Download - DBDH

Download - DBDH

Download - DBDH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

how EFFiCiEnt CAn it bE?<br />

By sales Director, Mr. Bent Have Johnsen, Aalborg engineering A/s<br />

During decades the Danish industry of energy producing equipment<br />

has been pushed for achieving higher and higher goals. the<br />

pressure has come from the shifting governments in order to<br />

release Denmark from import of energy to being independent.<br />

the results have been shown in many ways. these years the most<br />

visible effect has been the renewable energy market. there are<br />

however other technologies which has proven its co2 and emis-<br />

sion reducing capabilities previously.<br />

in 2003, Aalborg engineering was awarded the heat recovery boiler<br />

for the new block 8 on H.c. oerstedsvaerket in copenhagen. the<br />

plant would be a part of a master plan for the complete district<br />

heating system of the capital. Basis for the plant was a gas turbine<br />

(today known as a siemens sgt 600) which was moved from<br />

naestved to the site in copenhagen.<br />

in order to meet the required capacity the gas turbine had to<br />

be equipped with a heat recovery boiler with the possibility of<br />

increasing the production considerably. During the project study<br />

Aalborg engineering worked closely with the plant owner to make<br />

the best technical and feasible solution. the result was a heat<br />

recovery boiler with a high degree of supplementary firing using<br />

natural gas.<br />

in this solution we made it possible to increase the basic gas<br />

turbine load with additional app. 60 Mwt. the parameters were<br />

defined as low pressure steam for the copenhagen district<br />

heating system as well as district heating water. the plant was<br />

defined to have approx 500 annual operating hours. not much<br />

compared to the work carried out and investment made. But<br />

still the installed capacity had to cover for the expected ambi-<br />

ent conditions of the city and to make sure there were sufficient<br />

heat for the consumers.<br />

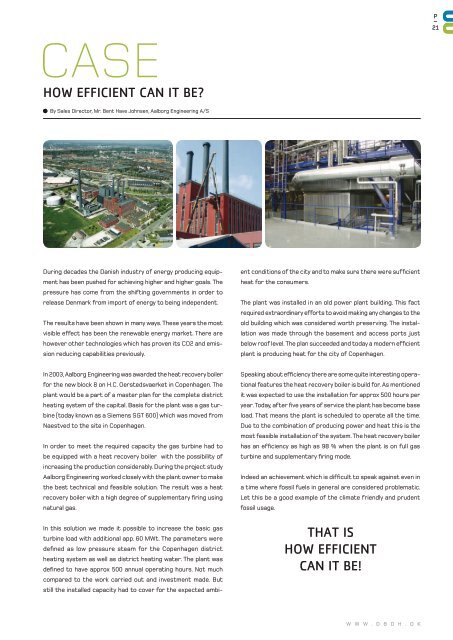

the plant was installed in an old power plant building. this fact<br />

required extraordinary efforts to avoid making any changes to the<br />

old building which was considered worth preserving. the installation<br />

was made through the basement and access ports just<br />

below roof level. the plan succeeded and today a modern efficient<br />

plant is producing heat for the city of copenhagen.<br />

speaking about efficiency there are some quite interesting operational<br />

features the heat recovery boiler is build for. As mentioned<br />

it was expected to use the installation for approx 500 hours per<br />

year. today, after five years of service the plant has become base<br />

load. that means the plant is scheduled to operate all the time.<br />

Due to the combination of producing power and heat this is the<br />

most feasible installation of the system. the heat recovery boiler<br />

has an efficiency as high as 98 % when the plant is on full gas<br />

turbine and supplementary firing mode.<br />

indeed an achievement which is difficult to speak against even in<br />

a time where fossil fuels in general are considered problematic.<br />

let this be a good example of the climate friendly and prudent<br />

fossil usage.<br />

thAt is<br />

how EFFiCiEnt<br />

CAn it bE!<br />

w w w . D B D H . D k<br />

p _<br />

21