Mine Rehabilitation Handbook - Mining and Blasting

Mine Rehabilitation Handbook - Mining and Blasting

Mine Rehabilitation Handbook - Mining and Blasting

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

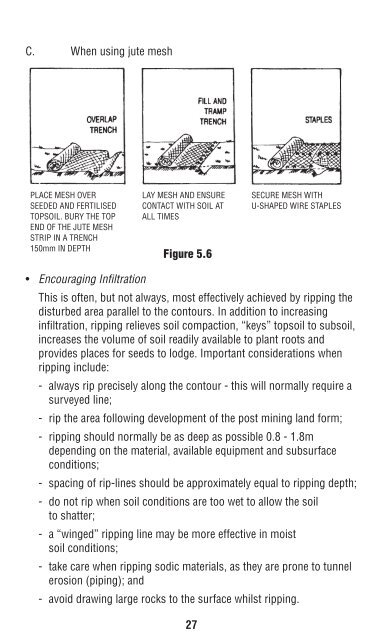

C. When using jute mesh<br />

PLACE MESH OVER<br />

SEEDED AND FERTILISED<br />

TOPSOIL. BURY THE TOP<br />

END OF THE JUTE MESH<br />

STRIP IN A TRENCH<br />

150mm IN DEPTH<br />

LAY MESH AND ENSURE<br />

CONTACT WITH SOIL AT<br />

ALL TIMES<br />

Figure 5.6<br />

• Encouraging Infiltration<br />

This is often, but not always, most effectively achieved by ripping the<br />

disturbed area parallel to the contours. In addition to increasing<br />

infiltration, ripping relieves soil compaction, “keys” topsoil to subsoil,<br />

increases the volume of soil readily available to plant roots <strong>and</strong><br />

provides places for seeds to lodge. Important considerations when<br />

ripping include:<br />

- always rip precisely along the contour - this will normally require a<br />

surveyed line;<br />

- rip the area following development of the post mining l<strong>and</strong> form;<br />

- ripping should normally be as deep as possible 0.8 - 1.8m<br />

depending on the material, available equipment <strong>and</strong> subsurface<br />

conditions;<br />

- spacing of rip-lines should be approximately equal to ripping depth;<br />

- do not rip when soil conditions are too wet to allow the soil<br />

to shatter;<br />

- a “winged” ripping line may be more effective in moist<br />

soil conditions;<br />

- take care when ripping sodic materials, as they are prone to tunnel<br />

erosion (piping); <strong>and</strong><br />

- avoid drawing large rocks to the surface whilst ripping.<br />

27<br />

SECURE MESH WITH<br />

U-SHAPED WIRE STAPLES<br />

• Managing Water Leaving the Site<br />

Water, which is discharged from the site, or is diverted away from the<br />

site, will generally have been controlled <strong>and</strong> the flow concentrated.<br />

Diversion of established drainage lines or watercourses would<br />

normally require specific approval from the State/Territory water<br />

authority. Similarly, diversion or discharge of runoff may have legal<br />

implications <strong>and</strong> necessary approval or permits should be obtained.<br />

Unless the water can be utilised by the mining operation, it must be<br />

managed to avoid pollution due to erosion <strong>and</strong> sediment deposition,<br />

either at the point of discharge or further downstream. As a guide:<br />

- Sediment dams are most commonly used to control <strong>and</strong> retain<br />

sediment laden runoff prior to discharge.<br />

- Most sediment will be carried by the infrequent high intensity<br />

rainfall events. Dams <strong>and</strong> spillways must be designed to<br />

accommodate these events or they will not function at the most<br />

critical times. Seek advice from appropriate authorities or detailed<br />

references for design techniques (refer Appendices 1 & 3).<br />

- Ensure that construction materials are suitable. Leakage from the<br />

dam may in itself not be critical but consequent instability of the<br />

dam wall due to tunnel erosion (piping) may result in failure.<br />

- Locate dams so that runoff from undisturbed catchments can be<br />

diverted to natural waterways. Ensure that channel gradients are<br />

not excessive <strong>and</strong> the need for protective measures within the<br />

channel is minimised.<br />

- In many dams, sediment levels greater than half of the total dam<br />

capacity will significantly reduce sediment removal rated. In these<br />

circumstances, sediment should be removed (refer figure 5.7).<br />

- In saline areas, be aware that the head (pressure) of a dam on a<br />

slope may cause salt scalding downslope of the dam.<br />

Figure 5.7<br />

28