3180,3 kB - Media Center - HAVI Logistics

3180,3 kB - Media Center - HAVI Logistics

3180,3 kB - Media Center - HAVI Logistics

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

04 09<br />

We Generate Our<br />

<strong>HAVI</strong> Has a Strong<br />

Presence at<br />

McDonald’s<br />

Worldwide<br />

Convention<br />

alphabet<br />

THE <strong>HAVI</strong> LOGISTICS MAGAZINE<br />

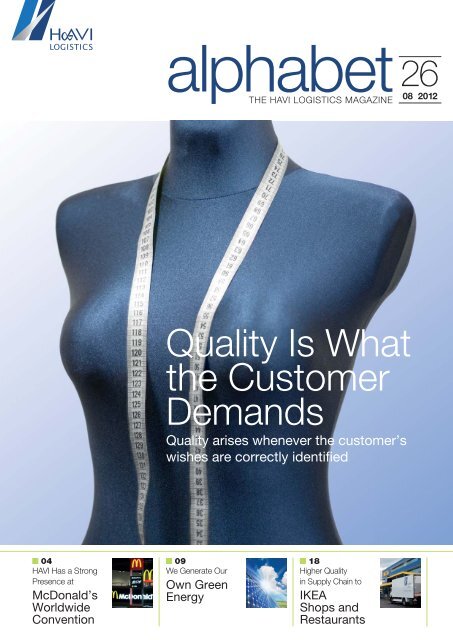

Quality Is What<br />

the Customer<br />

Demands<br />

Quality arises whenever the customer’s<br />

wishes are correctly identifi ed<br />

Own Green<br />

Energy<br />

18<br />

Higher Quality<br />

in Supply Chain to<br />

IKEA<br />

Shops and<br />

Restaurants<br />

26<br />

08 2012

2<br />

3<br />

9<br />

Content<br />

Editorial<br />

Development<br />

4<br />

6<br />

7<br />

Environment<br />

8<br />

<strong>HAVI</strong> Has a Strong<br />

Presence at McDonald’s<br />

Worldwide Convention<br />

Quality Without Compromise<br />

You Can’t Buy Compliance<br />

“Best of Sustainable<br />

Supply 2012” Award<br />

We Receive a<br />

“Sustainability Charter”<br />

We Generate Our<br />

Own Green Energy<br />

Publishing Information<br />

Proprietor:<br />

<strong>HAVI</strong> Global <strong>Logistics</strong> GmbH<br />

Publisher:<br />

Hans-Werner Krohn<br />

Content and Style Editor:<br />

Jasmin Schürgers<br />

Improvement<br />

10<br />

<strong>HAVI</strong> Global <strong>Logistics</strong> GmbH<br />

Geitlingstr. 20<br />

47228 Duisburg, Germany<br />

Phone: +49 (0) 20 65 / 695 541<br />

Fax: +49 (0) 20 65 / 695 252<br />

Email: info@havi-logistics.com<br />

www.havi-logistics.com<br />

Successful <strong>Logistics</strong> for the<br />

Euro 2012<br />

Quality & Service<br />

12<br />

14<br />

16<br />

17<br />

Quality Is What the<br />

Customer Demands<br />

Quality Is Not a Goal But<br />

a Never-Ending Process<br />

Interview with<br />

Lukas Curschellas<br />

Change for the Better<br />

10<br />

4 9<br />

Publishing Council:<br />

Haluk Ilkdemirci,<br />

Arnd Christochowitz,<br />

Hans-Werner Krohn,<br />

Sven-Carsten Sachse<br />

Layout:<br />

SanderWerbung GmbH<br />

Hans-Pfi tzner-Str. 31<br />

47057 Duisburg, Germany<br />

Printer:<br />

DRS Weirich<br />

Business Print Service GmbH<br />

Industriestrasse 17,<br />

41564 Kaarst, Germany<br />

Enlargement<br />

18<br />

19<br />

20<br />

21<br />

Just a Moment<br />

22<br />

23<br />

Higher Quality in the Supply<br />

Chain to IKEA Shops and<br />

Restaurants<br />

We Aquire Our First Customer<br />

in the Hotel Segment<br />

Llaollao - International<br />

Expansion Is Assisted by<br />

<strong>HAVI</strong> <strong>Logistics</strong><br />

<strong>HAVI</strong> <strong>Logistics</strong> Turkey<br />

Grows with Its New<br />

Customers<br />

Certifi ed as an “Especially<br />

Authentic Employer”<br />

Staying Focused…<br />

14<br />

Awards for <strong>HAVI</strong> <strong>Logistics</strong><br />

Poland<br />

This and the following editions could not be<br />

realized without the great help of our <strong>HAVI</strong><br />

<strong>Logistics</strong> members and all the other System<br />

Players. Thanks in advance for sending interesting<br />

topics to be published in the future.<br />

alphabet is printed on Satimat green (Antalis)<br />

200 g/sqm (cover) and 150/sqm (content).<br />

Satimat green is produced using 60% recovered<br />

fi ber with 40% virgin fi ber, and is an FSCcertifi<br />

ed product. Furthermore, Satimat green is<br />

climate neutral.<br />

www.fsc.org<br />

QUALITY<br />

MIX<br />

FSC ®<br />

Paper from<br />

responsible sources<br />

C021878<br />

QUALITY<br />

QU QUA QU QUA Q LIT IT ITY

source cover: thinkstock / sewing dummy over white<br />

source p. 3: fotolia / tom · source p. 14: thinkstock /Ryan McVay · source p. 20: LlaoLlao · source p. 22: Roberts Coffee<br />

20<br />

21<br />

Editorial<br />

Dear Friends and Partners<br />

of <strong>HAVI</strong> <strong>Logistics</strong>,<br />

The business of our customer, and<br />

therefore also our business, is infl uenced<br />

by many external and internal factors such<br />

as the situation of the world economy,<br />

food scandals and cost-cutting initiatives<br />

which hamper our efforts to carry out<br />

our growth plans. As we cope with these<br />

challenges, it is very important that we do<br />

not lose sight of our customers’ top priority,<br />

namely quality!<br />

Ever since our company was founded in<br />

1981, we have always tried our best to<br />

satisfy all our customers’ demands for<br />

the highest standards of quality and food<br />

safety, reliable supply chain management<br />

and innovative logistics concepts. At the<br />

same time our logistics activities were<br />

always in line with environmental sustainability<br />

and corporate social responsibility.<br />

This promise to our customers remains<br />

unchanged up to the present day and is<br />

becoming even more important.<br />

Achieving customer satisfaction is our top<br />

priority. We believe that it is not suffi cient<br />

to simply carry out our tasks well, to work<br />

carefully, to always be reliable, fast and<br />

clean, and to avoid making errors. It is not<br />

enough to just fi ne tune our range of services;<br />

instead, we also have to refi ne the<br />

quality of the services we deliver and the<br />

way they are performed. We want to be<br />

the perfect service provider – the one who<br />

does not only think the way its customers<br />

think but also anticipates their future requirements<br />

and comes up with innovative<br />

solutions.<br />

Quality and food safety are the essence<br />

of our customers’ business. Our customers<br />

expect a lot from us and our services.<br />

They expect to receive the goods they<br />

have ordered in the right quantity and<br />

quality and at the right time and place.<br />

They expect a proper fl ow of goods and<br />

information provided without any compromises.<br />

They expect that quality and food<br />

safety will not suffer while operational effi<br />

ciency continuously increases. It goes<br />

without saying that we are fully dedicated<br />

to meeting our customers’ expectations.<br />

Summing up, we acknowledge that our<br />

customers’ demands are nothing new for<br />

us. We can only achieve customer satisfaction<br />

by committing to and ensuring<br />

quality and food safety. We constantly<br />

strive to optimize our customers' supply<br />

chain and help them in becoming better<br />

and excelling in the products and services<br />

they offer.<br />

I hope you will enjoy reading the magazine.<br />

Yours sincerely,<br />

Haluk Ilkdemirci, President <strong>HAVI</strong> <strong>Logistics</strong> Europe<br />

alphabet I AUGUST 2012<br />

3

4<br />

Development<br />

<strong>HAVI</strong> Has a Strong<br />

Presence at<br />

McDonald’s Worldwide<br />

Convention<br />

On April 23-26, more than 15,000 McDonald’s owner/<br />

operators, suppliers and company employees gathered<br />

in Orlando, Florida for the 2012 McDonald’s<br />

Worldwide Convention. It was a celebration of System<br />

progress, a rally to drive for a bolder future and a<br />

showcase of the tools and solutions available<br />

to drive even greater results.<br />

<strong>HAVI</strong> had a strong presence at this<br />

year’s Convention, with employees from<br />

the <strong>HAVI</strong> Group and all three <strong>HAVI</strong> companies<br />

attending and making the most<br />

of the opportunity to connect with our<br />

customers. <strong>HAVI</strong> Global Solutions and<br />

The Marketing Store were two of the 250<br />

exhibiting suppliers on the exhibition<br />

fl oor, which covered more than 700,000<br />

square feet, while examples of <strong>HAVI</strong> were<br />

featured in multiple other booths.<br />

<strong>HAVI</strong> People all over the<br />

Convention Floor<br />

Over 100 <strong>HAVI</strong> employees from all of our<br />

business units and from countries around<br />

the world were present on the Convention<br />

fl oor to help share the <strong>HAVI</strong> story and listen<br />

to our customers as they toured the<br />

Convention fl oor over the fi ve days.

<strong>Logistics</strong> experts from <strong>HAVI</strong> <strong>Logistics</strong> Europe<br />

and <strong>HAVI</strong> <strong>Logistics</strong> Asia were ready<br />

to answer questions in the Supply Chain<br />

booth as were team members from <strong>HAVI</strong><br />

Global Solutions in the packaging area of<br />

the same booth.<br />

<strong>HAVI</strong> demonstrated its leadership on the<br />

sustainability front by coordinating the<br />

diversion of over 41 tons of food waste so<br />

that it could be composted rather than being<br />

dumped into a local landfi ll. A running<br />

ticker sign showed attendees how many<br />

pounds of waste were being diverted on<br />

a minute-by-minute basis - a great way to<br />

start a conversation about the recycling<br />

support <strong>HAVI</strong> can provide to Owner Op-<br />

erators both in the U.S. and around the<br />

world. A three minute video from <strong>HAVI</strong><br />

<strong>Logistics</strong> Environmental Service about the<br />

zero waste initiative in The Netherlands<br />

and Belgium ran continuously, reminding<br />

everyone who passed by that it is possible<br />

to convert or recycle all forms of waste<br />

that come out of a McDonald’s restaurant.<br />

This was the overall theme of the Convention<br />

and appeared in the global sessions,<br />

the area of the world sessions and all over<br />

the exhibit fl oor. The clear message was<br />

that consumers expect more from brands<br />

Brand Br Ambition – Good Food,<br />

Good G People, Good Neighbor<br />

Kevin Newell<br />

Think Bold. Act Bold. Be Bold.<br />

McDonald’s unveiled its<br />

new Brand Ambition in one<br />

of the global sessions, and<br />

it was reinforced in every<br />

area of the world session,<br />

showing alignment around<br />

the the System. Global Chief Brand Offi cer<br />

Kev Kevin Newell described the Brand Ambi-<br />

tio tion as a set of “internal screens” for ac-<br />

tio tion, not an external advertising campaign.<br />

HHe<br />

said it captures McDonald’s potential<br />

to<br />

touch the world like no other Brand and<br />

mmake<br />

a difference for customers, commu-<br />

nities nnities<br />

and the planet. He also emphasized<br />

the the importance of working together as a<br />

Syst System and with customers – because<br />

“inc “incredible power is unleashed when we<br />

do do things together.”<br />

Sustainability<br />

Su<br />

SSustainability<br />

was a big focus for the<br />

CConvention<br />

and will play an increasing<br />

rrole<br />

in McDonald’s business going forward.<br />

It was an integral part of the Brand<br />

Ambition messaging and the exhibit fl oor<br />

showcased it in a variety of ways: green<br />

leaf logos highlighted exhibit booths with<br />

a product or message supporting sustain-<br />

today than<br />

ever before, and McDonald’s must push<br />

for a bolder future. Continuing to lead in<br />

the marketplace will require out-of-the<br />

box thinking, creative ideas and bold<br />

action in line with McDonald’s priorities<br />

of optimizing the Menu, Modernizing the<br />

Experience and Broadening Accessibility.<br />

ability and recycling of various materials<br />

was available on the Convention fl oor.<br />

Leadership Transition<br />

McDonald’s CEO Jim Skinner retired at<br />

the end of June so the Convention was<br />

a celebration of his role in McDonald’s<br />

success and the legacy he leaves behind.<br />

Jim expressed his confi -<br />

dence in his successor,<br />

Don Thompson, and in<br />

new COO, Tim Fenton. Don<br />

made it clear that the transition<br />

would be seamless, emphasizing<br />

that McDonald’s<br />

would continue its focus<br />

on the Plan To Win and the<br />

three global priorities going<br />

forward.<br />

Don Thompson<br />

Tim Fenton<br />

“We at <strong>HAVI</strong> can be proud to be such an<br />

important supplier for McDonald’s,” says<br />

Russ Smith. “We should feel confi dent in<br />

the future direction of the company. There<br />

are plenty of opportunities for us to help<br />

McDonald’s continue to grow and, as a<br />

result, help our business grow. We have<br />

a key role to play in helping McDonald’s<br />

meet the challenges the future will bring,”<br />

he continued.<br />

alphabet I AUGUST 2012<br />

5

6<br />

Development<br />

Quality Without Compromise<br />

Now that <strong>HAVI</strong> <strong>Logistics</strong> has taken over salad distribution in Spain,<br />

it is delivering the entire range of goods for McDonald’s<br />

restaurants safely and reliably in this country, too.<br />

A McDonald’s restaurant uses up to 8<br />

different types of salad leaves – romaine,<br />

iceberg, batavia, frisee, spinach, rocket,<br />

Lollo Rosso and tatsoi (which originated<br />

in Asia) – and all of them are grown under<br />

controlled conditions that are carefully<br />

monitored. In Spain McDonald’s uses<br />

salad leaves and tomatoes grown in fi elds<br />

in the Spanish provinces Navarre, Málaga<br />

and Canary Islands. Just like all other<br />

locations of McDonald’s around the world,<br />

these sites are subject to strict quality<br />

controls – from cultivation and harvesting<br />

of the leaves, all the way to their use in<br />

one of the 428 Spanish McDonald’s restaurants.<br />

And supplying these extremely<br />

sensitive products requires safe and reliable<br />

logistics.<br />

<strong>HAVI</strong> <strong>Logistics</strong> in Spain assumed responsibility<br />

for this complex process in June of<br />

this year. Working in collaboration with STI<br />

Freight Management, it ensures smooth<br />

transportation of all salad items.<br />

If the greens are stored and transported<br />

at the optimum temperature, they can be<br />

kept for at least 7 to 13 days. During this<br />

period they are harvested, packaged and<br />

transported to the suppliers’ warehouses,<br />

and taken from there by STI to our Spanish<br />

DCs. Here they are stored, picked and<br />

dispatched to the McDonald’s restaurants,<br />

where they are freshly prepared for the<br />

customers – a tour de force of logistical<br />

organization that gives McDonald’s complete<br />

confi dence in our promise of quality.<br />

Controlling the supply chain to the<br />

McDonald’s stores on the Canary Islands<br />

is an additional challenge. Some salad<br />

products can be kept for a minimum of<br />

only seven days. To guarantee 100 percent<br />

quality and freshness for the goods, we<br />

had to adapt the weekly delivery schedule<br />

for those restaurants. Now the salad products<br />

reach all the 30 McDonald’s stores<br />

on Gran Canaria and Tenerife just one day<br />

after they are harvested.<br />

The customer service team receives orders<br />

for salad from Monday through Friday.<br />

Our employees work out the quantities<br />

they have to order from the three<br />

different factories. On average, they pass<br />

on about eight orders a day to the producers.<br />

On Fridays there are often up to 20<br />

orders since the quantities for the weekend<br />

have to be added. Each McDonald’s<br />

restaurant receives two to four salad deliveries<br />

per week. Over a year this amounts<br />

to around 6,000 tons of tomatoes, green<br />

leaves and fresh fruits.<br />

“Using our <strong>HAVI</strong> <strong>Logistics</strong> standards, we<br />

have been able to familiarize ourselves<br />

without any problem with the new workfl<br />

ows needed,” says Managing Director<br />

Pedro de Bernardo. “Now we supply the<br />

whole range of goods to all restaurants.<br />

McDonald’s had confi dence in our promise<br />

to always deliver 100 percent quality<br />

and food safety – without making any<br />

compromises.”<br />

Controlled<br />

quality at<br />

McDonald’s<br />

When the freshly harvested<br />

goods are received, their quality<br />

and temperature are checked.<br />

During processing the most<br />

varied factors are monitored,<br />

such as temperature, quality of<br />

the cut, cleanliness, composition<br />

and humidity.<br />

When the goods are packaged,<br />

there is another check for<br />

temperature, metal inclusions,<br />

appearance and tightness<br />

of the seal.<br />

Every day the company’s own<br />

lab conducts sensory tests and<br />

rapid microbial tests (for E. coli).<br />

Only if the results are absolutely<br />

faultless are the products<br />

allowed to be delivered to the<br />

McDonald’s restaurants.<br />

Retained samples are taken<br />

several times a day.<br />

As an extra safety measure,<br />

external laboratories regularly<br />

examine microbiological status<br />

and test for pesticides.

You Can’t Buy Compliance<br />

In business, compliance means conforming to relevant laws, rules, specifi cations or policies – both internal and<br />

external. Compliance is not an invention of smart lawyers but a basic principle of applicable law; a company’s longterm<br />

business success depends on following the rules. Now, what does compliance mean for <strong>HAVI</strong> <strong>Logistics</strong> and<br />

how do we ensure a holistic approach to compliance?<br />

With ever more regulations and the<br />

need for operational transparency, organizations<br />

are increasingly adopting consolidated<br />

and harmonized compliance<br />

measures. This ensures that all necessary<br />

governance requirements can be met<br />

without duplicating work unnecessarily.<br />

100% compliance –<br />

no exceptions!<br />

<strong>HAVI</strong> <strong>Logistics</strong> has implemented many<br />

compliance tools, the most important of<br />

which is our strong compliance culture.<br />

Ever since the company was established in<br />

1981, we have abided by our statements<br />

that “we uphold the laws of the land” and<br />

“law and order are social values we hold<br />

in the highest esteem” in our corporate<br />

culture and have always expected all our<br />

employees to be role models concerning<br />

these principles.<br />

In 2008, we stated that violations of these<br />

principles would not be tolerated, in our<br />

“Code of Ethical Business Conduct.” As<br />

a consequence, we established a whistleblower<br />

hotline and the Compliance Committee,<br />

which investigates potential violations<br />

of the applicable rules and initiates<br />

appropriate action. Throughout our corporate<br />

history, we have also issued a variety<br />

of guidelines and internal controls to guide<br />

our employees.<br />

Of course, this may seem like a lot. Yet our<br />

continuous growth brings new challenges.<br />

Different countries have different legal requirements,<br />

new customers have new<br />

needs regarding food quality and safety,<br />

and new employees might not always be<br />

aware of our cultural heritage. Given this<br />

development, it is apparent that we need<br />

to do more to ensure that we know what<br />

compliance means and can act compliantly.<br />

In particular, we need a more holistic<br />

and structured approach to compliance<br />

management.<br />

The <strong>HAVI</strong> <strong>Logistics</strong> Compliance Committee<br />

has assigned the task of successively<br />

optimizing our existing compliance management<br />

system to Petra Luzar, Director<br />

Corporate Legal Department. The international<br />

consultancy fi rm KPMG has helped<br />

us hold several workshops. We would now<br />

like to familiarize you with the status of the<br />

task and the next planned steps.<br />

First of all, the Compliance Committee reaffi<br />

rmed that compliance is recognized as<br />

a key success factor at <strong>HAVI</strong> <strong>Logistics</strong>.<br />

Petra Luzar, Director Corporate Legal Department<br />

“We formulated the misson statement:<br />

Compliance Management at <strong>HAVI</strong><br />

<strong>Logistics</strong> should foster the established<br />

culture of complete (100%) adherence<br />

to legal requirements and internal policies<br />

and standards while proactively addressing<br />

corporate risks in light of continuous<br />

growth.”<br />

In several reiterations, many of our internal<br />

specialists from different areas of expertise<br />

including Operations, Finance, HR and IT<br />

then helped identify our biggest compliance<br />

risks. They identifi ed worst case scenarios,<br />

supposing that we had not even<br />

implemented the existing mitigating measures<br />

(e.g. guidelines, internal controls) and<br />

evaluated which of these would harm <strong>HAVI</strong><br />

<strong>Logistics</strong> most – either fi nancially, or indirectly<br />

as a result of harming our customers.<br />

The gross risks will now form the basis<br />

for a thorough gap analysis, i.e. we will<br />

again apply our internal expertise to identify<br />

which mitigating measures we have<br />

implemented in relation to which risk, and<br />

whether these measures are appropriate<br />

and suffi cient to reduce said risk – preferably<br />

until it vanishes. The results of the gap<br />

analysis will be used to determine the optimum<br />

measures to close the gaps. These<br />

will probably include revising existing<br />

guidelines to increase their comprehensibility,<br />

and providing appropriate training for<br />

people expected to follow the guidelines.<br />

This will enable us, over the mid-term, to<br />

ensure that we have a structured and holistic<br />

compliance management system that<br />

enables people within our organization to<br />

access and understand the relevant rules<br />

easily and also enables <strong>HAVI</strong> <strong>Logistics</strong> to<br />

check and document for audit purposes<br />

that these rules have been followed.<br />

Yet the fact that we are optimizing our existing<br />

compliance management system<br />

does not mean we can now relax and wait<br />

for implementation. All of us must be aware<br />

that we are in charge of compliance and<br />

can be held responsible. We all need to<br />

be role models and to live our values and<br />

our culture. We need to know and apply all<br />

the relevant rules and should always ask<br />

ourselves whether what we’re doing is correct.<br />

Furthermore, we should seize the opportunity<br />

to address any questions we may<br />

have about compliance to the Compliance<br />

Committee, which will be able to provide<br />

guidance on all compliance matters.<br />

Any questions can be addressed<br />

to the Compliance Committee<br />

compliance@havilog.com,<br />

or call Petra Luzar at +49 2065 695695.<br />

alphabet I AUGUST 2012<br />

7

8<br />

Environment<br />

The specially designed green trucks are a familiar<br />

sight on the roads in the Netherlands and in<br />

Belgium.<br />

<strong>HAVI</strong> <strong>Logistics</strong> Environmental Services<br />

(HES) has received the award entitled<br />

“Best of Sustainable Supply 2012.” The<br />

<strong>HAVI</strong> <strong>Logistics</strong> environmental services<br />

company was honored by the McDonald’s<br />

Corporation for its Reverse <strong>Logistics</strong> project.<br />

Around 400 companies from all over<br />

the world were nominated for the award,<br />

with which McDonald’s pays tribute to<br />

suppliers who have introduced sustainable<br />

environmental management practices.<br />

A jury including McDonald’s top management<br />

and representatives of the World<br />

Wildlife Fund (WWF) chose HES as one of<br />

the winners.<br />

From restaurant to recycling point: since<br />

1991 <strong>HAVI</strong> <strong>Logistics</strong> Environmental Services<br />

in Amersfoort has been respon-<br />

“Best of Sustainable<br />

Supply 2012”<br />

Award<br />

Praise from McDonald’s<br />

for action on sustainable<br />

environmental protection.<br />

sible for waste management logistics for<br />

the McDonald’s restaurants in the Netherlands.<br />

The specially designed green<br />

trucks deployed by the environmental<br />

services company are a familiar sight on<br />

the roads in Belgium, too. They call at almost<br />

280 McDonald’s restaurants, where<br />

they pick up refuse such as paper, foil,<br />

vegetable fat and waste food and bring<br />

them to the recycling point. “The world of<br />

recycling and processing waste is a very<br />

dynamic one where new solutions come<br />

to market on a daily basis. It is <strong>HAVI</strong> Environmental<br />

Services’ role to develop from<br />

all these options the best solution for our<br />

customers and manage this on a daily<br />

basis,” explains Olav Gribnau, Managing<br />

Director of <strong>HAVI</strong> <strong>Logistics</strong> Environmental<br />

Services. The company has now received<br />

recognition for this commitment: “The<br />

nominations show that McDonald’s supply<br />

chain currently is in an excellent position<br />

to make safe and sustainable deliveries<br />

of food products,” says Jose Amario,<br />

Executive Vice President of the Global<br />

Supply Chain, Development & Franchising<br />

at McDonald's. “We really appreciate<br />

the efforts made by all our suppliers.”<br />

Olav Gribnau views the “Best of Sustainable<br />

Supply” award as both an honor and<br />

an incentive. “Being singled out for this<br />

award by McDonald’s is recognition of<br />

the work we have done in the past and at<br />

the same time a vote of confi dence from<br />

our customer in the new developments<br />

we will continue to pursue in the fi eld of<br />

reverse logistics.”<br />

<strong>HAVI</strong> <strong>Logistics</strong> Among the<br />

First Companies to Receive<br />

a “Sustainability Charter”<br />

Every year since 2008 <strong>HAVI</strong> <strong>Logistics</strong> Belgium has successfully obtained<br />

a national “Environmental Charter” issued by the Belgian government. Not<br />

only has the team located in Belgium been audited according to the applicable<br />

environmental regulations; it also had to meet at least three additional<br />

requirements with respect to the environment.

We Generate Our Own Green Energy<br />

New special photovoltaic system for generating our own electricity<br />

A total of 3,024 solar modules,<br />

350,000 kilowatt hours of energy, and CO2 emissions reduced by around 131 tonnes<br />

every year – these are the statistics for the<br />

new photovoltaic system that went into<br />

operation at the end of April on the <strong>HAVI</strong><br />

<strong>Logistics</strong> Distribution <strong>Center</strong> in Günzburg,<br />

Germany. It is based on a model that has<br />

been unique in Germany to date: <strong>HAVI</strong><br />

<strong>Logistics</strong> obtains green solar power generated<br />

by this system on good terms and<br />

conditions, and in return we waive the<br />

rental fee for having the installation on our<br />

roof.<br />

“With conventional systems, all the energy<br />

is fed into the electric power system and<br />

its monetary value is paid out to the solar<br />

In 2011 <strong>HAVI</strong> <strong>Logistics</strong> was one of a<br />

few companies chosen to participate in<br />

a new initiative: the “Sustainability Charter.”<br />

Whereas the Environmental Charter<br />

has an environmental focus, the requirements<br />

for obtaining the Sustainability<br />

Charter are far more extensive. First of all,<br />

a company must have received the Environmental<br />

Charter at least three years in<br />

succession. Furthermore, it has to pass a<br />

“Sustainability Check” aimed at evaluating<br />

its previous efforts in the areas of “people”<br />

and “prosperity.”<br />

energy producer,” explains Harald Klein,<br />

Senior Manager Customer Support, who<br />

is also responsible for <strong>HAVI</strong> <strong>Logistics</strong>’<br />

environmental projects in Germany. “In<br />

our case we make the 8,400 square meter<br />

roof available and in return we receive all<br />

the solar energy we need to supply our Distribution<br />

<strong>Center</strong>.” This comes to 350,000<br />

kilowatt hours of energy annually – which<br />

is a huge amount, equal to the average<br />

consumption of 100 German households<br />

– and it is generated on the roof of our<br />

Günzburg Distribution <strong>Center</strong>. We use<br />

100 percent of this green electricity ourselves.<br />

“At the same time our new photovoltaic<br />

system reduces annual CO2 emissions by around 131 tonnes,” Harald<br />

Klein points out. And this contribution to<br />

environmental conservation is truly visible<br />

in Günzburg: a large display at the Distribution<br />

<strong>Center</strong> shows employees and visitors<br />

the amount of energy produced daily,<br />

the total amount generated, and the CO2 savings realized since the solar power<br />

system was installed.<br />

Once a company has been accepted and<br />

allowed to apply for the Sustainability Charter,<br />

it has to meet the following minimum<br />

requirements:<br />

three requirements related<br />

to the environment<br />

two requirements related<br />

to people<br />

one requirement related<br />

to prosperity<br />

After <strong>HAVI</strong> <strong>Logistics</strong> introduced photovoltaic<br />

systems in Spain and Italy, Günzburg<br />

became the third company site in Europe<br />

to start generating solar power. With this<br />

system, <strong>HAVI</strong> <strong>Logistics</strong> reduces its CO2 emissions by approximately 400 tonnes<br />

every year. And the fi gure is set to rise:<br />

for the medium term <strong>HAVI</strong> <strong>Logistics</strong> is<br />

planning additional solar power installations<br />

on its Distribution <strong>Center</strong>s in Europe.<br />

Together with four other companies, <strong>HAVI</strong><br />

<strong>Logistics</strong> Belgium has successfully obtained<br />

the certifi cate. On June 1 of this year it was<br />

handed over to Els Thys, Management Assistant<br />

and QSE Coordinator at <strong>HAVI</strong> <strong>Logistics</strong><br />

Belgium, by Rik Röttger, member of<br />

the Antwerp government responsible for the<br />

environment.<br />

For the upcoming year the Belgian team has<br />

already committed again to obtain this charter<br />

as part of its efforts to ensure an optimized<br />

sustainable supply for our customers.<br />

alphabet I AUGUST 2012<br />

9

10<br />

Improvement<br />

Successful<br />

<strong>Logistics</strong> for<br />

the Euro 2012<br />

For Poland and Ukraine the Euro 2012 was surely the<br />

greatest sports event of all time. For <strong>HAVI</strong> <strong>Logistics</strong>,<br />

it presented a stupendous logistics challenge – probably<br />

the greatest we have faced since we started<br />

working for McDonald’s.<br />

From June 8 to July 1, 16 national<br />

teams fought for the European title in<br />

fi ercely-contested matches held in worldclass<br />

stadiums in Poland and Ukraine. Ultimately,<br />

Spain emerged the winner after a<br />

tense fi nal against Italy. The Spanish team<br />

won due to a combination of factors – precise<br />

preparation, tactics, teamwork, speed<br />

and perfection on the fi eld – that aptly<br />

describe the logistics provided by <strong>HAVI</strong><br />

<strong>Logistics</strong> for the numerous McDonald’s<br />

restaurants in the fan zones and stadiums.<br />

Working with McDonald’s, the <strong>HAVI</strong> <strong>Logistics</strong><br />

teams in Poland and Ukraine started<br />

more than a year in advance to do the<br />

groundwork for the major logistics effort<br />

that would be required during the Euro<br />

2012. Large-scale events of this kind require<br />

intricate coordination of our customer<br />

expertise, sales planning, and transport<br />

and warehousing logistics. Whereas<br />

our Ukrainian team “only” had to make<br />

deliveries to McDonald’s, their Polish<br />

counterparts also had to ensure that the<br />

services they provided to BP and Coffee<br />

Heaven were of the accustomed quality.<br />

“These intensive preparations were vital<br />

and made in close consultation with our<br />

customer,” says Andreas Röder, Managing<br />

Director of <strong>HAVI</strong> <strong>Logistics</strong> in Poland.<br />

“In addition to McDonald’s restaurants,<br />

the BP shops and Coffee Heaven outlets<br />

reported brisker business during the Euro<br />

2012.”<br />

Way before the games, McDonald’s and<br />

<strong>HAVI</strong> <strong>Logistics</strong> identifi ed locations in and<br />

around the fan zones in Poland and<br />

Ukraine where sales were expected to<br />

soar. “Emergency measures” were then<br />

introduced at both <strong>HAVI</strong> <strong>Logistics</strong> and Mc-<br />

Donald’s for the 355 existing McDonald’s<br />

restaurants and 13 McDonald’s restaurants<br />

to be set up especially for the tournament.

The idea was to prevent outof-stock<br />

situations at all costs.<br />

McDonald’s and our local <strong>HAVI</strong> <strong>Logistics</strong><br />

companies decided to boost warehouse<br />

stocks in both countries several weeks<br />

before the big event.<br />

Our goal was to keep all the restaurants<br />

fully supplied during the European Championship.<br />

This meant that on average 50%<br />

more pallet spaces had to be provided for<br />

each warehouse sector. To achieve this<br />

goal, additional warehouse space was<br />

rented near the stadiums in both countries.<br />

McCafé made its debut at the<br />

Euro 2012 this year.<br />

This happened, for example, at the media<br />

centers in the Polish and Ukrainian football<br />

stadiums. At the media center of the<br />

German Football Association in Danzig, a<br />

complete McCafé was set up to offer the<br />

German players and organizers typical<br />

German specialties as well as a new item<br />

currently making waves in Germany: bubble<br />

tea!<br />

Just setting up and equipping the McCafé<br />

outlets was a logistics tour de force: STI<br />

Freight Management transported all the<br />

restaurant equipment from Germany to Poland<br />

while <strong>HAVI</strong> <strong>Logistics</strong> Poland supplied<br />

the entire product assortment.<br />

Every employee of <strong>HAVI</strong> <strong>Logistics</strong> in Poland<br />

and Ukraine was involved in preparing<br />

for the expected onslaught of fans. The<br />

Customer Service teams were on duty 24/7<br />

and 86 trucks, many sporting the Euro 2012<br />

design, were on the road virtually non-stop.<br />

On top of all this, our dispatchers and<br />

drivers had to observe the special restric-<br />

tions imposed on suppliers to the stadiums<br />

and fan zones – such as making deliveries<br />

only at night or using vans instead<br />

of big trucks. Drivers delivering directly to<br />

the stadiums had to be accredited and underwent<br />

stringent security checks at the<br />

entrances.<br />

“Despite the many adverse conditions<br />

and the staggering amount of overtime<br />

we put in, our teams were in high spirits<br />

and really pulled together,” said Sergey<br />

Ustinov, Managing Director of <strong>HAVI</strong><br />

<strong>Logistics</strong> Ukraine. “Extra delivery trips,<br />

weekend work and night deliveries were<br />

all part of the package but none of this put<br />

a damper on the commitment and enthusiasm<br />

of our employees.” Andreas Röder<br />

added: “It is true that the employees involved<br />

were affected by Euro 2012 fever.<br />

More importantly, however, they were<br />

working together to reach the common<br />

goal of making the football tournament<br />

a success for our customer.” Thanks to<br />

perfect preparations and smooth deliveries,<br />

the Euro 2012 was a huge success<br />

for both McDonald's and <strong>HAVI</strong><br />

<strong>Logistics</strong>.<br />

alphabet I AUGUST 2012<br />

11

source: thinkstock / centimeter 4<br />

12<br />

Cover Theme<br />

Quality & Service<br />

Quality Is What the<br />

Customer Demands<br />

Our world is dominated by buzzwords concerning quality:<br />

automation, rationalization, lean management,<br />

globalization, Internet, etc. Quality management is<br />

another term heard frequently and often determines<br />

a company’s competitiveness.<br />

Quality arises whenever the customer’s<br />

wishes are correctly identifi ed.<br />

In other words, it is the customer who<br />

determines what quality is.<br />

Every company depends on<br />

satisfi ed customers.<br />

The quality of a company’s products and<br />

services, as well as the type of relationship<br />

it has with its customers, has always<br />

been a key factor determining its market<br />

value. Not only are ever higher demands<br />

being placed on quality; quality is now required<br />

in many different areas – ranging<br />

from a friendly reception over good service<br />

up to fast spare-part delivery. And all<br />

these demands are being made despite<br />

the constant pressure on prices.<br />

A binding defi nition of what constitutes<br />

good quality is drawn up by each industry<br />

and continually updated. Examples of<br />

industry-specifi c quality regulations are<br />

source: thinkstock / service bell<br />

the international HACCP hygiene<br />

standard in the food industry and the<br />

stringent quality standards that the automotive<br />

manufacturers demand of their<br />

suppliers.<br />

The Crafts and Trades Regulation Codes<br />

describe, in some cases very precisely,<br />

which technical rules are to be observed.<br />

Companies that do not meet the quality

source: thinkstock / sewing dummy over white<br />

standards in their industry are soon<br />

swept off the market.<br />

However, industry-specifi c standards<br />

alone are often inadequate.<br />

Entrepreneurs who want to succeed<br />

in the marketplace have<br />

to repeatedly ask themselves<br />

what else<br />

they can do in order to offer high-quality<br />

products (and to be better than their competitors).<br />

For this reason, every product and service<br />

has to undergo critical scrutiny on a<br />

regular basis. Can the service provided be<br />

improved? Could the customer service<br />

be better? Are the employees’<br />

customer orientation and<br />

knowhow up to date? Does<br />

the product meet customers’<br />

wishes today and will it meet<br />

them tomorrow?<br />

Paying attention to quality involves<br />

setting down the quality<br />

requirements for a product or<br />

The History of Quality Management<br />

Quality management was invented<br />

in the U.S. by William Edwards Deming.<br />

However, after the end of World War II<br />

his ideas were widely ignored: the international<br />

business community was more<br />

concerned at that time about rebuilding<br />

the production capacities destroyed<br />

worldwide during the war. Yet in wartorn<br />

Japan his ideas fell on more fertile<br />

PDCA cycle by William Edwards Deming<br />

The demands placed on the<br />

quality of a product change<br />

continually.<br />

ground. In the Land of the Rising Sun<br />

quality management soon became a<br />

respected philosophy: as early as 1951<br />

a Japanese company was the recipient<br />

of the Deming Award for especially<br />

high quality standards. In the following<br />

decades Japanese manufacturers conquered<br />

market shares around the world<br />

with their high-quality, reasonably priced<br />

source: panthermedia / Randolf Berold<br />

service. Quality must be controlled and is<br />

therefore a task for the management.<br />

However, quality management will not<br />

succeed until it is part of the corporate<br />

culture and infl uences the daily actions<br />

of all employees. The results of scientifi c<br />

studies conducted in the U.S. show that,<br />

in comparison with their competitors,<br />

companies with quality management programs<br />

have higher turnover and profi ts,<br />

greater productivity, better stock performance<br />

and faster-growing workforces.<br />

Despite all their efforts to achieve comprehensive<br />

quality management, companies<br />

should never lose sight of one central<br />

idea: quality is not a goal but a never-ending<br />

process guided by the ideal of perfect<br />

customer satisfaction.<br />

products. Eventually U.S. companies<br />

turned their attention toward Japan and<br />

discovered Deming's quality philosophy.<br />

In the 1970s and 1980s this philosophy<br />

was also introduced at U.S. companies,<br />

and in the late 1980s quality management<br />

fi nally reached Europe. Some of<br />

the fundamental principles of this philosophy<br />

are stated below:<br />

Quality is geared to the customer.<br />

Quality is achieved by employees<br />

in all sectors and at all levels.<br />

Quality has several dimensions;<br />

these have to be made<br />

operational by applying<br />

appropriate criteria.<br />

Quality is not a goal but a<br />

never-ending process.<br />

Quality refers to services<br />

as well as products.<br />

Quality requires a proactive<br />

approach and hard work.<br />

alphabet I AUGUST 2012<br />

13

source: thinkstock / Ryan McVay<br />

14<br />

Cover Theme<br />

Quality & Service<br />

QUALITY<br />

QUALITY<br />

We make sure all our corporate divisions<br />

get a thorough checkup on a regular<br />

basis. AIB GMP audits, the Distributor<br />

Quality Management Process (DQMP)<br />

and the Distribution Performance Index<br />

(DPI) are examples of the quality checks<br />

that external experts from independent<br />

institutes and McDonald’s management<br />

conduct at our Distribution <strong>Center</strong>s. Frequently<br />

the auditors cannot fi nd anything<br />

at all that needs to be improved. Almost<br />

all the <strong>HAVI</strong> <strong>Logistics</strong> companies come<br />

through these checks with fl ying colors,<br />

i.e. they are ranked either “excellent”<br />

(DQMP) or “superior” (AIB GMP).<br />

Several <strong>HAVI</strong> <strong>Logistics</strong> companies have<br />

had their quality management systems<br />

audited and are now certifi ed according<br />

to globally recognized standards such as<br />

EN ISO 9001, ISO 22000 or the environ-<br />

Quality Is Not a Goal<br />

But a Never-Ending Process<br />

For more than 30 years now <strong>HAVI</strong> <strong>Logistics</strong> has been the Lead <strong>Logistics</strong> Provider<br />

for the food service industry. We're in the premier league when it comes<br />

to quality. We have weathered various crises by consistently pursuing our goals:<br />

100% employee satisfaction, 100% customer satisfaction, zero tolerance on<br />

errors right from the outset, and continual improvements to all workfl ows.

mental standard ISO 14001. And it is true<br />

that our quality management system covering<br />

the <strong>HAVI</strong> <strong>Logistics</strong> group extends far<br />

beyond EU regulations. Food safety is a<br />

major aspect of the highest importance.<br />

All along our customers’ supply chains we<br />

guarantee the highest quality standards in<br />

line with HACCP and QIP. Our traceability<br />

system allows uninterrupted tracking of<br />

goods between the suppliers, our Distribution<br />

<strong>Center</strong>s and our customers’ delivery<br />

points.<br />

The indicators we use to measure our performance<br />

are equally vital in our efforts<br />

to guarantee quality. Our top priority is to<br />

ensure punctual and reliable deliveries.<br />

On average, 97% of all our deliveries in<br />

Europe during the fi rst quarter of this year<br />

arrived on schedule. Reliability of supply<br />

is something we can be proud of at <strong>HAVI</strong><br />

<strong>Logistics</strong>. During the same period an average<br />

of 93% of all deliveries were correctly<br />

picked and arrived at the customer in perfect<br />

condition.<br />

Yet, however much effort we put into our<br />

extensive quality management process,<br />

our guiding principle still remains the<br />

same: quality is not a goal but a never<br />

ending process geared to ensuring total<br />

customer satisfaction. “Not a day should<br />

go by without some improvement in the<br />

company,” is the thought behind the Japanese<br />

“kaizen” life and work philosophy.<br />

According to kaizen (kai = change; zen<br />

= for the better), one should aim for continuous,<br />

unending improvement in all areas<br />

– and this refers to all the employees,<br />

managers and executives. Better quality<br />

and lower costs ultimately result in greater<br />

customer satisfaction.<br />

Outside Japan the basic ideas of kaizen<br />

have been adopted under the name<br />

“Continuous Improvement Process” (CIP).<br />

This has become a permanent part of <strong>HAVI</strong><br />

<strong>Logistics</strong>’ quality management.<br />

“Consider each day how you<br />

can do something better.”<br />

CIP is not a tool but a way of thinking, a<br />

way of perceiving workfl ows and processes<br />

and making all of this second nature.<br />

The process is based on “empowering”<br />

the <strong>HAVI</strong> <strong>Logistics</strong> workforce and a fundamental<br />

openness coupled with the will<br />

to change in the company.<br />

CIP is implemented in an ongoing process<br />

of small improvements – unlike the<br />

large quantum leaps when far-reaching<br />

changes are made – realized through continuous<br />

team work. These basic thoughts<br />

are encouraged in our companies by the<br />

management and all staff members. We<br />

therefore hold regular quality circles in addition<br />

to the management and operational<br />

meetings.<br />

Quality begins in the mind and has become<br />

a fundamental way of life for all<br />

<strong>HAVI</strong> <strong>Logistics</strong> employees. In this respect<br />

our management acts as a role model<br />

because the ideas will only appear cred-<br />

QUALITY<br />

PUNCTUALITY<br />

ible to the workforce if the management<br />

also lives up to our quality standards. But<br />

nobody’s perfect! People in general, like<br />

employees and executives, are not infallible<br />

and learn something new every day.<br />

For this reason we regularly monitor our<br />

customers' satisfaction and obtain feedback<br />

on our quality and our services. The<br />

messages from our customers are very<br />

constructive and we use them as a springboard<br />

for the continuous, targeted exploitation<br />

of our potentials.<br />

Ultimately the customer determines what<br />

quality is, and our approach to customer<br />

relations is a major part of our quality<br />

strategy. For example, today we can even<br />

build on our punctuality, reliability and<br />

top quality by adding the forward-looking<br />

development of additional services and<br />

innovations. This enables us to solve<br />

problems before our customers are even<br />

aware of them. After all, their expectations<br />

are changing all the time, just like our own.<br />

In order to survive, <strong>HAVI</strong> <strong>Logistics</strong>, too, is<br />

forced to continually expand its portfolio<br />

of services and to anticipate how to satisfy<br />

our customers’ future expectations.<br />

IMPROVEMENT<br />

SERVICE<br />

INNOVATION<br />

alphabet I AUGUST 2012<br />

15<br />

source: thinkstock / Thinking men

16<br />

Cover Theme<br />

Quality & Service<br />

Interview with Lukas Curschellas<br />

Quality: An Unchanging Part<br />

of the <strong>HAVI</strong> <strong>Logistics</strong> World<br />

A quality management system geared to sustainability and continuity has<br />

to be carefully developed, implemented and controlled. This in turn requires<br />

particular structures within the company, such as an internal steering committee<br />

and one or more quality control offi cers who coordinate our quality<br />

management activities. To fi nd out more, alphabet interviewed Lukas<br />

Curschellas, Operations Manager at <strong>HAVI</strong> <strong>Logistics</strong> Switzerland, who has<br />

been responsible for implementing our Europe-wide quality management<br />

scheme since 2010.<br />

alphabet: How does our quality management<br />

compare with that of the competition?<br />

Lukas Curschellas: Compared with<br />

other logistics service providers in the<br />

food service industry, we are clearly in the<br />

passing lane – especially when it comes<br />

to customer satisfaction. We have often<br />

been a step ahead of the market and developed<br />

and defi ned quality standards<br />

that only became enshrined in law much<br />

later, or were introduced by other companies<br />

years afterward to improve their competitiveness.<br />

alphabet: Can you give us some examples?<br />

Lukas Curschellas: Yes, one would<br />

be the probe thermometer connected to a<br />

portable printer. Under HACCP, the temperature<br />

of the goods in the supply chain<br />

is measured at several critical control<br />

points. For this we developed an international<br />

standard for all <strong>HAVI</strong> <strong>Logistics</strong> companies:<br />

a thermometer that transmits its<br />

measurements to a portable printer via an<br />

infrared connection. The printer creates<br />

labels indicating not only the temperature<br />

measured, but also the date and time of<br />

the measurement. Our corporate history<br />

contains numerous examples of the introduction<br />

of such quality standards.<br />

alphabet: Since when have quality<br />

management and the development of<br />

standards been part of the <strong>HAVI</strong> <strong>Logistics</strong><br />

strategy?<br />

Lukas Curschellas: The topic is as<br />

old as <strong>HAVI</strong> <strong>Logistics</strong> itself. If there's one<br />

aspect in our <strong>HAVI</strong> <strong>Logistics</strong> world that<br />

never changes, it's delivering goods of<br />

the highest quality. We regard it as our<br />

responsibility to preserve the high qual-<br />

ity of the products entrusted to us all the<br />

way from the suppliers to the customers,<br />

thus satisfying our customers’ high quality<br />

standards.<br />

alphabet: How do you organize and<br />

implement quality standards?<br />

Lukas Curschellas: Food safety is our<br />

top priority. One very important aspect is<br />

to defi ne and communicate goals. This<br />

gives us a common understanding of the<br />

objective and how to achieve it. However,<br />

regular checks are equally important; they<br />

enable us to recognize when we have<br />

made errors or are on the wrong path –<br />

at a much earlier stage. Furthermore, a<br />

successful quality management system<br />

throughout the company needs to be<br />

backed up by an information concept –<br />

this creates transparency. Circulars, notices,<br />

departmental meetings, employee<br />

newspapers and Intranet pages all support<br />

and promote transparency for our<br />

customers, partners and employees. “Do<br />

good and then talk about it!” – The same<br />

applies to realizing quality management:<br />

“Talk about it and inform others.”<br />

alphabet: How can individual employees<br />

contribute to its implementation?<br />

Lukas Curschellas: Quality management<br />

is a joint task for everyone in the<br />

company. Therefore it is important that<br />

all of us are involved in carrying out the<br />

measures and activities. Knowledge and<br />

expertise are fundamental to this. <strong>HAVI</strong><br />

<strong>Logistics</strong>’ employees receive training in<br />

the basics of quality management and in

applying the relevant quality management<br />

tools. On-the-job training, support from<br />

colleagues and targeted practical application<br />

all hone our employees’ skills and<br />

increase safety in the continuous implementation<br />

of quality management.<br />

alphabet: Which tools and methods<br />

does <strong>HAVI</strong> <strong>Logistics</strong> use to realize quality<br />

management?<br />

<strong>HAVI</strong> <strong>Logistics</strong>’ employees’ receives training<br />

and the basics of quality management<br />

Lukas Curschellas: Tools such as the<br />

“PDCA* cycle,” which promote work in<br />

quality circles, internal audits, workshops,<br />

and surveys both of customers and of employees<br />

are all used to achieve structured,<br />

effi cient implementation of quality management.<br />

Of course, we also have to supply<br />

all the necessary human and other resources.<br />

Intelligent IT systems, suffi cient<br />

funding, employees and working time –<br />

which, incidentally, should not be underestimated<br />

– enable <strong>HAVI</strong> <strong>Logistics</strong> to put<br />

quality management into actual practice.<br />

Independent, external auditors verify <strong>HAVI</strong><br />

<strong>Logistics</strong>’ high quality standards at regular<br />

intervals in either scheduled or unannounced<br />

audits.<br />

alphabet: Thank you very much for<br />

talking to us.<br />

*PDCA cycle, see also page 13<br />

Change for the Better<br />

<strong>HAVI</strong> <strong>Logistics</strong> in Hungary is drawing on the basic<br />

principles of kaizen in order to implement a continuous<br />

improvement process (CIP).<br />

CIP is nothing new at <strong>HAVI</strong> <strong>Logistics</strong>.<br />

At many <strong>HAVI</strong> <strong>Logistics</strong>’ companies,<br />

continual improvements are developed in<br />

so-called quality circles. Our team in Hungary<br />

recently started using the Japanese<br />

work philosophy of kaizen, which means<br />

“change for the better.” The aim of kaizen<br />

is to optimize and perfect processes step<br />

by step. Teamwork lies at the heart of<br />

both CIP and kaizen.<br />

At <strong>HAVI</strong> <strong>Logistics</strong> Hungary CIP is supported<br />

by trainers and coaches from the<br />

KAIZEN Institute Hungary. These coaches<br />

fi rst briefed the<br />

company's management<br />

on how<br />

kaizen works and<br />

how it can be put<br />

into practice. The<br />

next step was to<br />

hold a training seminar<br />

for the 16 members<br />

of the quality<br />

circle.<br />

The quality circle<br />

is mentored by the<br />

management of the<br />

Hungarian company.<br />

Four mentors, including Managing<br />

Director Zoltán Valentinyi, have assumed<br />

the role of “kaizen ambassadors.” The<br />

members of the quality circle – drivers,<br />

warehouse workers, offi ce staff and managers<br />

– come from many different parts of<br />

the company and meet once a week during<br />

work hours. This process taps into the<br />

store of ideas, knowledge, experience and<br />

willingness to assume responsibility available<br />

at the company.<br />

The fi rst quality circle got underway at<br />

the beginning of the year. Under the supervision<br />

of a chairperson, four working<br />

groups identifi ed and analyzed possible<br />

in-house problems that could adversely<br />

affect quality. The employees self-reliantly<br />

developed solutions and tested their feasibility<br />

during the everyday operation of<br />

the company over a certain period of time.<br />

“We therefore did not work on theoretical<br />

solutions, but absolutely practical ones<br />

that were tested and introduced carefully,”<br />

explained Zoltán Valentinyi. “This fi rst<br />

quality circle based on kaizen already<br />

showed that we can optimize many small<br />

processes at the company by taking concerted<br />

joint action,” reported Zoltán happily.<br />

“It is not only<br />

operative aspects<br />

that play a role here<br />

but also possible<br />

fi nancial savings<br />

and the reduction of<br />

CO 2 emissions, and<br />

most importantly to<br />

me, It was amaizing<br />

to see that people<br />

from different functions<br />

just sit around<br />

one table and work<br />

hard on one subject…<br />

in different<br />

types of clothes…<br />

and they collect real business data by interviewing<br />

others, measuring distances,<br />

etc. in the warehouse and put all these<br />

information together to fi nd a good solution…”<br />

the Managing Director added.<br />

A variety of methods and tools are needed<br />

to plan and implement CIP successfully.<br />

There are no rigid requirements here:<br />

each company has the leeway to select<br />

the tools best suited to its problems. For<br />

<strong>HAVI</strong> <strong>Logistics</strong> Hungary the CIP method<br />

based on kaizen has proved its worth. The<br />

upshot is that the next quality circle will<br />

start in September.<br />

alphabet I AUGUST 2012<br />

17

18<br />

Enlargement<br />

Higher Quality in the Supply Chain<br />

to IKEA Shops and Restaurants<br />

It’s been one year since <strong>HAVI</strong> <strong>Logistics</strong> made its fi rst delivery to IKEA Portugal. The<br />

IKEA food business model is quite different from other customers and poses a real<br />

challenge. Nevertheless, not only the partnership between IKEA and <strong>HAVI</strong> <strong>Logistics</strong><br />

has evolved very successfully, but so have the quality and effi ciency of the stock<br />

management for the IKEA shops, restaurants and employee canteens in Portugal.<br />

source: Ikea<br />

There are three IKEA furniture stores<br />

in Portugal. Since 2011 <strong>HAVI</strong> <strong>Logistics</strong><br />

has been supplying the restaurants, shops<br />

and employee canteens with a total of 317<br />

items in all three temperature ranges. <strong>HAVI</strong><br />

<strong>Logistics</strong> is involved in the entire IKEA<br />

supply chain, all the way from procurement<br />

to delivery of goods to the stores.<br />

And the supply chain had to be defi ned in<br />

cooperation with the new customer before<br />

our work could begin.<br />

This was no easy task if you consider<br />

the geographical situation of the two<br />

Distribution <strong>Center</strong>s in Portugal and the<br />

distribution layout for supplying IKEA’s<br />

three locations. Neither the <strong>HAVI</strong> <strong>Logistics</strong><br />

warehouse in Porto in the north of the<br />

country, nor the Lisbon DC in the south,<br />

is designed for storing the complete IKEA<br />

range. The idea was to control the fl ow<br />

of goods between the suppliers, our Distribution<br />

<strong>Center</strong>s and the IKEA stores so<br />

Chilled<br />

Frozen<br />

Ambient<br />

that the majority of the items would only<br />

have to make a stopover with us. A full 85<br />

percent of the total volume only gets as far<br />

as the docks of our DCs, while we physically<br />

store the other 15 percent.<br />

Today ambient goods are stored in Lisbon,<br />

whereas the temperature-controlled<br />

goods are stored in Porto. Orders from the<br />

three IKEA stores arrive at our Distribution<br />

<strong>Center</strong> in Lisbon, where the steering<br />

process starts. We use a cross-docking<br />

procedure to redistribute the goods as required<br />

and pick them directly in the warehouses.<br />

Only then does the goods distribution<br />

get underway to the local IKEA<br />

stores.<br />

The greatest challenges within this special<br />

supply chain model arise in having to con-<br />

Porto DC<br />

Lisbon DC<br />

2 del/wk<br />

2 del/wk<br />

The graphic shows the supply chain model for IKEA Portugal<br />

Northern Region<br />

Southern Region

João Monteiro, Goods Receptionist IKEA Food,<br />

and our Portuguese driver Mário Correia<br />

sider goods rotation, the various shelf lives<br />

and the different storage temperatures all<br />

at the same time. Perishable goods with a<br />

short shelf life can only be integrated into<br />

the supply chain in close cooperation with<br />

the suppliers.<br />

“Ever since the fi rst contact with IKEA four<br />

years ago, we have been in very close<br />

communication with the company,” recalls<br />

Carlos Mendonca, Managing Director<br />

of <strong>HAVI</strong> <strong>Logistics</strong> Portugal. “The level<br />

of cooperation, the target alignment and<br />

our wish to make this project clearly advantageous<br />

to IKEA was something that<br />

we needed to reinforce. Both IKEA and<br />

<strong>HAVI</strong> <strong>Logistics</strong> have committed resources<br />

and ideas, and work towards successful<br />

implementation,” he continues.<br />

We are able to celebrate the fi rst year of<br />

our cooperation jointly with our customer,<br />

as this coincided with our monthly operational<br />

meeting review. Therefore we hear<br />

from IKEA about how our partnership has<br />

evolved as well as the quality and effi ciency<br />

of our operations and staff members.<br />

Helder Ferreira, responsible for IKEA Food<br />

in Portugal, said: “With <strong>HAVI</strong> <strong>Logistics</strong> we<br />

raised our quality standards in stock management<br />

as well as in HACCP – extremely<br />

important topics for IKEA Portugal. Many<br />

objectives that we have considered<br />

achieving together with <strong>HAVI</strong> <strong>Logistics</strong><br />

have already been accomplished during<br />

this fi rst year of work; the balance from this<br />

partnership is undoubtedly very positive.”<br />

We Acquire Our First Customer<br />

in the Hotel Segment<br />

Our Dutch team starts working with Van der Valk<br />

As of May 14, 2012 <strong>HAVI</strong> <strong>Logistics</strong><br />

Netherlands is the new logistic partner<br />

of Van der Valk International.<br />

The number one hotel chain in the<br />

Netherlands is <strong>HAVI</strong> <strong>Logistics</strong>’ fi rst<br />

customer in this segment.<br />

Besides being the number one hotel<br />

chain in the Netherlands, Van der Valk International<br />

is also quite a unique company<br />

in that it is totally family owned. In 1939<br />

Martien and Rie van der Valk opened a<br />

restaurant in Voorschoten. Thanks to hard<br />

work and a welcoming, family-friendly approach,<br />

their business was soon a success.<br />

Together with their eleven children,<br />

they built a large number of hotels and restaurants<br />

in the years following World War II.<br />

“Thanks to the challenging set-up of the Supply Chain<br />

Model for Van der Valk, we can deliver close to 5,000 articles<br />

to our new customer. Today the processes are stable and we<br />

are in the phase of optimization. The idea is that our success<br />

will attract other Van der Valk hotels, causing our company<br />

to grow.”<br />

Olav Gribnau,<br />

Managing Director<br />

at <strong>HAVI</strong> <strong>Logistics</strong><br />

Netherlands<br />

Today, their grandchildren and greatgrandchildren<br />

have managed to develop<br />

the company into the largest hotel and<br />

restaurant chain in the Netherlands with<br />

59 branches in this country and another 25<br />

hotels in countries all around the world. Total<br />

revenue amounts to 540 million Euros.<br />

The contract between <strong>HAVI</strong> <strong>Logistics</strong> and<br />

Van der Valk was signed on April 20, 2012.<br />

<strong>HAVI</strong> <strong>Logistics</strong> IS has developed an Internet-based<br />

ordering tool called iWeb especially<br />

for our new customer. With this excellent<br />

platform all the Van der Valk hotels<br />

are now able to make their orders and to<br />

transfer them directly to the <strong>HAVI</strong> <strong>Logistics</strong>’<br />

Customer Service Department.<br />

<strong>HAVI</strong> <strong>Logistics</strong> in the Netherlands serves 16<br />

Van der Valk hotels: 12 in the Netherlands,<br />

three in Germany and one on the island of<br />

Bonaire in the Dutch Antilles. All the core<br />

articles – around 180 frozen, 20 chilled and<br />

10 ambient products in total – are put on<br />

stock at our <strong>HAVI</strong> <strong>Logistics</strong> Distribution<br />

<strong>Center</strong> in Amersfoort. All other articles,<br />

such as for example fi sh, meat and vegetables,<br />

are delivered directly by the suppliers<br />

on a daily basis through a cross-dock<br />

process.<br />

Compared with other customers in the<br />

Netherlands like McDonald’s, BP and Vapiano,<br />

the hotel chain is much more versatile<br />

in terms of product assortment and<br />

demands. This is a new challenge not only<br />

for our Dutch Team, but for the entire <strong>HAVI</strong><br />

<strong>Logistics</strong> organization.<br />

alphabet I AUGUST 2012<br />

source: Van der Valk<br />

19

20<br />

Enlargement<br />

International Expansion is<br />

Assisted by <strong>HAVI</strong> <strong>Logistics</strong><br />

Since March of this year, <strong>HAVI</strong> <strong>Logistics</strong> in Spain has been making deliveries to the<br />

outlets of Llaollao. The local franchise company sells frozen yogurts and toppings<br />

made on its premises. Thanks to the great demand for these low-calorie treats,<br />

Llaollao will meet its impressive growth forecasts before the end of this year.<br />

Frozen yogurt has fewer calories than<br />

ice cream, but tastes every bit as good. In<br />

the U.S. it is available in many ice cream<br />

parlors and supermarkets. In Spain the<br />

rising demand has been covered by Llaollao<br />

for around two years now. Everyone<br />

is crazy about this frozen delicacy because<br />

it is healthy, fat-free, and low in calories,<br />

but at least as tasty as the “cream”<br />

version. The trendy franchise chain has<br />

discovered a niche in the market and now<br />

operates 76 ice cream parlors – sorry, frozen<br />

yogurt parlors – 70 of them in Spain,<br />

fi ve in Portugal and one in Belgium.<br />

Even the ambience is appealing: the<br />

shops have a modern décor in a combination<br />

of green tones and other light colors.<br />

The Llaollao slogan – The natural yogurt<br />

experience – obviously comes to life here.<br />

Customers can enhance the great basic<br />

fl avor with a large number of natural ingredients<br />

and choose from a wide selection<br />

of sauces, fruit, nuts and candies to create<br />

their very own frozen yogurt experience.<br />

The frozen yogurts are always freshly<br />

prepared at the counter to individual customers’<br />

orders. <strong>HAVI</strong> <strong>Logistics</strong> Spain supplies<br />

the Llaollao branches with 40 different<br />

articles in the fresh and dry goods ranges.<br />

Llaollao is expanding<br />

rapidly in Spain<br />

The franchise company plans to open 40<br />

new cafés by the end of the year. While<br />

neighboring Portugal and Belgium, too,<br />

have already caught the “Llaollao fever,”<br />

the Spanish frozen yogurt maker is planning<br />

to enter the markets in Russia, Singapore,<br />

France and Morocco as well.<br />

Pedro de Bernardo,<br />

Managing Director at<br />

<strong>HAVI</strong> <strong>Logistics</strong> Spain<br />

“Llaollao has a clear focus on the<br />

quality of all their products, and the role<br />

of <strong>HAVI</strong> <strong>Logistics</strong> is key to integral management<br />

of their supply chain, ensuring<br />

both excellent service and the highest<br />

quality standards. From the beginning,<br />

Llaollao has seen <strong>HAVI</strong> <strong>Logistics</strong> as a<br />

leading provider with a global presence<br />

that can assist the company in its<br />

planned international expansion.”<br />

source: LlaoLlao

<strong>HAVI</strong> <strong>Logistics</strong> Turkey Grows<br />

With Its New Customers<br />

Over recent years <strong>HAVI</strong> <strong>Logistics</strong> Turkey has been able to gain some strategic<br />

and important new customers. In the last twelve months alone, the Distribution<br />

<strong>Center</strong>s in Izmir and Sekerpinar have started supplying three new customers:<br />

the bistro and coffee chain Robert’s Coffee, the local burger restaurants of<br />

Etiler Marmaris, and the international supermarket chain Tesco Kipa.<br />

Etiler Marmaris<br />

For Etiler Marmaris, one of our largest<br />

competitive advantages is our growth<br />

alongside McDonald's. And the local fastfood<br />

restaurant chain also has a rich history.<br />

Etiler Marmaris was founded in Turkey<br />

in the early 1960s – even if at that time<br />

it was not like it is today, with its trendy,<br />

modern dishes.<br />

Etiler Marmaris has expanded greatly.<br />

Today it has 67 restaurants across the<br />

country, and since August of last year 43<br />

of them have been supplied by our Turkish<br />

Distribution <strong>Center</strong> in Sekerpinar. The<br />

deliveries include 120 different articles in<br />

three temperature categories. We have<br />

now been working together for about<br />

one year. Altan Sekmen, Managing Director<br />

at <strong>HAVI</strong> <strong>Logistics</strong> in Turkey, sums<br />

up the situation: “With our <strong>HAVI</strong> <strong>Logistics</strong><br />

service portfolio we are able to provide a<br />

tailor-made supply chain solution to Etiler<br />

Marmaris. Once the start-up period was<br />

over, we were heading for a win-win situation.<br />