necessary, replace<br />

them.<br />

HINT:<br />

If the lining of the disc is peeled off or discolored, or even<br />

if only a part of the printed numbers is damaged, replace<br />

all discs.<br />

Before assembling new discs, soak them in ATF for at<br />

least 15 minutes.<br />

20. REMOVE CLUTCH BALANCER NO.3<br />

(a) Place SST on the clutch balancer No.3, and compress the<br />

return spring with a press.<br />

SST 09387-00070, 09350-30020 (09350-07070)<br />

21. REMOVE REVERSE CLUTCH RETURN SPRING<br />

SUB-ASSY<br />

(a) Remove the reverse clutch return spring and the O-ring<br />

from the reverse clutch piston.<br />

82

40-64<br />

SST<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANS - CLUTCH DRUM & INPUT SHAFT ASSY (A750E/A750F)<br />

C59838<br />

D28511<br />

D28512<br />

D28513<br />

D28514<br />

22. INSPECT REVERSE CLUTCH RETURN SPRING<br />

SUB-ASSY<br />

(a) Using a vernier calipers, measure the free length of the<br />

spring together with the spring seat.<br />

Standard free length: 21.04 mm (0.828 in.)<br />

23. REMOVE REVERSE CLUTCH PISTON SUB-ASSY<br />

(a) Remove the reverse clutch piston, sub assy from the<br />

clutch drum sub assy.<br />

(b) Remove the O-ring from the reverse clutch piston sub<br />

assy.<br />

(c) Remove the O-ring from the clutch drum sub assy.<br />

24. REMOVE DIRECT CLUTCH PISTON SUB-ASSY<br />

(a) Place SST on the direct clutch piston, and compress the<br />

return spring with a press.<br />

SST 09320-89010, 09350-30020 (09350-07070)<br />

Author: Date:<br />

83

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANS - CLUTCH DRUM & INPUT SHAFT ASSY (A750E/A750F)<br />

D28515<br />

D28516<br />

D28517<br />

D28816<br />

C59838<br />

Author: Date:<br />

40-65<br />

(b) Using 2 screw drivers, remove the direct clutch piston sub<br />

assy from the clutch drum.<br />

(c) Remove the O-ring from the clutch drum.<br />

(d) Remove the clutch balancer No.2 and the direct clutch return<br />

spring sub assy from the direct clutch piston sub<br />

assy.<br />

(e) Remove the 2 O-rings from the direct clutch piston Sub-<br />

Assy.<br />

25. INSPECT DIRECT CLUTCH RETURN SPRING<br />

SUB-ASSY<br />

(a) Using a vernier calipers, measure the free length of the<br />

spring together with the spring seat.<br />

Standard free length: 19.51 mm (0.768 in.)<br />

84

40-66<br />

SST<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANS - CLUTCH DRUM & INPUT SHAFT ASSY (A750E/A750F)<br />

D28816<br />

D28517<br />

D28516<br />

D28514<br />

26. INSTALL DIRECT CLUTCH PISTON SUB-ASSY<br />

(a) Coat 2 new O-rings with ATF, and install them in the direct<br />

clutch piston.<br />

(b) Install the clutch balancer No.2 and the direct clutch return<br />

spring to the direct clutch piston sub assy.<br />

(c) Coat a new O-ring with ATF, and install them on the clutch<br />

drum sub assy.<br />

(d) Be careful not to damage the O-rings. Press in the direct<br />

clutch piston into the clutch drum with both hands.<br />

(e) Place SST on the direct clutch piston, and compress the<br />

return spring with a press.<br />

SST 09320-89010, 09350-30020 (09350-07070)<br />

(f) Install the snap ring with a snap ring expander.<br />

NOTICE:<br />

Be sure the end gap of the snap ring is not aligned<br />

with the spring retainer claw.<br />

Stop Pressing when the spring sheet is lowered to the<br />

place 1 - 2 mm (0.039 - 0.078 in.) from the snap ring<br />

groove to prevent the spring sheet from being deformed.<br />

Do not expand the snap ring excessively.<br />

Author: Date:<br />

85

Stopper<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANS - CLUTCH DRUM & INPUT SHAFT ASSY (A750E/A750F)<br />

D28536<br />

D28513<br />

D28512<br />

D28511<br />

D28510<br />

Author: Date:<br />

40-67<br />

(g) Set the end gap of the snap ring in the piston as shown<br />

in the illustration.<br />

27. INSTALL REVERSE CLUTCH PISTON SUB-ASSY<br />

(a) Coat a new O-ring with ATF, and install it on the clutch<br />

drum sub assy.<br />

(b) Coat a new O-ring with ATF, and install it on the reverse<br />

clutch piston sub assy.<br />

(c) Be careful not to damage the O-ring. Press in the clutch<br />

drum sub assy into the reverse clutch piston with both<br />

hands.<br />

28. INSTALL REVERSE CLUTCH RETURN SPRING<br />

SUB-ASSY<br />

(a) Coat a new O-ring with ATF, and install it on the reverse<br />

clutch piston sub assy.<br />

(b) Install the reverse clutch return spring onto the reverse<br />

clutch piston sub assy.<br />

86

40-68<br />

GAP<br />

F<br />

P<br />

P<br />

P<br />

P<br />

P<br />

P<br />

SST<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANS - CLUTCH DRUM & INPUT SHAFT ASSY (A750E/A750F)<br />

D<br />

D<br />

D<br />

D<br />

D<br />

D28509<br />

D28534<br />

D28508<br />

29. INSTALL CLUTCH BALANCER NO.3<br />

(a) Place SST on the clutch balancer No.3, and compress the<br />

clutch balancer with a press.<br />

SST 09387-00070, 09350-30020 (09350-07070)<br />

(b) Install the snap ring with a snap ring expander.<br />

(c) Be sure the end gap of the snap ring is not aligned with<br />

the spring retainer claw.<br />

NOTICE:<br />

Stop pressing when the spring sheet is lowered to the<br />

place 1 - 2 mm (0.039 - 0.078 in.) from the snap ring<br />

groove to prevent the spring sheet from being deformed.<br />

Do not expand the snap ring excessively.<br />

(d) Set the end gap of the snap ring in the piston as shown<br />

in the illustration.<br />

30. INSTALL DIRECT CLUTCH DISK<br />

(a) Install the reverse clutch flange, the 6 plates and the 5<br />

discs on the clutch drum sub assy.<br />

Author: Date:<br />

87

A<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANS - CLUTCH DRUM & INPUT SHAFT ASSY (A750E/A750F)<br />

D28507<br />

D29841<br />

D28506<br />

Author: Date:<br />

40-69<br />

(b) Using a screwdriver, install the 2 hole snap rings on the<br />

clutch drum sub assy.<br />

31. INSPECT PACK CLEARANCE OF DIRECT CLUTCH<br />

(a) Using a dial gauge, measure the moving distance (distance<br />

A) of the clutch flange at the both end across a diameter<br />

while blowing air from the oil hole as shown in the<br />

illustration, and calculate the average.<br />

Pack Clearance: 0.5 - 0.8 mm<br />

NOTICE:<br />

Install a selective flange (t 3.4 mm) when measuring the<br />

moving distance. (shaded area in the illustration.)<br />

HINT:<br />

Flange moving distance A = 0.26 - 1.14 mm<br />

Pack Clearance = Flange moving distance A - 0.05 mm<br />

(b) If the pack clearance is outside the standard, select &<br />

install a clutch flange that makes the pack clearance to be<br />

within the standard.<br />

HINT:<br />

Select the flange from 9 kinds (in thickness) of the selective<br />

flanges to adjust the pack clearance.<br />

Flange thickness<br />

No. Thickness No. Thickness<br />

0 3.0 (0.118) 5 3.5 (0.138)<br />

1 3.1 (0.122) 6 3.6 (0.142)<br />

2 3.2 (0.126) 7 3.7 (0.146)<br />

3 3.3 (0.130) 8 3.8 (0.150)<br />

4 3.4 (0.134) - -<br />

32. INSTALL REVERSE CLUTCH FLANGE<br />

(a) Install the reverse clutch flange to the clutch drum sub<br />

assy.<br />

88

40-70<br />

A<br />

A750E, A750F A/T <strong>REPAIR</strong> <strong>MANUAL</strong> (RM999U)<br />

<strong>AUTOMATIC</strong> <strong>TRANSMISSION</strong> / TRANS - CLUTCH DRUM & INPUT SHAFT ASSY (A750E/A750F)<br />

D29843<br />

D29844<br />

33. INSTALL REVERSE CLUTCH REACTION SLEEVE<br />

(a) Install the reverse clutch reaction sleeve, the clutch cushion<br />

plate, the reverse clutch flange, the 5 reverse clutch<br />

discs, and the 4 clutch plates to the reverse clutch hub.<br />

(b) Using a screwdriver, install the hole snap ring.<br />

34. INSPECT PACK CLEARANCE OF REVERSE CLUTCH<br />

(a) Using a dial gauge, measure the reverse clutch piston<br />

stroke (distance A) and the moving distance (distance B)<br />

of the reverse clutch flange at the both end across a diameter<br />