Installation 1.10 (pdf)

Installation 1.10 (pdf)

Installation 1.10 (pdf)

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Industrial renovation and<br />

super flat floors<br />

Loading platform, with resin or PU coating<br />

<strong>Installation</strong> - phase by phase<br />

Substrate preparation:<br />

13.5.2011<br />

• Grind, shot blaster or mill off any material layers that could weaken the bond,<br />

such as old paints, screeds, gypsym, magnesia, asphalt, cement lime, grease, oil<br />

soaked layers, glue or similar. Vacuum clean any residual dust. The pull off<br />

strenght of the cleaned concrete should be >1.5 MPa. If this cannot be<br />

achieved, see the weber Substrate Guide for possibilities of how to strengthen<br />

the substrate.<br />

• Hair cracks in old, dried concrete will usually not need any special attention.<br />

Cracks, visible with the bare eye and cracks where the concrete has clearly<br />

suffered should however be injected with weber.floor 4712 epoxy primer.<br />

Dilatation joints and cracks throughout the whole concrete slab will most likely still<br />

move with changes in the ambient temperature and such cracks will therefore<br />

most likely show up also in the new floor.<br />

Preparations:<br />

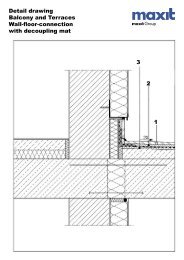

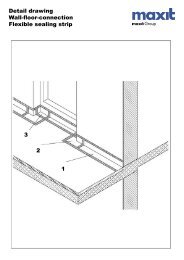

• Install eventually needed stoppers and tighten any possible leakages. Separate<br />

the floor from the vertical structures by using weber 4960 Soft Strips towards the<br />

walls and tighten these with eg. PU-foam or acrylic mastix between the strips and<br />

the old floor. This hinders movements in prefabricated structures to damage the<br />

edge of the floor surface, as columns and walls move in comparison to the slabs.<br />

First epoxy primer layer:<br />

• The two components of the product must be mixed according to the data sheet<br />

or the information on the buckets. Then, the weber.floor 4712 epoxy primer is<br />

evenly applied on to the prepared surface and distributed evenly with a rubber<br />

squeegee and a lamb's wool roller. The formation of puddles must be avoided.<br />

Material consumption is approximately 400 - 600 g/m².<br />

Second epoxy primer layer:<br />

• Make sure that the previous coating adheres firmly to the substrate.<br />

• The second primer layer should be applied within 24 hours, if the ambient<br />

temperature is 23°C. Otherwise layer 1 will become hard and glossy and the<br />

bond between the two layers might suffer.<br />

• Mix the two components as above. The weber.floor 4712 is applied directly on<br />

top of the hardened first primer. The formation of puddles must be avoided.<br />

Material consumption is approximately 400 -500 g/m².<br />

• The fresh second layer is scattered with fire-dried quartz sand, in such an amount,<br />

that the upmost sand remains dry. After the primer has set, excess quartz sand<br />

should be brushed or vacuumed off the surface before starting the next<br />

application. The surface tensile strength has to be at least 1.5 N/mm².<br />

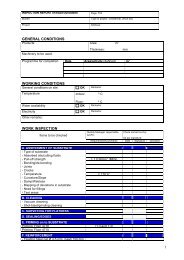

Setting time before First layer 4712 Second layer 4712<br />

next layer 12 h, max 24 h 12 h<br />

Epoxy coating, 4740, layer 1:<br />

• Before application of the coat, make sure that the surface is dry and clean, i.e.<br />

free from any debris that could cause delamination.<br />

• The two components of the weber.floor 4740 must be mixed according to the<br />

data sheet or the information on the buckets.<br />

• Then mix two parts (by weight) of the mixed weber.floor 4740 to one part<br />

weber.floor 4935 fire dried special sand 0.1 - 0.4 mm. Consumtion, approx 1.2<br />

kg/m² of weber.floor 4740 and approx 0.6 kg/m² of weber.floor 4935.<br />

1<br />

<strong>1.10</strong>

13.5.2011<br />

• Distribute the top coat evenly with a toothed spatula and roll over with a pig<br />

roller to remove trapped air. Work in crosswise directions.<br />

• Scatter with fire-dried quartz sand. Excess quartz sand should be brushed or<br />

vacuumed off the surface after the layer has set.<br />

Setting time before<br />

weber.floor 4740<br />

next layer 12 h<br />

Top coating, 4740 (option A):<br />

• Before application of the top coat, make sure that the surface is dry and clean,<br />

i.e. free from any debris that could cause delamination.<br />

• The two components of the weber.floor 4740 must be mixed according to the<br />

data sheet or the information on the buckets.<br />

• Then mix two parts (by weight) of the mixed weber.floor 4740 to one part<br />

weber.floor 4935 fire dried special sand 0.1 - 0.4 mm. Consumtion, approx 1.2<br />

kg/m² of weber.floor 4740 and approx 0.6 kg/m² of weber.floor 4935.<br />

• Distribute the top coat evenly with a toothed spatula and roll over with a pig<br />

roller to remove trapped air. Work in crosswise directions.<br />

Setting time<br />

weber.floor 4740<br />

12 h<br />

Optionally a 4753 Coating PU is applied as top coat (Option B):<br />

• Before application of the top coat, make sure that the surface is dry and clean,<br />

i.e. free from any debris that could cause delamination.<br />

• The two components of the weber.floor 4753 must be mixed according to the<br />

data sheet or the information on the buckets. Consumtion, approx 1.45 kg/m².<br />

• Distribute the top coat evenly with a toothed spatula and roll over with a pig<br />

roller to remove trapped air. Work in crosswise directions.<br />

Setting time<br />

Notes concerning all 2-component work:<br />

weber.floor 4753<br />

12 h<br />

• Ambient air and surface temperature: minimum +8°C, maximum +40°C.<br />

• The temperature of the surface should be 3°C higher than the dew point.<br />

• Relative Humidity: at +10°C maximum 75 %, at +30°C maximum 80 %.<br />

• Do not work during rising temperatures since this may result in the formation of air<br />

bubbles (through direct exposure to sunlight).<br />

2