A Novel Defect Inspection Method for the TFT-LCD Image Based on ...

A Novel Defect Inspection Method for the TFT-LCD Image Based on ...

A Novel Defect Inspection Method for the TFT-LCD Image Based on ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

A <str<strong>on</strong>g>Novel</str<strong>on</strong>g> <str<strong>on</strong>g>Defect</str<strong>on</strong>g> <str<strong>on</strong>g>Inspecti<strong>on</strong></str<strong>on</strong>g> <str<strong>on</strong>g>Method</str<strong>on</strong>g> <str<strong>on</strong>g>for</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>TFT</str<strong>on</strong>g>-<str<strong>on</strong>g>LCD</str<strong>on</strong>g><br />

<str<strong>on</strong>g>Image</str<strong>on</strong>g> <str<strong>on</strong>g>Based</str<strong>on</strong>g> <strong>on</strong> Human Visual System<br />

Tae-Eun S<strong>on</strong>g 1 , Se-Yun Kim 2 , J<strong>on</strong>g-Hwan Kim 3 , and Kil-Houm Park 4<br />

1 Department Name, University Name, City, State, Country<br />

2 Department Name, Company / Instituti<strong>on</strong> Name, City, State, Country<br />

Abstract - The <str<strong>on</strong>g>TFT</str<strong>on</strong>g>-<str<strong>on</strong>g>LCD</str<strong>on</strong>g> image has n<strong>on</strong>-uni<str<strong>on</strong>g>for</str<strong>on</strong>g>m<br />

brightness that is <str<strong>on</strong>g>the</str<strong>on</strong>g> major difficulty of finding <str<strong>on</strong>g>the</str<strong>on</strong>g> defect<br />

regi<strong>on</strong> called Mura. In order to facilitate Mura detecti<strong>on</strong>,<br />

globally large-varying background signal has to be leveled<br />

and also Mura signal has to be enlarged. In this paper,<br />

Mura signal magnificati<strong>on</strong> and background signal<br />

flattening methods by <str<strong>on</strong>g>the</str<strong>on</strong>g> use of adapted c<strong>on</strong>trast sensitivity<br />

functi<strong>on</strong>(ACSF) in DCT domain and polynomial<br />

regressi<strong>on</strong>(PR) are proposed. In <str<strong>on</strong>g>the</str<strong>on</strong>g> enhanced image, Trimodal<br />

thresholding segmentati<strong>on</strong> technique is used <str<strong>on</strong>g>for</str<strong>on</strong>g><br />

finding both Dark and White Mura at <strong>on</strong>ce. To leave out<br />

reliable defect, false regi<strong>on</strong> eliminati<strong>on</strong> algorithms based<br />

<strong>on</strong> HVS (Human Visual System) are also proposed. The<br />

experimental results prove that <str<strong>on</strong>g>the</str<strong>on</strong>g> proposed algorithm is<br />

novel enhancement method and it can be applicable to real<br />

automated inspecti<strong>on</strong> system.<br />

Keywords: <str<strong>on</strong>g>TFT</str<strong>on</strong>g>-<str<strong>on</strong>g>LCD</str<strong>on</strong>g> (Thin Film Transistor-Liquid Crystal<br />

Display), Polynomial Regressi<strong>on</strong>, Discrete Cosine<br />

Trans<str<strong>on</strong>g>for</str<strong>on</strong>g>m, Human Visual System, C<strong>on</strong>trast Sensitivity<br />

Functi<strong>on</strong>.<br />

1 Introducti<strong>on</strong><br />

Recently, <str<strong>on</strong>g>the</str<strong>on</strong>g> thin film transistor liquid crystal displays<br />

(<str<strong>on</strong>g>TFT</str<strong>on</strong>g>-<str<strong>on</strong>g>LCD</str<strong>on</strong>g>s) has become <str<strong>on</strong>g>the</str<strong>on</strong>g> major flat panel displays<br />

(FPDs) <str<strong>on</strong>g>for</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g>ir volume and versatile usage [1]. The more<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>TFT</str<strong>on</strong>g>-<str<strong>on</strong>g>LCD</str<strong>on</strong>g> market grows <str<strong>on</strong>g>the</str<strong>on</strong>g> more need <str<strong>on</strong>g>for</str<strong>on</strong>g> automated<br />

inspecti<strong>on</strong> systems exist. However most of <str<strong>on</strong>g>the</str<strong>on</strong>g> final<br />

inspecti<strong>on</strong>s of <str<strong>on</strong>g>LCD</str<strong>on</strong>g> panels have been d<strong>on</strong>e by human<br />

observers. Human visi<strong>on</strong>-based inspecti<strong>on</strong> [2] systems have<br />

some disadvantages that each observer tends to have<br />

subjective defect decisi<strong>on</strong> levels which can vary according<br />

to time and physical c<strong>on</strong>diti<strong>on</strong>s. There<str<strong>on</strong>g>for</str<strong>on</strong>g>e, in order to<br />

increase <str<strong>on</strong>g>the</str<strong>on</strong>g> productivity and reliability of products<br />

automated inspecti<strong>on</strong> systems are highly required.<br />

The <str<strong>on</strong>g>TFT</str<strong>on</strong>g>-<str<strong>on</strong>g>LCD</str<strong>on</strong>g> panel images have n<strong>on</strong>-uni<str<strong>on</strong>g>for</str<strong>on</strong>g>m illuminati<strong>on</strong><br />

variati<strong>on</strong>s due to imperfecti<strong>on</strong> of light source and unequal<br />

liquid crystal distributi<strong>on</strong> and so <strong>on</strong>. The <str<strong>on</strong>g>TFT</str<strong>on</strong>g>-<str<strong>on</strong>g>LCD</str<strong>on</strong>g> panels<br />

do not have a light source, <str<strong>on</strong>g>the</str<strong>on</strong>g>y need an external light source<br />

called back light unit (BLU). Despite every ef<str<strong>on</strong>g>for</str<strong>on</strong>g>t to make<br />

BLU as an ideal plane light source, BLU still allow<br />

illuminati<strong>on</strong> variati<strong>on</strong>s measured by luminance uni<str<strong>on</strong>g>for</str<strong>on</strong>g>mity<br />

(LU) as more than 80% [3]. The LU is expressed by <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

following equati<strong>on</strong>:<br />

Luminance<br />

L min<br />

Uni<str<strong>on</strong>g>for</str<strong>on</strong>g>mity (LU) 100<br />

(1)<br />

L<br />

where L and max L are <str<strong>on</strong>g>the</str<strong>on</strong>g> maximum and minimum<br />

min<br />

luminance values under <str<strong>on</strong>g>the</str<strong>on</strong>g> predefined positi<strong>on</strong>s of a <str<strong>on</strong>g>TFT</str<strong>on</strong>g>-<br />

<str<strong>on</strong>g>LCD</str<strong>on</strong>g> panel.<br />

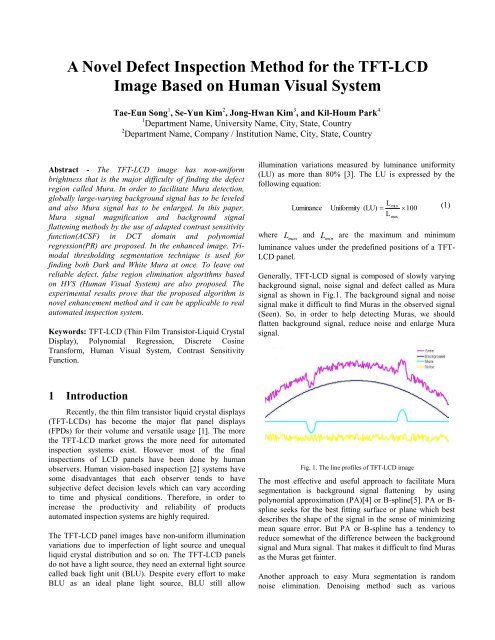

Generally, <str<strong>on</strong>g>TFT</str<strong>on</strong>g>-<str<strong>on</strong>g>LCD</str<strong>on</strong>g> signal is composed of slowly varying<br />

background signal, noise signal and defect called as Mura<br />

signal as shown in Fig.1. The background signal and noise<br />

signal make it difficult to find Muras in <str<strong>on</strong>g>the</str<strong>on</strong>g> observed signal<br />

(Seen). So, in order to help detecting Muras, we should<br />

flatten background signal, reduce noise and enlarge Mura<br />

signal.<br />

max<br />

Fig. 1. The line profiles of <str<strong>on</strong>g>TFT</str<strong>on</strong>g>-<str<strong>on</strong>g>LCD</str<strong>on</strong>g> image<br />

The most effective and useful approach to facilitate Mura<br />

segmentati<strong>on</strong> is background signal flattening by using<br />

polynomial approximati<strong>on</strong> (PA)[4] or B-spline[5]. PA or Bspline<br />

seeks <str<strong>on</strong>g>for</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> best fitting surface or plane which best<br />

describes <str<strong>on</strong>g>the</str<strong>on</strong>g> shape of <str<strong>on</strong>g>the</str<strong>on</strong>g> signal in <str<strong>on</strong>g>the</str<strong>on</strong>g> sense of minimizing<br />

mean square error. But PA or B-spline has a tendency to<br />

reduce somewhat of <str<strong>on</strong>g>the</str<strong>on</strong>g> difference between <str<strong>on</strong>g>the</str<strong>on</strong>g> background<br />

signal and Mura signal. That makes it difficult to find Muras<br />

as <str<strong>on</strong>g>the</str<strong>on</strong>g> Muras get fainter.<br />

Ano<str<strong>on</strong>g>the</str<strong>on</strong>g>r approach to easy Mura segmentati<strong>on</strong> is random<br />

noise eliminati<strong>on</strong>. Denoising method such as various

Wavelet Trans<str<strong>on</strong>g>for</str<strong>on</strong>g>m domain research has <str<strong>on</strong>g>the</str<strong>on</strong>g> best results in<br />

case of precise noise modeling [6][7]. There is a problem in<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> random noise modeling because <str<strong>on</strong>g>the</str<strong>on</strong>g> random noise is<br />

expressed by camera noise, camera distorti<strong>on</strong> and random<br />

noise, etc.<br />

And <str<strong>on</strong>g>the</str<strong>on</strong>g> o<str<strong>on</strong>g>the</str<strong>on</strong>g>r method to help Mura segmentati<strong>on</strong> is <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

enlargement of Mura signal. If <str<strong>on</strong>g>the</str<strong>on</strong>g> frequency band of Mura<br />

signal could be found exactly, we could emphasize it by<br />

magnifying this band. Generally, because <str<strong>on</strong>g>the</str<strong>on</strong>g> signal affects<br />

all frequency spectrums, finding precise cut-off frequency of<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> Mura signal is impossible. But from <str<strong>on</strong>g>the</str<strong>on</strong>g> human visual<br />

system point of view, we can emphasize more visible<br />

frequency given by <str<strong>on</strong>g>the</str<strong>on</strong>g> CSF experiment [8-10]. One of<br />

major HVS characteristics is that <str<strong>on</strong>g>the</str<strong>on</strong>g> HVS has different<br />

frequency sensitivity. Adapted CSF is proposed to visualize<br />

more salient object such as Muras.<br />

In this paper, <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>TFT</str<strong>on</strong>g>-<str<strong>on</strong>g>LCD</str<strong>on</strong>g> image defect detecti<strong>on</strong><br />

algorithm based <strong>on</strong> HVS is proposed. The PR is used <str<strong>on</strong>g>for</str<strong>on</strong>g><br />

background signal flattening while <str<strong>on</strong>g>the</str<strong>on</strong>g> proposed ACSF are<br />

used to enlarge Mura signal. Then tri-modal thresholding,<br />

which determines defect candidate as out of mean value, is<br />

employed <str<strong>on</strong>g>for</str<strong>on</strong>g> Mura segmentati<strong>on</strong>. Finally, false positive<br />

defects are eliminated based <strong>on</strong> HVS.<br />

2 The Characteristics of <str<strong>on</strong>g>TFT</str<strong>on</strong>g>-<str<strong>on</strong>g>LCD</str<strong>on</strong>g> <str<strong>on</strong>g>Image</str<strong>on</strong>g><br />

Inherently <str<strong>on</strong>g>TFT</str<strong>on</strong>g>-<str<strong>on</strong>g>LCD</str<strong>on</strong>g> panel is n<strong>on</strong>-light emitting<br />

display devices, thus <str<strong>on</strong>g>the</str<strong>on</strong>g>y need an external light source<br />

called BLU. There have been many ef<str<strong>on</strong>g>for</str<strong>on</strong>g>ts to make BLU as<br />

ideal plane light sources so that <str<strong>on</strong>g>the</str<strong>on</strong>g> illuminati<strong>on</strong> from <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

fr<strong>on</strong>tal panel can be uni<str<strong>on</strong>g>for</str<strong>on</strong>g>m [7]. Because <str<strong>on</strong>g>the</str<strong>on</strong>g> BLU is placed<br />

at <str<strong>on</strong>g>the</str<strong>on</strong>g> panel border, <str<strong>on</strong>g>the</str<strong>on</strong>g> light from <str<strong>on</strong>g>the</str<strong>on</strong>g> source would decrease<br />

according to <str<strong>on</strong>g>the</str<strong>on</strong>g> distance. To make <str<strong>on</strong>g>the</str<strong>on</strong>g> light more uni<str<strong>on</strong>g>for</str<strong>on</strong>g>mly<br />

distributed several additi<strong>on</strong>al sheets such as diffuser sheet,<br />

horiz<strong>on</strong>tal and vertical prism sheets are required. Through<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g>se sheets a light can be diffused and be c<strong>on</strong>centrated.<br />

Examples of a BLU structure and highlighted n<strong>on</strong>-uni<str<strong>on</strong>g>for</str<strong>on</strong>g>m<br />

light transmissi<strong>on</strong> from <str<strong>on</strong>g>the</str<strong>on</strong>g> source are shown in Fig. 2.<br />

(a)<br />

Gray Level<br />

(b)<br />

Fig. 2. The structure of a BLU and light transmissi<strong>on</strong> from <str<strong>on</strong>g>the</str<strong>on</strong>g> light source<br />

(a) The BLU structure (b) light emitting from a light source.<br />

(a)<br />

(b)<br />

Line Profiles<br />

200 Line<br />

183 Line<br />

190<br />

180<br />

170<br />

160<br />

150<br />

140<br />

130<br />

120<br />

110<br />

100<br />

90<br />

0 50 100 150 200 250<br />

Positi<strong>on</strong><br />

(c)<br />

Fig.3. Sample <str<strong>on</strong>g>TFT</str<strong>on</strong>g>-<str<strong>on</strong>g>LCD</str<strong>on</strong>g> image with Mura defects and its characteristics.<br />

(a) The <str<strong>on</strong>g>TFT</str<strong>on</strong>g>-<str<strong>on</strong>g>LCD</str<strong>on</strong>g> image with Mura defects, (b) signal generated <str<strong>on</strong>g>TFT</str<strong>on</strong>g>-<str<strong>on</strong>g>LCD</str<strong>on</strong>g><br />

image having Muras of various size and strength and (c) line profiles of<br />

dotted circle and arrow.

The light is diffused and c<strong>on</strong>centrated through <str<strong>on</strong>g>the</str<strong>on</strong>g>se sheets.<br />

But <str<strong>on</strong>g>the</str<strong>on</strong>g>re still exist some illuminati<strong>on</strong> variati<strong>on</strong>s measured<br />

by LU of more than 80%. Above 80% LU is c<strong>on</strong>sidered<br />

acceptable in industry. The luminance values <str<strong>on</strong>g>for</str<strong>on</strong>g> calculating<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> LU are acquired from <str<strong>on</strong>g>the</str<strong>on</strong>g> predetermined positi<strong>on</strong>s.<br />

Mura defects are darker or brighter than <str<strong>on</strong>g>the</str<strong>on</strong>g>ir neighboring<br />

normal regi<strong>on</strong>s in <str<strong>on</strong>g>TFT</str<strong>on</strong>g>-<str<strong>on</strong>g>LCD</str<strong>on</strong>g> images. They have various<br />

shapes and strengths according to <str<strong>on</strong>g>the</str<strong>on</strong>g> cause of generati<strong>on</strong>.<br />

Some of <str<strong>on</strong>g>the</str<strong>on</strong>g>m occur when unexpected <str<strong>on</strong>g>for</str<strong>on</strong>g>eign materials are<br />

inserted into <str<strong>on</strong>g>the</str<strong>on</strong>g> layers in a display panel and <str<strong>on</strong>g>the</str<strong>on</strong>g>y can be<br />

generated due to n<strong>on</strong>-uni<str<strong>on</strong>g>for</str<strong>on</strong>g>m liquid crystal distributi<strong>on</strong>, air<br />

inserti<strong>on</strong>, and partial press by external <str<strong>on</strong>g>for</str<strong>on</strong>g>ces, etc [8].<br />

Because of <str<strong>on</strong>g>the</str<strong>on</strong>g> n<strong>on</strong>-uni<str<strong>on</strong>g>for</str<strong>on</strong>g>m illuminati<strong>on</strong> characteristic of <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

background signal, dark Mura can be brighter than <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

normal background regi<strong>on</strong>. Two of our experimental <str<strong>on</strong>g>TFT</str<strong>on</strong>g>-<br />

<str<strong>on</strong>g>LCD</str<strong>on</strong>g> panel images are shown in Fig. 3(a), (b). Fig. 3(a)<br />

includes 4 White and Dark Mura defects and Fig. 3(b) has<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> signal generated Muras with various size and strength.<br />

The positi<strong>on</strong> of Muras are encircled or marked with arrows.<br />

The line profile of dotted circle and arrow is shown in Fig.3<br />

(c). From <str<strong>on</strong>g>the</str<strong>on</strong>g>se figures, <str<strong>on</strong>g>the</str<strong>on</strong>g> illuminati<strong>on</strong> of <str<strong>on</strong>g>TFT</str<strong>on</strong>g>-<str<strong>on</strong>g>LCD</str<strong>on</strong>g> image<br />

shows local and global variati<strong>on</strong>s at <str<strong>on</strong>g>the</str<strong>on</strong>g> same time.<br />

3 Proposed <str<strong>on</strong>g>Defect</str<strong>on</strong>g> Detecti<strong>on</strong> Algorithm<br />

No<br />

Not Mura<br />

Input <str<strong>on</strong>g>Image</str<strong>on</strong>g><br />

Discrete Cosine Trans<str<strong>on</strong>g>for</str<strong>on</strong>g>m<br />

Adapted CSF Filtering<br />

Inverse<br />

Discrete Cosine Trans<str<strong>on</strong>g>for</str<strong>on</strong>g>m<br />

Polynomial Regressi<strong>on</strong> Analysis<br />

Tri-modal Thresholding<br />

Labeling<br />

L<br />

if C<br />

L<br />

Result <str<strong>on</strong>g>Image</str<strong>on</strong>g><br />

Mura<br />

Fig.4. The proposed block diagram <str<strong>on</strong>g>for</str<strong>on</strong>g> <str<strong>on</strong>g>TFT</str<strong>on</strong>g>-<str<strong>on</strong>g>LCD</str<strong>on</strong>g> image defect detecti<strong>on</strong><br />

Yes<br />

The flow chart of <str<strong>on</strong>g>the</str<strong>on</strong>g> proposed algorithm is seen in Fig.<br />

4. First, <str<strong>on</strong>g>the</str<strong>on</strong>g> input image is DCT trans<str<strong>on</strong>g>for</str<strong>on</strong>g>med and <str<strong>on</strong>g>the</str<strong>on</strong>g>n<br />

proposed ACSF filter is applied to enlarge <str<strong>on</strong>g>the</str<strong>on</strong>g> Mura signal.<br />

After <str<strong>on</strong>g>the</str<strong>on</strong>g> signal is inverse Discrete Cosine Trans<str<strong>on</strong>g>for</str<strong>on</strong>g>med,<br />

polynomial regressi<strong>on</strong> (PR) process is employed <str<strong>on</strong>g>for</str<strong>on</strong>g><br />

flattening. Then <str<strong>on</strong>g>the</str<strong>on</strong>g> enhanced image is segmented by trimodal<br />

thresholding to find White and Dark Mura at <strong>on</strong>ce.<br />

To leave out reliable defects, false defects are eliminated if<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> mean gray level of a defect does not have much<br />

difference from <str<strong>on</strong>g>the</str<strong>on</strong>g>ir background.<br />

3.1 Adapted CSF in DCT Domain<br />

The human visual system(HVS) has different<br />

frequency sensitivity and that is ma<str<strong>on</strong>g>the</str<strong>on</strong>g>matically represented<br />

as CSF given by <str<strong>on</strong>g>the</str<strong>on</strong>g> experiment[8][9][10]. The HVS can<br />

detect more easily <str<strong>on</strong>g>the</str<strong>on</strong>g> difference varying in low frequency<br />

than high frequency. The CSF can be expressed by a<br />

functi<strong>on</strong> and CSF graph is shown in Fig. 5.<br />

Where,<br />

1.<br />

1<br />

H( f ) 2.<br />

6(<br />

0.<br />

192 0.<br />

114 f ) exp( (<br />

0.<br />

114 f ) ) (2)<br />

f f f is <str<strong>on</strong>g>the</str<strong>on</strong>g> frequency having unit of<br />

2<br />

x<br />

2<br />

y<br />

cycle/degree. HVS have best sensitivity around<br />

8[cycles/degree] and above 40[cycles/degree] its value<br />

become smaller and smaller.<br />

CSF Value<br />

1.4<br />

1.2<br />

1<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

0<br />

CSF Graph<br />

0 4 8 12 16 20 24 28 32 36 40 44 48 52 56 60<br />

Frequency[Cycle/Degree]<br />

Fig.5. The c<strong>on</strong>trast sensitivity functi<strong>on</strong> graph.<br />

There have been many ef<str<strong>on</strong>g>for</str<strong>on</strong>g>ts to use CSF to <str<strong>on</strong>g>the</str<strong>on</strong>g>ir<br />

applicati<strong>on</strong>s, especially in compressi<strong>on</strong>. In order to use <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

CSF in real applicati<strong>on</strong> relative sensitivity value is<br />

important[10]. Without loss of generality, <str<strong>on</strong>g>the</str<strong>on</strong>g> maximum<br />

CSF frequency can be normalized as 2 in DCT domain.<br />

The DCT has good energy compacti<strong>on</strong> property and it has<br />

also fast algorithm. The DCT has no phase in<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong>, it<br />

<strong>on</strong>ly c<strong>on</strong>sider <str<strong>on</strong>g>the</str<strong>on</strong>g> magnitude of trans<str<strong>on</strong>g>for</str<strong>on</strong>g>med data. The CSF<br />

has <strong>on</strong>ly magnitude, so it will be enough to c<strong>on</strong>sider <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

proposed ACSF in DCT domain. The proposed adapted CSF<br />

in DCT is ma<str<strong>on</strong>g>the</str<strong>on</strong>g>matically expressed by <str<strong>on</strong>g>the</str<strong>on</strong>g> followings.

H(<br />

f / 64<br />

2<br />

)<br />

ACSF( f Nor ) <br />

H(<br />

0)<br />

Where, H ( 0)<br />

is <str<strong>on</strong>g>the</str<strong>on</strong>g> c<strong>on</strong>stant value having 0.4992 and <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

adapted 1-d and 3-d CSF are shown in Fig. 6.<br />

Value<br />

2.5<br />

2<br />

1.5<br />

1<br />

0.5<br />

0<br />

0<br />

Proposed Adapted CSF in DCT Domain<br />

<br />

Frequency<br />

(a)<br />

(b)<br />

Fig. 6. The adapted CSF in DCT domain. (a) 1-d ACSF, (b) 3-d ACSF.<br />

The proposed ACSF is low frequency boost and high<br />

frequency reducti<strong>on</strong> filter shape. This filter enlarge Mura<br />

signal regi<strong>on</strong> approximately 2 times and it also enlarge<br />

background signal fluctuati<strong>on</strong> a little. As <str<strong>on</strong>g>the</str<strong>on</strong>g> LU is<br />

decreased, <str<strong>on</strong>g>the</str<strong>on</strong>g> background signal is more magnified so level<br />

adjustment process must be needed. The following secti<strong>on</strong><br />

describes how to flat <str<strong>on</strong>g>the</str<strong>on</strong>g> emphasized signal.<br />

3.2 Polynomial Regressi<strong>on</strong><br />

In general, regressi<strong>on</strong> method is used to trace general<br />

tendency of <str<strong>on</strong>g>the</str<strong>on</strong>g> signal. This method represents its target<br />

signal with best fitting functi<strong>on</strong> in mean square error (MSE)<br />

point. Out of trace signal such as Mura signal in <str<strong>on</strong>g>TFT</str<strong>on</strong>g>-<str<strong>on</strong>g>LCD</str<strong>on</strong>g><br />

image does not much affect to find degenerated signal. Each<br />

line of <str<strong>on</strong>g>TFT</str<strong>on</strong>g>-<str<strong>on</strong>g>LCD</str<strong>on</strong>g> image can be degenerated by<br />

2<br />

(3)<br />

f<br />

B<br />

R<br />

M<br />

<br />

<br />

f ( x,<br />

y)<br />

x<br />

1or<br />

y 1<br />

( x,<br />

y)<br />

<br />

M<br />

( fˆ<br />

m<br />

R ( x,<br />

y)<br />

f ( x,<br />

y))<br />

(4)<br />

Where, f ( x,<br />

y)<br />

B is biased PR functi<strong>on</strong>, R f ( x,<br />

y)<br />

is original<br />

signal, fˆ ( x,<br />

y)<br />

m is m th order estimated PR functi<strong>on</strong> and<br />

R<br />

M is <str<strong>on</strong>g>the</str<strong>on</strong>g> number of pixels.<br />

The PR in horiz<strong>on</strong>tal directi<strong>on</strong> is expressed as<br />

m<br />

m<br />

i<br />

fˆ<br />

( x,<br />

y)<br />

a x <br />

(5)<br />

R<br />

<br />

i0<br />

Where, a is i th order weight value, m is PR estimated<br />

i<br />

order and is <str<strong>on</strong>g>the</str<strong>on</strong>g> error.<br />

MSE is used to find <str<strong>on</strong>g>the</str<strong>on</strong>g> best fitting line. One horiz<strong>on</strong>tal- line<br />

MSE, E, is expressed to <str<strong>on</strong>g>the</str<strong>on</strong>g> following Eq. (6)<br />

E <br />

n<br />

<br />

i0<br />

2<br />

n<br />

m<br />

m<br />

<br />

f x,<br />

y)<br />

fˆ<br />

R ( x,<br />

y)<br />

f ( x,<br />

y)<br />

<br />

i<br />

k <br />

( ak<br />

xi<br />

<br />

(6)<br />

i0<br />

<br />

k0<br />

<br />

In order to find minimizing E , partial differentiati<strong>on</strong><br />

employed given by<br />

E<br />

a<br />

j<br />

<br />

<br />

n<br />

<br />

i0<br />

n<br />

<br />

i0<br />

<br />

2<br />

f ( x,<br />

y)<br />

<br />

<br />

f ( x ) x<br />

i<br />

j<br />

i i<br />

The equati<strong>on</strong> is expressed as<br />

n<br />

j<br />

f ( xi<br />

) x i i<br />

i0<br />

<br />

a<br />

n<br />

<br />

a<br />

m<br />

m<br />

<br />

k0<br />

n<br />

a <br />

k<br />

k0<br />

i0<br />

jk<br />

xi<br />

a<br />

m<br />

k j<br />

ak<br />

xi<br />

(<br />

xi<br />

)<br />

<br />

x<br />

jk<br />

i<br />

j<br />

xi<br />

a1<br />

0<br />

i0<br />

i0<br />

k<br />

i0<br />

i0<br />

Matrix representati<strong>on</strong> is given by<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

n<br />

<br />

x<br />

x<br />

i<br />

m<br />

i<br />

<br />

<br />

<br />

<br />

x<br />

x<br />

x<br />

i<br />

2<br />

i<br />

m1<br />

i<br />

<br />

<br />

<br />

<br />

n<br />

<br />

<br />

<br />

x<br />

<br />

x<br />

m<br />

i<br />

m1<br />

i<br />

x<br />

2m<br />

i<br />

n<br />

x<br />

n<br />

jm<br />

i<br />

0<br />

x<br />

j1<br />

i<br />

0<br />

a<br />

0 <br />

<br />

<br />

<br />

a1<br />

<br />

<br />

<br />

<br />

<br />

<br />

am<br />

<br />

<br />

<br />

<br />

<br />

2<br />

E is<br />

a<br />

i<br />

(7)<br />

(8)<br />

f ( xi<br />

) <br />

<br />

f ( xi<br />

) xi<br />

(9)<br />

<br />

m <br />

f ( xi<br />

) xi<br />

<br />

Gauss-Jordan eliminati<strong>on</strong> is used to find <str<strong>on</strong>g>the</str<strong>on</strong>g> polynomial<br />

coefficient a . i<br />

3.3 Tri-modal Thresholding<br />

After <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>TFT</str<strong>on</strong>g>-<str<strong>on</strong>g>LCD</str<strong>on</strong>g> image is enhanced, tri-modal<br />

Thresholding [3] is used to segment Dark and Bright Mura

at <strong>on</strong>ce. The tri-modal thresholding functi<strong>on</strong> fT ( x,<br />

y)<br />

is<br />

given by<br />

f T<br />

255<br />

if ( f ( x,<br />

y)<br />

m k<br />

)<br />

<br />

( x,<br />

y)<br />

128<br />

else if ( f ( x,<br />

y)<br />

m k<br />

)<br />

<br />

0<br />

else<br />

(10)<br />

Where, f ( x,<br />

y)<br />

is <str<strong>on</strong>g>the</str<strong>on</strong>g> gray level at positi<strong>on</strong> at ( x , y)<br />

, m , <br />

are <str<strong>on</strong>g>the</str<strong>on</strong>g> mean and standard deviati<strong>on</strong> respectively and k is<br />

c<strong>on</strong>trolled c<strong>on</strong>stant to access <str<strong>on</strong>g>the</str<strong>on</strong>g> amounts of abnormal gray<br />

level. After tri-modal thresholding <str<strong>on</strong>g>the</str<strong>on</strong>g> Bright Muras have<br />

value of 255, <str<strong>on</strong>g>the</str<strong>on</strong>g> Dark Muras have 128 and background<br />

regi<strong>on</strong> have value of 0.<br />

3.4 <str<strong>on</strong>g>Defect</str<strong>on</strong>g> Analysis<br />

The segmented result can have false defects such noise,<br />

neglectful small regi<strong>on</strong>, etc. So reliable defect c<strong>on</strong>firmati<strong>on</strong>,<br />

defect analysis process is needed. In this paper, HVS based<br />

false regi<strong>on</strong> eliminati<strong>on</strong> method is proposed. The noticeable<br />

Luminance difference is given by <str<strong>on</strong>g>the</str<strong>on</strong>g> Weber C<strong>on</strong>stant C Weber<br />

in <str<strong>on</strong>g>the</str<strong>on</strong>g> Weber regi<strong>on</strong> as <str<strong>on</strong>g>the</str<strong>on</strong>g> following Equati<strong>on</strong> (11) [11].<br />

C W eber<br />

L<br />

(11)<br />

L<br />

Where, L, L<br />

are <str<strong>on</strong>g>the</str<strong>on</strong>g> background regi<strong>on</strong> luminance and <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

luminance differences between <str<strong>on</strong>g>the</str<strong>on</strong>g> background regi<strong>on</strong> and<br />

defect regi<strong>on</strong>. We use C value as 0.02 in this paper.<br />

Weber<br />

4 Experimental Results<br />

The proposed method is tested by using <str<strong>on</strong>g>the</str<strong>on</strong>g> 160 real<br />

Muras and 40 generated <strong>on</strong>es. The acquired <str<strong>on</strong>g>TFT</str<strong>on</strong>g>-<str<strong>on</strong>g>LCD</str<strong>on</strong>g><br />

images have 400 m spatial resoluti<strong>on</strong> <str<strong>on</strong>g>for</str<strong>on</strong>g> each pixel and an<br />

8-bit brightness resoluti<strong>on</strong>. To evaluate <str<strong>on</strong>g>the</str<strong>on</strong>g> per<str<strong>on</strong>g>for</str<strong>on</strong>g>mance of<br />

proposed algorithm, <strong>on</strong>e dimensi<strong>on</strong>al line profile, <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

enhanced result image and final segmented Muras al<strong>on</strong>g<br />

with detecti<strong>on</strong> accuracy table are shown in this paper.<br />

The proposed defect detecti<strong>on</strong> results are shown in Fig. 7.<br />

The test image Fig. 7(a) has artificially generated Muras<br />

with various strengths and sizes. In <str<strong>on</strong>g>the</str<strong>on</strong>g> enhanced result<br />

image, Fig. 7(b), <str<strong>on</strong>g>the</str<strong>on</strong>g> defect is more visible than original<br />

image and that are evident in Fig.7 (e),(h),(k) also. The<br />

original image of Fig. 7(g) has much background variati<strong>on</strong>,<br />

so <str<strong>on</strong>g>the</str<strong>on</strong>g> defects are rarely seen in <str<strong>on</strong>g>the</str<strong>on</strong>g> original image. But <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

enhanced image has relatively flattening background and <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

defects are more salient. In <str<strong>on</strong>g>the</str<strong>on</strong>g> test image Fig. 7(j), novel<br />

enhancement result is given and that helps final<br />

segmentati<strong>on</strong> result.<br />

(a) (b) (c)<br />

(d) (e) (f)<br />

(g) (h) (i)<br />

(j) (k) (l)<br />

Fig. 7 The results of proposed methods. (a),(d),(g),(j) are test images,<br />

(b),(e),(h),(k) are enhanced results and (c),(f),(i),(l) are final segmented<br />

results of original image (a),(d),(g),(j) respectively.<br />

The microscopic enhancement results by <str<strong>on</strong>g>the</str<strong>on</strong>g> line profiles are<br />

shown in Fig. 8. Fig. 8 is <str<strong>on</strong>g>the</str<strong>on</strong>g> enhancement results’ profiles<br />

of Fig. 7. By that, <str<strong>on</strong>g>the</str<strong>on</strong>g> effectiveness of our algorithm is seen<br />

more clearly. In <str<strong>on</strong>g>the</str<strong>on</strong>g> filtered line profile results, our proposed<br />

enhancement method can flatten <str<strong>on</strong>g>the</str<strong>on</strong>g> background signal<br />

fluctuati<strong>on</strong> and emphasize <str<strong>on</strong>g>the</str<strong>on</strong>g> defect regi<strong>on</strong>.<br />

The final per<str<strong>on</strong>g>for</str<strong>on</strong>g>mance results are summarized in Table 1.<br />

false-positive and false-negative measure are used to<br />

evaluate <str<strong>on</strong>g>the</str<strong>on</strong>g> accuracy of defect detecti<strong>on</strong> result. There are<br />

some problems to <str<strong>on</strong>g>the</str<strong>on</strong>g> eliminati<strong>on</strong> of defects existing at <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

boundary regi<strong>on</strong> and very weak-small-size defects. Except<br />

such cases, <str<strong>on</strong>g>the</str<strong>on</strong>g> false-positive rate and false-negative rate are<br />

quite acceptable.<br />

Table 1. Experimental results <str<strong>on</strong>g>for</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> detecti<strong>on</strong> of <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

Muras.<br />

Number of<br />

<str<strong>on</strong>g>Defect</str<strong>on</strong>g>s<br />

False-positive Falsenegative<br />

Artificially<br />

Generated Mura<br />

160 0.04 0.03<br />

Real Mura 40 0.03 0.02

Gray Level<br />

Gray Level<br />

Gray Level<br />

Gray Level<br />

150<br />

140<br />

130<br />

120<br />

110<br />

100<br />

Line Profiles<br />

Original 183 Line<br />

Enhanced 183 Line<br />

90<br />

0 50 100 150 200 250<br />

110<br />

105<br />

100<br />

95<br />

90<br />

85<br />

Positi<strong>on</strong><br />

(a)<br />

Line Profiles<br />

Original 95 Line<br />

Enhanced 95 line<br />

80<br />

0 50 100 150 200 250<br />

190<br />

180<br />

170<br />

160<br />

150<br />

140<br />

130<br />

Positi<strong>on</strong><br />

(b)<br />

Line Profiles<br />

Original 200 Line<br />

Enhanced 200 Line<br />

120<br />

0 50 100 150 200 250<br />

200<br />

190<br />

180<br />

170<br />

160<br />

Positi<strong>on</strong><br />

(c)<br />

Line Profiles<br />

Original 128 Line<br />

Enhanced 128 Line<br />

150<br />

0 50 100 150 200 250<br />

Positi<strong>on</strong><br />

(d)<br />

Fig. 8 The line profiles of original image and enhanced result. (a),(b),(c),(d)<br />

are line profiles of Fig. 7(a),(d),(g),(j) and Fig. 7(b),(e),(h),(k) respectively.<br />

5 C<strong>on</strong>clusi<strong>on</strong>s<br />

In this paper, a novel defect detecti<strong>on</strong> algorithm in <str<strong>on</strong>g>TFT</str<strong>on</strong>g>-<br />

<str<strong>on</strong>g>LCD</str<strong>on</strong>g> image with <str<strong>on</strong>g>the</str<strong>on</strong>g> guidance of enhanced image using<br />

ACSF and PR is proposed. The ACSF in DCT domain is<br />

used to emphasize defect regi<strong>on</strong> while PR is employed to<br />

level <str<strong>on</strong>g>the</str<strong>on</strong>g> background signal. Tri-modal thresholding<br />

segmentati<strong>on</strong> method is utilized in order to find White Mura<br />

and Dark Mura at <str<strong>on</strong>g>the</str<strong>on</strong>g> same time. The defect candidates are<br />

given by <str<strong>on</strong>g>the</str<strong>on</strong>g> distant gray level from <str<strong>on</strong>g>the</str<strong>on</strong>g> mean. For reliable<br />

defect c<strong>on</strong>firmati<strong>on</strong>, Weber’s C<strong>on</strong>stant is used <str<strong>on</strong>g>for</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

purpose of eliminating false detected defects.<br />

The effectiveness of our methods is tested by <str<strong>on</strong>g>the</str<strong>on</strong>g> two points.<br />

One is image enhancement and <str<strong>on</strong>g>the</str<strong>on</strong>g> o<str<strong>on</strong>g>the</str<strong>on</strong>g>r is final<br />

segmentati<strong>on</strong> result. Mura signal is clearly enlarged al<strong>on</strong>g<br />

with background signal flatten. The final defect detecti<strong>on</strong><br />

results are evaluated by false-positive and false-negative<br />

measure. By <str<strong>on</strong>g>the</str<strong>on</strong>g> experimental results our proposed method<br />

has novel result in finding defects in <str<strong>on</strong>g>TFT</str<strong>on</strong>g>-<str<strong>on</strong>g>LCD</str<strong>on</strong>g> image and it<br />

can be applicable to similar FPD images.<br />

6 References<br />

[1] B. K. Noh, K. H. Kim, et al., <str<strong>on</strong>g>LCD</str<strong>on</strong>g> ENGINEERING,<br />

Sung An Dang, 2002.<br />

[2] VESA Flat Panel Display Measurements Standard Ver<br />

2.0, June 1,2001.<br />

[3] J.H. Oh, D.M. Kwak, K. B Lee, et al. "Line defect<br />

detecti<strong>on</strong> in <str<strong>on</strong>g>TFT</str<strong>on</strong>g>-<str<strong>on</strong>g>LCD</str<strong>on</strong>g> using directi<strong>on</strong>al filter bank and<br />

adaptive multilevel thresholding", Key Engineering<br />

Materials, vol..270-273, 233-238 2004.<br />

[4] Seung-Il Baek, Woo-Seob, Tak-mo Koo, Il Choi and<br />

Kil-Houm Park, "INSPECTION OF DEFECT ON <str<strong>on</strong>g>LCD</str<strong>on</strong>g><br />

PANEL USING POLYNOMIAL APPROXIMATION,"<br />

TENCON 2004.2004 IEEE Regi<strong>on</strong> 10 C<strong>on</strong>ference Volume<br />

A. 21-24 Nov. 2004 pp. 235~238.Vol. 2004.<br />

[5] Gyu-B<strong>on</strong>g Lee, Cho<strong>on</strong>g-Gun Lee, Se-Yun Kim, Kil-<br />

Houm Park, "Adative Surface Fitting <str<strong>on</strong>g>for</str<strong>on</strong>g> <str<strong>on</strong>g>Inspecti<strong>on</strong></str<strong>on</strong>g> of FPD<br />

Devicess Using Multilevel B-spline Approximati<strong>on</strong>," The<br />

21st Internati<strong>on</strong>al Technical C<strong>on</strong>ference <strong>on</strong> Circuits/Systems,<br />

Computers and Communicati<strong>on</strong>s vol. 2, pp. 205~208. 2006.<br />

[6] David L.D<strong>on</strong>oho, Iain M. Johnst<strong>on</strong>e, et al, "Adapting<br />

to Unknown Smoothness via Wavelet Shrinkage",<br />

[7] Imola K. Fodor, Chandrika Kamath, "Denoising<br />

Through Wavelet Shrinkage: An Empirical Study", Journal<br />

of Electr<strong>on</strong>ic Imaging, July 27, 2001<br />

[8] Xiao Liang, Wu Huizh<strong>on</strong>g, "Multiple Perceptual<br />

Watermarks Using Multiple-<str<strong>on</strong>g>Based</str<strong>on</strong>g> Number C<strong>on</strong>versi<strong>on</strong> in<br />

Wavelet Domain," Proceedings of ICCT2003, pp. 213 - 216,<br />

2003<br />

[9] Ajeetkumar Gaddipatti, Raghu Maciraju, R<strong>on</strong>i Yagel,<br />

"Steering <str<strong>on</strong>g>Image</str<strong>on</strong>g> Generati<strong>on</strong> with Wavelet <str<strong>on</strong>g>Based</str<strong>on</strong>g> Perceptual<br />

Metric",Gaddipati et al.<br />

[10] Garrett M.Johns<strong>on</strong> and Mark D.Fairchild Munsell<br />

Color Science Laboratory, Center <str<strong>on</strong>g>for</str<strong>on</strong>g> Imaging Science<br />

Rochester Institude of Technology, Rochester New York,<br />

"On C<strong>on</strong>trast Sensitivity in an <str<strong>on</strong>g>Image</str<strong>on</strong>g> Diffrence Model"<br />

[11] Hecht, "The visual discriminati<strong>on</strong> of intensity and <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

Weber-Fechner law", J. Gen. Phsiol., vol.7, pp.241, 1924.

[12] S. G. Mallat, "A <str<strong>on</strong>g>the</str<strong>on</strong>g>ory of multiresoluti<strong>on</strong> signal<br />

decompositi<strong>on</strong> : <str<strong>on</strong>g>the</str<strong>on</strong>g> wavelet representati<strong>on</strong>," IEEE Trans.<br />

Patten Analysis Machine Intell. Vol. 11, pp. 674-493, 1989.<br />

[13] Leslie Lamport. “LaTeX: A Document Preparati<strong>on</strong><br />

System”. Addis<strong>on</strong>-Wesley Publishing Company, 1986.<br />

[14] Ree Source Pers<strong>on</strong>. “Title of Research Paper”; name of<br />

journal (name of publisher of <str<strong>on</strong>g>the</str<strong>on</strong>g> journal), Vol. No., Issue<br />

No., Page numbers (eg.728—736), M<strong>on</strong>th, and Year of<br />

publicati<strong>on</strong> (eg. Oct 2006).