Se den samlede liste med beskrivelser her - Agromek

Se den samlede liste med beskrivelser her - Agromek

Se den samlede liste med beskrivelser her - Agromek

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

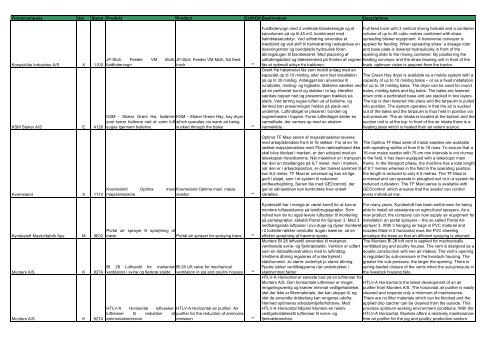

Firma/company Hal Stand Produkt Product EUR/DK Beskrivelser Descriptions<br />

Kongskilde Industries A/S X 1100<br />

KSM Stoker A/S E 4126<br />

Kverneland X 1110<br />

Kyndestoft Maskinfabrik Aps M 9632<br />

Munters A/S K 8274<br />

Munters A/S K 8274<br />

JF-Stoll, Feeder VM Multi,<br />

fuldfodervogn<br />

JF-Stoll, Feeder VM Multi, full feed<br />

truck **<br />

KSM - Stoker Grønt Hø, høtørrer KSM – Stoker Green Hay, hay dryer<br />

som tørrer ballerne ved at varm luft which operates via warm air being<br />

suges igennem ballerne.<br />

sucked through the bales **<br />

Kverneland Optima maxi<br />

majssåmaskine<br />

Kverneland Optima maxi maize<br />

seeder **<br />

Portal air sprayer til sprøjtning af<br />

træer Portal air sprayer for spraying trees **<br />

BI 28 Loftventil for mekanisk<br />

ventilation i svine og fjerkræ stalde<br />

Bl 28 Lift valve for mechanical<br />

ventilation in pig and poultry houses **<br />

HTLV-A Horisontal luftvasker, HTLV-A Horizontal air purifier. Air<br />

luftrenser til reduktion af purifier for the reduction of ammonia<br />

ammoniakemission<br />

emission **<br />

Fuldfodervogn <strong>med</strong> 3 vertikale blandesnegle og et<br />

karvolumen på op til 45 m3, kombineret <strong>med</strong><br />

halmblæserudstyr. Ved udfodring anvendes et<br />

tværbånd og ved skift til halmstrøning nedsænkes en<br />

doseringsrotor og bundplade hydraulisk foran<br />

åbningslugen til blandekarret. Med placering af<br />

udfodringsbånd og blæserenhed på fronten af vognen<br />

fås et optimalt udsyn fra traktoren.<br />

Grønt Hø høtørreriet fås som mobilt anlæg <strong>med</strong> en<br />

kapacitet op til 10 minibig, eller som fast installation<br />

på op til 30 minibig. Anlægget kan anvendes til<br />

rundballer, minibig- og bigballer. Ballerne sænkes ned<br />

på en perforeret bund og stables i to lag. Herefter<br />

sænkes toppen ned og presenningen trækkes på<br />

plads. Ved tørring suges luften ud af ballerne, og<br />

der<strong>med</strong> kan presenningen holdes på plads ved<br />

undertryk. Luftindtaget er placeret i bun<strong>den</strong> og<br />

sugeenhe<strong>den</strong> i toppen. Foran luftindtaget sidder en<br />

varmeflade, der varmes op <strong>med</strong> en ekstern<br />

varmekilde.<br />

Full feed truck with 3 vertical mixing helicals and a container<br />

volume of up to 45 cubic metres combined with straw<br />

spreading blower equipment. A transverse conveyor is<br />

applied for feeding. When spreading straw a dosage rotor<br />

and base plate is lowered hydraulically in front of the<br />

opening slide to the mixing container. By positioning the<br />

feeding conveyor and the straw blowing unit in front of the<br />

truck, optimum vision is assured from the tractor.<br />

The Green Hay dryer is available as a mobile system with a<br />

capacity of up to 10 minibig bales – or as a fixed installation<br />

for up to 30 minibig bales. The dryer can be used for round<br />

bales, minibig bales and big bales. The bales are lowered<br />

down onto a perforated base and are stacked in two layers.<br />

The top is then lowered into place and the tarpaulin is pulled<br />

into position. The system operates in that the air is sucked<br />

out of the bales and the tarpaulin is thus held in position via<br />

sub-pressure. The air intake is located at the bottom and the<br />

suction unit is at the top. In front of the air intake t<strong>her</strong>e is a<br />

heating plate which is heated from an extern source.<br />

Optima TF Maxi serien af majssåmaskiner leveres<br />

<strong>med</strong> arbejdsbredder fra 6 til 16 rækker. For at en 16 The Optima TF Maxi serie of maize seeders are available<br />

rækket majssåmaskine <strong>med</strong> 75cm rækkeafstand ikke with operating widths of from 6 to 16 rows. To ensure that a<br />

skal blive klodset i marken, er <strong>den</strong> udstyret <strong>med</strong> en 16-row maize seeder with 75 cm row intervals is not clumsy<br />

teleskopisk hovedramme. Når maskinen er i transport in the field, it has been equipped with a telescopic main<br />

har <strong>den</strong> en totallængde på 9,7 meter, men i marken, frame. In the transport phase, the machine has a total length<br />

når <strong>den</strong> er i arbejdsposition, er <strong>den</strong> trukket sammen til of 9.7 metres w<strong>her</strong>eas in the field in the operating position,<br />

kun 6,5 meter. TF Maxi er universal og kan så lige the length is reduced to only 6.5 metres. The TF Maxi is<br />

godt i pløjet, som i et system til reduceret<br />

universal and can operate in ploughed soil or in a system for<br />

jordbearbejdning. <strong>Se</strong>rien fås <strong>med</strong> GEOcontrol, der reduiced cultivation. The TF Maxi series is available with<br />

gør at såmaskinen kan kontrollere hver enkelt GEOcontrol which ensures that the seeder can control<br />

sårække.<br />

every individual row.<br />

Kyndestoft har i mange år været kendt for at kunne<br />

montere luftassistance på landbrugssprøjter. Som<br />

nyhed kan de nu også levere luftudstyr til montering<br />

på portalsprøjter, såkaldt Portal Air Sprayer 3. Med 3<br />

nedhængende luftposer i pvc-duge og dyser monteret<br />

i 2 lodrette rækker omslutter dugen træerne, så en<br />

effektiv sprøjtning af træerne opnås.<br />

Munters BI 28 loftventil anvendes til mekanisk<br />

ventilerede svine- og fjerkræstalde. Ventilen er udført<br />

som en dobbeltkonstruktion <strong>med</strong> to luftindtag.<br />

Ventilens åbning reguleres af undertrykket i<br />

staldrummet. Jo større undertryk jo større åbning.<br />

Fjedre lukker ventilklapperne når undertrykket i<br />

staldrummet falder.<br />

HTLV-A Horisontal er seneste bud på en luftrenser fra<br />

Munters A/S. Den horisontale luftrenser er meget<br />

rengøringsvenlig og kræver minimal vedligeholdelse,<br />

idet der ikke er filtermateriale, der kan stoppe til, og<br />

idet de anvendte dråbefang kan rengøres udefra.<br />

Her<strong>med</strong> optimeres arbejdsmiljøforhol<strong>den</strong>e. Med<br />

HTLV-A Horisontal tilbyder Munters en relativ<br />

vedligeholdelsesfri luftrenser til svine- og<br />

fjerkræbranchen.<br />

For many years, Kyndestoft has been well-known for being<br />

able to install air assistance on agricultural sprayers. As a<br />

new product, the company can now supply air equipment for<br />

installation on portal sprayers – the so-called Portal Airsprayer<br />

3. With 3 hanging air bags in PVC material and<br />

nozzles fitted in 2 horizontal rows the PVC sheeting<br />

envelops the trees so that an efficient spraying is attained.<br />

The Munters Bl 28 loft vent is applied for mechanically<br />

ventilated pig and poultry houses. The vent is designed as a<br />

double construction with two air intakes. The vent’s opening<br />

is regulated by sub-pressure in the livestock housing. The<br />

greater the sub-pressure, the larger the opening. T<strong>her</strong>e is<br />

spring-loaded closure of the vents when the sub-pressure in<br />

the livestock housing falls.<br />

HTLV-A Horizontal is the latest development of an air<br />

purifier from Munters A/S. The horizontal air purifier is easily<br />

cleaned and requires only a minimum of maintenance.<br />

T<strong>her</strong>e are no filter materials which can be blocked and the<br />

applied drip catc<strong>her</strong> can be cleaned from the outside. This<br />

provides optimum working environment conditions. With the<br />

HTLV-A Horizontal, Munters offers a relatively maintenancefree<br />

air purifier for the pig and poultry production sectors.