DuroStone Inspection Report

DuroStone Inspection Report

DuroStone Inspection Report

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

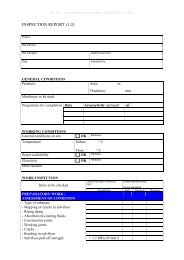

INSPECTION REPORT of maxit <strong>DuroStone</strong><br />

Builder<br />

Project<br />

GENERAL CONDITIONS<br />

Products:<br />

Machinery to be used:<br />

Programme for completion<br />

Page 1/4<br />

Type of project (residential, office etc)<br />

Address:<br />

Area: m 2<br />

Thickness: mm<br />

Date Area/activity (defined) m 2<br />

WORKING CONDITIONS<br />

General conditions on site OK Remarks:<br />

Temperature Indoor: º C<br />

Floor: º C<br />

Water availability OK Remarks:<br />

Electricity OK Remarks:<br />

Other remarks:<br />

WORK INSPECTION<br />

Items to be checked<br />

A. ASSESSMENT OF SUBSTRATE<br />

- Type of substrate<br />

- Absorbed oils/cutting fluids<br />

- Pull-off strength > 1.0 N/mm 2 (MPa)<br />

- Bonding/de-bonding<br />

- Joints<br />

- Cracks<br />

- Temperature > +10 C o<br />

- Curvature/Slope<br />

- Damp/Wetness<br />

- Mapping of deviations in substrate<br />

- Need for fillings<br />

- Test areas<br />

B. CLEANING<br />

- Vacuum cleaning<br />

- Shot-blast/grinding cleaning<br />

C. SURVEYING FOR FLATNESS<br />

D. SEALING/EDGES<br />

E. PRIMING on to SUBSTRATE<br />

Priming: Floor 4716 (1:3 and 1:3)<br />

Priming: Floor 4710<br />

F. REINFORCEMENT<br />

- Floating Steel net Ø 4-5 mm, mesh 150 mm<br />

Quality Manager responsible<br />

AmFC:<br />

Check carried out by:<br />

As per signature:<br />

Requirement/Comments Date Signature Deviation<br />

1

INSPECTION REPORT of maxit <strong>DuroStone</strong><br />

Builder<br />

Project<br />

- Bolted Steel net Ø 4-5 mm, mesh 150 mm<br />

Page 2/4<br />

Type of project (residential, office etc)<br />

Address:<br />

G. LEVELLING BASE LAYER<br />

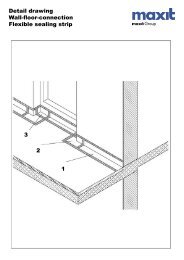

- Foam barriers<br />

- Soft strips (around vertical structures)<br />

- Pump report/flow test<br />

Cutting of joints/profiles for constr. joints<br />

- Floor 4360 surface strength > 1.0 N/mm 2 (MPa)<br />

H. LEVELLING <strong>DuroStone</strong> maxitFloor 4635<br />

- Priming between layers 1 and 2<br />

- Foam barriers<br />

- Pump report/flow test<br />

- Cutting of joints/profiles for constr. joints<br />

I. <strong>DuroStone</strong> Grinding Process<br />

If grinding process is done by other contractor then AmFC use the QA – transfer part.<br />

Always use the QA inspection check points in Appendix 1.<br />

QA transfer to Grinding Contractor<br />

- <strong>Inspection</strong>/approval of levelled areas Appendix 1<br />

QA transfer to AmFC<br />

- <strong>Inspection</strong>/approval of levelled areas Appendix 1<br />

GRINDING PROCESS<br />

Grinding process QA - report Appendix 1<br />

J. SUBSEQUENT ADJUSTMENTS<br />

- Checking flatness/curvature<br />

- Checking surface structure<br />

- Bonding<br />

K. SURFACE TREATMENT<br />

- Cleaning of surface <strong>DuroStone</strong><br />

- Application of Surface Treatment System<br />

L. SQUARED GROVE PATTERN<br />

- Guiding rails<br />

- Cut grooves<br />

M. FINISHED SHOP FLOOR<br />

- Visual appearance: Groove pattern<br />

- Visual appearance: Overall<br />

- Pull-off strength<br />

- Bonding<br />

N. PROTECTION OF FINISHED FLOOR<br />

- Foot traffic: Paper boards<br />

- Wheel traffic: Hard-pressed woodfibre board<br />

O. DIRECTIVES FOR MAINTENANCE<br />

For deviations see separate Non-Conformity <strong>Report</strong><br />

Signature of responsible Quality Manager AmFC<br />

Signature of responsible Site Manager<br />

Place, date<br />

Place, date<br />

2

INSPECTION REPORT of maxit <strong>DuroStone</strong><br />

Builder<br />

Project<br />

AmFC:<br />

Page 3/4<br />

Type of project (residential, office etc)<br />

Address:<br />

QA TRANSFER & INSPECTION GRINDING PROCESS – Appendix 1<br />

Grinding Contractor :<br />

QA Transfer to: Grinding Contractor<br />

Check points Requirements Date Signature Deviation<br />

<strong>Inspection</strong> of section A-G<br />

Responsible Grinding Contractors’ signature<br />

Quality responsible AmFC signature<br />

Place, date<br />

Place, date<br />

Transfer to: AmFC<br />

Check points Requirements Date Signature Deviation<br />

<strong>Inspection</strong> Grinding Process I: 1 -<br />

Responsible Grinding Contractors’ signature<br />

Quality responsible AmFC signature<br />

Place, date<br />

Place, date<br />

3

INSPECTION REPORT of maxit <strong>DuroStone</strong><br />

Builder<br />

Project<br />

Page 4/4<br />

Type of project (residential, office etc)<br />

Address:<br />

INSPECTION REPORT GRINDING PROCESS – APPENDIX 1<br />

I. GRINDING PROCESS<br />

Check-points Requirements Date Signature Deviation<br />

- Dry out time for maxitFloor 4635 min 1 day<br />

- Step 1– EZ CA2-DS Remove all separating layer<br />

- Vacuum the floor<br />

- Impregnation: HTC Cure<br />

- Step 2: Grinding – EZ CA4-DS<br />

- Vacuum the floor<br />

Remove the “grinding<br />

scratches/marks” for Step 1<br />

- Step 3: Grinding EZ SR 10 Remove the “grinding<br />

scratches/marks” for Step 2<br />

- Vacuum the floor (if needed)<br />

- Step 4: Grinding - Fenix Blue<br />

- Vacuum the floor (if needed)<br />

Remove the “grinding<br />

scratches” for Step 3<br />

- Step 5: Grinding - Fenix White Gloss value app 25 – 30.<br />

- Step 6: Grinding - Fenix Green Gloss value app 50<br />

- Step 7: Grinding at edges Do step 1-6<br />

- <strong>Inspection</strong> of final surface<br />

- Check surface for voids See work instructions<br />

- Filling of voids if needed See work instructions<br />

- Grinding after filling of voids As specified final gloss<br />

value<br />

- Step 8: Surface treatment As specified<br />

4