BASIC MECHANICAL REFRIGERATION SYTEM COMPONENTS ...

BASIC MECHANICAL REFRIGERATION SYTEM COMPONENTS ...

BASIC MECHANICAL REFRIGERATION SYTEM COMPONENTS ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

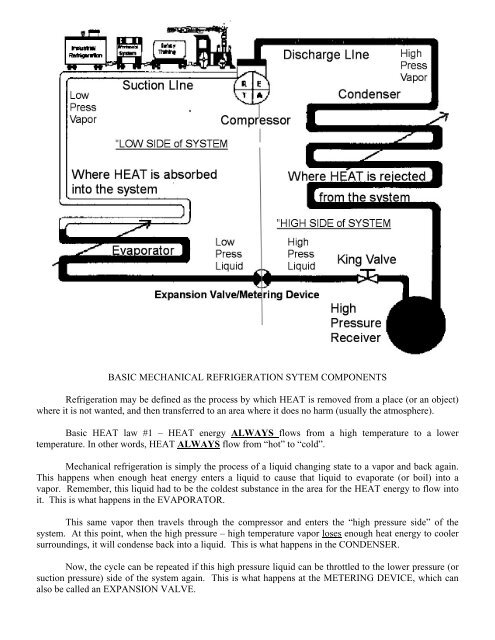

<strong>BASIC</strong> <strong>MECHANICAL</strong> <strong>REFRIGERATION</strong> <strong>SYTEM</strong> <strong>COMPONENTS</strong><br />

Refrigeration may be defined as the process by which HEAT is removed from a place (or an object)<br />

where it is not wanted, and then transferred to an area where it does no harm (usually the atmosphere).<br />

Basic HEAT law #1 – HEAT energy ALWAYS flows from a high temperature to a lower<br />

temperature. In other words, HEAT ALWAYS flow from “hot” to “cold”.<br />

Mechanical refrigeration is simply the process of a liquid changing state to a vapor and back again.<br />

This happens when enough heat energy enters a liquid to cause that liquid to evaporate (or boil) into a<br />

vapor. Remember, this liquid had to be the coldest substance in the area for the HEAT energy to flow into<br />

it. This is what happens in the EVAPORATOR.<br />

This same vapor then travels through the compressor and enters the “high pressure side” of the<br />

system. At this point, when the high pressure – high temperature vapor loses enough heat energy to cooler<br />

surroundings, it will condense back into a liquid. This is what happens in the CONDENSER.<br />

Now, the cycle can be repeated if this high pressure liquid can be throttled to the lower pressure (or<br />

suction pressure) side of the system again. This is what happens at the METERING DEVICE, which can<br />

also be called an EXPANSION VALVE.

1. Refrigeration<br />

2. Temperature<br />

3. Pressure<br />

4. To transfer heat requires a:<br />

5. Three methods of heat transfer are:<br />

6. A BTU is the:<br />

7. Specific heat is:<br />

8. Sensible heat is:<br />

9. Latent heat is:<br />

10. Superheat is:<br />

11. Saturation temp is:<br />

12. Subcooling is:<br />

<strong>REFRIGERATION</strong> – <strong>BASIC</strong> TERMS<br />

13. One ton of refrigeration is: Btuh or Btum<br />

14. Psig means:<br />

15. Psia means<br />

16. A refrigerant is a:<br />

17. Any gauge pressure reading above atmosphere is in below atmosphere<br />

is in:<br />

18. The 3 states of a material are:<br />

19. The latent heat of water to ice is: Btu/lb<br />

20. The latent heat of water to steam is Btu/lb (atmospheric pressure)<br />

21. Heat:<br />

22. Pressure/Temperature Relationship:<br />

23. The four basic system cycle components:<br />

24. Insulation<br />

25. Liquid Slugging<br />

26. Flash Gas

Thinking outside the box for the duties of a refrigeration system operator:<br />

As an operator, you are a heat transfer specialist. ….<br />

Or.…<br />

As an operator, you are a transportation system specialist.<br />

As an operator, you specialize in transporting (or moving) heat from one place to<br />

another, so you must understand every necessary step in this transportation system.<br />

As an operator, you control the boiling points of liquid refrigerants.<br />

As an operator, you control the condensing points of refrigerant vapor.<br />

As an operator, you are supposed to be an expert in understanding what is required to get<br />

the heat energy to leave the product and transfer it to the cooling medium. (A<br />

temperature difference must exist between the “warmer” product and the “cooler”<br />

cooling medium).<br />

As an operator, you must understand what the cooling medium is. Is it air, or water, or<br />

glycol, or is it just the refrigerant?<br />

As an operator, you specialize in either getting the “hot” stuff to the “cold” stuff (i.e. hot<br />

wine or water to the cold chiller surface), or the “cold” stuff to the “hot” stuff (i.e. cold<br />

air to the warm strawberries or cold water to the warm celery or broccoli). As a heat<br />

transfer specialist you realize if you can’t accomplish this step, you can’t transfer heat!<br />

As an operator, you must first know what the “product” is. (The “product” is the<br />

specific item that you are intending to cool, or said differently, that you are intending to<br />

remove heat from). Examples of “product” could be lettuce, celery, strawberries, apples,<br />

milk, wine, chicken parts, air, water, glycol, etc., etc.<br />

As an operator, you must also identify what the heat transfer surface is that you are<br />

transferring the heat through to transport that heat into the refrigerant. Is it a bare steel<br />

tube or pipe? Is it a finned tube? Is it a flatter surface of steel like a plate or jacketed<br />

tank wall? Depending on your specific type of evaporator, you may have all of these<br />

surfaces in one system.<br />

As an operator you must understand what role the refrigerant plays. The refrigerant is the<br />

heart of this transportation system. The refrigerant carries the heat like a semi-truck<br />

carries a load of pallets or lumber…..kind of.<br />

As an operator, you must understand what the final destination is for the heat in your<br />

transportation system. (The Atmosphere). You must completely understand this final<br />

step.

NOTES

NOTES

NOTES