Awareness Training Goals - Salinas Valley Ammonia Safety Day

Awareness Training Goals - Salinas Valley Ammonia Safety Day

Awareness Training Goals - Salinas Valley Ammonia Safety Day

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Ammonia</strong> <strong>Safety</strong> <strong>Day</strong><br />

“We will not accept another operator injury or death due to exposure to ammonia;<br />

evidence shows that it is far too simple to avoid! Basic safety knowledge and personal<br />

protective equipment (PPE) WILL SAVE YOUR LIFE! Consider that all pipelines are<br />

pressurized and do not trust that a valve position is as you think it is – double check and<br />

treat routine circumstances with caution – trust but verify! Use lock-out-tag-out, process<br />

safety measures like cutting/welding permits, and wear your PPE!”<br />

“Most emergency events last for an average of 3 hours and require the evacuation of<br />

downwind populations since the smell of ammonia creates community unrest: this is<br />

unacceptable. A properly prepared operator can stop most ammonia incidents through<br />

preventative action. If a release occurs, the operator (with proper PPE) can take steps to<br />

stop the incident when it is small (incidental response mode). If the incident becomes an<br />

emergency event, the relationship with public safety and regulators becomes very<br />

critical. Unified command and appropriate incident action plans and safety plans should<br />

lead to safe and effective control of the emergency event.”<br />

<strong>Awareness</strong> <strong>Training</strong> <strong>Goals</strong><br />

Use “Prevention, Mitigation, and Preparedness- P.M.P.” work safe and point out hazards<br />

and risks; be disciplined to work within the Standards of Operation; ask questions if you<br />

don’t know and learn the consequences of your actions; and when considering whether to<br />

operate an ammonia system valve, don’t go if you don’t know, let the professionals who<br />

know how to operate the system train you before working on a system.<br />

“Prevent them all or stop them small” and safely approach with proper PPE when<br />

performing service, maintenance, leak investigation, and response to emergency events; if<br />

you are not involved in the system repair, maintenance, service, or leak investigation then<br />

avoid the area, move to a safe location away from a potential release.<br />

Use the “One-Plan” to coordinate the emergency event effectively; learn how to effectively<br />

put L.A.N.C.E. into service; work in conjunction with the facility emergency response plan<br />

©ASTI – www.ammonia-safety.com – August 2008 1

<strong>Ammonia</strong> <strong>Safety</strong> <strong>Day</strong><br />

Chemical Characteristics of NH3<br />

-Boiling at -28ºF; Freezing -108°F<br />

-Expansion rate = 840 to 1<br />

-Vapor absorption rate into water =1300 to 1<br />

-Vapor density = 0.6 (Air = 1.0)<br />

-Alkaline = pH of 11.6<br />

-Flammability = 1204 ºF ignition temperature,<br />

850 ºF disassociation, 16% to 25% mix with<br />

air, widens with compressor oil and humidity<br />

-Reacts dangerously with chlorine, oxidizers,<br />

and acids (see MSDS for details)<br />

-Avoid copper, brass, silver, zinc or their alloys<br />

Physical Characteristics<br />

-Cone-shaped cloud with a v-pattern; rises and<br />

falls depending on humidity and climatic<br />

pressure inversions<br />

-Aerosol Dense Gas/Stream, Vapor, or Liquid<br />

-Loves water, moisture, vegetation, cool places;<br />

will move cross-wind to get to water<br />

-Warm air moves to cooler NH3 gas clouds<br />

-Aerosol releases are extremely cold and may<br />

reach -80ºF to -100ºF; NH3 freezes at -108ºF<br />

Health - “Rule of 5’s”<br />

5 – 20 PPM = Detectible by smell<br />

25 PPM = California/Washington PEL<br />

35 PPM = STEL for 15 minutes<br />

50 PPM = OSHA Permissible Exposure Limit<br />

300 PPM = IDLH – Must wear a SCBA<br />

1,500 to 1,700 PPM = Coughing and choking<br />

5,000 PPM = Extremely dangerous/deadly<br />

15,000 to 30,000 PPM = Skin burning/blisters<br />

Threats<br />

-Overpressure: Caution for NH3 liquid being<br />

trapped between valves; ammonia builds<br />

pressure when heated (check your condenser)<br />

-Release: Extreme caution for aerosol stream<br />

and dense gas; sub-cooled liquid may flash<br />

and spit when exposed to ambient conditions<br />

-Fire: <strong>Ammonia</strong> gas will ignite when trapped in<br />

a room or area at 16% to 25%; high risk<br />

concern begins at 15,000 PPM (ventilate and<br />

control sources of ignition before entering)<br />

2<br />

“The Entire Picture”<br />

Make the Connections Among:<br />

• Chemical/Physical<br />

• Health Effects<br />

• Potential Scenarios<br />

• Hazards and Threats<br />

• Prevention, Mitigation, Preparedness<br />

• Emergency Response and EMS<br />

Emergency Scenario Situations<br />

-Aerosol release in close proximity to community<br />

-Release while working near the system doing<br />

maintenance, service, and while investigating a leak<br />

or filling the system – Wear your PPE!<br />

-Contained dense gas in a room with source of ignition<br />

-Vapor release affecting evacuation<br />

-Trapping liquid ammonia or allowing a slug of liquid<br />

ammonia to enter the compressor<br />

-Theft, terrorism, natural disaster<br />

Service, Incidental, and Emergency Events<br />

-Maintenance release – Wear PPE and follow SOP<br />

-Incidental release – Escape when risk threatens<br />

workers or others exposed people; wear PPE<br />

-Emergency event – Discovery, Initial Response,<br />

Sustained Response, Termination<br />

Prevention and Mitigation<br />

-Inspection, maintenance, and housekeeping<br />

-Ventilation and pressure management<br />

-Containment and Control systems<br />

-Crash mitigation<br />

-Monitoring system for leaks/pressure<br />

-Valve and pipeline inspection<br />

-Replace threaded short nipples<br />

-Manage ice build up<br />

-Calibrate ammonia monitors<br />

Preparedness – Readiness and Discipline<br />

-SOPs for operations and leak control<br />

-Warning signs, valve tags, pipeline labels<br />

-P&ID charts, site and building plans<br />

-Service and maintenance training<br />

-Responder equipment and PPE readiness<br />

-Public safety training and preparedness<br />

-Emergency Response Plan strategy in sync<br />

with PPE and training readiness<br />

-Open valves slowly, consider every pipeline to<br />

be pressurized, review SOP and valve<br />

position; “If you don’t KNOW don’t GO!”<br />

Response<br />

-Establish incidental response protocols<br />

-Train on LANCE and SIMPLE<br />

-Downwind and community SIP/Evacuation<br />

-Check the P&IDs and Leak Control SOPs<br />

-Check the facility ERP or EAP<br />

Emergency Medical Concerns<br />

Managing Risks and Hazards<br />

-Vapor exposure: Causes discomfort (tears,<br />

-<strong>Ammonia</strong> may cause olfactory fatigue at low levels<br />

coughing, mucous) that clears up with fresh<br />

-Crash may cause damaged vessel, pipeline, or valve<br />

air or transitions to pain when breathing; lung<br />

(reduce pressure, isolate and contain NH3)<br />

sounds should be checked out by a doctor<br />

-Broken line or fitting or leaking valve (isolate, control -Aerosol or Liquid: Burns require 15 to 30<br />

pressure and re-direct liquid flow) – consider all<br />

minutes of water flushing; frozen clothing<br />

pipelines pressurized and be aware of sub-cooled<br />

must be thawed before removal<br />

liquid ready to spit out when exposed to ambient air<br />

-Eye exposure: 15 to 30 min. of water flushing<br />

-Over-filled vessel or cylinder (reduce pressure and<br />

-Heart Attack: CPR beginning with 300<br />

bleed off the vapor – requires 20% vapor space)<br />

compressions and immediately call 9-1-1<br />

-Overpressure from heated or over-filled vessel or<br />

-Heat-related injury: Cool the victim, treat for<br />

cylinder (reduce pressure and re-direct liquid flow)<br />

shock, check vitals, and call 9-1-1<br />

-Slugging or trapping (operate within technical<br />

-Emergency medical information available by<br />

specifications)<br />

calling CHEMTREC at 800-262-8200<br />

©ASTI – www.ammonia-safety.com – August 2008

Lowest Common Denominators<br />

For <strong>Safety</strong> and Readiness<br />

“Prevent them all or Stop them Small!”<br />

PMP<br />

Prreeveentt<br />

Mi itti igattee<br />

Prreeparree<br />

“Wal lk tthee<br />

Tal lk”<br />

Plan for On-Site<br />

and Off-Site<br />

Readiness;<br />

Evaluate and<br />

Continuously<br />

Improve!<br />

Identify Risks and<br />

Manage Hazards<br />

Cycle of <strong>Safety</strong><br />

and One-Plan<br />

Emergency<br />

Readiness<br />

Response and<br />

Recovery<br />

LANCE<br />

SIMPLE<br />

The One Pllan<br />

Emergency<br />

Response<br />

PPE & SOP<br />

Peerrssonal l<br />

Prrotteecctti ivee<br />

Equi ipmeentt<br />

Establish<br />

Strategy,<br />

Train, and<br />

Build the<br />

Defensive and<br />

Offensive<br />

SOPs<br />

“Strengthen the ‘Cyclle of <strong>Safety</strong>’ and buiilld a<br />

stronger safety cullture connectiion between<br />

emplloyees,, publliic safety and the communiity!”<br />

<strong>Ammonia</strong> <strong>Safety</strong> <strong>Day</strong><br />

©ASTI – www.ammonia-safety.com – August 2008 3

<strong>Ammonia</strong> <strong>Safety</strong> <strong>Day</strong><br />

4<br />

Workbook Questions - Ask SAL Monia – Chemical and Physical Traits<br />

Meet SAL Monia – Some Friendly and Live Saving Advice<br />

SAL Monia – Self Alarming<br />

Liquid - The <strong>Ammonia</strong> Genie<br />

SAL sleeps in his bottle (vessel)<br />

when under low pressure &<br />

temperature and as a liquid,<br />

SAL spits as an aerosol with a<br />

freezing sting<br />

SAL is cool and loves water and<br />

may form a dense gas<br />

SAL half as heavy as air except<br />

when he mixes with water vapor<br />

SAL travels in predictable ways<br />

move lateral and upwind or SIP to<br />

avoid him<br />

SAL if he gets on you wash him off<br />

30 minutes be aware of frozen<br />

clothing – wear safety gear!<br />

1. What is the significance of SAL’s name?<br />

2. What are his “two very different sides”?<br />

3. Why is SAL a “challenging character” to humans; a real “stinker”?<br />

4. What is SAL’s warning to those of you who work on ammonia systems? What’s he say about you<br />

“messing with the system”?<br />

5. SAL mentions that when operators don’t respect him and work on his system without PPE or proper<br />

SOP he “spits out an aerosol spray with a freeze burn” – What’s the lesson in that statement?<br />

Chemical and Physical Characteristics Get to know SAL<br />

Four Phases of <strong>Ammonia</strong><br />

Aerosol and Dense Gas<br />

Vapor and Liquid<br />

Aerosol, Dense Gas, & Vapor<br />

High Pressure Aerosol<br />

Low Pressure Aerosol<br />

©ASTI – www.ammonia-safety.com – August 2008

<strong>Ammonia</strong> <strong>Safety</strong> <strong>Day</strong><br />

6. Why is SAL “so darn thirsty”? Where does he find water? What forms when he mixes with water?<br />

7. What are the four types of ammonia releases that emergency responders should be aware of?<br />

8. What happens to SAL’s pressure as he heats up and cools down?<br />

9. Why is SAL considered as a great refrigerant?<br />

10. At what temperature does SAL sleep? Can he get colder than his boiling point? Why?<br />

11. When SAL escapes his vessel what powers does he have to be very dangerous?<br />

12. How do we contain SAL in a building or when leaking from a vessel?<br />

13. What happens when SAL’s vapor moves downwind and hits the buildings in the downwind or mixes<br />

with humidity and vegetation?<br />

14. Identify three ways you would escape from SAL’s vapors:<br />

15. Why does SAL need a vapor space when contained in a pipe or vessel? What’s it mean when SAL<br />

“pops the cork so to speak”?<br />

16. What is the significance of the term olfactory fatigue?<br />

17. What are the key concerns about proper shelter in place tactics?<br />

18. What is SAL’s warning about an aerosol burn? How long should you flush with water? Should you<br />

rub the burn area? Why are your eyes so vulnerable to injury by SAL?<br />

6<br />

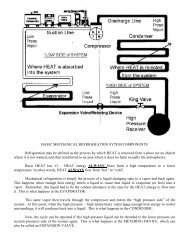

<strong>Ammonia</strong> Contained<br />

KING VALVE<br />

OUT SIDE SPACE<br />

Head Pressure<br />

(Ambient)<br />

(High Side)<br />

RECEIVER 5<br />

MECHANICAL ROOM<br />

(ENGINE-ROOM)<br />

LP LIQ<br />

HP LIQ<br />

soleniod valve<br />

7<br />

HP LIQ<br />

FLASH<br />

COOLER<br />

LP LIQ /VAP<br />

EXPANSION<br />

VALVE<br />

3<br />

Heat Load - Out<br />

B.T.U's<br />

CONDENSER<br />

LOW PRESSURE RECEIVER<br />

9<br />

AMMONIA PUMP<br />

Heat Load - In<br />

B.T.U's<br />

EVAPORATOR<br />

CONDITIONED SPACE<br />

(WAREHOUSE FREEZER OR COOLER)<br />

LP VAP /LIQ<br />

COMPONENTS HIGH SIDE / LOW SIDE SEPARATION AMMONIA STATE SUB-SPLITS INTERCOOLER VESSEL AMMONIA PUMP<br />

FLOW KING VALVE HEAT GAINS STATE CHANGES LOW PRESSURE VESSEL SHUT-OFF VALVES<br />

HIGH PRESSURE RECEIVER HEAT REMOVAL SOLENIOD VALVES<br />

PRESSURES / TEMPERATURES<br />

8<br />

2<br />

4<br />

©ASTI – www.ammonia-safety.com – August 2008 5<br />

HP VAP<br />

LP VAP<br />

HP VAP<br />

COMPRESSOR<br />

1<br />

LP VAP<br />

INTERMEDIATE PRESSURE<br />

(Low Side)<br />

MAIN<br />

COMPRESSOR<br />

SUCTION<br />

SIDE<br />

PORT<br />

SUCTION<br />

S-6

<strong>Ammonia</strong> <strong>Safety</strong> <strong>Day</strong><br />

6<br />

Flammability<br />

19. What is SAL’s warning when large amounts of his vapor enter a confined room with no ventilation?<br />

What is needed for SAL to ignite into a powerful ball of flame?<br />

20. Why is SAL more sensitive when water is dumped on him rather than for him to jump into the water?<br />

LANCE – The super hero!<br />

Readiness for a Release<br />

21. What does L.A.N.C.E. stand for?<br />

43<br />

Respiratory<br />

System<br />

Upper Respiratory:<br />

large particulate<br />

capture, water<br />

soluble gases<br />

Lower Respiratory:<br />

5 μ particles, low<br />

solubility gases<br />

Mucocilary<br />

escalator<br />

removes<br />

contaminants<br />

LANCE Implemented: LANCE is an acronym designed to help focus on priority concerns when<br />

assessing a potential ammonia emergency event. LANCE should take less than a minute to mentally<br />

review. The LANCE protocol should be continually evaluated for as long as the incident is “out of<br />

control.” LANCE stands for:<br />

Life safety first<br />

©ASTI – www.ammonia-safety.com – August 2008

<strong>Ammonia</strong> <strong>Safety</strong> <strong>Day</strong><br />

Initiate emergency action plan. Set the hot zone and define the area most at risk for the first stage of your<br />

response; help people escape - rescue (when properly trained and PPE equipped). If the leak is incidental,<br />

stop the leak by following equipment shutdown procedures if it’s possible to do so without being exposed<br />

to ammonia above the permissible exposure limit or IDLH when wearing proper PPE.<br />

Alert facility response team<br />

Contact the Facility Emergency Coordinator and on-site response team. When the personnel arrive, inform<br />

them of the site status, employee location, medical emergencies and severity of the incident. The Facility<br />

Emergency Coordinator (FEC) should take command and implement LANCE and SIMPLE protocols. All<br />

members of the response team must be properly trained and equipped with PPE.<br />

Notify<br />

Call 911 for local emergency response support; call them early to stop the problem when it is small. Also<br />

report to local, state, and national response officials immediately (within 15 minutes) if containment of the<br />

release is not achieved and the release is perceived to have reached the reportable quantity, or if exposure<br />

to offsite receptors is likely or has occurred. The Facility Emergency coordinator may request trained<br />

office staff to make the actual calls using the “One Plan” forms. Reporting requirements for local and state<br />

regulatory agencies must be incorporated into the response plan.<br />

Contain and Control<br />

Restrict the release by closing doors. Consider closing the king valve or the main liquid and hot gas<br />

supply valve to stop the flow of ammonia to the affected equipment if applicable to the situation. These<br />

valves are defined in the P&IDs, valve tags, pipeline labels, and leak control SOP’s with digital<br />

photographs. In some instances the trained operator may elect to operate certain equipment in order to<br />

help minimize the release in affected areas.<br />

Evacuate<br />

Move laterally and upwind. Some instances may be suited for sheltering in place. Move all personnel not<br />

involved in refrigeration control activities to a safe distance from the affected area. Assess the extent of a<br />

release area with monitoring equipment and include the property perimeter to determine whether any<br />

neighboring off-site receptors are affected and notification must be issued. Refer to the building and site<br />

plans and map out the evacuation strategy. The FEC should consider appointing an Evacuation<br />

Coordinator and use Public Address System communications to alert facility employees to the direction of<br />

the ammonia release and any specific evacuation considerations.<br />

Transition to SIMPLE Plan: When LANCE is completed, take a breath, gather your composure and<br />

consider the containment and control plan by reviewing the SIMPLE plan.<br />

Injury Prevention & Health Concerns<br />

22. Give an example of Prevention, Mitigation, and Preparation?<br />

23. What type of personal protective equipment (PPE) should an operator wear when working around the<br />

ammonia system?<br />

24. What’s the immediate area of concern should a problem develop while working on the system?<br />

©ASTI – www.ammonia-safety.com – August 2008 7

<strong>Ammonia</strong> <strong>Safety</strong> <strong>Day</strong><br />

25. What is the lowest level that most people can smell ammonia? What is the PEL for SAL? _______<br />

PPM and what does that mean? What is the IDLH: ______ PPM and what does that mean?<br />

Evacuation and Emergency Medical<br />

8<br />

No Tolerance for Injury –<br />

Escape and Safe Location is<br />

VERY Doable!<br />

Escape: Lateral, upwind, or shelter<br />

in place; go for the person with the<br />

PPE<br />

Decide: Time to evacuate or need to<br />

Shelter in Place?<br />

Evacuation: Must be coordinated<br />

and communicated – everyone<br />

must participate!<br />

Shelter in Place: Works especially<br />

well for ammonia – SAL seeks the<br />

cool and moves with the wind; just<br />

shut down HVAC and tune into the<br />

emergency broadcast radio station<br />

for instructions.<br />

26. Identify three concerns you would have if you were approaching an ammonia cloud?<br />

27. Identify three choices you have when escaping an ammonia release:<br />

28. Identify three different emergency response leaders you would attempt to contact should you be<br />

trapped inside and unable to escape an ammonia release?<br />

29. How would you communicate with the Facility Emergency Coordinator or the public safety Incident<br />

Commander if you did not have a radio?<br />

30. What are four things you can do to protect yourself during an ammonia release that is threatening your<br />

shelter in place location?<br />

31. You are doing maintenance and smell an odor of ammonia, you check it out and see that it is a leaking<br />

valve packing. What protocol would you use?<br />

32. How does your body react when it takes in a lot of ammonia vapor? At what point does the level of<br />

ammonia cause your breathing to stop?<br />

33. Identify four steps to helping a person who has just met you after escaping through an aerosol<br />

ammonia release? What would you do if the person swallowed some ammonia liquid?<br />

©ASTI – www.ammonia-safety.com – August 2008

The SIMPLE Plan<br />

Take a breath and think SIMPLE<br />

Sources of ignition: Confined gas<br />

cloud? Electrical, gas fired<br />

appliances?<br />

Isolation: King valve, isolate<br />

upstream and downstream without<br />

trapping liquid<br />

Manage Pressure: High side – shut<br />

down compressors; Low side<br />

transfer pressure and reduce<br />

overall pressures<br />

Positive Pressure Ventilation: Plan<br />

for the spread of vapor downwind<br />

LANCE: Do it again!<br />

Emergency Response Plan: The 30<br />

Minute Plan<br />

<strong>Ammonia</strong> <strong>Safety</strong> <strong>Day</strong><br />

34. What’s LANCE’s recommendation about ammonia and its mixture with chlorine? What’s the threat of<br />

ammonia soaking into the ground?<br />

Sources of ignition<br />

Evaluate explosion (flash fire – deflagration hazard) potential in enclosed rooms and confined spaces with<br />

monitoring equipment as needed. <strong>Ammonia</strong> can ignite when in its explosive range of 16% to 25%<br />

concentration or less in air when other flammables are present with an ignition source. Disconnecting<br />

electrical service to the facility may be required which may affect the operation of ventilation equipment.<br />

Assure that ventilation equipment is properly wired for operations in high ammonia concentrations:<br />

separate circuitry and electrical code requirements for Class and Division wiring techniques vary from<br />

local and state mandates. Relocate employees and response personnel to a safe distance when necessary.<br />

Isolate the release<br />

Manage the liquid source by turning off the supply (King Valve) or upstream and downstream valves<br />

without trapping liquid. The P&IDs, digital photographs, and leak control SOPs should indicate all key<br />

valves and containment options.<br />

Manage the Pressure<br />

Reduce system pressure to reduce system flow. If the leak is on the high side, stop the compressors. If the<br />

leak is on the low side, transfer of pressure or re-direction of the liquid flow and the temperature demand<br />

may be required to reduce flow by operating equipment. Consult your PSM protocols and SOPs for<br />

system controls.<br />

Positive pressure ventilation<br />

Reduce exposure potential whenever possible to lowest levels possible. Be aware of downwind receptors<br />

and air movement within the facility.<br />

©ASTI – www.ammonia-safety.com – August 2008 9<br />

44

<strong>Ammonia</strong> <strong>Safety</strong> <strong>Day</strong><br />

LANCE again<br />

Do it again! LANCE and immediately notify local, state and federal authorities. Make sure that local,<br />

state, and the National Response Center notifications are completed within 15 minutes of the FEC<br />

recognizing the emergency incident – assign trained security or administrative personnel to do the calling.<br />

Emergency Response Plan<br />

Follow the facility response procedures of the 30-Minute Plan structure, written Incident Action Plan, and<br />

<strong>Safety</strong> Plan. First Responders meet in one location to coordinate information and resources with the<br />

Incident Commander. Develop a written safety plan and incident action plan before proceeding with<br />

offensive tactics and strategy. Prepare the entry TEAM with back-up responders and communications<br />

when deemed necessary. Repairs involving Hazmat response activity are permitted only when conducted<br />

within the incident command structure of Public <strong>Safety</strong> officials with jurisdiction.<br />

10<br />

Preparing for and Preventing <strong>Ammonia</strong> Releases<br />

1. How ammonia is released:<br />

• Opening the system:<br />

o Maintenance<br />

o Construction<br />

• Accidents:<br />

o Piping or equipment hit<br />

o Fire<br />

o Natural disasters<br />

• Equipment failure:<br />

o Solenoid: wire drawn, plug stuck, etc.<br />

o Pressure regulator: diaphragm failure, piston stuck<br />

o Compressor: internal part wearing<br />

o Seal failure<br />

o Corrosion<br />

• No operating procedure or not following procedures<br />

• Lack of or inadequate training for a task<br />

• Theft<br />

2. Preparedness and prevention of releases:<br />

• Education and <strong>Training</strong>:<br />

o IIAR (Video and DVD)<br />

Basic <strong>Ammonia</strong> Refrigeration (6 modules): Introduction to <strong>Ammonia</strong> Refrigeration;<br />

<strong>Ammonia</strong> Refrigeration Systems; Evaporators; Compressors; Condensers; Shut-off<br />

Valves<br />

<strong>Ammonia</strong> <strong>Safety</strong> (4 modules): Introduction to Personal Protective Equipment; Use of<br />

Personal Protective Equipment; Emergency Response; <strong>Ammonia</strong> <strong>Safety</strong>: Emergency<br />

Response Procedures<br />

Removing oil from an ammonia refrigeration system<br />

o IIAR Technical Papers<br />

o IIAR Condenser<br />

o RETA Course Books<br />

Refrigeration Series<br />

©ASTI – www.ammonia-safety.com – August 2008

<strong>Ammonia</strong> <strong>Safety</strong> <strong>Day</strong><br />

Electricity Series<br />

Control Theory, Schematics and Troubleshooting<br />

Energy Conservation<br />

<strong>Safety</strong> and Regulatory<br />

Practical Problems in Mathematics for Heating and Cooling Technicians<br />

o RETA “The Technical Report”<br />

o RETA Breeze<br />

o RETA Convention Chronicle<br />

o IIAR and RETA annual conventions<br />

• IIAR Bulletins and Guidelines:<br />

o <strong>Ammonia</strong> Refrigeration <strong>Training</strong> Guideline<br />

o Bulletin 107 – Guidelines for: Suggested <strong>Safety</strong> and Operating Procedures when Making<br />

Refrigeration Plant Tie-Ins<br />

o Bulletin 108 – Guidelines for: Water Contamination in <strong>Ammonia</strong> Refrigeration Systems<br />

o Bulletin 109 – Guidelines for: IIAR Minimum <strong>Safety</strong> Criteria for a Safe <strong>Ammonia</strong><br />

Refrigeration System<br />

o Bulletin 110 – Guidelines for: Start-up, Inspection and Maintenance of <strong>Ammonia</strong><br />

Mechanical Refrigeration Systems<br />

o Bulletin 111 – Guidelines for: <strong>Ammonia</strong> Machinery Room Ventilation<br />

o Bulletin 112 – Guidelines for: <strong>Ammonia</strong> Machine Room Design<br />

o Bulletin 114 – Guidelines for: Identification of <strong>Ammonia</strong> Refrigeration System Piping and<br />

System Components<br />

o Bulletin 116 – Avoiding Component Failure in Industrial Refrigeration Systems Caused by<br />

Abnormal Pressure or Shock<br />

• Standards:<br />

o American National Standard: <strong>Safety</strong> Code for Mechanical Refrigeration - ANSI/ASHRAE<br />

Standard 15 - 2007<br />

o American National Standard for Equipment, Design and Installation of <strong>Ammonia</strong><br />

Mechanical Refrigerating Systems - ANSI/IIAR Standard 2 -1999<br />

o <strong>Ammonia</strong> Refrigeration Valves - ANSI/IIAR Standard 3 – 2005<br />

• Regulatory Guidelines (IIAR):<br />

o Risk Management Program Guidelines For <strong>Ammonia</strong> Refrigeration<br />

o Process <strong>Safety</strong> Management Guidelines For <strong>Ammonia</strong> Refrigeration<br />

o <strong>Ammonia</strong> Refrigeration Management (facilities with less than 10,000 lbs.)<br />

• Continuing Education:<br />

o Hazmat Courses: Operations, Technician, Incident Commander<br />

o Refrigeration <strong>Training</strong> courses from technical colleges<br />

o Seminars<br />

o <strong>Ammonia</strong> equipment supplier presentations<br />

o In-house<br />

Incident Action Planning Using LANCE and SIMPLE Procedures<br />

The Emergency Action or Emergency Response Plan and Fire Prevention plans include procedures for<br />

incidental ammonia release, fire or other emergencies. The Plan provides information necessary to protect<br />

employees from various hazards during emergency situations by relocating individuals away from the<br />

affected area to a Designated Meeting Location or by Sheltering in Place.<br />

©ASTI – www.ammonia-safety.com – August 2008 11

<strong>Ammonia</strong> <strong>Safety</strong> <strong>Day</strong><br />

First Responder <strong>Awareness</strong> training is provided to employees who are assigned duties by the Facility<br />

Emergency Coordinators (FEC).<br />

Pre-Incident: These are critical first steps to operations BEFORE considering any move to control an<br />

emergency event:<br />

• Response plan agreement between all of the responders and response agencies (public safety and<br />

local regulator)<br />

• PPE readiness and safety – PROTECT your team members by having them wear proper PPE<br />

before the system is opened or manipulated<br />

• Valve and pipeline readiness concerns:<br />

o Consider all lines to be pressurized – never open a system and think it’s completely void of<br />

ammonia – special caution for the sub-cooled liquid<br />

o Double check valves before you open the system, downstream and upstream<br />

o When you work on a system and you aren’t sure of the consequences of your actions<br />

DON’T do it. Check the protocols and SOPs and work with a supervisor or a systems<br />

engineer to understand the consequences of a possible failure in the system!<br />

General: Upon discovery of an incident, it’s important for the First Responder to size up an emergency<br />

situation and identify what happened. Are lives and the environment at risk? What stage of the event is<br />

happening now? What needs to be done next? Answer these key questions in order to prioritize which<br />

actions to take and determine what the initial response will be.<br />

Employees will be required to take the following action in the event of an emergency due to an<br />

unintentional ammonia release, fire or other emergency:<br />

1. Upon notification, employees and visitors immediately follow the procedures described in the<br />

Emergency Action and Fire Prevention plans for evacuation. They will either assemble at a designated<br />

meeting location or shelter in place, and will be accounted for by the emergency coordinator.<br />

2. The engineering manager, the refrigeration operators, or refrigeration contractor, are permitted to take<br />

defensive action to control the leak to the extent of their training but will take no aggressive action that<br />

would require entry into an area containing ammonia concentrations above the permissible exposure<br />

limits without first donning the appropriate level of respiratory protection and personal protective<br />

equipment.<br />

On Site Readiness: Facility Emergency Coordinator (FEC): The person in charge of any emergency<br />

incident must be designated and trained to fill that position. At least 2 people for each working shift<br />

should be trained at that level. <strong>Training</strong> will be in accordance with the following:<br />

Level 1: Defense only, under 300 PPM, supported by local public safety trained to a pre-described level of<br />

readiness: a minimum of 8 hours of Operational training annually refreshed (8 hours) is recommended for<br />

response team members. FECs shall be trained to Technician level with special training on how to engage<br />

and utilize the Incident Command System.<br />

Level 2: Offense to 5,000 PPM with continuous monitoring while inside the hot zone. SCBA and<br />

chemical resistant suits recommended to have at least 60 minutes impermeability for ammonia, with the<br />

best being 480 minutes; Technician trained with 24 hours of training supported by 8 hours of refresher<br />

mandated; skill tested with Level B equipment at least 3 times per year for each response team member;<br />

12<br />

©ASTI – www.ammonia-safety.com – August 2008

<strong>Ammonia</strong> <strong>Safety</strong> <strong>Day</strong><br />

FECs shall be trained to Technician level with special training on how to engage and utilize the Incident<br />

Command System, with emphasis on how to operate in a Unified Command.<br />

Level 3: Offense with the highest level of PPE supported by the fire department hazmat team. Situations<br />

in which flammability is a concern should be avoided (ammonia escaping into an enclosed room that is<br />

not effectively ventilating gases to the outside). The flammable limits are generally 16% to 25%<br />

(compressor oil and other contaminants may change the limits). ASTI recommends extreme caution at<br />

15,000 PPM and extreme concern at 40,000 PPM, as the speed of concentration of an “out of control”<br />

ammonia release in an enclosed room can reach flammable limits within a few minutes. The Level A<br />

responder must also be aware of the low temperature hazards and risk when working around liquid stream<br />

aerosols and dense gas cloud releases. Technician trained 24 hours of training supported by 8 hours of<br />

refresher mandated; skill tested with Level A PPE at least 4 times per year (ASTI recommendation) for<br />

each member of the response team; FECs shall be trained to Technician level with special training on how<br />

to engage and utilize the Incident Command System and participating in a Unified Command operation.<br />

Note: Trained employee responders should take no offensive response without the support of local<br />

emergency authorities. All response activities must occur within the incident command structure and be<br />

coordinated with public safety officials in charge of emergency response scene management.<br />

Practices for First Responders when dealing with emergency situations:<br />

ASTI recommends that the Facility Emergency Coordinator request to work under a “Unified<br />

Command” structure with Public <strong>Safety</strong> Officials. This is the accepted method and approach for private<br />

industry to assist with mitigation during an emergency response. Offensive action to control a release<br />

should be coordinated with public safety officials using “One Plan” logic and conducted within “Incident<br />

Command System” scene management. Only employees who meet the qualifications required by OSHA<br />

29 CFR 1910.120 may be certified by the employer to participate in response to emergency events<br />

involving ammonia. HAZWOPER regulations must be applied to handling hazardous waste and<br />

hazardous materials other than the ammonia emergency response.<br />

Hazard and Risk in Focus – I.T.C. “In-Total-Control”<br />

Treatment of the injury is more costly than Preventing the problem! Don’t waste your PMP dollars.<br />

Spend them with a focus on high risk/high frequency challenges!<br />

Risks + Hazards + Frequency of Risks and Hazards = Level of Concern<br />

Level of Concern + PMPs + <strong>Safety</strong> Discipline = Acceptable Level of Risk<br />

Acceptable Level of Risk + Emergency Response Readiness = Managed Risk<br />

Three Golden Rules of Safe and Effective Hazard Control<br />

1. WEAR your PPE! <strong>Ammonia</strong> is dangerous, but it’s easy to protect yourself. At a minimum, wear<br />

respiratory and face protection, helmet, gloves, full skin coverage at ANY time you are going to open<br />

or manipulate the system in a fashion that could allow SAL Monia to escape!<br />

2. If you don’t know, don’t go! ALWAYS know the consequences (domino effect) of your actions<br />

while working on a system. Review the P&IDs and the SOPs. If you are unsure, or don’t know, ASK<br />

your supervisor, and remember that the installation engineer, installation contractor, and/or the<br />

equipment vendors are great sources of informational support.<br />

3. ALWAYS consider pipelines pressurized, double check the position of the upstream and<br />

downstream valves, and open valves slowly before commencing service, maintenance, or repair<br />

operations.<br />

©ASTI – www.ammonia-safety.com – August 2008 13

<strong>Ammonia</strong> <strong>Safety</strong> <strong>Day</strong><br />

Preparation for Maintenance, Repair, Service, Leak Investigation<br />

“All pipelines should be considered pressurized and the status of the valves CANNOT be trusted –<br />

double check and treat circumstances for the risk they present rather than to trust that things are what<br />

they seem to be! Wear PPE and follow SOP! This procedure provides guidance on how to approach<br />

maintenance, service, and leak investigation, and how to survive an incidental release and transition, if<br />

necessary, to emergency response mode.<br />

Facility Emergency Coordinator/Technician Operator Preparation Discussion:<br />

Review and test the method of contacting the on-site emergency response team; learn how to quickly<br />

and effectively engage the on-site response team<br />

Review the LANCE and SIMPLE procedures – use them to size up the situation and mentally prepare<br />

for developing the actual response plan.<br />

Make sure the facility Emergency Action Plan, leak control SOPs, P&IDs, and other plans that support<br />

emergency operations are available in an emergency.<br />

Take a digital picture of service, maintenance, or repair locations for future reference in an emergency.<br />

This also serves as a good record of repair.<br />

Fill out the “Worksheet: Service, Maintenance, Investigate, Repair, Incidental and Emergency Event<br />

Response Readiness” or other forms used to record service, maintenance, or repairs.<br />

Determining if the event is an “Incidental” or an “Emergency” event: Criteria for determining when<br />

the “incidental” release becomes an emergency event:<br />

1. A response is required from outside the immediate release area by an emergency response<br />

team; danger is imminent and an emergency exit is not readily available<br />

2. The incident requires evacuation of employees in the area<br />

3. The incident poses, or has potential to pose, conditions that are immediately dangerous to<br />

life and health (IDLH); more than 300 PPM of ammonia in the exit pathway<br />

4. The incident poses a serious threat of fire or explosion (a fire starts or overpressure exceeds<br />

safety mitigations)<br />

5. The incident requires immediate emergency response because of imminent danger (control<br />

or containment is unclear and building is in danger or at risk)<br />

6. The incident may cause high levels of exposure to toxic substances<br />

7. It is uncertain whether the employee in the work area can handle the severity of the hazard<br />

with the PPE and equipment that has been provided and the exposure limit could easily be<br />

exceeded<br />

8. The situation is unclear, or data is lacking on important factors<br />

Readiness for Fire, Overpressure and Release:<br />

Fire Readiness: Check location, service, and readiness of the fire extinguisher(s): travel distance<br />

within 75 feet of the work area and always immediately available when doing cutting and welding.<br />

Identify fire doors, fire walls, primary and secondary exits, and the fire safety readiness of the area to<br />

be worked on. Use cutting and welding permits, lock out/tag out, and any other process safeguards as<br />

established by facility safety SOPs.<br />

14<br />

Review SOP(s) for: Leak control, shut down/start up of compressors, King Valve operation,<br />

emergency ventilation, pressure management, and control/containment for overpressure, fire, or<br />

release<br />

Identify the location and operation of system components prior to operation, service or repair, or<br />

leak investigation;<br />

©ASTI – www.ammonia-safety.com – August 2008

Piping and Instrumentation Diagram (P&ID), site plan, building plan, drainage plan<br />

Review the location and operation of key shut-off valves<br />

Do not trap liquid ammonia between closed valves with no relief valve protection<br />

<strong>Ammonia</strong> <strong>Safety</strong> <strong>Day</strong><br />

Emergency Control System Location: Review the location and operation of each; provide digital<br />

pictures of the locations:<br />

Compressors Emergency Controls<br />

Low Side Pressure Management and Monitoring<br />

Ventilation Emergency Controls<br />

Electrical Power Control Panels<br />

King Valve Location/Operation<br />

Downwind Concerns (Site Plan)<br />

Downstream – Sewer/Storm Drainage and Floor Drain Stop Points<br />

ALWAYS lock out/tag out when working on the system<br />

<strong>Safety</strong> and Personal Protective Equipment Readiness: Location(s) for First Aid and<br />

Decontamination:<br />

First Aid: _____________________________________________________________________<br />

Eye Wash: ____________________________________________________________________<br />

Emergency Shower: ____________________________________________________________<br />

Emergency Response Equipment: ________________________________________________<br />

Personal Protective Equipment: <strong>Ammonia</strong> <strong>Safety</strong> Protective Equipment (ASPE gear) should be worn<br />

within 20 feet of a repair and at any time during repair, maintenance, service, or leak investigation and<br />

when working on the system in elevated locations. The maintenance engineer or system operators must be<br />

ready to act should an incident occur, and follow a daily check-out:<br />

Check operation of ammonia monitor<br />

Check operation of radio<br />

Check operation of flashlight<br />

Check condition and readiness of respirator (APR or SCBA)<br />

Check inventory: <strong>Ammonia</strong> Monitor (300 PPM), Emergency Response Cards (and emergency<br />

preparedness documents), inner and outer gloves, master key access/egress and control box,<br />

helmet, goggles, hearing protection, respirator mask, overalls (covering all skin) and safety boots<br />

PREVENTION of Fire, Overpressure and Release<br />

Access: Unobstructed access to exits, emergency controls, and emergency equipment<br />

Safe Storage: Hazardous materials, housekeeping, and stable storage structure so that access and<br />

movement of product is safe; pipe guards and clearance for access; clearance of combustibles from heat<br />

producing equipment<br />

Valve Operation: Key valves operate effectively (serviced and exercised regularly) and relief valves<br />

serviced and ready for operation (five-year change out)<br />

System Integrity: Corrosion control, repair all leaks, regular inspection and upgrade; eliminate threaded<br />

pipe connection, especially short nipples<br />

MITIGATION of Fire, Overpressure and Release<br />

©ASTI – www.ammonia-safety.com – August 2008 15

<strong>Ammonia</strong> <strong>Safety</strong> <strong>Day</strong><br />

System Monitoring: Calibrated and monitored for overpressure, release, and system operations<br />

High and Low Side: Identify key control valves and operational methods for manipulating the flow of<br />

ammonia to and from key components of the system (condensers, compressors, receivers, evaporators);<br />

methods of mitigating a release from oil pot and defrost problems; methods of managing pressure on the<br />

high, intermediate, and low side of the system<br />

Alert System: Method of issuing an incident alert and a communications system for employee/visitor<br />

movement; radio controlled communications on the PA system<br />

Fire Control Systems: Fire sprinkler system, fire extinguishers, water supply, fire access<br />

PREPARATION for Fire, Overpressure and Release<br />

PPE: For Facility Emergency Coordinator and on-site response team; those needed to implement LANCE<br />

and SIMPLE – minimum of two sets, one for Facility Emergency Coordinator and another for Operations<br />

trained person who can perform LANCE and SIMPLE<br />

Leak Control SOPs: Developed for each section of the ammonia system; high and low sides of the<br />

engine room; key control valves to isolate and contain releases to all components within the system. Leak<br />

control SOPs include a definition of the P&ID location of the isolation valves with due consideration of<br />

trapping ammonia – the strategy will be to control the amount of ammonia flowing to the problem<br />

location and to reduce system pressures in the location of the problem.<br />

Communications: Between Facility Emergency Coordinator and Technician- or Operations-trained<br />

personnel, and with those in charge of notification and evacuation; provide adequate access to phones and<br />

alerting systems<br />

SOPs and Plans: Evacuation, Emergency Notification, Maintenance, Incidental, Emergency Response,<br />

Restart, and Termination/Debriefing; also P&ID, Site and Building Plans. We recommend copies of the<br />

Emergency Response Cards for all key responders.<br />

Methods of Alert: Giving notice of an incident; communicating to those on site (audio alert and voice<br />

communications). We recommend setting up the radios used by command and control leaders to broadcast<br />

on the facility public address system to alert employees of special hazard circumstances.<br />

Emergency Response Equipment: PPE for responders and their back-up teams; one (preferably two) gas<br />

powered fan for emergency ventilation and decontamination; zone and control markers (placards, tape and<br />

cones to mark hot, warm and cold zones); decontamination equipment (fan, hose, water, catch basins,<br />

extra overalls); downwind/downstream, ammonia monitor to the limits of PPE, wind speed and direction<br />

indicators, valve control wrenches (placed strategically in multiple locations), and pH monitor.<br />

Emergency Medical Readiness: Water is your best friend when dealing with ammonia contamination.<br />

Flush with water, but do not rub. Continue for 15 to 30 minutes to draw ammonia out of the skin tissue.<br />

Also, be prepared to treat heat-related stresses: an emergency responder is subject to stress and high body<br />

heat, especially while wearing PPE. In some cases, the body will go into shock and a cardiac event may be<br />

triggered: be prepared to perform CPR. People exposed to higher doses of ammonia may experience<br />

nausea.<br />

Nausea is caused by a number of factors, the most common being the shock syndrome. Someone<br />

overcome with toxic fumes suffers system (body) compromise, setting up classic shock symptoms of<br />

weakness, shortness of breath, and nausea. Nausea may also result from swallowing minute amounts of<br />

ammonia which, when bound to saliva or fluid that is then mixed with gastric acid, causes a<br />

retching/nausea reaction. Inhalation of any toxic gas or offensive odor affects not only the olfactory<br />

system, but causes gagging and retching, a natural protective reaction of the body. This is similar to the<br />

nausea suffered by firefighters who choke and cough when overcome by smoke.<br />

16<br />

©ASTI – www.ammonia-safety.com – August 2008

<strong>Ammonia</strong> <strong>Safety</strong> <strong>Day</strong><br />

Worksheet: Service, Maintenance, Investigate, Repair, Incidental and<br />

Emergency Event Response Readiness<br />

Name(s) Technician: ____________________________________________________________________<br />

Facility Emergency Coordinator: _________________________________________________________<br />

Radio: _____________________ Cell Phone: ___________________ Phone: _____________________<br />

Describe the operation to be performed and take a digital picture of the repair site:<br />

______________________________________________________________________________________<br />

Entry Date/Time: _______________ Check-In Time(s): _______________________________________<br />

Termination of Incident Time/Date:____________________ Details:_____________________________<br />

_______________________________________________________________________________________<br />

Emergency Entry PPE Readiness:<br />

Entry and Back-Up are trained and certified to act in accordance with the ERP<br />

<strong>Ammonia</strong> <strong>Safety</strong> Protective Gear - Communications, NH3 monitor, respirator, gloves, overalls, boots,<br />

goggles, Emergency Response Cards, etc.<br />

Emergency response equipment to include ventilation fans – serviced and ready to operate<br />

P&ID, leak SOPs, building, and site plans available<br />

LANCE Preparation:<br />

Life safety: Set the Hot Zone and evacuate non-essential personnel; check your PPE.<br />

Names of those working in the hot zone: _________________________________________________<br />

Set perimeters and post placards: ______________________________________________________<br />

Alert: Radio contact to the Facility Emergency Coordinator who will coordinate emergency response.<br />

Radio and/or phone contact for Facility Emergency Coordinator:____________________________<br />

Who are the response team members available? ___________________________________________<br />

Notification: Contact 9-1-1 for any probable emergency event.<br />

Give a LANCE and SIMPLE size up to Facility Emergency Coordinator and Emergency<br />

Responders<br />

Contain/Incidental Control: Close the doors and contain the release; control the leak source.<br />

Location of exit and entry doors:_________________________________________________________<br />

Other Containment and Control Measures:________________________________________________<br />

Evacuate or Shelter in Place: Evacuate upwind; S.I.P. if caught in the downwind.<br />

Describe the downwind: ________________________________________________________________<br />

Describe the downwind SIP locations:____________________________________________________<br />

Evacuation Coordinator: ______________________________________________________________<br />

After completing LANCE, take a breath and begin working on the SIMPLE plan on<br />

the next page.<br />

©ASTI – www.ammonia-safety.com – August 2008 17

<strong>Ammonia</strong> <strong>Safety</strong> <strong>Day</strong><br />

The SIMPLE Plan for Emergency Events: Date:_________ Time:________<br />

Name(s) Technician:___________________________________________________________________<br />

Facility Emergency Coordinator: ______________________________________________________<br />

LANCE and SIMPLE: What happened? Who is at risk? What is anticipated? What is the plan?<br />

____________________________________________________________________________________<br />

What type and amount of problem (fire, overpressure, release – aerosol, dense gas, vapor, liquid)?<br />

________________________________________________________________________<br />

Sources of Ignition: If the release approaches 15,000 PPM, aggressively control sources of ignition.<br />

Define control of potential sources:___________________________________________________<br />

Isolate the Release: Consult P&ID for location of valves to control a potential release; make sure liquid<br />

isn’t trapped.<br />

Upstream valve: ___________________________________________________________________<br />

Downstream valve:_________________________________________________________________<br />

Trapping concerns:_________________________________________________________________<br />

Manage the Pressure: Reduce system pressure, reduce cooling demand, isolate the amount of ammonia<br />

flowing to leak site.<br />

High Side:_________________________________________________________________________<br />

Intermediate:______________________________________________________________________<br />

Low Side:_________________________________________________________________________<br />

Positive Pressure Ventilation: Plan for the downwind and/or route of your ventilation release. Sources of<br />

ignition controlled? Fire spread potential? Public safety access, traffic control concerns?<br />

Inside travel of gases (Building Plan):_________________________________________________<br />

Downwind concerns (Site Plan):______________________________________________________<br />

LANCE Again: Continuously check in with LANCE and improve upon the plan.<br />

Recheck LANCE: _________________________________________________________________<br />

Notify the local, state and federal environmental regulators: Date/Time/Initials<br />

Emergency Response Plan: Transition to the 30-Minute Plan; size up, notification, incident action plan,<br />

safety plan and command and control.<br />

IAP, <strong>Safety</strong> Plan, backup staffing, EMS, decontamination, rehabilitation<br />

Site Plan/Building Plans, P&IDs and Photographs<br />

18<br />

©ASTI – www.ammonia-safety.com – August 2008

PSM Readiness Outline<br />

1. Employee Participation – A team approach!<br />

Who is on the team? Engineering, Operations and<br />

Maintenance, fork lift drivers, general laborers,<br />

supervisors, managers<br />

How are you looking at your problems?<br />

Impacts – priorities – perceived vs. real threats<br />

Economics – most benefit for the investment<br />

Tracking and recording problems, challenges, needs<br />

The cost of a forgotten fix?<br />

Yearly awareness training – readiness to evaluate<br />

the facts; focus on making good fixes<br />

Keep minutes and good records of your efforts<br />

Employee access to the information (with conditions)<br />

2. Process <strong>Safety</strong> Information<br />

Knowing the chemical and hazards – data book, MSDS<br />

Understanding your system – P&ID and valve tagging<br />

Operational SOPs<br />

Materials, electrical, certification of service relief valves<br />

Operational limits/capacities, consequences of deviation<br />

Unobstructed and accessible exits<br />

Monitoring systems – pressure and release monitoring<br />

Ventilation systems controls and valve operation<br />

Compliance to “good engineering practices”<br />

3. Process Hazard Analysis – site specific<br />

What if/checklist methodology<br />

Every piece of equipment (unless exactly the same)<br />

documented and problems addressed ASAP<br />

Facility and human factors<br />

Updated every five years<br />

4. Operational Procedures<br />

Clearly documented initial start up, normal operations,<br />

emergency/normal shut down, start up after turn-around<br />

SOPs – preventing slugging, trapping, overfilling<br />

<strong>Safety</strong>, health, PPE, lockout/tagout, operating limits,<br />

deviation, safeties, confined space, operator qualification<br />

Recognizing a problem and tracking its repair<br />

IIAR Bulletin 107<br />

Maintenance, review, access, training plan<br />

5. <strong>Training</strong><br />

Identify who is to be trained and set competency levels<br />

<strong>Awareness</strong>, Technician, Operator – Initial and Refresher<br />

Operator training – efficiency, effectiveness, and safety<br />

Records and recognition – testing and certifying readiness<br />

<strong>Ammonia</strong> properties, refrig. cycle, mechanical integrity,<br />

normal operations and operating limits, correcting<br />

abnormal operations, power failure, responsibilities,<br />

emergency plans, basic electrical, MSDS, etc.<br />

6. Contractors<br />

Contractor packet, sign-in, sign-off procedures – readiness<br />

and tracking; SOP – who is in charge of an emergency<br />

incident involving contractor-related work, WHAT IS<br />

THE PLAN, Process Hazard Analysis (PHA) the worst<br />

case scenario<br />

7. Pre-Start Review<br />

Manufacture support; qualified start-ups;<br />

IIAR Bulletin 110<br />

<strong>Ammonia</strong> <strong>Safety</strong> <strong>Day</strong><br />

8. Mechanical Integrity – system and components<br />

Pressure vessels, piping, valves, controls, emergency shut<br />

down systems and every refrigeration component<br />

Log book – safety valves checked – PM schedule<br />

IIAR Bulletin 109<br />

Planned maintenance, inspection, testing, training,<br />

documentation, equipment inventory, manufacturer<br />

details<br />

Inspections: check sheets, daily inspection/log, oil<br />

samples, scans, scheduled maintenance<br />

Operators and technicians must be trained<br />

Documentation! Deficiency list addressed!<br />

Annual audit and Preventive Maintenance manuals<br />

9. Hot Works Permit<br />

Program – training – discipline – fire and LANCE and<br />

SIMPLE readiness<br />

Welding, grinding, and cutting safety checklist<br />

Procedures: initiating, issuing, performing, and completing<br />

Hot Work Permits<br />

10. Management of Change – technical basis for change<br />

Impact of change on safety and health; time period for<br />

change; authorization for change<br />

PHA – MOC – SOP in sync<br />

Deficiencies and concerns addressed – walk the talk<br />

Not needed for “replacement in kind”<br />

11. Incident Investigation<br />

ALL near misses and incidents investigated – do the PMP<br />

within 48 hours of the incident; recommendations must<br />

be addressed in timely manner<br />

Records and reports – 5-year history<br />

Investigation team trained and ready to do the evaluation<br />

Notifications timely and recorded – follow up<br />

Documentation<br />

12. Emergency Response<br />

The ERP – Strategy – PPE/SOP – connection with public<br />

safety, evacuation alarm systems, meeting places,<br />

accountability of employees<br />

<strong>Training</strong> and readiness to respond – medical, physical<br />

<strong>Training</strong> records and follow-up – PMP opportunities<br />

Spill notification – numbers and readiness forms<br />

PPE and response equipment readiness<br />

13. Audit<br />

Credibility (trained, tested, complete)<br />

Deficiencies recorded and resolved and documented<br />

Certify that compliance has been audited at least once<br />

every three years; include an audit checklist and<br />

deficiency tracking log<br />

14. <strong>Ammonia</strong> Calculations – Know your system!<br />

System capacities, release amount charts, delivery log<br />

RMP details/compliance<br />

©ASTI – www.ammonia-safety.com – August 2008 19

<strong>Ammonia</strong> <strong>Safety</strong> <strong>Day</strong><br />

20<br />

Workbook Questions – <strong>Safety</strong>, Health, Hazard, and Risk<br />

1. When considering hazard and risk, what are the Three Golden Rules of Safe and Effective Hazard<br />

Control?<br />

2. Define at least one “PMP” and “PSM” issues that match the following risks:<br />

a. Fire in a fork lift in the loading dock:<br />

i. Prevention:<br />

ii. Mitigation:<br />

iii. Preparedness:<br />

iv. PSM requirements:<br />

b. Overpressure circumstance in the condenser:<br />

i. Prevention:<br />

ii. Mitigation:<br />

iii. Preparedness:<br />

iv. PSM requirements:<br />

c. Aerosol release from an oil pot release in the engine room:<br />

i. Prevention:<br />

ii. Mitigation:<br />

iii. Preparedness:<br />

iv. PSM requirements:<br />

d. Expansion valve leak noticed by a fork lift operator:<br />

i. Prevention:<br />

ii. Mitigation:<br />

iii. Preparedness:<br />

iv. PSM requirements:<br />

3. Describe the EMS protocols for:<br />

a. Exposure to 300 PPM vapor<br />

b. Hit by an aerosol release (clothing frozen to skin)<br />

c. Droplet of ammonia propelled into an eye<br />

d. Heart attack<br />

e. Heat exhaustion<br />

4. What are the reporting requirements for local, state, and federal regulatory compliance?<br />

©ASTI – www.ammonia-safety.com – August 2008

Glove Box Version of the One-Plan Standard for Emergency Response<br />

Section I—Plan Introduction Elements<br />

1. Purpose and Scope of Plan Coverage<br />

2. Table of Contents<br />

3. Current Revision Date<br />

4. General Facility Identification Information<br />

a. Facility name<br />

b. Owner/operator/agent (include physical and<br />

mailing address and phone number)<br />

c. Physical address of the facility (include<br />

county/parish/borough, latitude/longitude, and<br />

directions)<br />

d. Mailing address of the facility<br />

e. Other identifying information (e.g., ID numbers, SIC<br />

Code, oil storage start-up date)<br />

f. Key contact(s) for plan development/maintenance<br />

g. Phone number for key contact(s)<br />

h. Facility phone number<br />

i. Facility fax number<br />

Section II—Core Plan Elements – 4 Phases of Response<br />

I. Discovery – Size-up LANCE<br />

II. Initial Response - SIMPLE<br />

1. Procedures for internal and external notifications (i.e.,<br />

contact, organization name, and phone number of<br />

Facility Emergency Coordinator, facility response team<br />

personnel, federal, state, and local officials)<br />

2. Establishment of response management system<br />

procedures for preliminary assessment of the situation,<br />

including an identification of incident type, hazards<br />

involved, magnitude of the problem, and resources<br />

threatened<br />

3. Procedures for establishment of objectives and priorities<br />

for response to the specific incident, including: (1)<br />

Immediate goals/tactical planning (e.g., protection of<br />

workers and public as priorities); (2) Mitigating actions<br />

(e.g., discharge/release control, containment, and<br />

recovery, as appropriate); (3) Identification of resources<br />

required for response<br />

4. Procedures for implementation of tactical plan<br />

5. Procedure for mobilization of resources<br />

III. Sustained Actions: 30-Minute Plan/IAP/<strong>Safety</strong> Plan<br />

IV. Termination and Follow-Up Actions<br />

Section III-Annexes<br />

Annex 1. Facility and Locality Information<br />

a. Facility maps<br />

b. Facility drawings<br />

c. Facility description/layout, including identification of<br />

facility hazards and vulnerable resources and populations<br />

on and off the facility that may be impacted by an incident<br />

<strong>Ammonia</strong> <strong>Safety</strong> <strong>Day</strong><br />

Annex 2. Notification<br />

a. Internal notifications<br />

b. Community notifications<br />

c. Federal and state agency notifications<br />

Annex 3. Response Management System<br />

a. General<br />

b. Command<br />

(1) List facility Incident Commander and Qualified<br />

Individual (if applicable) by name and/or title and<br />

provide information on their authorities and duties<br />

(2) Information (i.e., internal and external communications)<br />

(3) <strong>Safety</strong><br />

(4) Liaison—Staff mobilization<br />

c. Operations<br />

(1) Operational response objectives<br />

(2) Discharge or release control<br />

(3) Personal Protective Equipment<br />

(4) Assessment/monitoring<br />

(5) Containment<br />

(6) Recovery<br />

(7) Decontamination<br />

(8) Non-responder medical needs including information on<br />

ambulances and hospitals<br />

(9) Salvage plans<br />

d. Planning<br />

(1) Hazard assessment - facility hazards identification,<br />

vulnerability analysis, prioritization of risks<br />

(2) Protection<br />

(3) Coordination with natural resource trustees<br />

(4) Waste management<br />

e. Logistics<br />

(1) Medical needs of responders<br />

(2) Site security<br />

(3) Communications (internal and external resources)<br />

(4) Transportation (air, land, water)<br />

(5) Personnel support (e.g., meals, housing, equipment)<br />

(6) Equipment maintenance and support<br />

f. Finance/procurement/administration<br />

(1) Resource list<br />

(2) Personnel management<br />

(3) Response equipment<br />

(4) Support equipment<br />

(5) Contracting<br />

(6) Claims procedures<br />

(7) Cost documentation<br />

ADDITIONAL INFORMATION – NOT GLOVE BOX<br />

Annex 4. Incident Documentation<br />

a. Post accident investigation<br />

b. Incident history<br />

Annex 5. <strong>Training</strong> and Exercises/Drills<br />

Annex 6. Response Critique and Plan Review and<br />

Modification Process<br />

Annex 7. Prevention<br />

Annex 8. Regulatory Compliance/Cross-Ref. Matrices<br />

©ASTI – www.ammonia-safety.com – August 2008 21

<strong>Ammonia</strong> <strong>Safety</strong> <strong>Day</strong><br />

Initial and Sustained Response: “Coordinate with public safety to create a safe and<br />

methodical response plan”<br />

Important NOTE: Your written Emergency Response Plan and all supporting SOPs should be<br />

completed, adopted and formally in place BEFORE the emergency event. This is the value of<br />

PREPAREDNESS for emergency response.<br />

Define Strategy: Identify the downwind/downstream threats and the degree of concern; determine the<br />

strategy for control after considering the strength and availability of on-site facility and public safety<br />

response capabilities. Meet with the local fire department and consider the Leak Control SOPs for the<br />

following concerns:<br />

• Defensive Strategy: Performing LANCE and SIMPLE within levels below the IDLH (300 PPM)<br />

and engaging incidental response safely in IDLH atmospheres, as defined within the facility<br />

Emergency Response Plan.<br />

• Offensive Strategy: Define which of the following offensive strategies you intend to perform:<br />

rescue, reconnaissance, isolation, containment, control, and/or product management; determine the<br />

level of PPE and entry PPM levels for responders and review the use of P&ID and Leak Control<br />

SOPs. The <strong>Safety</strong> Officer, Facility Emergency Coordinator and/or the Incident Commander shall<br />

assess the timing of the entry with the hazards and risks associated with the entry; provide back-up<br />

staffing; assess entry team physical, mental and PPE readiness; develop a written IAP and <strong>Safety</strong><br />

Plan that clearly define the entry objectives, PPE, and personnel accountability when entering at<br />

levels that could reach or exceed 5,000 PPM.<br />

• Form a Unified Command between on-site Facility Emergency Coordinator and the public safety<br />

Incident Commander. Assess whether you will be engaging public safety for entry to achieve<br />

specified offensive strategies (described herein), valve control, back up, support (decontamination,<br />

safety, rehab, EMS). Describe how the on-site and public safety response teams will coordinate,<br />

e.g. facility operation of system controls supported with back-up from public safety or public<br />

safety operation of system components as advised by facility response team members located<br />

outside of the hot zone.<br />

• Use personal protective equipment (PPE) based upon the strategy set in the Emergency Response<br />

Plan. Make sure to address service and maintenance, leak investigation, incidental response,<br />

defense, offense, and support systems (decontamination, downwind/downstream monitoring, etc.).<br />

The back-up system for entry should also be defined; 1 in 1 out for investigation and incidental<br />

response; ASTI recommends 2 in and 2 out for emergency entry to levels that exceed 300 PPM.<br />

Size up: Recite LANCE and SIMPLE; describe current status. What happened? Who is at risk? What do<br />

you expect will happen? What plan do you recommend? What is the nature and type of release? (dense<br />

gas and/or streaming aerosol, vapor, liquid – incidental, out of control, or peaked and recovering)<br />

Set the Zones and Control Access: Hot Zone >300 PPM; Warm Zone access route out of the Hot Zone <<br />

300 PPM; Cold Zone (0 PPM). ASTI recommends that command post, EMS support, and Rehab be<br />

placed at least 150 feet upwind in the Cold Zone. Control access to property and downwind (coordinate<br />

with public safety) - 1 in and 1 out for under 300 PPM and 2 in 2 out for entry to levels >300 PPM. Decon<br />

should occur in Warm Zone. Those performing decon must wear PPE at least one level below those being<br />

decontaminated; the decon process will cause vapor to gas off.<br />

Incident Action Plan (IAP) and <strong>Safety</strong> Plan: Write an IAP and <strong>Safety</strong> Plan and set up zones and<br />

controls, decon, rehab and EMS assignments when your plan involves entry for “offensive” actions.<br />

Termination of the Incident: Maintain a minimum of 1 in and 1 out back-up and appropriate PPE as<br />

would be used for IDLH atmosphere until the re-start process is completed and the system is working<br />

properly.<br />

22<br />

©ASTI – www.ammonia-safety.com – August 2008

<strong>Ammonia</strong> <strong>Safety</strong> <strong>Day</strong><br />

Containment: When ammonia aerosol releases are covered with a tarp (or otherwise contained), the<br />

contained area significantly cools down and the reduced temperature will also reduce pressures within the<br />

system or vessel holding the ammonia supply. Be aware that the aerosol spray will deflect against the<br />

containment tarp and form a pool of liquid ammonia.<br />

Summary of Response Strategy, Tactics, and PPE Considerations<br />

Note: Read each Response Strategy from left to right across the table<br />

Strategy Tactic(s) Pers. Prot. Equip. Special Concerns<br />

Incidental Control:<br />

Implemented at<br />

< 300 PPM;<br />

This strategy is<br />

NOT an emergency<br />

event<br />

Implementation of<br />

LANCE and<br />

SIMPLE inside the<br />

Hot Zone >300<br />

PPM to accomplish<br />

rescue,<br />

reconnaissance,<br />

control,<br />

containment,<br />

product movement,<br />

etc.<br />

Rescue within the<br />

standards of the<br />

PPE and training<br />

Offensive Entry to<br />

control and contain<br />

the release<br />

Use the refrigeration control<br />

systems outside of the Hot<br />

Zone to manage the release:<br />

compressor control, remote<br />

isolation valves, electrical<br />

system controls, ventilation<br />

controls, etc. Contain the<br />

release – close doors<br />

-Follow the guidance provided<br />

within facility-adopted<br />

Emergency Response Plan<br />

and adopted SOPs<br />

-Continuous atmospheric<br />

monitoring required<br />

- Evaluate the risk BEFORE<br />

developing an entry plan;<br />

consider the phase of the<br />

release: incidental, out-ofcontrol,<br />

peaked, or<br />

recovering<br />

-Do aggressive LANCE and<br />

SIMPLE<br />

-Communicate with the victim<br />

-Advise location and condition<br />

of victim; engage ventilation<br />

support for the victim<br />

-<strong>Training</strong>, and ability to<br />

search, rescue/carry the<br />

victim<br />

-Written Incident Action Plan<br />

and <strong>Safety</strong> Plan<br />

-Entry team must be clear on<br />

task assignments; keep tasks<br />

short (10 min.); make sure<br />

the plan is clear and<br />

achievable BEFORE<br />

allowing entry<br />

Air purifying respirator or<br />

SCBA, ammonia monitor,<br />

radio, safety boots, helmet,<br />

and full skin protection;<br />

continuous atmospheric<br />

monitoring required<br />

SCBA, ammonia monitor,<br />

radio and level A or B PPE<br />

-Level B 5,000 PPM<br />

-Flash protected at >15,000<br />

PPM for an inside release<br />

-Thermal rated -87ºF dense<br />

gas and -100ºF for working<br />

in an aerosol stream<br />

-NIOSH approved<br />

permeation rated for<br />

aerosol<br />

-Atmospheric monitoring<br />

and PPE required for the<br />

rescuer as certified, fit<br />

tested, medically cleared to<br />

use SCBA<br />

-2 in 2 out coverage<br />

recommended<br />

-PPE for search and rescue<br />

team and for the victim<br />

-Atmospheric monitoring<br />

and risk assessment<br />

required to determine the<br />

proper PPE (as described<br />

within this column)<br />

-2 in 2 out coverage<br />

required<br />

Follow incidental response<br />

guidance provided within the<br />

plan; 1 in 1 out coverage; keep<br />

exit available for escape and<br />

back off when a life threat or<br />

when immediate control is not<br />

readily available and safe to<br />

accomplish.<br />

-Keep exit available for escape<br />

-2 in 2 out coverage<br />

recommended<br />

-Fire hose line in place for<br />

safety and support for<br />

potential fire risk<br />

-When the release is<br />

recovering and SIMPLE is<br />

engaged, entry can be<br />

considered at

<strong>Ammonia</strong> <strong>Safety</strong> <strong>Day</strong><br />

24<br />