37531922 - 10/2004 - heidenhain

37531922 - 10/2004 - heidenhain

37531922 - 10/2004 - heidenhain

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

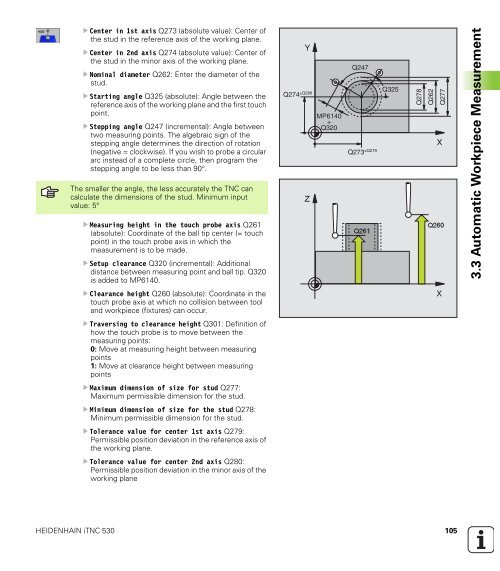

Center in 1st axis Q273 (absolute value): Center of<br />

the stud in the reference axis of the working plane.<br />

Center in 2nd axis Q274 (absolute value): Center of<br />

the stud in the minor axis of the working plane.<br />

Nominal diameter Q262: Enter the diameter of the<br />

stud.<br />

Starting angle Q325 (absolute): Angle between the<br />

reference axis of the working plane and the first touch<br />

point.<br />

Stepping angle Q247 (incremental): Angle between<br />

two measuring points. The algebraic sign of the<br />

stepping angle determines the direction of rotation<br />

(negative = clockwise). If you wish to probe a circular<br />

arc instead of a complete circle, then program the<br />

stepping angle to be less than 90°.<br />

The smaller the angle, the less accurately the TNC can<br />

calculate the dimensions of the stud. Minimum input<br />

value: 5°<br />

Measuring height in the touch probe axis Q261<br />

(absolute): Coordinate of the ball tip center (= touch<br />

point) in the touch probe axis in which the<br />

measurement is to be made.<br />

Setup clearance Q320 (incremental): Additional<br />

distance between measuring point and ball tip. Q320<br />

is added to MP6140.<br />

Clearance height Q260 (absolute): Coordinate in the<br />

touch probe axis at which no collision between tool<br />

and workpiece (fixtures) can occur.<br />

Traversing to clearance height Q301: Definition of<br />

how the touch probe is to move between the<br />

measuring points:<br />

0: Move at measuring height between measuring<br />

points<br />

1: Move at clearance height between measuring<br />

points<br />

Maximum dimension of size for stud Q277:<br />

Maximum permissible dimension for the stud.<br />

Minimum dimension of size for the stud Q278:<br />

Minimum permissible dimension for the stud.<br />

Tolerance value for center 1st axis Q279:<br />

Permissible position deviation in the reference axis of<br />

the working plane.<br />

Tolerance value for center 2nd axis Q280:<br />

Permissible position deviation in the minor axis of the<br />

working plane<br />

HEIDENHAIN iTNC 530 <strong>10</strong>5<br />

Y<br />

Q274 ±Q280<br />

MP6140<br />

+<br />

Q320<br />

Q247<br />

Q273 ±Q279<br />

Q325<br />

Q278<br />

Q262<br />

Q277<br />

X<br />

3.3 Automatic Workpiece Measurement