NATO/CCMS Pilot Study Evaluation of Demonstrated and ... - CLU-IN

NATO/CCMS Pilot Study Evaluation of Demonstrated and ... - CLU-IN

NATO/CCMS Pilot Study Evaluation of Demonstrated and ... - CLU-IN

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>NATO</strong>/<strong>CCMS</strong> <strong>Pilot</strong> Project on Contaminated L<strong>and</strong> <strong>and</strong> Groundwater (Phase III) January 2001<br />

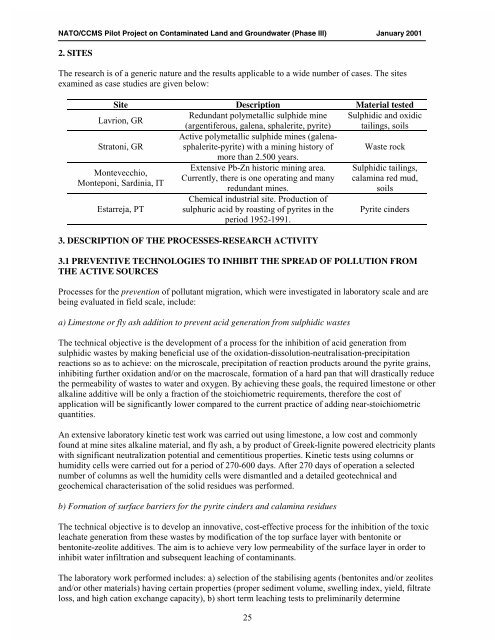

2. SITES<br />

The research is <strong>of</strong> a generic nature <strong>and</strong> the results applicable to a wide number <strong>of</strong> cases. The sites<br />

examined as case studies are given below:<br />

Site Description Material tested<br />

Lavrion, GR<br />

Redundant polymetallic sulphide mine<br />

(argentiferous, galena, sphalerite, pyrite)<br />

Active polymetallic sulphide mines (galena-<br />

Sulphidic <strong>and</strong> oxidic<br />

tailings, soils<br />

Stratoni, GR sphalerite-pyrite) with a mining history <strong>of</strong><br />

more than 2.500 years.<br />

Waste rock<br />

Montevecchio,<br />

Monteponi, Sardinia, IT<br />

Extensive Pb-Zn historic mining area.<br />

Currently, there is one operating <strong>and</strong> many<br />

redundant mines.<br />

Chemical industrial site. Production <strong>of</strong><br />

Sulphidic tailings,<br />

calamina red mud,<br />

soils<br />

Estarreja, PT sulphuric acid by roasting <strong>of</strong> pyrites in the<br />

period 1952-1991.<br />

Pyrite cinders<br />

3. DESCRIPTION OF THE PROCESSES-RESEARCH ACTIVITY<br />

3.1 PREVENTIVE TECHNOLOGIES TO <strong>IN</strong>HIBIT THE SPREAD OF POLLUTION FROM<br />

THE ACTIVE SOURCES<br />

Processes for the prevention <strong>of</strong> pollutant migration, which were investigated in laboratory scale <strong>and</strong> are<br />

being evaluated in field scale, include:<br />

a) Limestone or fly ash addition to prevent acid generation from sulphidic wastes<br />

The technical objective is the development <strong>of</strong> a process for the inhibition <strong>of</strong> acid generation from<br />

sulphidic wastes by making beneficial use <strong>of</strong> the oxidation-dissolution-neutralisation-precipitation<br />

reactions so as to achieve: on the microscale, precipitation <strong>of</strong> reaction products around the pyrite grains,<br />

inhibiting further oxidation <strong>and</strong>/or on the macroscale, formation <strong>of</strong> a hard pan that will drastically reduce<br />

the permeability <strong>of</strong> wastes to water <strong>and</strong> oxygen. By achieving these goals, the required limestone or other<br />

alkaline additive will be only a fraction <strong>of</strong> the stoichiometric requirements, therefore the cost <strong>of</strong><br />

application will be significantly lower compared to the current practice <strong>of</strong> adding near-stoichiometric<br />

quantities.<br />

An extensive laboratory kinetic test work was carried out using limestone, a low cost <strong>and</strong> commonly<br />

found at mine sites alkaline material, <strong>and</strong> fly ash, a by product <strong>of</strong> Greek-lignite powered electricity plants<br />

with significant neutralization potential <strong>and</strong> cementitious properties. Kinetic tests using columns or<br />

humidity cells were carried out for a period <strong>of</strong> 270-600 days. After 270 days <strong>of</strong> operation a selected<br />

number <strong>of</strong> columns as well the humidity cells were dismantled <strong>and</strong> a detailed geotechnical <strong>and</strong><br />

geochemical characterisation <strong>of</strong> the solid residues was performed.<br />

b) Formation <strong>of</strong> surface barriers for the pyrite cinders <strong>and</strong> calamina residues<br />

The technical objective is to develop an innovative, cost-effective process for the inhibition <strong>of</strong> the toxic<br />

leachate generation from these wastes by modification <strong>of</strong> the top surface layer with bentonite or<br />

bentonite-zeolite additives. The aim is to achieve very low permeability <strong>of</strong> the surface layer in order to<br />

inhibit water infiltration <strong>and</strong> subsequent leaching <strong>of</strong> contaminants.<br />

The laboratory work performed includes: a) selection <strong>of</strong> the stabilising agents (bentonites <strong>and</strong>/or zeolites<br />

<strong>and</strong>/or other materials) having certain properties (proper sediment volume, swelling index, yield, filtrate<br />

loss, <strong>and</strong> high cation exchange capacity), b) short term leaching tests to preliminarily determine<br />

25