2012 METU Lecture 5 Control of Smart Systems - Department of ...

2012 METU Lecture 5 Control of Smart Systems - Department of ...

2012 METU Lecture 5 Control of Smart Systems - Department of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

<strong>Lecture</strong> 1: Introduction to <strong>Smart</strong> Materials and<br />

<strong>Systems</strong><br />

<strong>Lecture</strong> 2: Sensor technologies for smart systems<br />

and their evaluation criteria.<br />

<strong>Lecture</strong> 3: Actuator technologies for smart<br />

systems and their evaluation criteria.<br />

<strong>Lecture</strong> 4: Piezoelectric Materials and their<br />

Applications.<br />

<strong>Lecture</strong> 5: <strong>Control</strong> System Technologies.<br />

<strong>Lecture</strong> 6: <strong>Smart</strong> System Applications.<br />

S. Eswar Prasad,<br />

Adjunct Pr<strong>of</strong>essor, <strong>Department</strong> <strong>of</strong> Mechanical & Industrial Engineering,<br />

Chairman, Piemades Inc,<br />

⎋ Piemades, Inc.<br />

1

<strong>Control</strong> Technologies<br />

for <strong>Smart</strong> <strong>Systems</strong><br />

S. Eswar Prasad,<br />

Adjunct Pr<strong>of</strong>essor, <strong>Department</strong> <strong>of</strong> Mechanical & Industrial Engineering,<br />

Chairman, Piemades Inc,<br />

⎋ Piemades, Inc.<br />

2

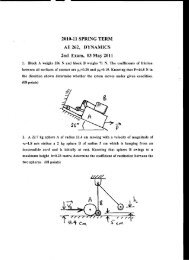

<strong>Control</strong> Technologies for <strong>Smart</strong> <strong>Systems</strong><br />

• <strong>Control</strong> <strong>Systems</strong> Overview<br />

Open loop and closed loop systems<br />

• <strong>Control</strong> System Characteristics<br />

Steady State, Transient Response and Stability<br />

• <strong>Control</strong>ler Operation<br />

Proportional, Compensated<br />

• Digital <strong>Control</strong> <strong>Systems</strong><br />

<strong>Control</strong> algorithms, implementation, hardware<br />

• <strong>Control</strong> System Design<br />

3<br />

3

<strong>Control</strong> <strong>Systems</strong> Overview<br />

•<br />

•<br />

•<br />

•<br />

Deals with influencing the behaviour <strong>of</strong> dynamic systems<br />

Interdisciplinary field, which originated in engineering and<br />

mathematics, and evolved into use by the social sciences, like<br />

psychology, sociology, criminology and in financial systems.<br />

<strong>Control</strong> systems have four basic functions; Measure,<br />

Compare, Compute, and Correct.<br />

These four functions are completed by three elements;<br />

Sensors, Actuators, <strong>Control</strong> System. In a smart system, these<br />

three elements are typically contained in one unit.<br />

4

<strong>Control</strong> <strong>Systems</strong> Overview<br />

Definition <strong>of</strong> a <strong>Smart</strong> System<br />

5

<strong>Control</strong> <strong>Systems</strong> Overview<br />

Historical<br />

Feedback control (Bode,1945)<br />

Theory <strong>of</strong> Stochastic Processes (Weiner, 1930)<br />

Root Locus Theory (Evans, 1948)<br />

Modern <strong>Control</strong> (1950s, Kalman, Bellman, Pontryagin)<br />

• Root locus theory remains an important technique today.<br />

• Suitable for design and stability analysis.<br />

Root locus analysis is a graphical method for examining how the<br />

roots <strong>of</strong> a system change with variation <strong>of</strong> a certain system<br />

parameter, commonly the gain <strong>of</strong> a feedback system. This is a<br />

technique used in the field <strong>of</strong> control systems developed by Walter<br />

R. Evans.<br />

6

<strong>Control</strong> <strong>Systems</strong> Overview<br />

Root locus approach<br />

Assumption<br />

The definition <strong>of</strong> the damping ratio and natural frequency<br />

presumes that the overall feedback system is well approximated by<br />

a second order system, that is, the system has a dominant pair <strong>of</strong><br />

poles.<br />

Uses<br />

• Determine the stability <strong>of</strong> the system<br />

• Design for the damping ratio and natural frequency <strong>of</strong> a<br />

feedback system.<br />

• Lag, lead, PI, PD and PID controllers can be designed<br />

approximately with this technique.<br />

7

<strong>Control</strong> <strong>Systems</strong> Overview<br />

•<br />

•<br />

•<br />

Example: cruise control <strong>of</strong> a car<br />

Cruise <strong>Control</strong> is a device designed to<br />

maintain vehicle speed at a constant desired<br />

or reference speed provided by the driver.<br />

The controller is the cruise control, the plant<br />

is the car, and the system is the car and the<br />

cruise control. The system output is the car's<br />

speed, and the control itself is the engine's<br />

throttle position which determines how<br />

much power the engine generates.<br />

8

<strong>Control</strong> System Technology<br />

•<br />

•<br />

Method-1. Implement cruise control by simply locking the<br />

throttle position when the driver engages cruise control.<br />

However, if the cruise control is engaged on a stretch <strong>of</strong> flat<br />

road, then the car will travel slower going uphill and faster<br />

when going downhill.<br />

Method-2. Use the system output (the car's speed) to<br />

control the throttle position. As a result, the controller can<br />

compensate for changes acting on the car, like a change in<br />

the slope <strong>of</strong> the road.<br />

9

<strong>Control</strong> <strong>Systems</strong> Overview<br />

Types <strong>of</strong> <strong>Control</strong> systems<br />

• Open Loop <strong>Control</strong><br />

• Closed Loop <strong>Control</strong><br />

10

Open Loop System<br />

•<br />

•<br />

Reference<br />

Input<br />

<strong>Control</strong>ler<br />

Actuating<br />

Signal<br />

<strong>Control</strong>led Process<br />

(Plant)<br />

General block diagram <strong>of</strong> an open-loop system<br />

<strong>Control</strong>led<br />

Variable<br />

(output)<br />

An open-loop controller is <strong>of</strong>ten used in simple processes<br />

because <strong>of</strong> its simplicity and low cost, especially in systems<br />

where feedback is not critical<br />

An open-loop controller, also called a non-feedback controller,<br />

is a type <strong>of</strong> controller that computes its input into a system<br />

using only the current state and its model <strong>of</strong> the system.<br />

11

Open Loop System<br />

Reference<br />

Input<br />

•<br />

•<br />

<strong>Control</strong>ler<br />

Actuating<br />

Signal<br />

<strong>Control</strong>led Process<br />

(Plant)<br />

General block diagram <strong>of</strong> an open-loop system<br />

<strong>Control</strong>led<br />

Variable<br />

(output)<br />

A characteristic <strong>of</strong> the open-loop controller is that it<br />

does not use feedback to determine if its output has<br />

achieved the desired goal <strong>of</strong> the input. This means that<br />

the system does not observe the output <strong>of</strong> the<br />

processes that it is controlling.<br />

It also may not compensate for disturbances in the<br />

system.<br />

12

Open Loop System<br />

Reference<br />

Input<br />

•<br />

<strong>Control</strong>ler<br />

Actuating<br />

Signal<br />

<strong>Control</strong>led Process<br />

(Plant)<br />

General block diagram <strong>of</strong> an open-loop system<br />

<strong>Control</strong>led<br />

Variable<br />

(output)<br />

Typical examples: Washing Machine, for which the length <strong>of</strong><br />

machine wash time is entirely dependent on the judgment<br />

and estimation <strong>of</strong> the human operator. Some Irrigation<br />

Sprinklers are programmed to turn on/<strong>of</strong>f at set times. It<br />

does not measure soil moisture as a form <strong>of</strong> feedback. Even if<br />

rain is pouring down on the lawn, the sprinkler system would<br />

activate on schedule, wasting water.<br />

13

Closed Loop System<br />

Reference<br />

Input<br />

Error<br />

Detector<br />

+ -<br />

Feedback<br />

Signal<br />

Error<br />

Signal<br />

<strong>Control</strong>ler<br />

Actuating<br />

Signal<br />

Feedback Path Elements<br />

<strong>Control</strong>led<br />

Process<br />

(Plant)<br />

General block diagram <strong>of</strong> a closed-loop control system<br />

<strong>Control</strong>led<br />

Variable<br />

(output)<br />

A closed-loop controller uses feedback to control states or outputs<br />

<strong>of</strong> a dynamical system. Its name comes from the information path in<br />

the system: Process inputs have an effect on the process outputs,<br />

which is measured with sensors and processed by the controller;<br />

the result (the control signal) is used as input to the process, closing<br />

the loop.<br />

14

Error<br />

Detector<br />

Closed Loop System<br />

Reference<br />

Input<br />

Signal<br />

<strong>Control</strong>ler<br />

Closed-loop controllers have the following advantages over open-loop<br />

controllers:<br />

• Reduce error (eliminating the error)<br />

• Reduce sensitivity or Enhance robustness<br />

• Disturbance rejection or elimination<br />

• Improve dynamic performance or adjust the transient response (such as<br />

reduce time constant) rejection (such as unmeasured friction in a motor)<br />

+ -<br />

Feedback<br />

Signal<br />

• unstable processes can be stabilized<br />

• improved reference tracking performance<br />

Error<br />

Actuating<br />

Signal<br />

Feedback Path Elements<br />

<strong>Control</strong>led<br />

Process<br />

(Plant)<br />

General block diagram <strong>of</strong> a closed-loop control system<br />

<strong>Control</strong>led<br />

Variable<br />

15

Closed Loop System<br />

•<br />

•<br />

•<br />

•<br />

•<br />

Examples <strong>of</strong> Closed Loop <strong>Systems</strong><br />

An air conditioning system or a heating system in a house.<br />

The mouse on a computer<br />

A joystick on a video game<br />

Reference<br />

Input<br />

<strong>Control</strong>ler<br />

The speed control (cruise control) on an automobile.<br />

+ -<br />

Feedback<br />

Signal<br />

Error<br />

Error<br />

Signal<br />

Actuating<br />

Signal<br />

Feedback Path Elements<br />

<strong>Control</strong>led<br />

Process<br />

(Plant)<br />

General block diagram <strong>of</strong> a closed-loop control system<br />

<strong>Control</strong>led<br />

Variabl<br />

16

Closed Loop System<br />

Sensor<br />

The output <strong>of</strong> the system y(t) is fed back through a sensor<br />

measurement F to the reference value r(t). The controller C<br />

then takes the error e (difference) between the reference and the<br />

output to change the inputs u to the system under control P.<br />

This kind <strong>of</strong> controller is a closed-loop controller or feedback<br />

controller.<br />

This is called a single-input-single-output (SISO) control system;<br />

MIMO (i.e., Multi-Input-Multi-Output) systems, with more than one<br />

input/output, are common. In such cases variables are represented<br />

through vectors instead <strong>of</strong> simple scalar values.<br />

17

Closed Loop System<br />

Sensor<br />

If we assume the controller C, the plant P, and the sensor F are linear and timeinvariant<br />

(i.e., elements <strong>of</strong> their transfer function C(s), P(s), and F(s) do not depend on<br />

time), the systems above can be analyzed using the Laplace transform on the<br />

variables. This gives the following relations:<br />

Solving for Y(s) in terms <strong>of</strong> R(s) gives:<br />

18

Closed Loop System<br />

The expression<br />

Sensor<br />

is referred to as the closed-loop transfer function <strong>of</strong> the system. The numerator is<br />

the forward (open-loop) gain from r to y, and the denominator is one plus the gain in<br />

going around the feedback loop, the so-called loop gain. If , i.e., it has a large norm<br />

with each value <strong>of</strong> s, and if ,<br />

then Y(s) is approximately equal to R(s) and the output closely tracks the reference<br />

input.<br />

19

Selection <strong>of</strong> a <strong>Control</strong> System<br />

Trade-<strong>of</strong>fs<br />

An open-loop<br />

system<br />

• Simplicity and low cost<br />

• Complexity and higher cost<br />

A closed-loop<br />

system<br />

20

Elements <strong>of</strong> <strong>Control</strong> <strong>Systems</strong> Response Characteristics<br />

• Steady State Response<br />

• Transient Response<br />

• Stability<br />

21

Elements <strong>of</strong> <strong>Control</strong> <strong>Systems</strong> Response Characteristics<br />

Steady State Response is defined as the output <strong>of</strong> the plant.<br />

Difference between final value and the desired value is known as<br />

the steady-state error.<br />

Amplitude<br />

Input Command<br />

Overshoot<br />

Transient Response<br />

Time<br />

Steady State Response<br />

Steady State<br />

Error<br />

22

Elements <strong>of</strong> <strong>Control</strong> <strong>Systems</strong> Response Characteristics<br />

Transient Response is defined as the change undergone by plant from<br />

time input is applied to the time taken to reach steady state. The ideal<br />

situation is to reach the final state accurately and in as little time as<br />

possible.<br />

Four parameters define the transient response.<br />

Amplitude<br />

Input Command<br />

Overshoot<br />

Transient Response<br />

Time<br />

Steady State Response<br />

Steady State<br />

Error<br />

23

Elements <strong>of</strong> <strong>Control</strong> <strong>Systems</strong> Response Characteristics<br />

Amplitude<br />

Input Command<br />

Overshoot<br />

Transient Response<br />

Settling time, ts, is the time it takes output to settle within a specified boundary<br />

typically 2%).<br />

Rise time, tr, is the time it takes for the output to change from 10% to 90% <strong>of</strong> final<br />

value.<br />

Peak time, tp, is the time to reach the vicinity <strong>of</strong> set point, and usually the largest,<br />

peak.<br />

Overshoot, Mp, is the amount that the peak exceeds the steady state value at the<br />

peak time. generally expressed as a percentage <strong>of</strong> the final steady state value.<br />

Time<br />

Steady State Response<br />

Steady State<br />

Error<br />

24

Elements <strong>of</strong> <strong>Control</strong> <strong>Systems</strong> Response Characteristics<br />

• Stability is defined as the ability <strong>of</strong> a control system to<br />

achieve its goal without going into oscillation.<br />

• The total response <strong>of</strong> a control system is a combination<br />

<strong>of</strong> the natural response, totally governed by the plant,<br />

and the forced response, typically governed by the<br />

controller.<br />

• It is a mandatory requirement that a control system be<br />

stable.<br />

25

Open loop<br />

Closed Loop<br />

Step response <strong>of</strong> a control system<br />

26

Elements <strong>of</strong> <strong>Control</strong> <strong>Systems</strong> Response Characteristics<br />

Considering a second order system, we can derive expressions for<br />

the terms using the pole location parameters ζ and ωn.<br />

27

Elements <strong>of</strong> <strong>Control</strong> <strong>Systems</strong> Response Characteristics<br />

Considering a second order system, we can derive expressions for<br />

the terms using the pole location parameters ζ and ωn.<br />

28

<strong>Control</strong>ler Operation<br />

<strong>Control</strong>ler provides a means to allow the output <strong>of</strong> a system to<br />

track the input. Using frequency domain analysis methods, the<br />

transfer function can be expressed as,<br />

Ideally , Y(s)=1, and the output tracks input perfectly. <strong>Control</strong>lers<br />

are broadly classified into two types.<br />

• Proportional <strong>Control</strong>lers<br />

• Compensated <strong>Control</strong>lers<br />

29

Proportional <strong>Control</strong>lers<br />

In the proportional control algorithm, the controller output is<br />

proportional to the error signal, which is the difference between<br />

the set point and the process variable. In other words, the output<br />

<strong>of</strong> a proportional controller is the multiplication product <strong>of</strong> the<br />

error signal and the proportional gain.<br />

This can be mathematically expressed as<br />

where<br />

Pout: Output <strong>of</strong> the proportional controller<br />

Kp: Proportional gain<br />

e(t): Instantaneous process error at time 't'. e(t) = SP − PV<br />

SP: Set point<br />

PV: Process variable<br />

30

Compensated <strong>Control</strong>lers<br />

• Compensation is a technique used to change the root locus so<br />

that it passes through a desired pole position.<br />

• This process involves the selective positioning <strong>of</strong> additional<br />

poles and zeros into the overall response <strong>of</strong> the system.<br />

• Compensation can be used to improve both the steady state<br />

error and the transient response.<br />

• Most controllers now are implemented digitally.<br />

31

PID <strong>Control</strong>lers<br />

A proportional–integral–derivative controller (PID controller) is a<br />

generic control loop feedback mechanism (controller) widely used<br />

in industrial control systems – a PID is the most commonly used<br />

feedback controller. A PID controller calculates an "error" value as<br />

the difference between a measured process variable and a desired<br />

set point. The controller attempts to minimize the error by<br />

adjusting the process control inputs.<br />

u(t)<br />

+<br />

-<br />

P<br />

+<br />

e(t)<br />

+<br />

∑ ∑ Plant/Process<br />

I<br />

D<br />

+<br />

y(t)<br />

32

PID <strong>Control</strong>lers<br />

• The PID controller calculation (algorithm) involves three separate constant<br />

parameters, the proportional, the integral and derivative values, denoted P, I, and<br />

D.<br />

• These values can be interpreted in terms <strong>of</strong> time: P depends on the present<br />

error, I on the accumulation <strong>of</strong> past errors, and D is a prediction <strong>of</strong> future<br />

errors, based on current rate <strong>of</strong> change. The weighted sum <strong>of</strong> these three<br />

actions is used to adjust the process via a control element.<br />

• In the absence <strong>of</strong> knowledge <strong>of</strong> the underlying process, a PID controller is the<br />

best controller. By tuning the three parameters in the PID controller algorithm,<br />

the controller can provide control action designed for specific process<br />

requirements.<br />

• The the use <strong>of</strong> the PID algorithm for control does not guarantee optimal<br />

control <strong>of</strong> the system or system stability.<br />

CONTROL SYSTEMS, ROBOTICS, AND AUTOMATION – Vol. II - PID <strong>Control</strong> - Araki M.<br />

http://en.wikipedia.org/wiki/Special:BookSources/9-780863412998<br />

http://en.wikipedia.org/wiki/PI_controller#PI_controller<br />

33

PID <strong>Control</strong>lers<br />

In PID control the sum <strong>of</strong> its three correcting terms constitutes<br />

the manipulated variable (MV). The proportional, integral, and<br />

derivative terms are summed to calculate the output <strong>of</strong> the PID<br />

controller. Defining u(t) as the controller output, the final form <strong>of</strong><br />

the PID algorithm is:<br />

where<br />

Kp : Proportional gain, a tuning parameter<br />

Ki : Integral gain, a tuning parameter<br />

Kd : Derivative gain, a tuning parameter<br />

e : Error = SP − PV<br />

t : Time or instantaneous time (the present)<br />

34

PID <strong>Control</strong>lers<br />

u(t)<br />

+<br />

P<br />

+<br />

e(t)<br />

+<br />

∑ ∑ Plant/Process<br />

-<br />

Parameter Rise Time Overshoot Settling Time<br />

I<br />

D<br />

+<br />

Steady-state<br />

Error<br />

y(t)<br />

Stability<br />

Kp Decrease Increase Small Change Decrease Degrade<br />

Ki Decrease Increase Increase<br />

Kd<br />

Small Increase<br />

Small<br />

decrease<br />

Small<br />

decrease<br />

Large<br />

decrease<br />

No effect in<br />

theory<br />

Ang, K.H., Chong, G.C.Y., and Li, Y. (2005) PID control system analysis, design, and technology.<br />

IEEE Transactions on <strong>Control</strong> <strong>Systems</strong> Technology, 13 (4). pp. 559-576.<br />

Jinghua Zhong (2006). PID <strong>Control</strong>ler Tuning: A Short Tutorial.<br />

Degrade<br />

Improve if Kd<br />

is small<br />

35

PID <strong>Control</strong>lers<br />

Open Loop step response (OL) Proportional <strong>Control</strong> (P) Proportional Derivative control (PD)<br />

http://www.engin.umich.edu/group/ctm/PID/PID.html<br />

Proportional Integral control (PI) Proportional-Integral-Derivative <strong>Control</strong> (PID)<br />

36

PID <strong>Control</strong>lers - Limitations<br />

• While PID controllers are applicable to many control problems,<br />

and <strong>of</strong>ten perform satisfactorily without any improvements or<br />

even tuning, they can perform poorly in some applications, and<br />

do not in general provide optimal control.<br />

• The fundamental difficulty with PID control is that it is a<br />

feedback system, with constant parameters, and no direct<br />

knowledge <strong>of</strong> the process, and thus overall performance is<br />

reactive and a compromise.<br />

37

PID <strong>Control</strong>lers - Limitations<br />

• PID controllers, when used alone, can give poor performance<br />

when the PID loop gains must be reduced so that the control<br />

system does not overshoot, oscillate or hunt about the control<br />

set point value.<br />

• PID controllers have difficulties in the presence <strong>of</strong> nonlinearities,<br />

may trade-<strong>of</strong>f regulation versus response time, do not<br />

react to changing process behaviour (say, the process changes<br />

after it has warmed up), and have lag in responding to large<br />

disturbances.<br />

38

PID <strong>Control</strong>lers - Limitations & Solutions<br />

• While PID control is the best controller with no model <strong>of</strong> the<br />

process, better performance can be obtained by incorporating a<br />

model <strong>of</strong> the process.<br />

• The most significant improvement is to incorporate feedforward<br />

control with knowledge about the system, and using<br />

the PID only to control error.<br />

• PIDs can also be modified in more minor ways, such as by<br />

changing the parameters (either gain scheduling in different use<br />

cases or adaptively modifying them based on performance),<br />

improving measurement (higher sampling rate, precision, and<br />

accuracy, and low-pass filtering if necessary), or cascading<br />

multiple PID controllers.<br />

39

Design <strong>of</strong> <strong>Control</strong> <strong>Systems</strong> - Process<br />

Objectives<br />

• To aid the product or process - the mechanism, the robot, the<br />

chemical plant, the aircraft, etc to do its job.<br />

• Optimize performance for stability, disturbance regulation,<br />

tracking accuracy or reduction <strong>of</strong> the effects <strong>of</strong> parameter<br />

variations.<br />

40

Design <strong>of</strong> <strong>Control</strong> <strong>Systems</strong> - Process Steps<br />

• Understand the process and its performance requirements.<br />

• Select the number and type <strong>of</strong> sensor(s) considering the<br />

location, technology and noise.<br />

• Select the number and types <strong>of</strong> actuators considering the<br />

location, technology, noise and power.<br />

• Develop a linear model <strong>of</strong> the process, actuator and sensor.<br />

• Design a compensated controller.<br />

• Test, modify and re-test.<br />

Feedback <strong>Control</strong> <strong>of</strong> dynamic <strong>Systems</strong>, Franklin, Powell and Emami-Naeini, 2006 Prentice-Hall.<br />

41

Design <strong>of</strong> <strong>Control</strong> <strong>Systems</strong> - Analogue <strong>Systems</strong><br />

• Typically consist <strong>of</strong> an operational amplifier based active filter<br />

with either lowpass or bandpass characteristics.<br />

• Responses are governed by available filter types - Bessel,<br />

Chebyshev and Butterworth.<br />

• Low pass compensators also known as lag compensators or PI<br />

(Proportional Integral) controllers.<br />

• Bandpass networks are referred as lead-lag compensators or<br />

PID controllers.<br />

42

Design <strong>of</strong> <strong>Control</strong> <strong>Systems</strong> - Digital <strong>Systems</strong><br />

Desired<br />

Response<br />

+<br />

+<br />

-<br />

Error<br />

Digital<br />

<strong>Control</strong>ler<br />

Response<br />

Analogueto-Digital<br />

Converter<br />

Digital-to-<br />

Analogue<br />

COnverter<br />

Feedback<br />

Sensor<br />

Response<br />

Digital <strong>Systems</strong> typically mimic analogue varieties.<br />

Plant<br />

Response<br />

Exception is that <strong>of</strong> data conversion <strong>of</strong> both controller output and<br />

feedback signals.<br />

Output<br />

Response<br />

43

Design <strong>of</strong> <strong>Control</strong> <strong>Systems</strong> - Digital <strong>Systems</strong><br />

Advantages<br />

• Easier implementation, since responses can be programmed.<br />

• Parameter drift is eliminated.<br />

• Changes are easy and almost always require no circuit<br />

modifications.<br />

• Reductions in size, power, weight and cost.<br />

• Reliability (easier testing and verification regimes).<br />

44

Design <strong>of</strong> <strong>Control</strong> <strong>Systems</strong> - Digital <strong>Systems</strong><br />

Digital controllers, in addition to PID, provide additional<br />

algorithms.<br />

• Notch Filter<br />

Notch filters are used to control mechanical resonances in a<br />

plant.<br />

• Dead Beat <strong>Control</strong>ler<br />

Deadbeat controller provides very short settling times in a<br />

control system by replacing all <strong>of</strong> the poles in the systems with<br />

poles at the origin.<br />

• Adaptive Filter<br />

Adaptive filters are useful when plant response cannot be<br />

determined due to insufficient information or if it is subjected<br />

to time varying change. Can also be used to characterize an<br />

unknown plant.<br />

45

Algorithm Implementation Considerations<br />

Digital processing systems operate using sampled data instead <strong>of</strong><br />

continuous data as is used in analogue systems. Mathematically,<br />

differential equations are used to model DSP functions.<br />

A DSP contains a MAC or Multiply-Accumulate Instruction. This<br />

allows the multiplication <strong>of</strong> one variable by another and the<br />

subsequent summation <strong>of</strong> the resulting product with the<br />

accumulator, all operations occurring in one processor cycle.<br />

This fact makes DSP processors ideal candidates for medium to<br />

high performance embedded control applications requiring<br />

computation intensive processing.<br />

Two <strong>of</strong> the most important building blocks <strong>of</strong> DSP are FIT and the<br />

IIR filters.<br />

46

Algorithm Implementation Considerations - FIR Filter<br />

"FIR" means "Finite Impulse Response".<br />

They can easily be designed to be "linear phase" (and usually are).<br />

Put simply, linear-phase filters delay the input signal but don’t<br />

distort its phase.<br />

They are simple to implement. On most DSP microprocessors, the<br />

FIR calculation can be done by looping a single instruction.<br />

They are suited to multi-rate applications.<br />

FIR Filters are feedforward filters where the output values are a<br />

function <strong>of</strong> a finite number <strong>of</strong> past input values.<br />

FIR filters tend to be used where pass band characteristics are<br />

specified. These include the start and end <strong>of</strong> passband and ripple.<br />

47

Algorithm Implementation Considerations - IIR Filter<br />

IIR means "Infinite Impulse Response".<br />

The impulse response is "infinite" because there is feedback in the<br />

filter.<br />

IIR filters can achieve a given filtering characteristic using less<br />

memory and calculations than a similar FIR filter.<br />

They are however more susceptible to problems <strong>of</strong> finite-length<br />

arithmetic, such as noise generated by calculations, and limit cycles.<br />

They are harder (slower) to implement using fixed-point<br />

arithmetic.<br />

They don't <strong>of</strong>fer the computational advantages <strong>of</strong> FIR filters for<br />

multirate (decimation and interpolation) applications.<br />

48

Algorithm Implementation Considerations - Filter Comparison<br />

IIR FIR<br />

More efficient Less efficient<br />

Analog equivalent No analog equivalent<br />

May be unstable Always stable<br />

Non-liner phase response Linear phase response<br />

No efficiency gained by<br />

decimation<br />

Decimation increases<br />

efficiency<br />

49

<strong>Control</strong> System Hardware Implementation<br />

Sensor<br />

Input<br />

condition<br />

Desired<br />

Response<br />

Input<br />

• The heart <strong>of</strong> the controller is the processor.<br />

• It is <strong>of</strong>ten single chip device.<br />

Digital<br />

Signal<br />

Processor<br />

Plant<br />

• There are three types:<br />

microcontrollers, microprocessors<br />

DSPs.<br />

Code/Data<br />

Memory<br />

Output<br />

condition<br />

Functional Diagram <strong>of</strong> a DSP based <strong>Control</strong>ler<br />

Driver<br />

50

<strong>Control</strong> System Hardware Implementation - Microcontrollers<br />

• Microcontrollers are single chip devices with a low to medium<br />

performance core, a basic for <strong>of</strong> I/O (input/output), memory.<br />

• Processors do not contain any inherent mathematical type<br />

functions. complex operations must be performed with simpler<br />

arithmetic, logical, and data move functions.<br />

• Can be used in low performance applications. best suited for<br />

high volume, simple function control systems that do not<br />

demand high performance.<br />

• Cost is relatively low.<br />

• Examples are: PIC family, Motorola 68H series and Intel 8051<br />

series.<br />

51

<strong>Control</strong> System Hardware Implementation - Microprocessors<br />

• Microprocessors are generally low to high performance devices<br />

that rely on external I/O peripherals and memory for proper<br />

operation.<br />

• Operational speeds are higher than microcontrollers.<br />

• More complex instructions are available as well as some floating<br />

point arithmetic on the chip or as a processor.<br />

• can be used in low to moderate performance control systems,<br />

including ancillary functions such as human-machine interfaces.<br />

• Cost is moderate to high.<br />

• Examples are Motorola’s 68000 and Power PC families; AMD<br />

Opteron family, Cypress Semiconductor PSoC family and Intel<br />

i960 family.<br />

52

<strong>Control</strong> System Hardware Implementation - DSPs<br />

• DSPs are high performance processors, optimized for<br />

computational efficiency.<br />

• built in ports for interfacing with ADCs and DACs and other<br />

processors.<br />

• Data can be represented in fixed point or floating point<br />

formats. Programs can be loaded from eternal memory.<br />

• Handle moderate to high performance control systems.<br />

• Cost is low to moderate.<br />

• Examples are Analog Devices 21xx family, Texas Instruments<br />

C6000 family and Motorola 96000 family.<br />

53

<strong>Control</strong> System Hardware Implementation - Factors<br />

• Sensor input<br />

dynamic range, sampling rate, number <strong>of</strong> sensor inputs<br />

interface, polled or interrupt driven.<br />

• <strong>Control</strong> algorithm<br />

fixed point or floating point, computational performance<br />

requirements, data storage requirement, program storage<br />

requirement.<br />

• <strong>Control</strong>ler output considerations<br />

Same as sensor input.<br />

• Cost and Schedule<br />

COST versus product development.<br />

54

<strong>Control</strong> System Hardware Implementation - Typical Plant Parameters<br />

Parameter Sensing Method<br />

Position<br />

Speed<br />

Acceleration<br />

Potentiometer (linear or angular)<br />

LVDT (Linear)<br />

Resolver (Angular)<br />

Optical Encoder (Linear or Angular)<br />

Tachometer (RPM to voltage)<br />

Hall Effect (Frequency)<br />

Optical Encoder (Frequency)<br />

Piezoelectric Accelerometer<br />

Strain Gage Accelerometer<br />

55

<strong>Control</strong> System Hardware Implementation - Typical Plant Parameters<br />

Parameter Sensing Method<br />

Temperature<br />

Pressure<br />

Force<br />

Flow Rate<br />

Thermocouple<br />

Semiconductor Junction<br />

Thermisotr<br />

Strain Gage<br />

Piezoelectric Force Transducer<br />

Strain Gage<br />

Piezoelectric Force Transducer<br />

Differential Pressure<br />

Impeller (Frequency)<br />

Thermal (Differential temperature)<br />

56

<strong>Control</strong> System Hardware Implementation - Factors<br />

LNA<br />

BPF<br />

DSP Input Schematic Diagram<br />

VGA<br />

ADC<br />

VGA <strong>Control</strong><br />

from DSP<br />

• Input Signal Conditioning<br />

Amplification <strong>of</strong> sensor signals, filtered, variable gain amplifier for<br />

adjustment, analogue to digital converter and interface to DSP.<br />

• <strong>Control</strong>ler Response<br />

local control - no operator inout<br />

control by another processor through a port - interactive<br />

control<br />

Data to<br />

DSP<br />

57

<strong>Control</strong> System Hardware Implementation - Factors<br />

Data<br />

from DSP<br />

<strong>Control</strong><br />

from DSP<br />

DAC<br />

PWM<br />

DSP Output Schematic Diagram<br />

Plant<br />

Drive<br />

• <strong>Control</strong>ler Output<br />

Output signal is converted back to analogue signal with a DAC,<br />

filtered, fed to power amplifier.<br />

LPF<br />

Buffer<br />

PA<br />

PA<br />

Plant<br />

Drive<br />

58

<strong>Control</strong> System Hardware Implementation - Method<br />

• Translate the system requirements into a design specification<br />

• Translate the design specification into a functional block<br />

diagram.<br />

• Optimize the block diagram.<br />

• Translate the block diagram into a mathematical model.<br />

• Optimize the mathematical model.<br />

59

<strong>Control</strong> System Hardware Implementation - Block Diagram<br />

60

<strong>Control</strong> System Hardware Implementation - Case Studies<br />

• Computer Hard disk <strong>Control</strong> System.<br />

This case study demonstrates the ability to perform classical<br />

digital control design by going through the design <strong>of</strong> a<br />

computer hard-disk read/write head position controller.<br />

• Automobile Active Suspension System.<br />

The vehicle suspension system is responsible for driving<br />

comfort and safety as the suspension caries the vehicle body<br />

and transmits all forces between the body and the road. By<br />

adding an active suspension comfort and safety are<br />

considerably improved compared to suspension setups with<br />

fixed properties.<br />

61

Hard Disc Drive Description<br />

62

Hard Disc Drive Description<br />

• Disk read/write heads are the small parts <strong>of</strong> a disk drive, that move<br />

above the disk platter and transform platter's magnetic field into<br />

electrical current (read the disk) or vice versa – transform electrical<br />

current into magnetic field (write the disk)<br />

• They are high-precision, high- performance machines produced in very<br />

high volumes and sold at relatively low cost.<br />

63

Performance <strong>of</strong> a Hard Disc Drive<br />

There are three ways to measure the performance <strong>of</strong> a hard disk:<br />

• Data Rate – The data rate is the number <strong>of</strong> bytes per second<br />

that the drive can deliver to the CPU. Rates between 5 and 40<br />

megabytes per second are common.<br />

• Seek Time – The seek time is the amount <strong>of</strong> time between<br />

when the CPU requests a file and when the first byte <strong>of</strong> the file<br />

is sent to the CPU. Times between 10 and 20 milliseconds are<br />

common.<br />

• Capacity - The other important parameter is the capacity <strong>of</strong> the<br />

drive, which is the number <strong>of</strong> bytes it can hold.<br />

64

Hard Disc Drive Description<br />

• In a hard drive, the heads 'fly' above the disk surface with clearance <strong>of</strong> as<br />

little as 3 nanometres. The "flying height" is constantly decreasing to<br />

enable higher areal density. The flying height <strong>of</strong> the head is controlled by<br />

the design <strong>of</strong> an air-bearing etched onto the disk-facing surface <strong>of</strong> the<br />

slider. The role <strong>of</strong> the air bearing is to maintain the flying height constant<br />

as the head moves over the surface <strong>of</strong> the disk. If the head hits the disk's<br />

surface, a catastrophic head crash can result.<br />

66

Hard Disc Drive Construction Details<br />

Platters <strong>of</strong> a Hard disc Hard disc head<br />

The microphotograph <strong>of</strong> the head shows that the size <strong>of</strong> the front face<br />

is about 0.3 mm. One functional part <strong>of</strong> the head is the round, orange<br />

structure in the middle - the lithographically defined copper coil <strong>of</strong> the<br />

write transducer.<br />

67

Hard Disc Drive Description<br />

• The plates are manufactured to amazing tolerances and are mirrorsmooth<br />

and typically spin at 3,600 or 7,200 rpm when the drive is<br />

operating.<br />

• The light and fast-moving arm holds the read/write heads and is<br />

controlled by the voice-coil actuator. The arm is able to move the<br />

heads from the hub to the edge <strong>of</strong> the drive and can do this, back<br />

and forth, up to 50 times per second.<br />

• In order to keep the magnetic head as close to the disk surface as<br />

possible, a self-pressurized air-bearing design is used for the sliders.<br />

68

Design Challenges<br />

• To design each <strong>of</strong> the four main components <strong>of</strong> the disk drive<br />

servo system – plant dynamics, sensors, actuators, and control<br />

algorithms – and to reduce the effect <strong>of</strong> mechanical disturbances<br />

to the drive.<br />

• Disturbances arise from many sources: external shocks and<br />

vibrations, mechanical imperfections in the bearings <strong>of</strong> the disk<br />

spindle, disk vibrations, turbulent flow over the actuator due to<br />

air currents generated by the rapidly spinning disks, and the<br />

occasional contact between the slider and the disk.<br />

• Plant dynamics which affect servo performance are mechanical<br />

resonances in the suspension (the leaf spring that holds the head<br />

against the disk), the actuator arm, the pivot bearing, and the<br />

voice coil.<br />

69

Design Challenges<br />

• The pivot bearing also has nonlinear friction dynamics, which<br />

include hysteresis and which primarily affect seek performance.<br />

• Flutter vibration modes in the disks and other modes in the<br />

spindle contribute to tracking errors by moving the data track<br />

relative to an inertial frame <strong>of</strong> reference.<br />

• Noise and distortion are two other important sources <strong>of</strong><br />

tracking error in disk drives. Noise arises not only from<br />

electronics, but also from the magnetic media.<br />

• The magnetoresistive head readers are nonlinear devices.<br />

• Quantization noise is, <strong>of</strong> course, present in this digital control<br />

system.<br />

70

Functional Block Diagram<br />

71

Computer Hard Disc Drive - Transfer Function<br />

Using Newton's law, a simple model for the read/write head is the<br />

differential equation:<br />

where J is the inertia <strong>of</strong> the head assembly, C is the viscous damping<br />

coefficient <strong>of</strong> the bearings, K is the return spring constant, Ki is the<br />

motor torque constant, θ is the angular position <strong>of</strong> the head, and i is<br />

the input current.<br />

Taking the Laplace transform, the transfer function from i to θ is<br />

Using the values J = 0.01 kg m 2 , C = 0.004 Nm/(rad/sec), K = 10 Nm/<br />

rad, and Ki = 0.05 Nm/rad, form the transfer function description <strong>of</strong> this<br />

system.<br />

Transfer function:<br />

72

<strong>Control</strong> System Performance<br />

Step Response with large Phase margin Step response with filter<br />

Step response with controller implemented<br />

73

Active Suspension <strong>Systems</strong> - Introduction<br />

Active or adaptive suspension technology controls the<br />

vertical movement <strong>of</strong> the wheels with an onboard system<br />

rather than the movement being determined entirely by<br />

the road surface.<br />

The system virtually eliminates body roll and pitch<br />

variation in many driving situations including cornering,<br />

accelerating, and braking.<br />

This technology allows car manufacturers to achieve a<br />

greater degree <strong>of</strong> ride quality and car handling by keeping<br />

the tires perpendicular to the road in corners, allowing<br />

better traction and control.<br />

74

<strong>Control</strong> System Hardware Implementation -<br />

Active Suspension <strong>Systems</strong> Studies<br />

• The vehicle suspension system is responsible for<br />

driving comfort and safety as the suspension caries<br />

the vehicle body and transmits all forces between the<br />

body and the road.<br />

• Active systems enable the suspension system to<br />

adapt to various driving conditions. By adding a<br />

variable damper and/or spring, driving comfort and<br />

safety are considerably improved compared to<br />

suspension setups with fixed properties.<br />

75

Suspension <strong>Systems</strong> - Safety and Stability Issues<br />

• Safety is the result <strong>of</strong> a good suspension design in terms <strong>of</strong><br />

wheel suspension, springing, steering, and braking, and is<br />

reflected in an optimal dynamic behaviour <strong>of</strong> the vehicle.<br />

• Tire load variation is an indicator for the road contact and can<br />

be used for determining a quantitative value for safety.<br />

• Driving comfort results from keeping the physiological stress<br />

that the vehicle occupants are subjected to by vibrations, noise,<br />

and climatic conditions down to as low a level as possible.<br />

• The acceleration <strong>of</strong> the body is an obvious quantity for the<br />

motion and vibration <strong>of</strong> the car body and can be used for<br />

determining a quantitative value for driving comfort.<br />

76

Suspension <strong>Systems</strong> - Conflicting Criteria<br />

• In order to improve the ride quality, it is necessary to isolate<br />

the body.<br />

• To improve the ride stability, it is important to keep the tire in<br />

contact with the road surface.<br />

• For a given suspension spring, the better isolation <strong>of</strong> the sprung<br />

mass from road disturbances can be achieved with a s<strong>of</strong>t<br />

damping by allowing a larger suspension deflection.<br />

• Better road contact can be achieved with a hard damping<br />

preventing unnecessary suspension deflections.<br />

Therefore, the ride quality and the drive stability are two<br />

conflicting criteria.<br />

77

Suspension <strong>Systems</strong> - Currently Available <strong>Systems</strong><br />

• Currently three types <strong>of</strong> vehicle suspensions are used: passive,<br />

semi-active, and active.<br />

• <strong>Systems</strong> implemented in automobiles today are based on<br />

hydraulic or pneumatic operation.<br />

• These solutions do not satisfactorily solve the vehicle oscillation<br />

problem, or they are very expensive and increase the vehicle’s<br />

energy consumption.<br />

• Significant improvement <strong>of</strong> suspension performance is achieved<br />

by active systems, however, they are expensive and complex.<br />

78

Suspension <strong>Systems</strong> - Model<br />

Inputs<br />

The system has ten inputs, six <strong>of</strong> which are exogenous and the others<br />

controllable. These inputs are:<br />

• Exogenous:<br />

The road velocity inputs experienced at each wheel<br />

Vehicle pitch force (due to accelerating/braking/cornering the vehicle)<br />

Vehicle roll input (due to cornering the vehicle)<br />

• <strong>Control</strong>lable:<br />

Actuator forces applied to the suspension system at each corner <strong>of</strong><br />

the vehicle.<br />

• Outputs<br />

The ride quality can be quantified by examining the vertical and angular<br />

accelerations <strong>of</strong> the vehicle body, as well as the ability for the vehicle to<br />

remain level regardless <strong>of</strong> operating conditions.<br />

79

Suspension <strong>Systems</strong> - Operating Scenarios for<br />

modelling<br />

1. Driving over a speed bump (generates a vertical<br />

velocity pr<strong>of</strong>ile input).<br />

2. Braking at 1 g by applying the appropriate pitch<br />

moment to the vehicle centre <strong>of</strong> gravity.<br />

3. Cornering by applying the appropriate pitch and roll<br />

moment to the vehicle centre <strong>of</strong> gravity.<br />

80

Suspension <strong>Systems</strong> - LQR Models<br />

Design <strong>of</strong> an LQR <strong>Control</strong> Strategy for Implementation on a Vehicular Active Suspension System<br />

Ben Creed, Nalaka Kahawatte, Scott Varnhagen 2010 – University <strong>of</strong> California, Davis<br />

81

Suspension <strong>Systems</strong> - Bose System<br />

• The Bose system uses a linear electromagnetic motor (LEM) at<br />

each wheel in lieu <strong>of</strong> a conventional shock- and-spring setup.<br />

Amplifiers provide electricity to the motors in such a way that<br />

their power is regenerated with each compression <strong>of</strong> the<br />

system.<br />

• The main benefit <strong>of</strong> the motors is that they are not limited by<br />

the inertia inherent in conventional fluid-based dampers. As a<br />

result, an LEM can extend and compress at a much greater<br />

speed, virtually eliminating all vibrations in the passenger cabin.<br />

• The wheel's motion can be so finely controlled that the body <strong>of</strong><br />

the car remains level regardless <strong>of</strong> what's happening at the<br />

wheel. The LEM can also counteract the body motion <strong>of</strong> the car<br />

while accelerating, braking, and cornering, giving the driver a<br />

greater sense <strong>of</strong> control.<br />

82

Bose Active Suspension System<br />

83

Active Suspension <strong>Systems</strong><br />

Bose Active Suspension<br />

84

Active Suspension <strong>Systems</strong><br />

The Siemens eCorner project<br />

The eCorner concept replaces the conventional wheel suspension with hydraulic shock<br />

absorbers, mechanical steering, hydraulic brakes and internal combustion engines with<br />

integrated in-wheel systems<br />

85

Resources<br />

Feedback <strong>Control</strong> <strong>of</strong> Dynamic <strong>Systems</strong>, Gene Franklin, David<br />

Powell and Abbas Emami-Naeini, Pearson Prentice-Hall, 2006.<br />

Feedback <strong>Control</strong> <strong>Systems</strong>, Charles Phillips and Royce Harbour,<br />

Prentice-Hall, 2000.<br />

Mechatronics, G.S. Hegde, Jones and Bartlett Publishers LLC, 2010.<br />

Introduction to Mechatronics and Measurement <strong>Systems</strong>, A.<br />

Alciatore and M. Histand, McGraw Hill, 2003.<br />

86

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

<strong>Lecture</strong> 1: Introduction to <strong>Smart</strong> Materials and<br />

<strong>Systems</strong><br />

<strong>Lecture</strong> 2: Sensor technologies for smart systems<br />

and their evaluation criteria.<br />

<strong>Lecture</strong> 3: Actuator technologies for smart<br />

systems and their evaluation criteria.<br />

<strong>Lecture</strong> 4: Piezoelectric Materials and their<br />

Applications.<br />

<strong>Lecture</strong> 5: <strong>Control</strong> System Technologies.<br />

<strong>Lecture</strong> 6: <strong>Smart</strong> System Applications.<br />

S. Eswar Prasad,<br />

Adjunct Pr<strong>of</strong>essor, <strong>Department</strong> <strong>of</strong> Mechanical & Industrial Engineering,<br />

Chairman, Piemades Inc,<br />

⎋ Piemades, Inc.<br />

87